Z source reverser and soft start method

A source inverter and soft start technology, applied in the direction of converting AC power input to DC power output, output power conversion device, electrical components, etc., can solve the problem of short circuit of input voltage source, distortion of output waveform, circuit damage of switching tube, etc. Problems, to avoid large voltage and current, small capacitor voltage stress, safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

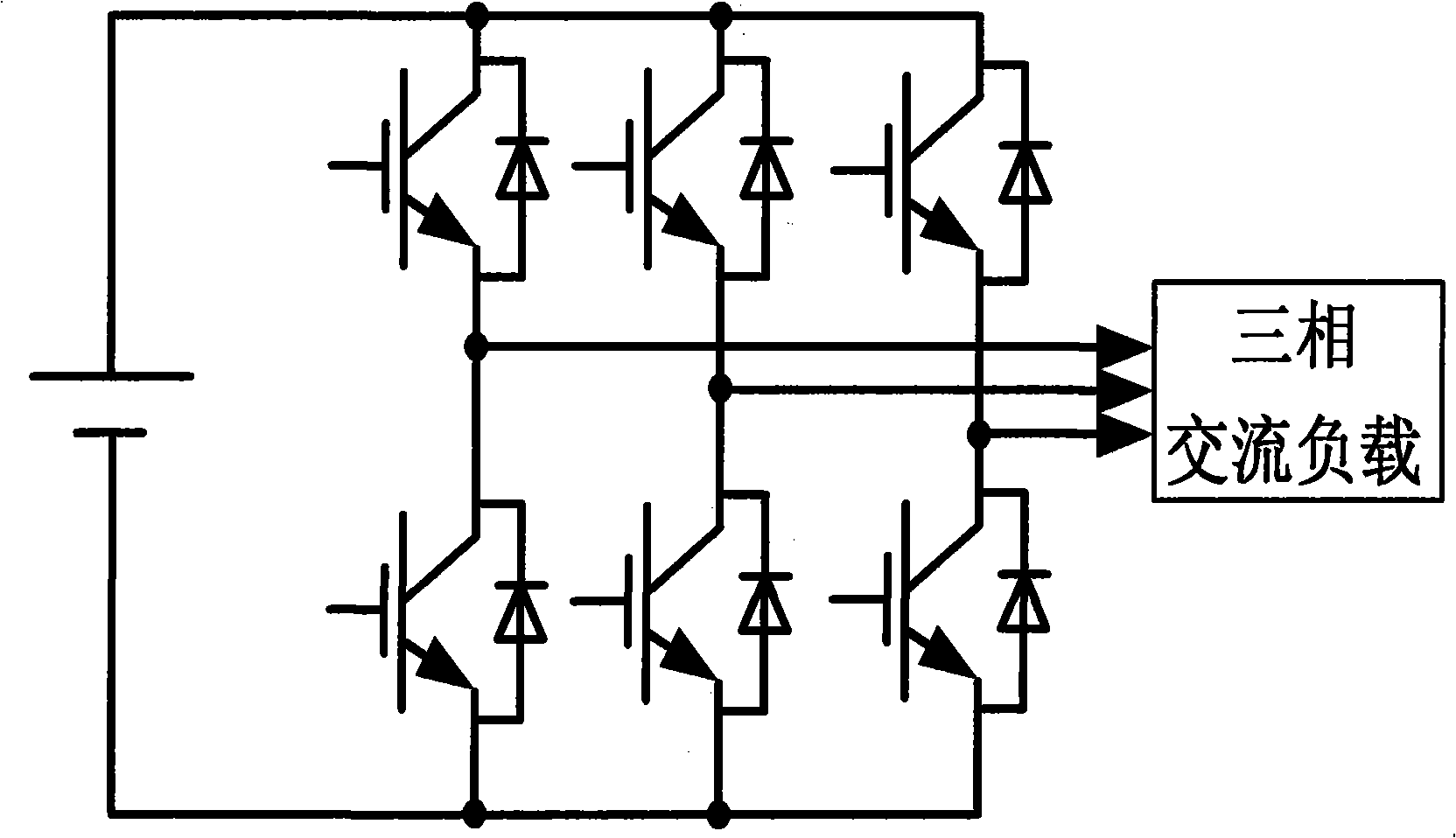

