Organic Rankine cycle power output device with space heat regenerator

A Rankine cycle, power output technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve problems such as space occupation, structural limitations of organic Rankine cycle systems, adverse effects of vehicle lightweighting, etc., and achieve freedom of layout. , the effect of improving cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

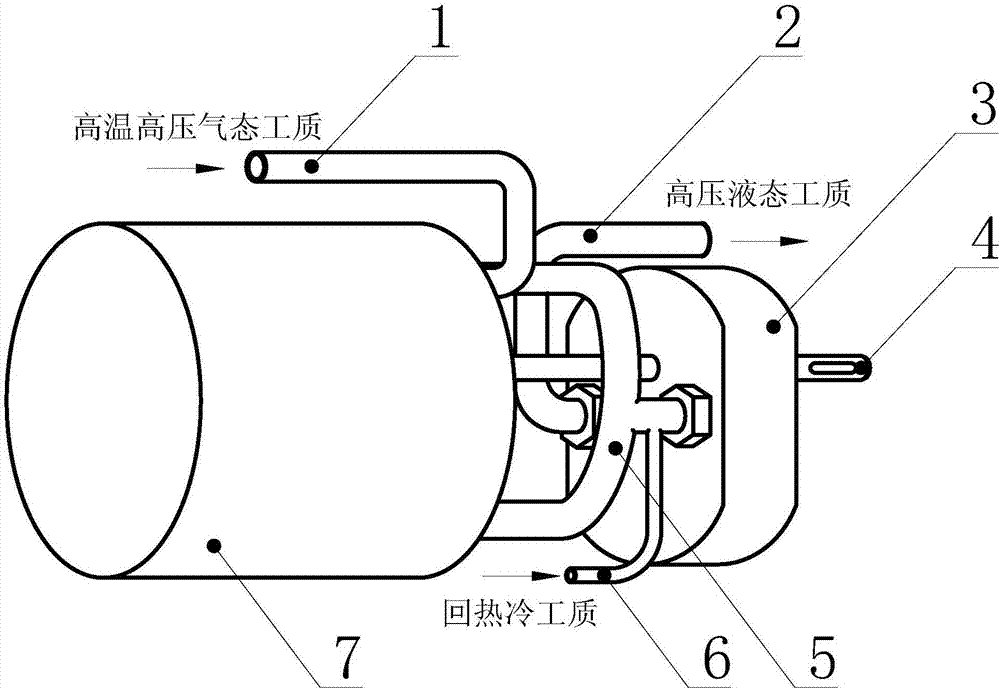

[0016] Such as figure 1 As shown, the present invention consists of a high-temperature working medium pipe 1, a high-pressure liquid working medium pipe 2, a working medium pump 3, a power output shaft 4, an air motor exhaust pipe 5, a reheating cold working medium pipe 6 and an air motor 7.

