Wavelength division multiplexer

A wavelength division multiplexer and filter technology, which is applied in the direction of instruments, light guides, optics, etc., can solve the problems of complex manufacturing, low production efficiency, and difficult adjustment of wavelength division multiplexers, and achieve the best light propagation angle and structure The effect of simple, simplified structure settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

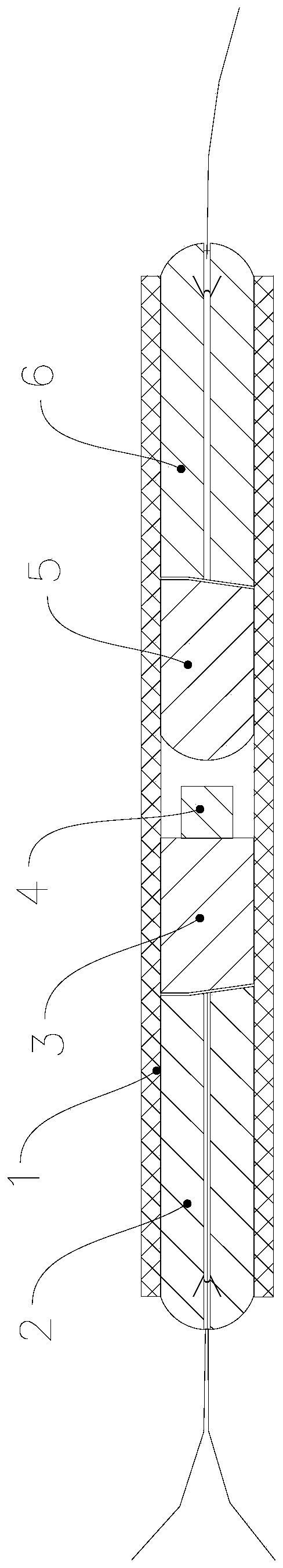

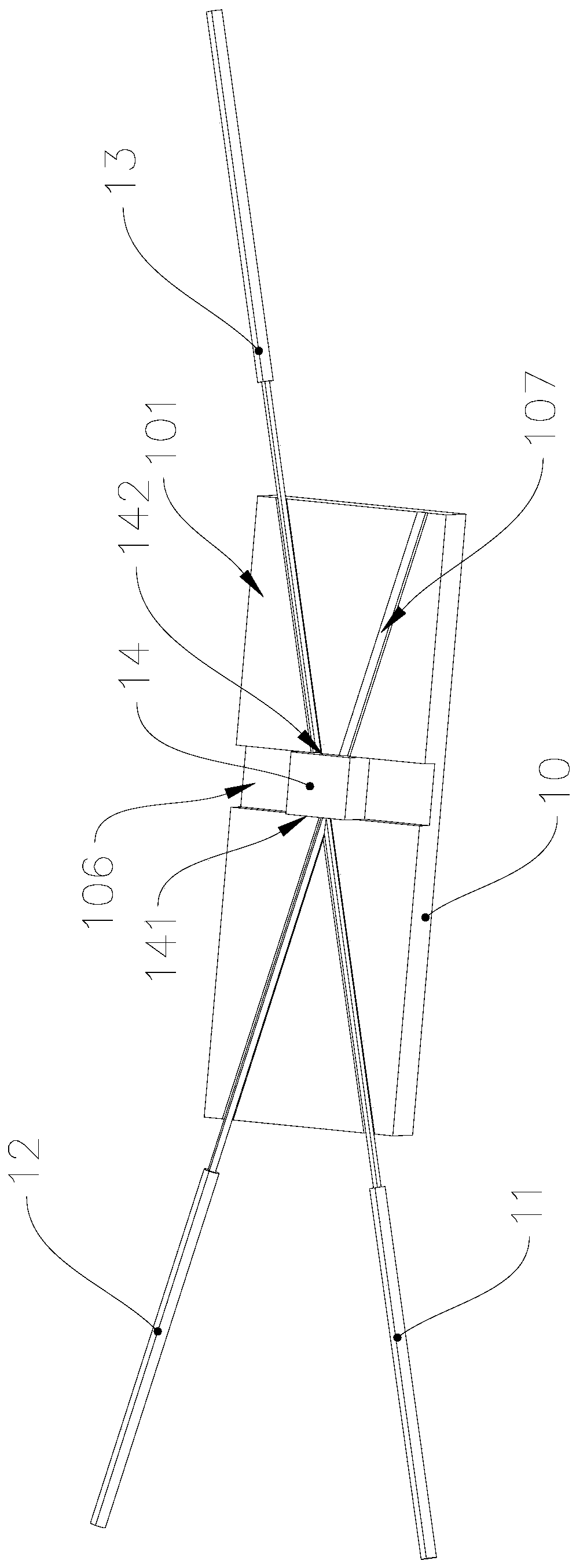

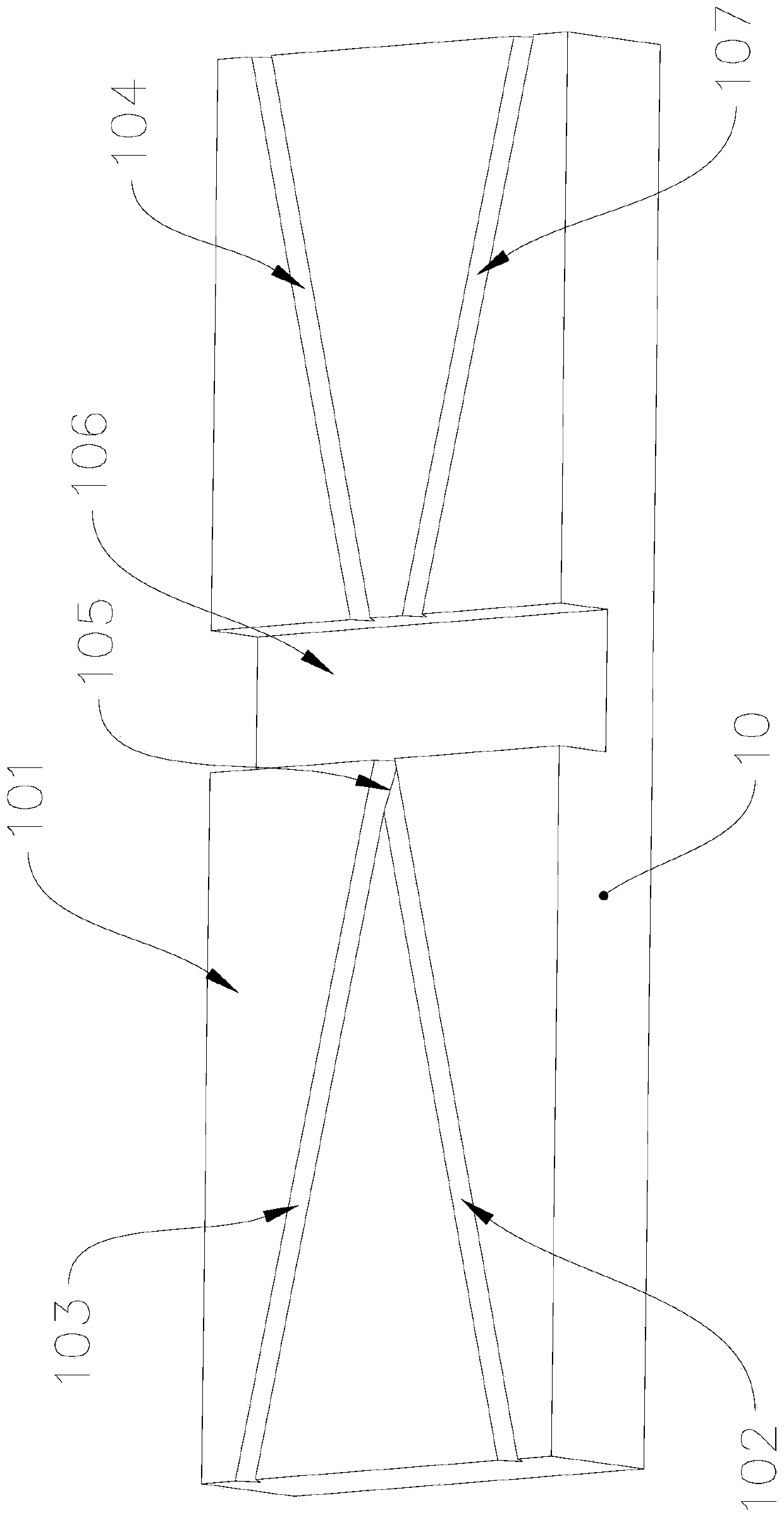

[0022] Such as figure 2 As shown, the wavelength division multiplexer of this embodiment includes a substrate 10 , an optical fiber 11 at an incident end, an optical fiber 12 at a reflection end, an optical fiber 13 at a passing end, and a filter 14 , wherein the substrate 10 is a glass substrate. see image 3 , the first side wall 101 of the substrate 10 is provided with an incident end groove 102, a reflective end groove 103 and a passing end groove 104, the incident end groove 102 and the reflecting end groove 103 intersect at a preset angle, and the passing end groove The groove 104 is arranged coaxially with the groove 102 at the incident end, preferably, the preset angle is 60 degrees. The filter 14 is installed at the junction 105 of the incident end groove 102 and the reflective end groove 103, the incident end optical fiber 11 is installed in the incident end groove 102, the reflective end optical fiber 12 is installed in the reflective end groove 103, and the passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com