Vena cava filter

A vena cava and filter technology, applied in the field of medical devices, can solve the problems of difficult to take out, difficult to deform, and too deep penetration of the filter, and achieve the effects of reliable connection, good compliance and smooth process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

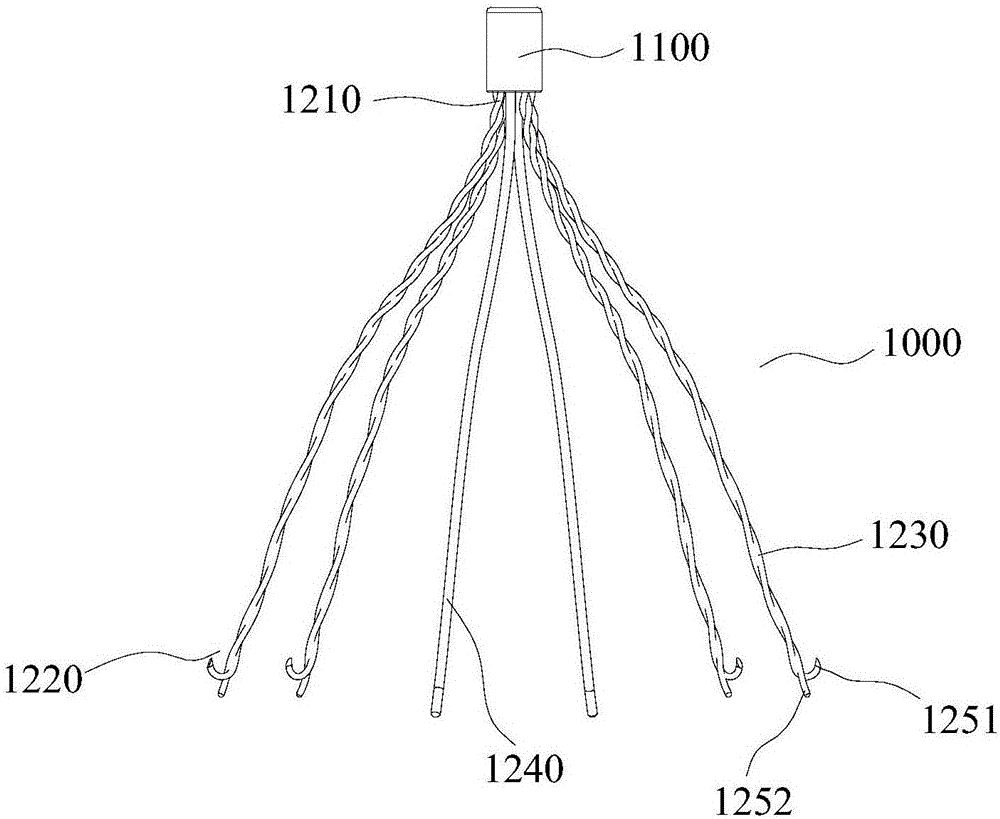

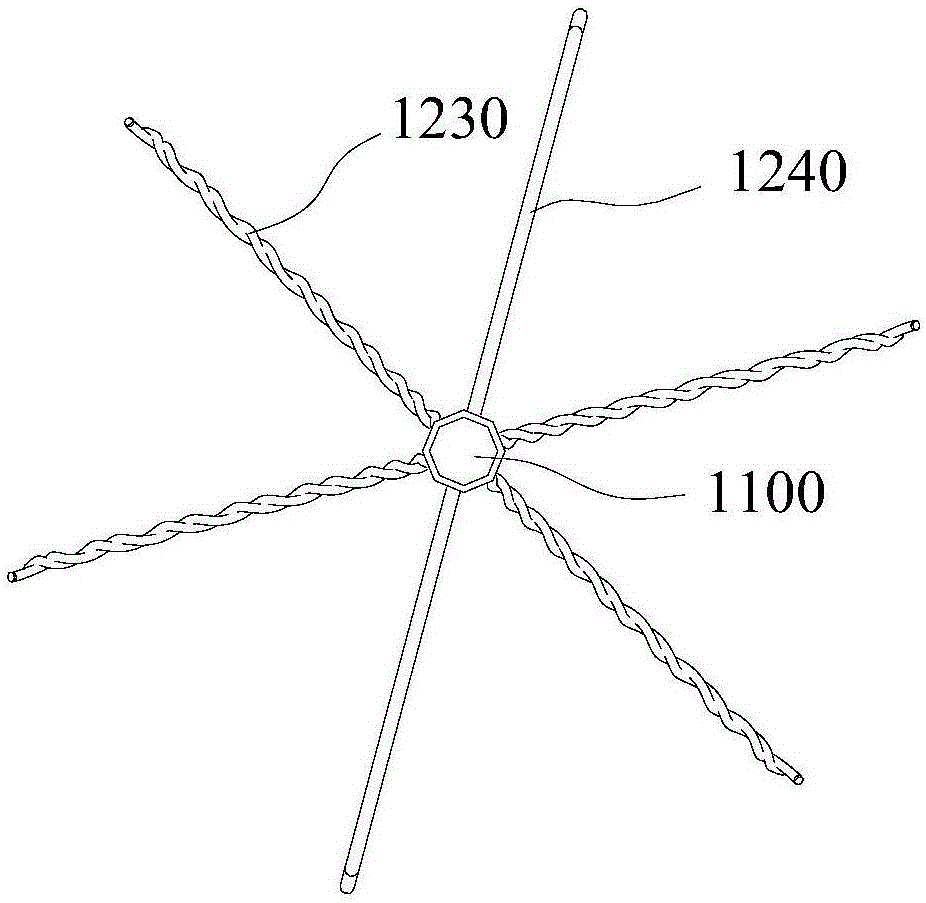

[0072] Such as Figure 1a , Figure 1b As shown, the vena cava filter 1000 of this embodiment includes a plurality of struts, one end of the plurality of struts is gathered and restrained in a 2.0mm sleeve 1100, and is fixed by argon arc welding to form a gathered end 1210, and the ends of the plurality of struts are The other end radiates to form a diverging end 1220 in the released state.

[0073] In the released state, a plurality of struts are roughly distributed on the same conical surface, and the diameter of the circle surrounded by each strut at the divergent end 1220 is the largest. The length of each strut is 30-70 mm, and the maximum diameter of the circle surrounded by the diverging ends 1220 is about 20-80 mm.

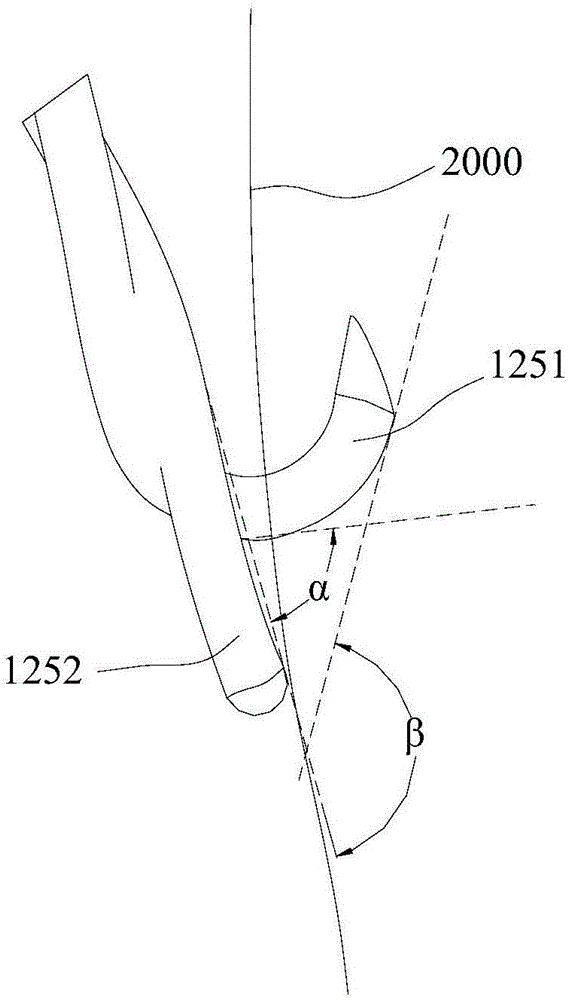

[0074] The number of poles is usually 4 to 18. In this embodiment, the number of poles is 6, of which 4 poles are twisted poles 1230, and 2 poles are non-twisted poles 1240. In the released state, The two non-twisted struts 1240 and the central axis of t...

Embodiment 2

[0087] Such as Figure 2a , Figure 2b As shown, the difference between this embodiment and Embodiment 1 is that the wire diameters of the twisting struts 2230 are different. The twisting rod 2230 is formed by twisting two metal wires with different diameters, wherein the wire 2261 with a thicker diameter does not twist, and the wire 2262 with a thinner diameter is wound around the wire 2261 with a thicker diameter. , and the winding pitch of the converging end 2210 is smaller than that of the diverging end 2220 .

[0088] Such as Figure 2b , at the diverging end 2220 of the twisting pole 2230, the metal wire 2261 with a thicker wire diameter maintains the original extension direction, and the end of the metal wire 2262 with a smaller wire diameter bends toward the gathering end 2210 to form an anchor hook 2251.

[0089] The release process of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0091] Such as Figure 3a , Figure 3b As shown, the difference between this embodiment and Embodiment 1 is that the twisting strut is formed by intertwining three metal wires, the diameters of the three metal wires are the same, and the twist gradually decreases from the converging end 3210 to the diverging end 3220 . One metal wire of the twisted strut is bent near the divergent end 3220 to form an anchor hook 3251 , and the other two metal wires are side by side near the divergent end 3220 to maintain the original extension direction.

[0092] The release process of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com