Template support installed at bay window through heat-preservation and template integrated plates and strengthening method thereof

A technology for thermal insulation formwork and bay windows, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., which can solve problems such as easy falling off, position deviation, and weak reinforcement, so as to ensure the quality of pouring , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

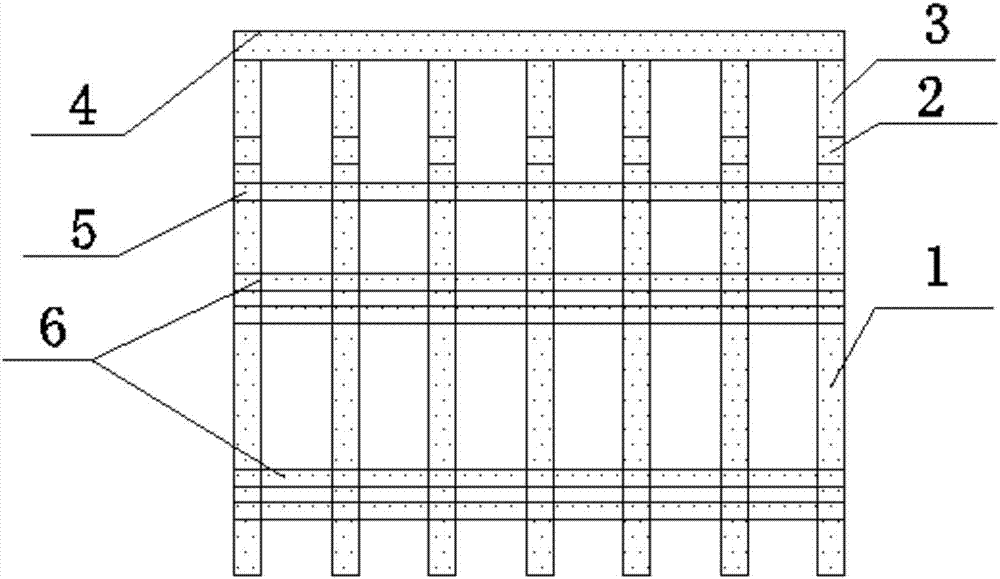

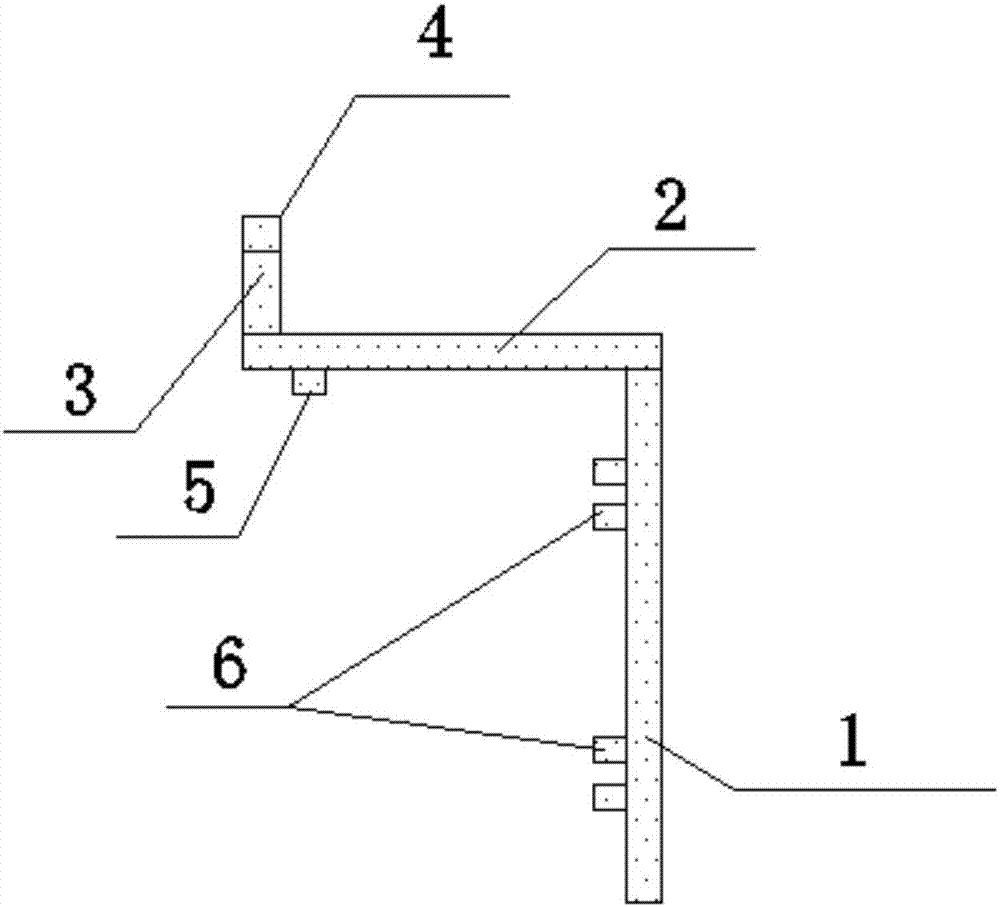

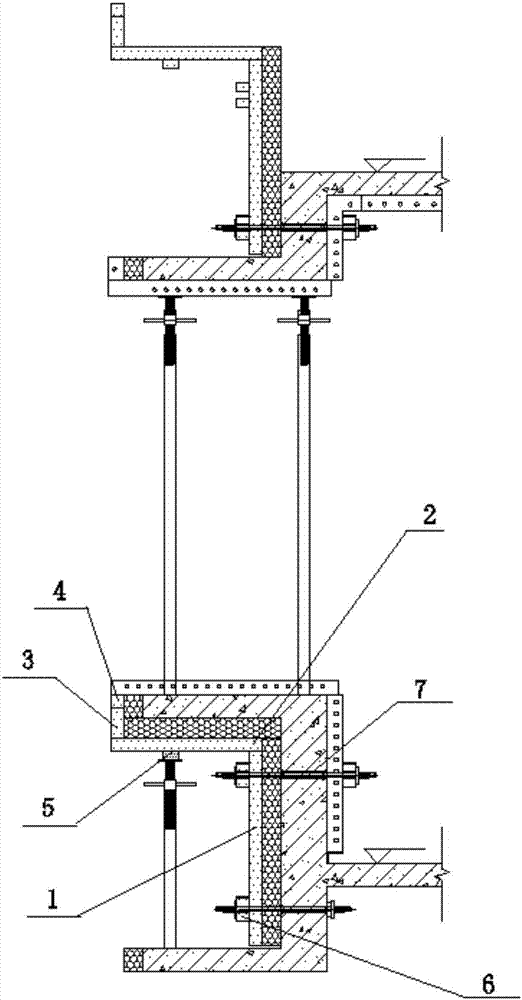

[0020] as attached figure 1 , figure 2 As shown, in this embodiment, a thermal insulation formwork integrated panel is installed with a template bracket at the bay window panel, including several vertical supports 1 at the wall under the window, several horizontal supports 2 for the bottom mold of the outer bay window panel, and several floating window panels. The vertical support 3 on the outer side of the window panel, the top connection square pipe 4, the vertical rod support point connection square pipe 5, and the four opposite pull screw pull nodes connection square pipe 6; the vertical support 1 at the wall under the window The top is vertically connected to one end of the horizontal support 2 of the bottom mold of the outer bay window panel, and the other end of the horizontal support 2 of the bottom mold of the outer bay window panel is vertically connected to the bottom end of the vertical support 3 on the outer side of the bay window panel. The top connection squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com