Apparatus for forming penetrating cracks in rock sample and operation method thereof

A technology for rock samples and penetrating cracks, which is applied in the field of devices for preparing rock samples, and can solve the problems of the space position and size of the penetrating cracks, the concentricity of the two ends of the cracks, the difficulty of precise control, the health hazards of the workers, and the change of the mechanical properties of the rock. and other issues to achieve the effect of improving production efficiency, reducing labor intensity, and producing accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below.

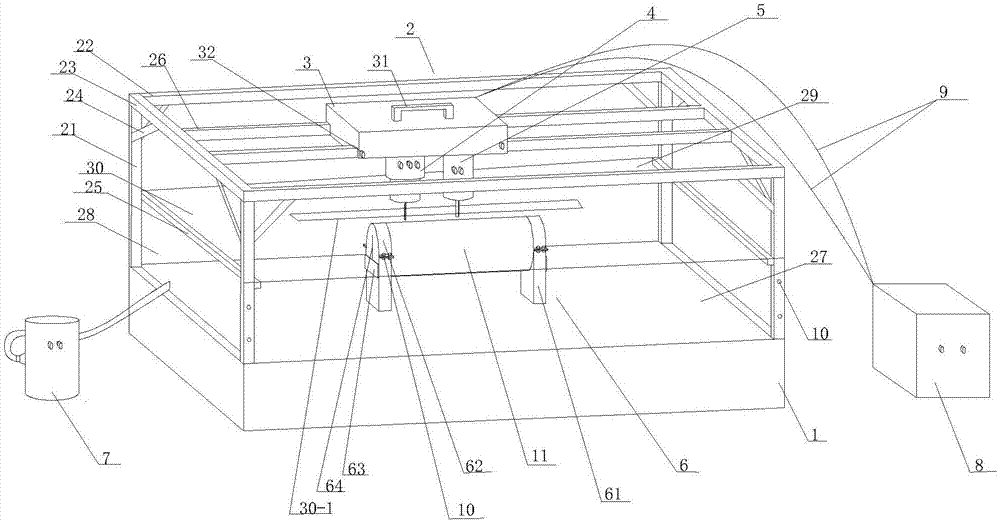

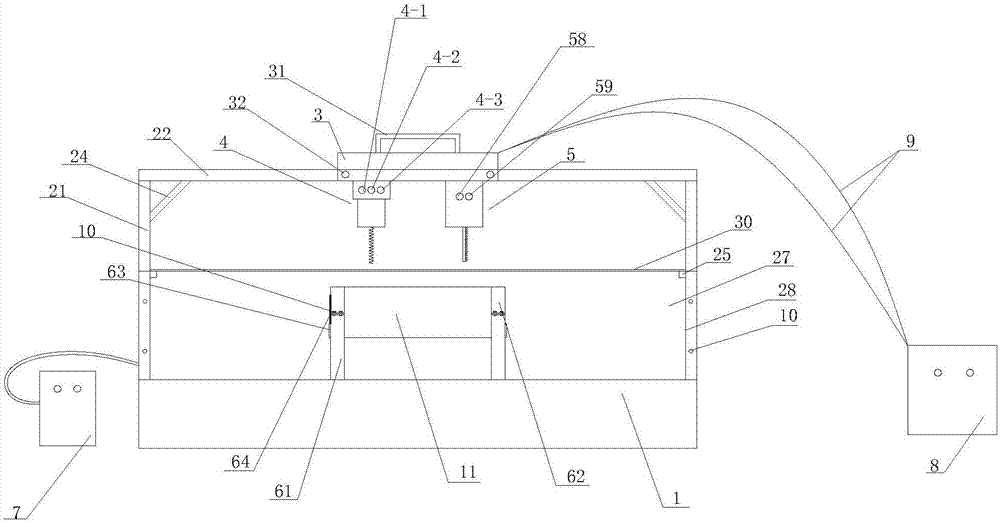

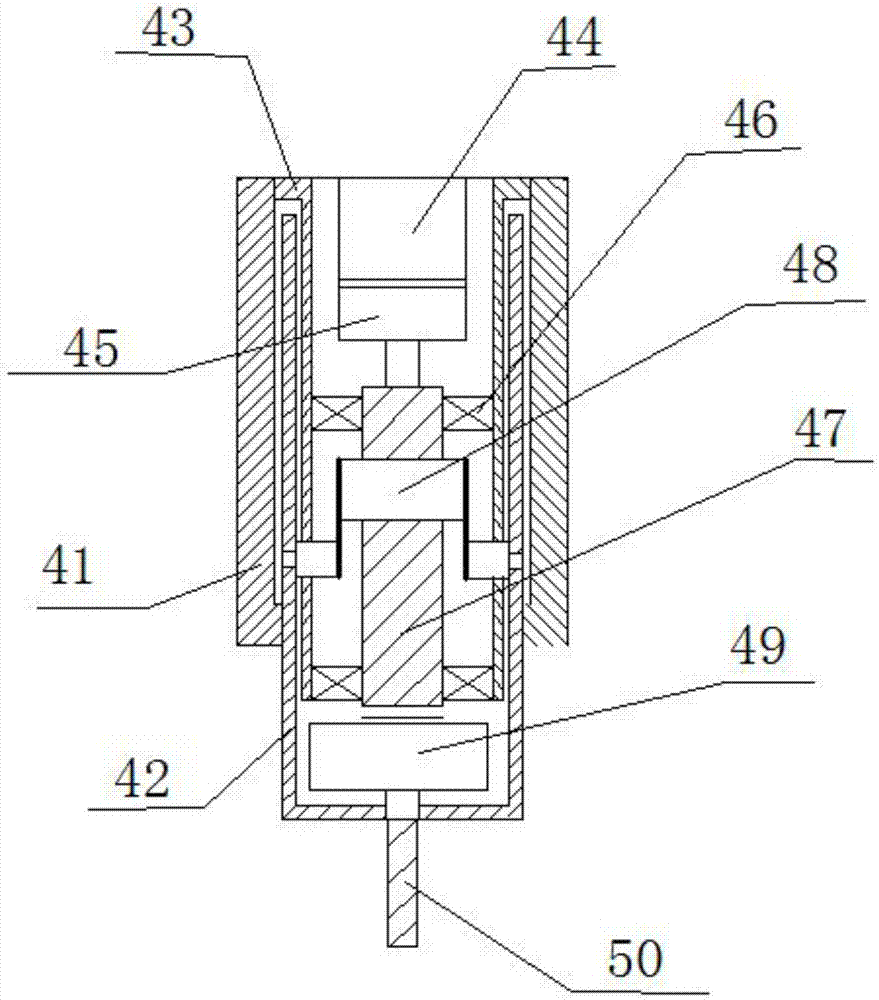

[0032] Such as Figure 1 to Figure 6As shown, a device for preparing rock samples through cracks, including a base 1, a support structure 2, a work platform 3, a drilling device 4, a cutting device 5, a sample fixing device 6, and a dust removal device 7 And power source 8, bracket structure 2 is fixed on the base 1, and bracket mechanism 2 includes column 21, beam 22, connecting beam 23, bracket bar 25, slide rail 26, front glass plate 27, side glass plate 28, rear glass Plate 29 and glass cover plate 30, four columns 21 are vertically fixed on the base 1, two beams 22 and two connecting beams 23 are fixedly connected to form a rectangular frame, and the rectangular frame is fixed on the upper end of the column 21, and the supporting rod 25 is horizontally fixed in the middle of the two columns 21, and there are two support rods 25. The two support rods 25 are arranged symmetrically and on the same horizontal pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com