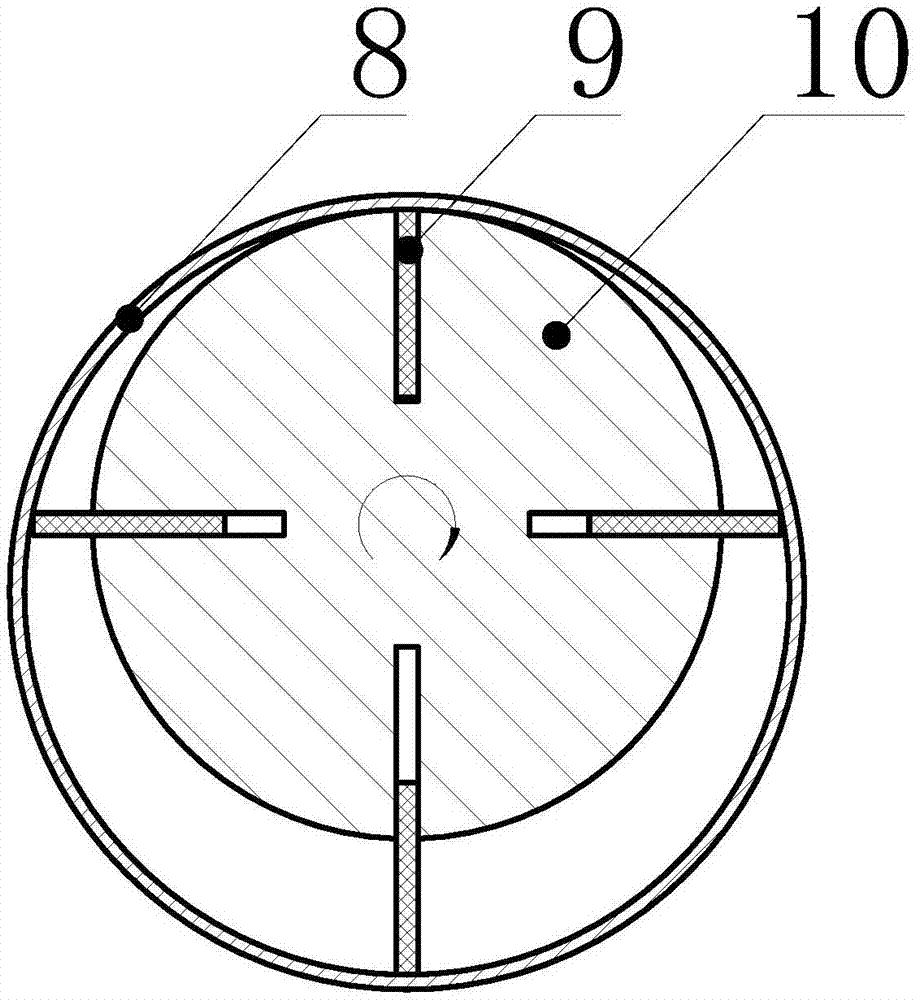

[0017] Such as figure 2 As shown, the air motor 7 is mainly composed of an air motor housing 8 , an air motor blade 9 and an air motor rotor 10 .

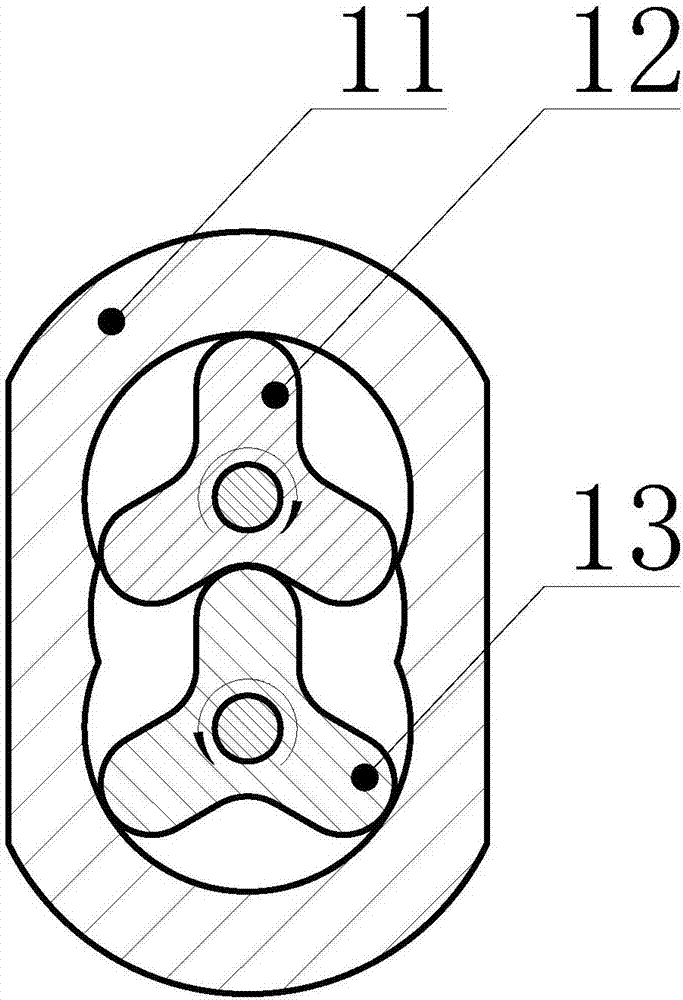

[0018] Such as image 3 As shown, the working medium pump 3 is mainly composed of a working medium pump casing 11 , a working medium pump driving rotor 12 and a working medium pump driven rotor 13 .

[0019] The present invention provides an organic Rankine cycle power output device with space recuperation, wherein the high-temperature working medium pipe 1 is connected with the air inlet of the air motor 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com