Method for prevent displacement of embedded steel plate by bolt fixation

A pre-embedded steel plate and bolt technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as quality problems, installation difficulties, delays in construction period and labor waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further illustrated below by specific examples.

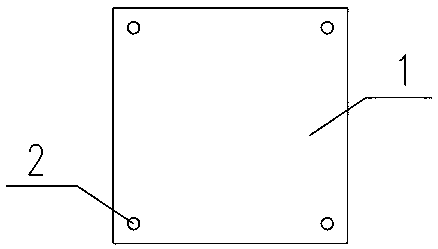

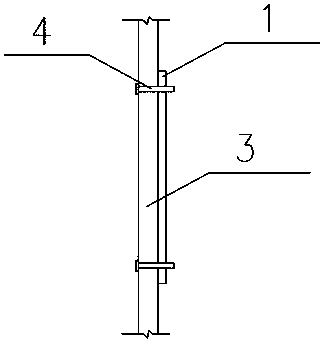

[0018] Such as figure 1 , figure 2 As shown, a method of fixing with bolts to prevent displacement of embedded steel plates, including

[0019] Step 1, pre-embedded steel plate drilling: use a punching machine to punch holes 2 in the four corners of the pre-embedded steel plate 1, for threading bolts 4;

[0020] Step 2, making the embedded steel plate: according to the design requirements of the drawing, weld the anchor claw of the embedded steel plate 1 and make the embedded part;

[0021] Step 3, install the embedded steel plate 1: Install the prepared embedded steel plate 1 at the design position of the drawing, and fix it with wire tie;

[0022] Step 4, positioning and drilling on the formwork: drill holes on the formwork corresponding to the pre-embedded steel plate 1 with an electric drill;

[0023] Step 5, install the bolt 4: penetrate the bolt 4 from the outside of the template into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com