Knitting machine

A knitting machine and drive shaft technology, applied in the field of knitting machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

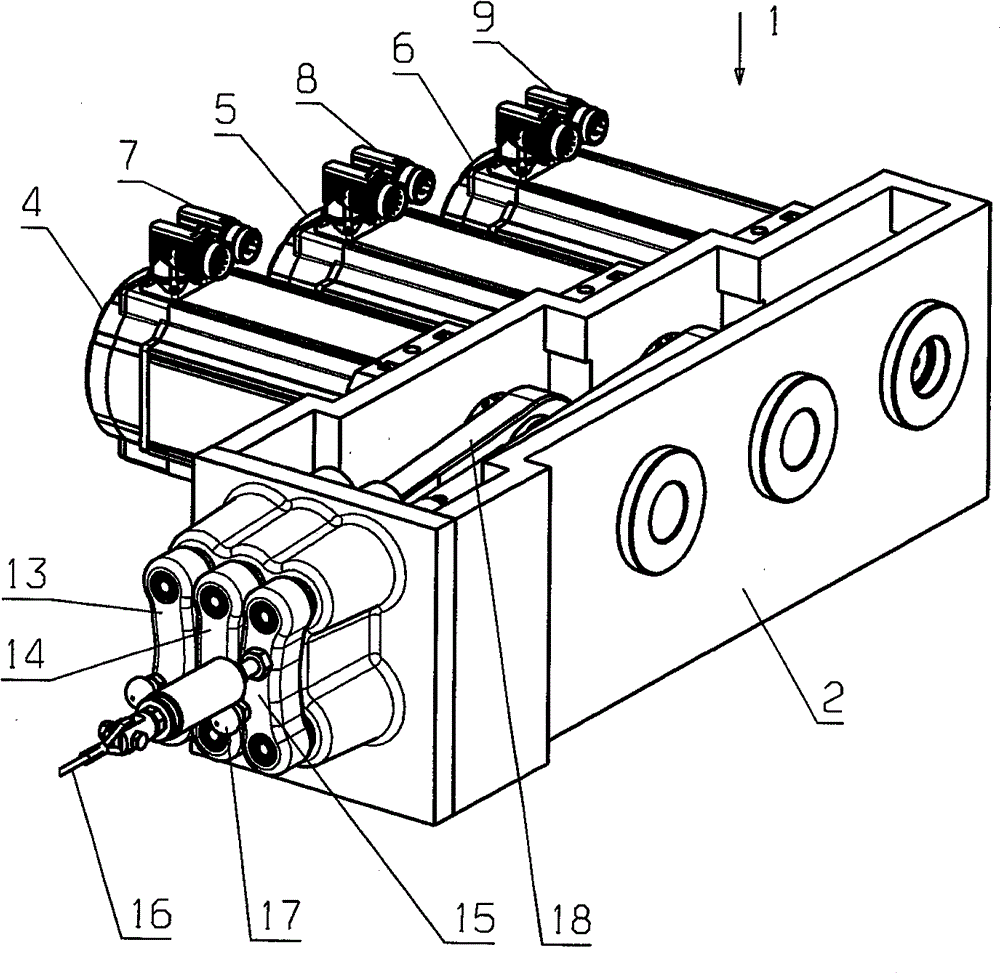

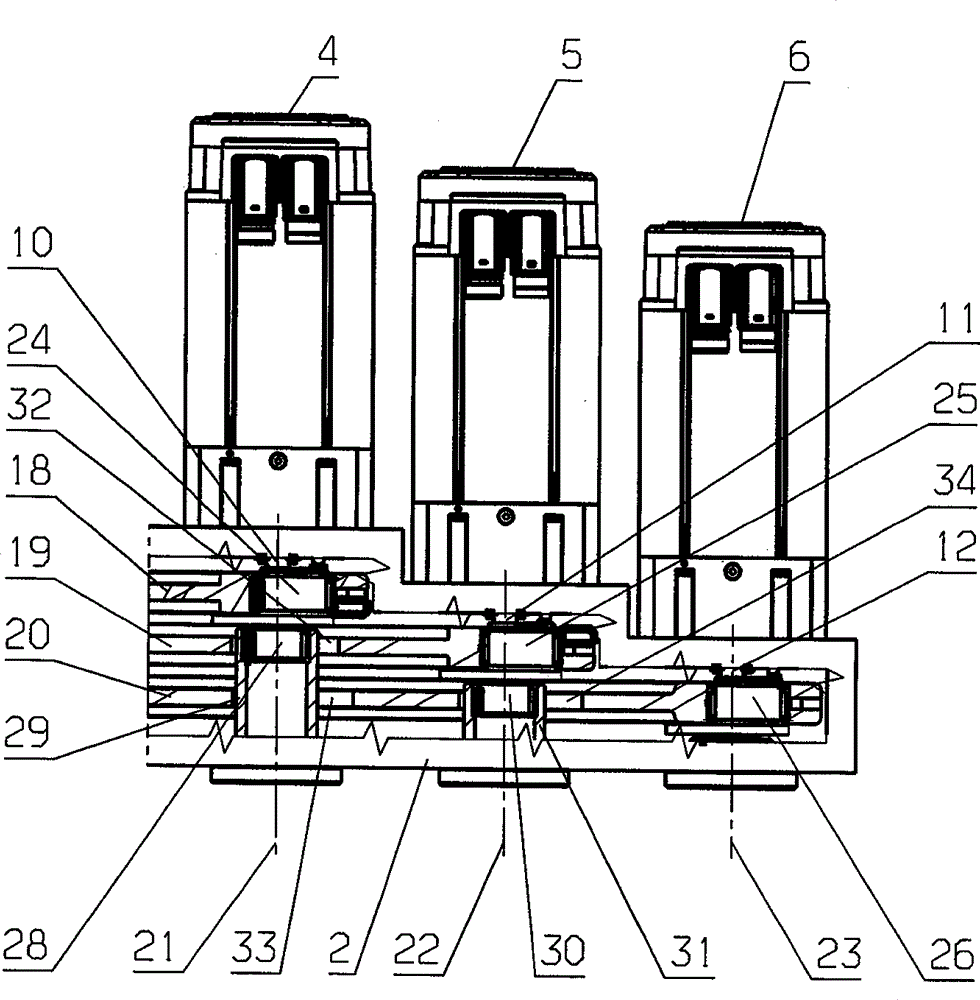

[0023] figure 1 A jacquard device 1 of a warp knitting machine is shown schematically with a housing 2 and three drive motors 4 , 5 , 6 . The drive motor is designed as a so-called "brushless DC motor", ie as a permanently excited synchronous machine, which is actuated via the control interfaces 7 , 8 , 9 . The motors 4, 5, 6 can rotate in two rotational directions. The drive shafts 10 , 11 , 12 can be controlled with high precision in such a way that they assume a defined angular position.

