Durable intaglio printing rubber roller

A technology of gravure printing and rubber rollers, applied in printing, printing machines, printing processes, etc., can solve problems such as unusable, high labor intensity, deformation of metal mandrel and end cover, etc., to speed up the recovery of force deformation, Improved printing quality, easy refill effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with embodiment.

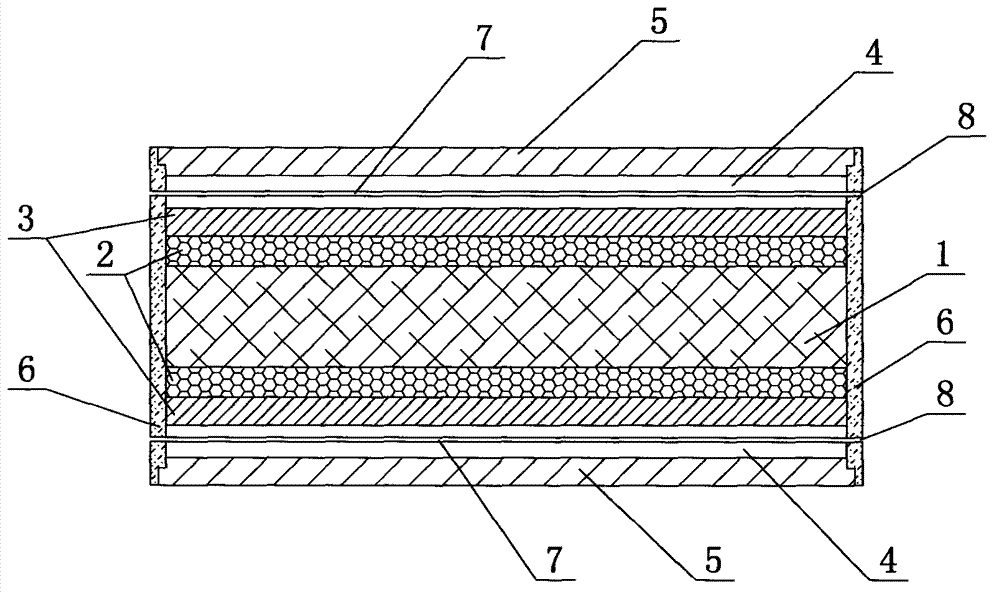

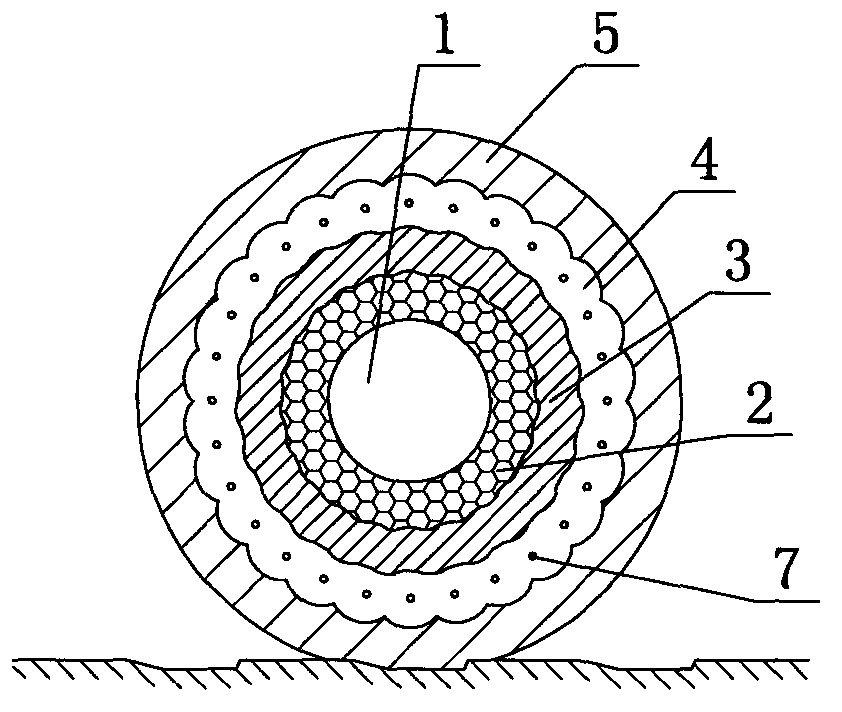

[0021] A durable gravure printing rubber roller of the present invention comprises: a metal mandrel 1, a foam layer 2 coated on the outside of the metal mandrel 1, an inner rubber layer 3, a middle rubber layer 4, and an outer rubber layer 5 and the two end caps 6 on the side, the center of the end cap 6 is the roll neck;

[0022] Shore hardness: inner rubber layer 3>middle rubber layer 4>outer rubber layer 5;

[0023] The middle rubber layer 4 is provided with hollow passages 7 arranged at equal intervals;

[0024] The two end caps 6 on the side are provided with openings 8 corresponding to the positions of openings at both ends of the hollow channel 7 inside the middle rubber layer 4 .

[0025] The metal mandrel 1 is a general hole-shaped hollow cylinder.

[0026] The foam layer 2 is a granular flexible polyurethane foam layer.

[0027] The Shore hardness of the inner rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com