Clamp for preventing shrinkage fit from shifting

A technology of fixture and steel block, which is applied in the field of fixtures to prevent displacement of heat sleeves, can solve problems such as complicated process and poor product quality, and achieve the effect of simple material, convenient processing, and easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

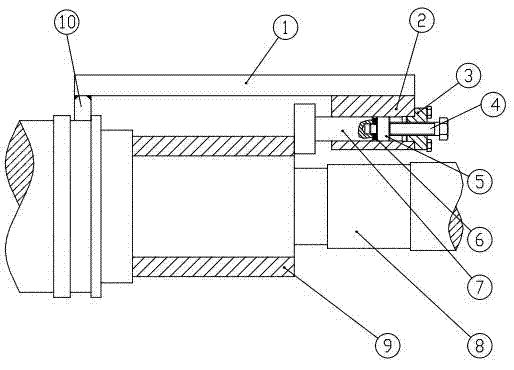

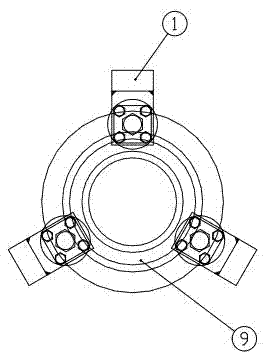

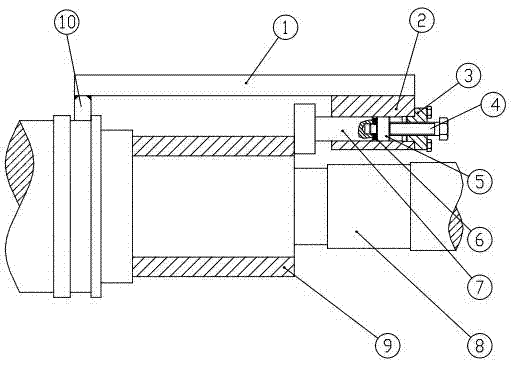

[0010] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, the middle section of the clamp of the present invention is a rectangular flat steel 1, one end welds the flat steel 10, and the other end welds a steel block 2 with a round hole; In the round hole of the block 2, the concentricity of the pin 5 and the indenter 7 is ensured by inserting the protrusion at the head of the pin 5 into the hole at the tail of the indenter 7; Screw in the stop bolt 4 in the central threaded hole of the stop bolt 4, and the tail end face of the stop bolt 4 butts against the pin 5.

[0012] After the heat-fit workpiece 9 is heat-fitted on the outer periphery of the shaft part 8, place the flat steel 10 of the fixture on the protrusion of the shaft part 8, and tighten the limit bolt 4 at the other end of the fixture so that the pressure head 7 is placed on the disc spring 6 Under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com