Large-sized material storage yard gas guide and discharge well and well cementing construction method

A construction method and material pile technology, which are applied in the field of gas guide and discharge of material piles, can solve the problems of reducing the amount of biogas, dislocation of gabions, blockage of guide pipes, etc., and achieve the effects of convenient construction and maintenance, good stability and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

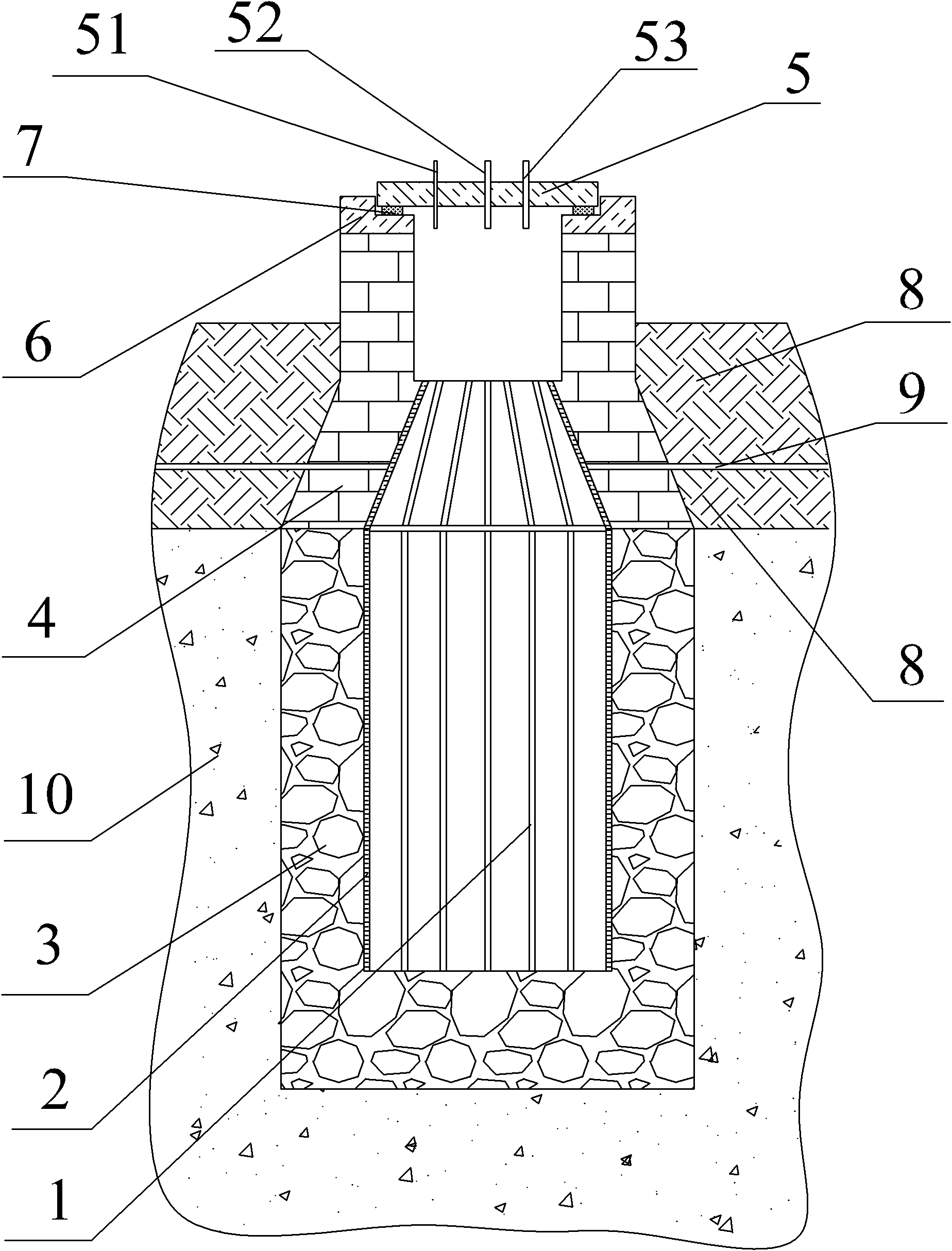

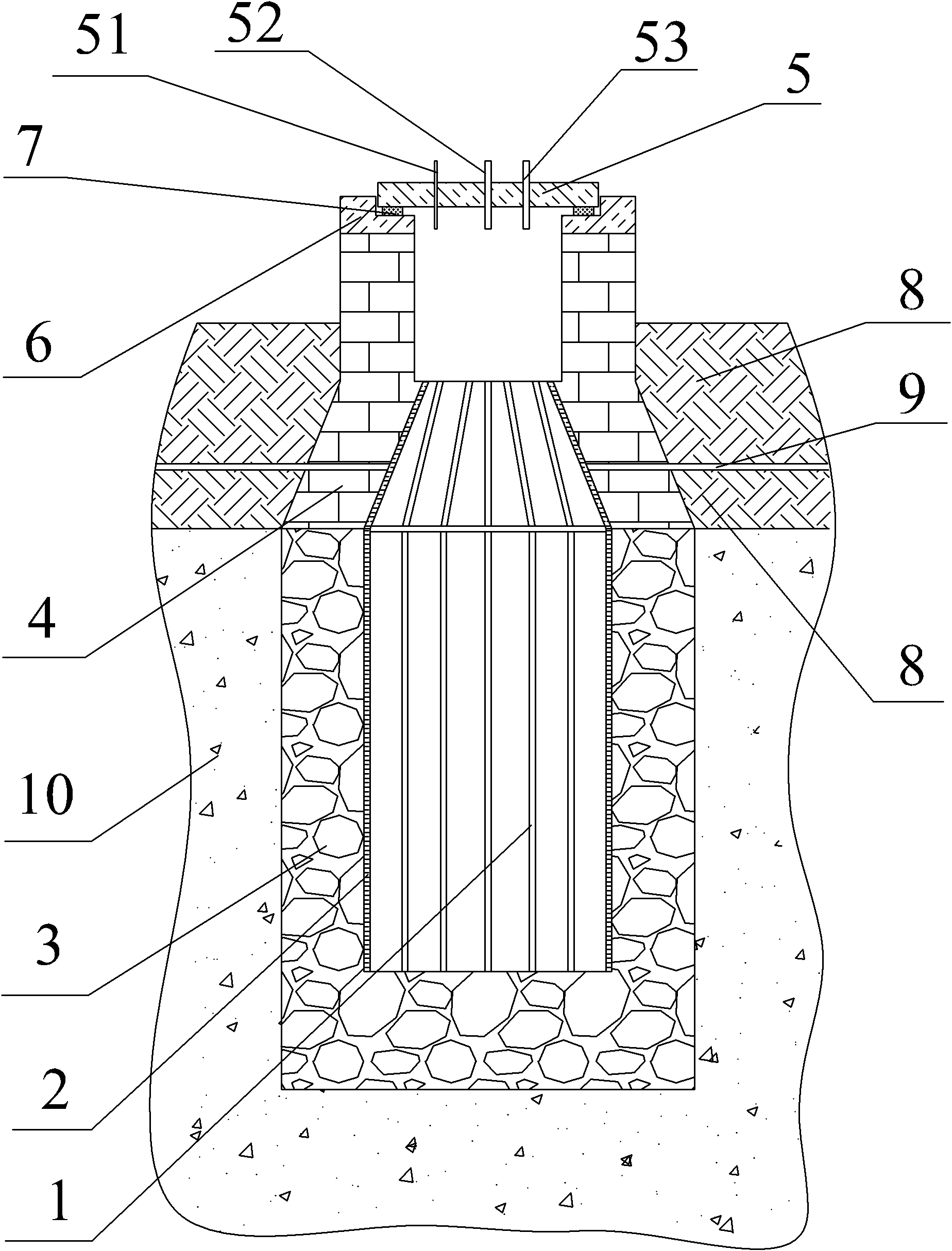

[0013] figure 2 The gas guide and exhaust well of the large-scale material storage yard shown in the embodiment of the present invention includes: a guide and exhaust well hole arranged in the material storage yard, a cylindrical skeleton 1 arranged in the guide and exhaust well hole, and a cylindrical skeleton enclosed in the tubular skeleton. The external flexible filter layer 2, the crushed stone filter layer 3 filled between the wall of the guide well hole and the flexible filter layer, the sealing cylinder 4 sealed outside the flexible filter layer 2 and arranged on the upper part of the guide well hole, and the The cover seals the well cover 5 of the cylindrical body 4 .

[0014] The cylindrical skeleton 1 is welded by section steel, and the bottom is made of cross braces.

[0015] The flexible filter layer 2 is formed by winding the cylindrical frame 1 with a material with certain strength and flexibility with ventilation holes. By filling the crushed rock between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com