Template positioning device for circuit board production

A positioning device and circuit board technology, which is applied to printed circuits, printed circuit manufacturing, printed circuit assembly of electrical components, etc., can solve the problems of lower printing quality, less tin on circuit boards, time-consuming and labor-intensive problems, and achieve uniform force and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

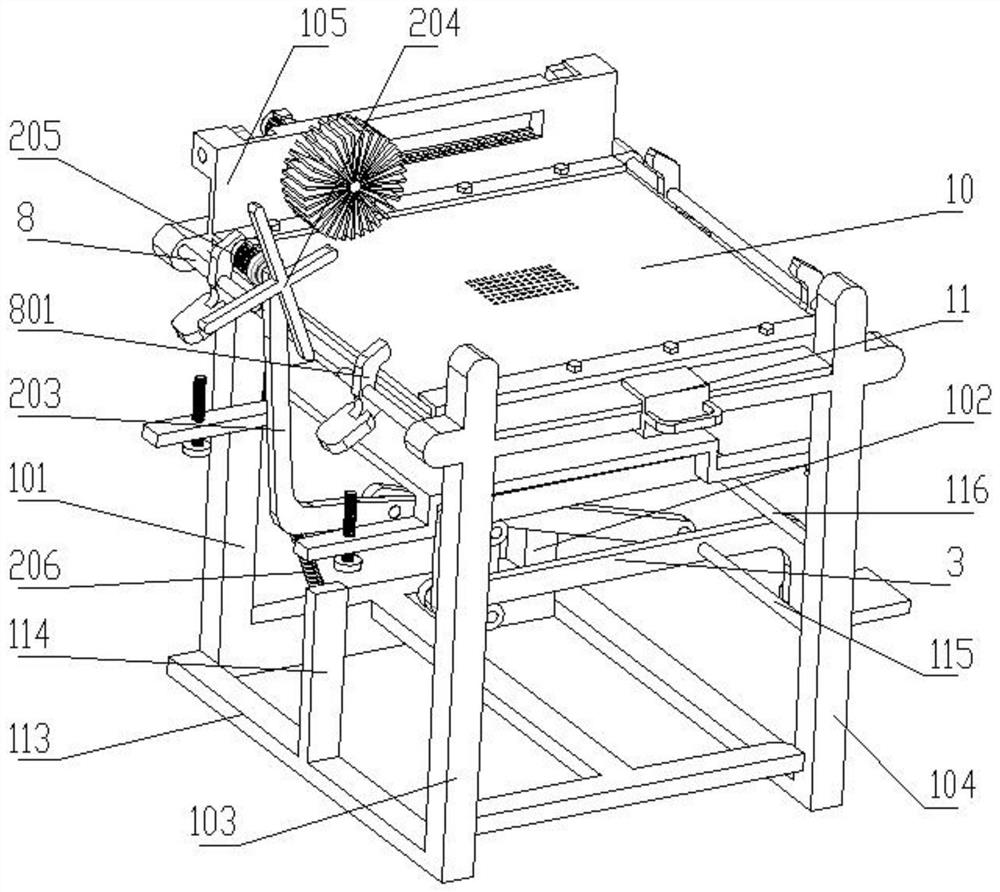

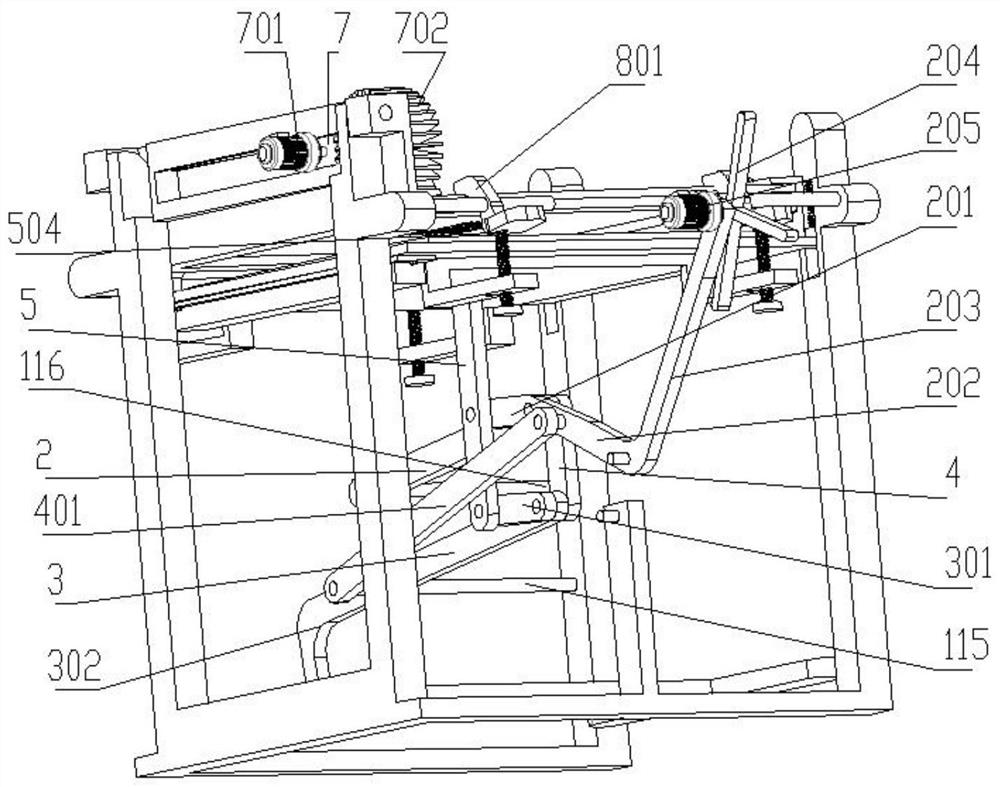

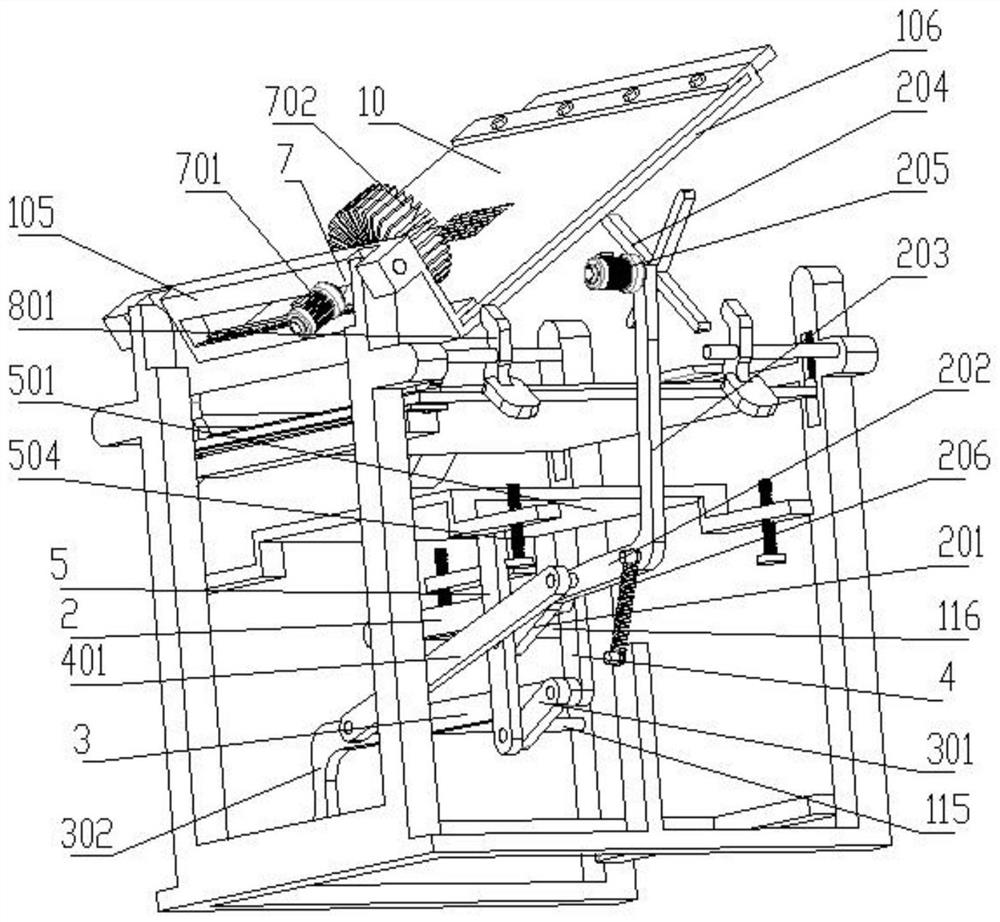

[0034] see Figure 1-Figure 8 , a template positioning device for circuit board production, including a printing pad, the printing pad includes symmetrically arranged column one 101 and column two 102, column three 103 and column four 104, and the outer sides of the column one 101 and column two 102 are hingedly provided with a vertical plate 105 , the inner side of the lower end of the vertical plate 105 is fixedly provided with a rectangular frame 106, the outer side of the other end of the rectangular frame 106 is fixedly provided with an external connection plate 112, a fixed plate is arranged between the top of the column three 103 and the column four 104, and the external connection plate 112 is lapped on On the fixed plate 119 and the rectangular frame 106 is horizontal;

[0035] On the printing pad and directly below the rectangular frame 106, a placement plate 6 is arranged, and sliding columns 602 are arranged symmetrically at both ends of the opposite sides of the p...

Embodiment 2

[0047] see Figure 1-Figure 8 , a template positioning device for circuit board production, including a printing pad, the printing pad includes symmetrically arranged column one 101 and column two 102, column three 103 and column four 104, and the outer sides of the column one 101 and column two 102 are hingedly provided with a vertical plate 105 , the inner side of the lower end of the vertical plate 105 is fixedly provided with a rectangular frame 106, the outer side of the other end of the rectangular frame 106 is fixedly provided with an external connection plate 112, a fixed plate is arranged between the top of the column three 103 and the column four 104, and the external connection plate 112 is lapped on On the fixed plate 119 and the rectangular frame 106 is horizontal;

[0048] On the printing pad and directly below the rectangular frame 106, a placement plate 6 is arranged, and sliding columns 602 are arranged symmetrically at both ends of the opposite sides of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com