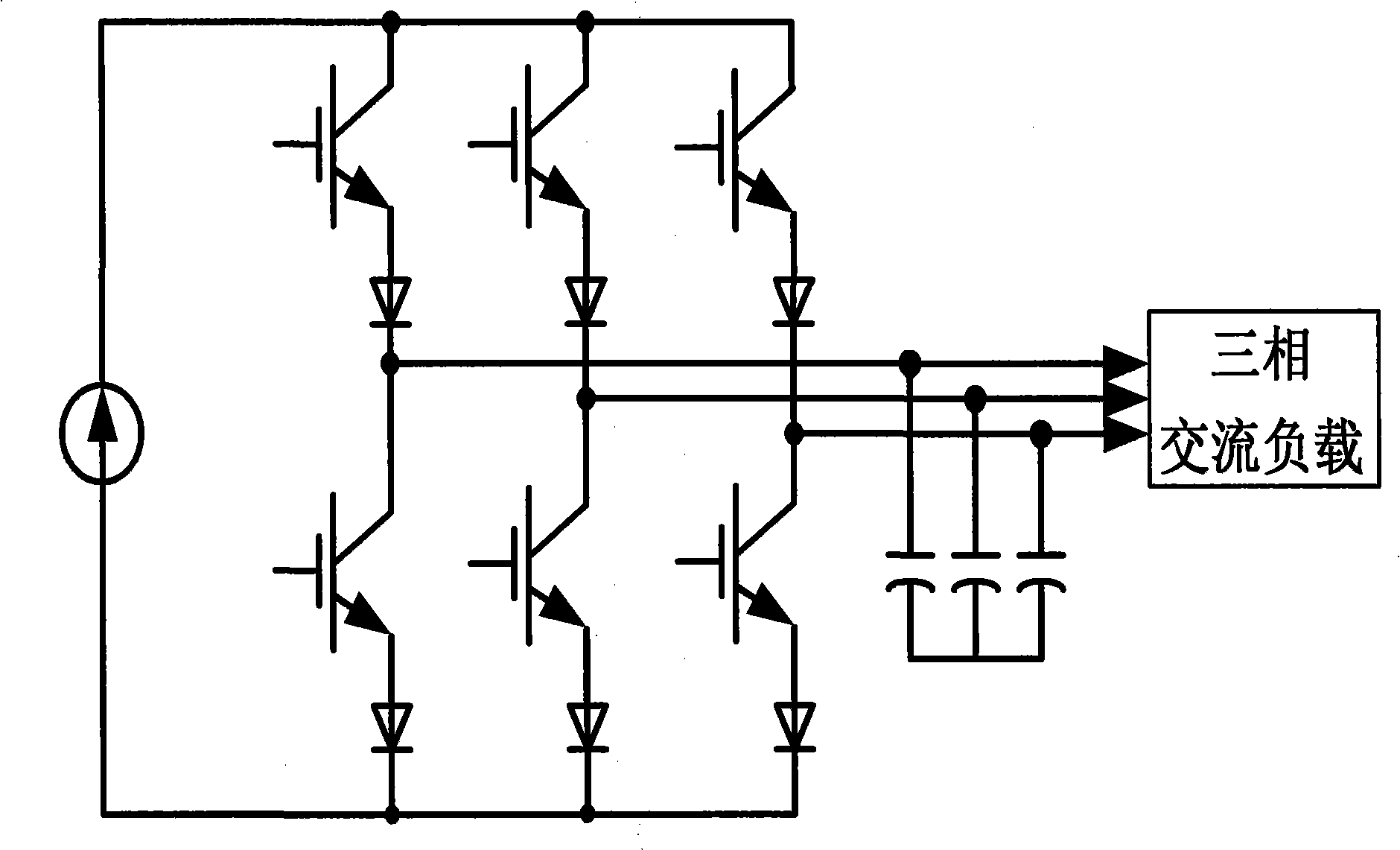

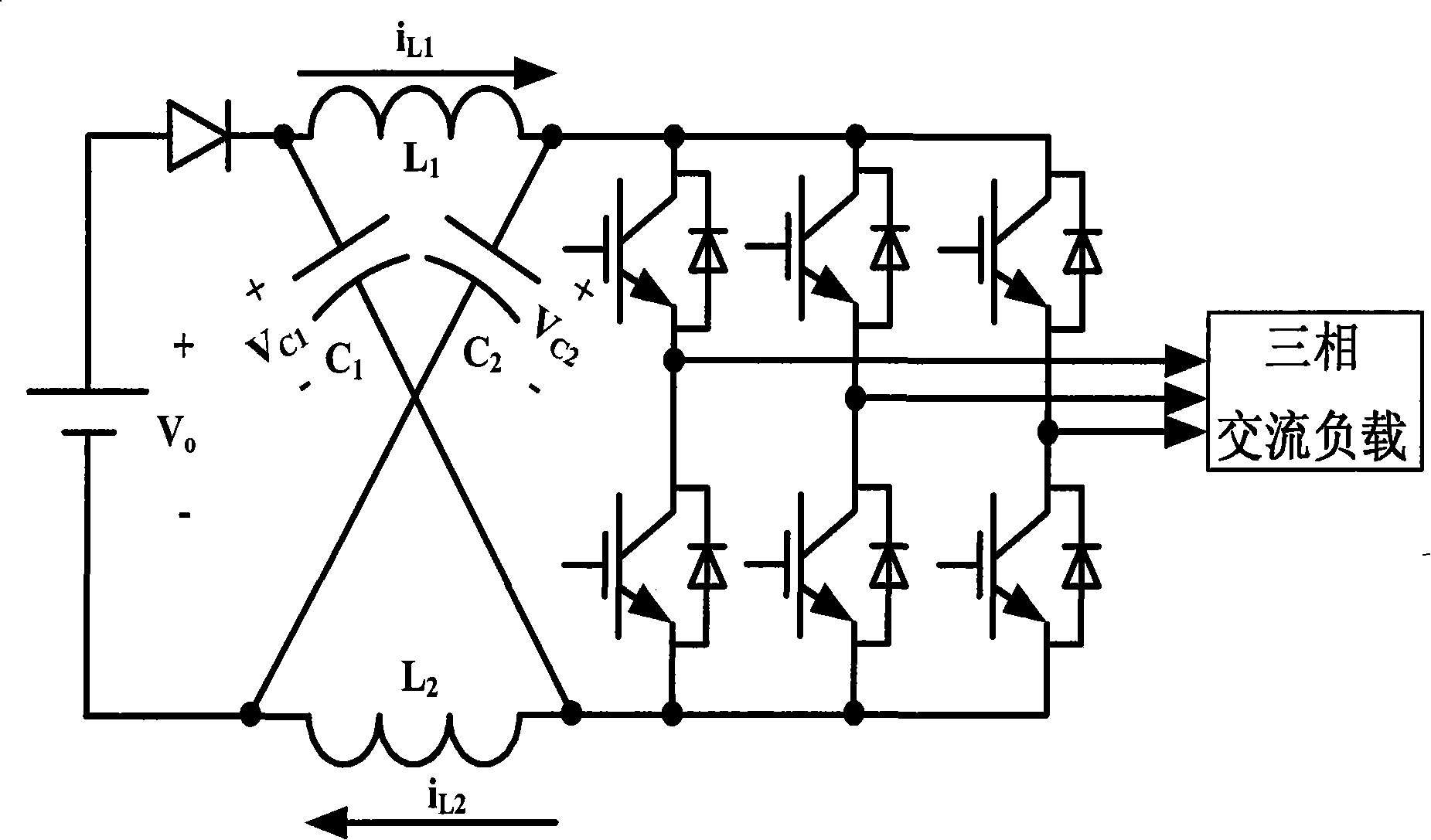

[0016] attached Figure 4 Is the Z source inverter main circuit. Compared with the traditional voltage source inverter, this inverter replaces some of the traditional zero vectors with direct zero vectors to realize the function of boosting. On the other hand, the impact of the through zero vector and the traditional zero vector on the output is the same, so the addition of the through zero vector will not affect the output waveform. The converter controls the capacitor voltage of the Z source network by controlling the direct duty cycle of the inverter bridge arm, and controls the output voltage by controlling the modulation ratio. When the converter starts, it controls the direct duty cycle of the inverter bridge arm from Slowly increase from zero to the rated value, so as to realize the soft start of the converter and avoid the overshoot of the inductor current and capacitor voltage in the converter. Specifically, it includes the following four soft start methods: 1. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com