Non-dismantling heat-insulation form board cast-in-place fixing piece

A technology of thermal insulation formwork and fixing parts, which is applied in the direction of building components, walls, buildings, etc., and can solve the problems of easily damaged and non-dismantling steel wire mesh frame and steel wire flat mesh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

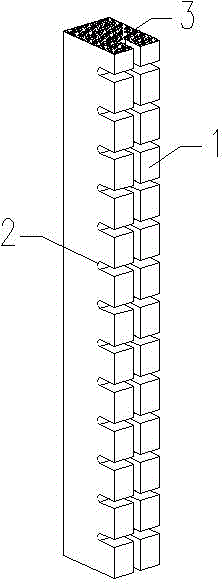

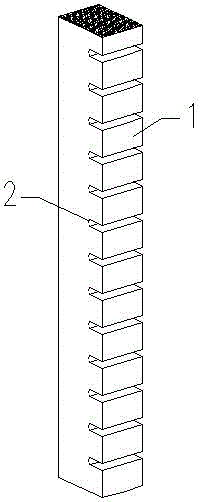

[0014] Attached below figure 1 , 2 , 3 the present invention is described in detail:

[0015] A cast-in-place fixture for a non-dismantling thermal insulation formwork, which includes a long strip-shaped fixture body, and only horizontal grooves 2 or horizontal grooves 2 and vertical grooves 3 are evenly distributed on one side of the fixture body;

[0016] One side of the fixing member is divided into several squares 2 by the horizontal groove 2 and / or the vertical groove 3 for supporting the insulation board. So that it does not shift during concrete pouring.

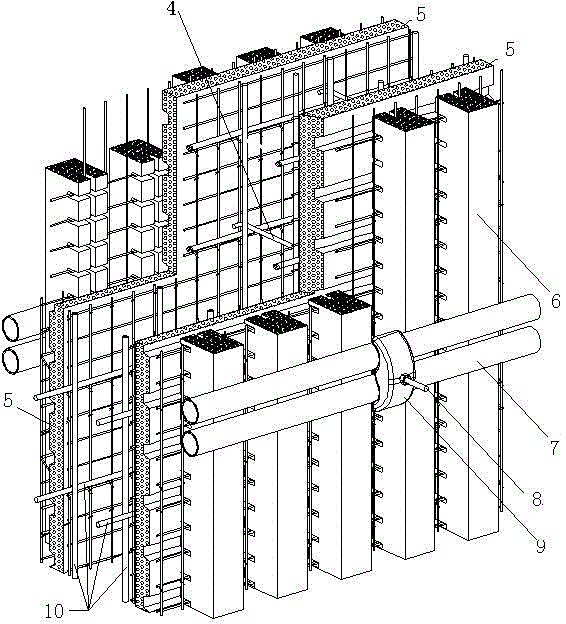

[0017] image 3 Middle: 4- tie bars, 5- steel wire grid insulation board, 6- cast-in-place fixing parts of the insulation formwork without dismantling of the present invention, 7- outer keel, 8- pull screw, 9- fastener, 10- shear force Wall reinforcement skeleton.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com