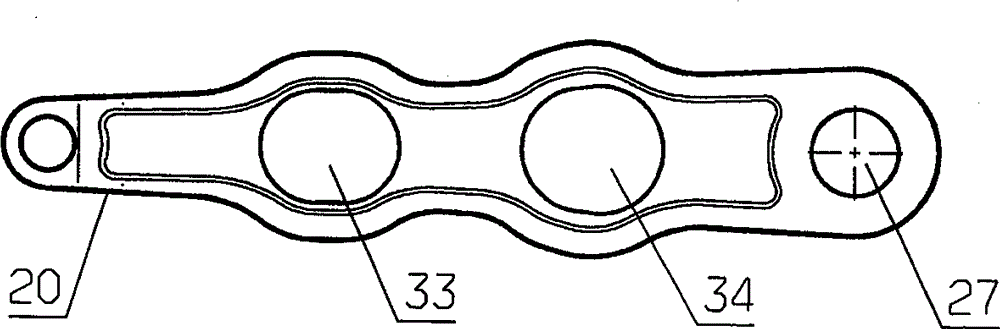

[0024] Each motor acts on a coupling element 13, 14, 15, which is reciprocable in a deflection direction, ie in the longitudinal extension of the thread guide bar not described in detail. A strand 16 is fastened to the coupling element 15 , which establishes a connection to a thread guide bar not described in detail. Corresponding twisted wires (or other connecting elements) can also be fastened to other connecting elements 13 , 14 . Each linking element 13, 14, 15 also has a fixing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com