Patents

Literature

119results about How to "Easy overload protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

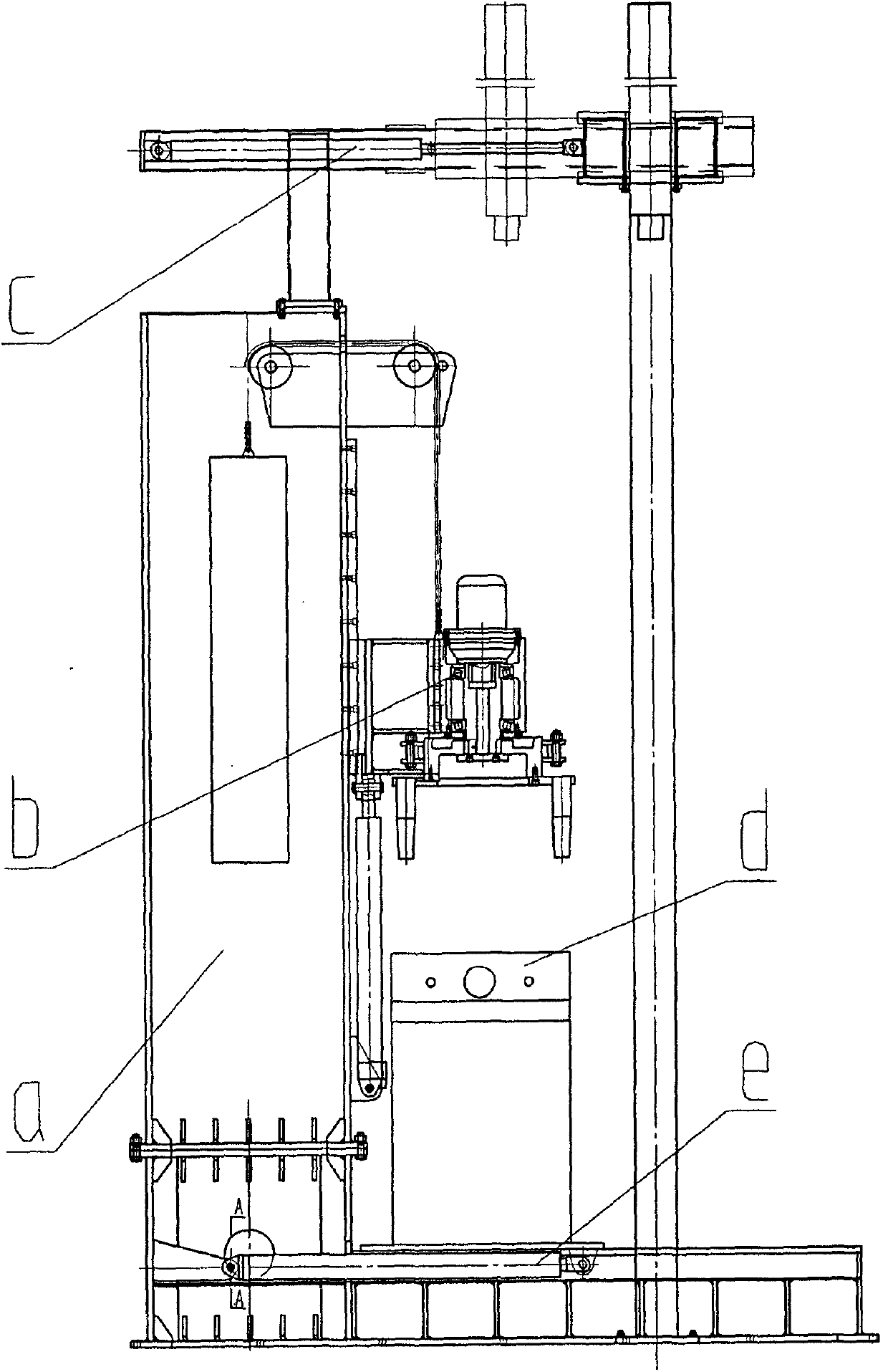

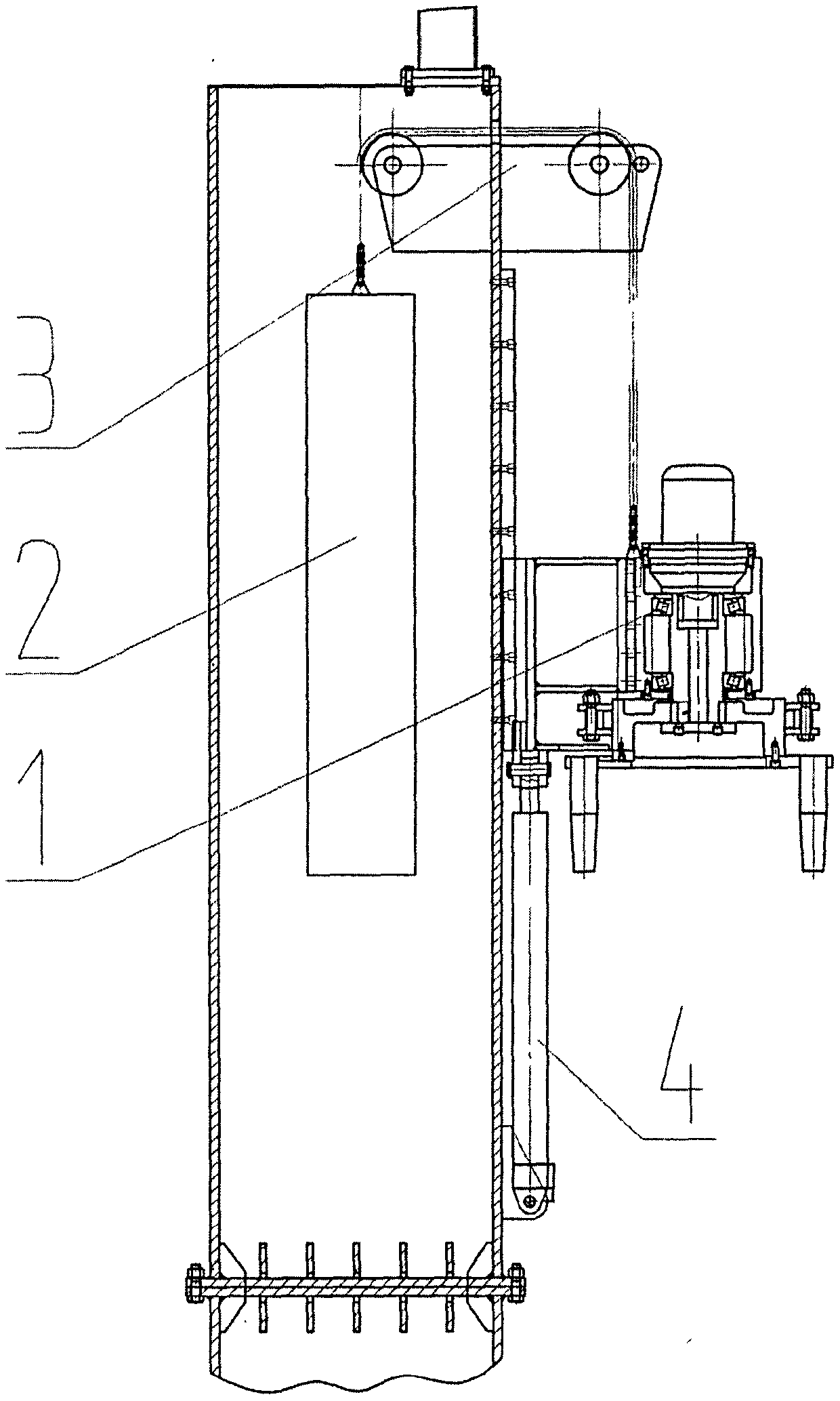

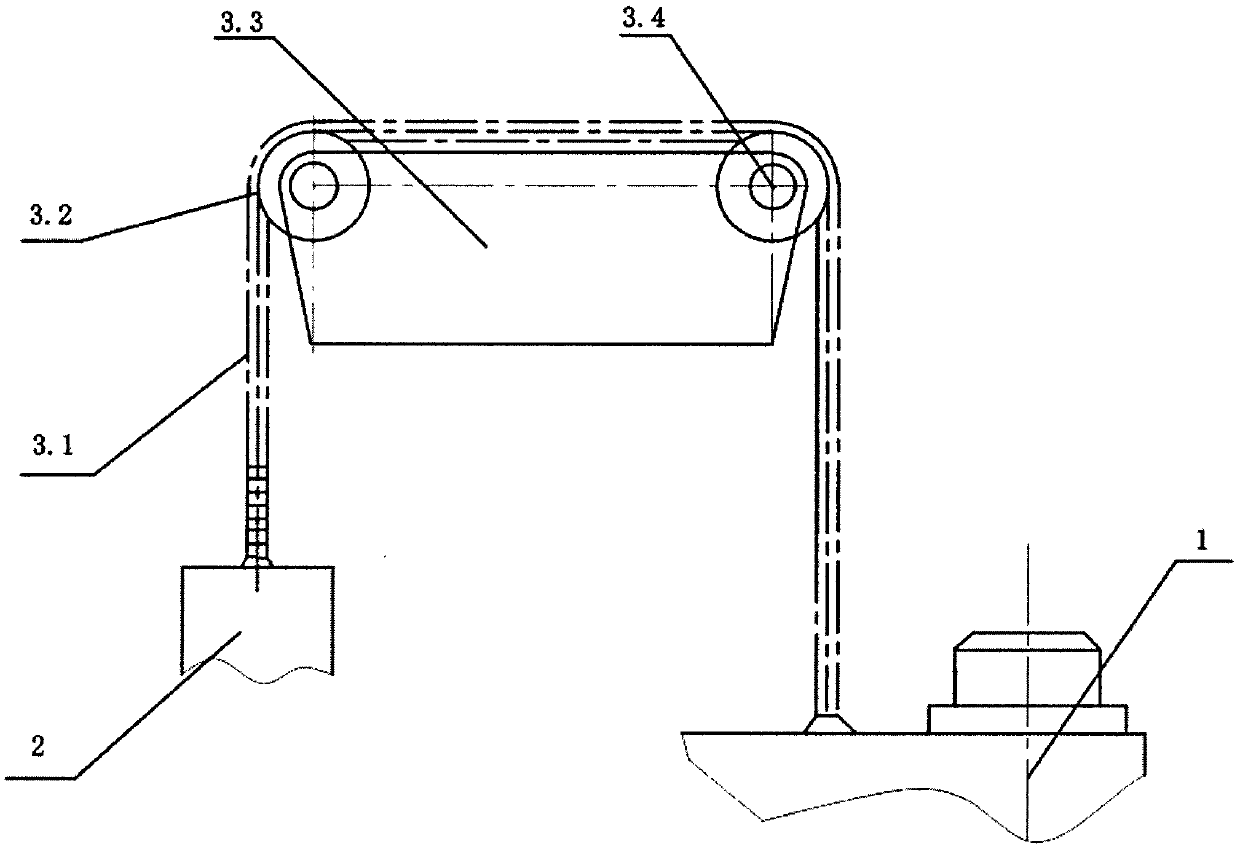

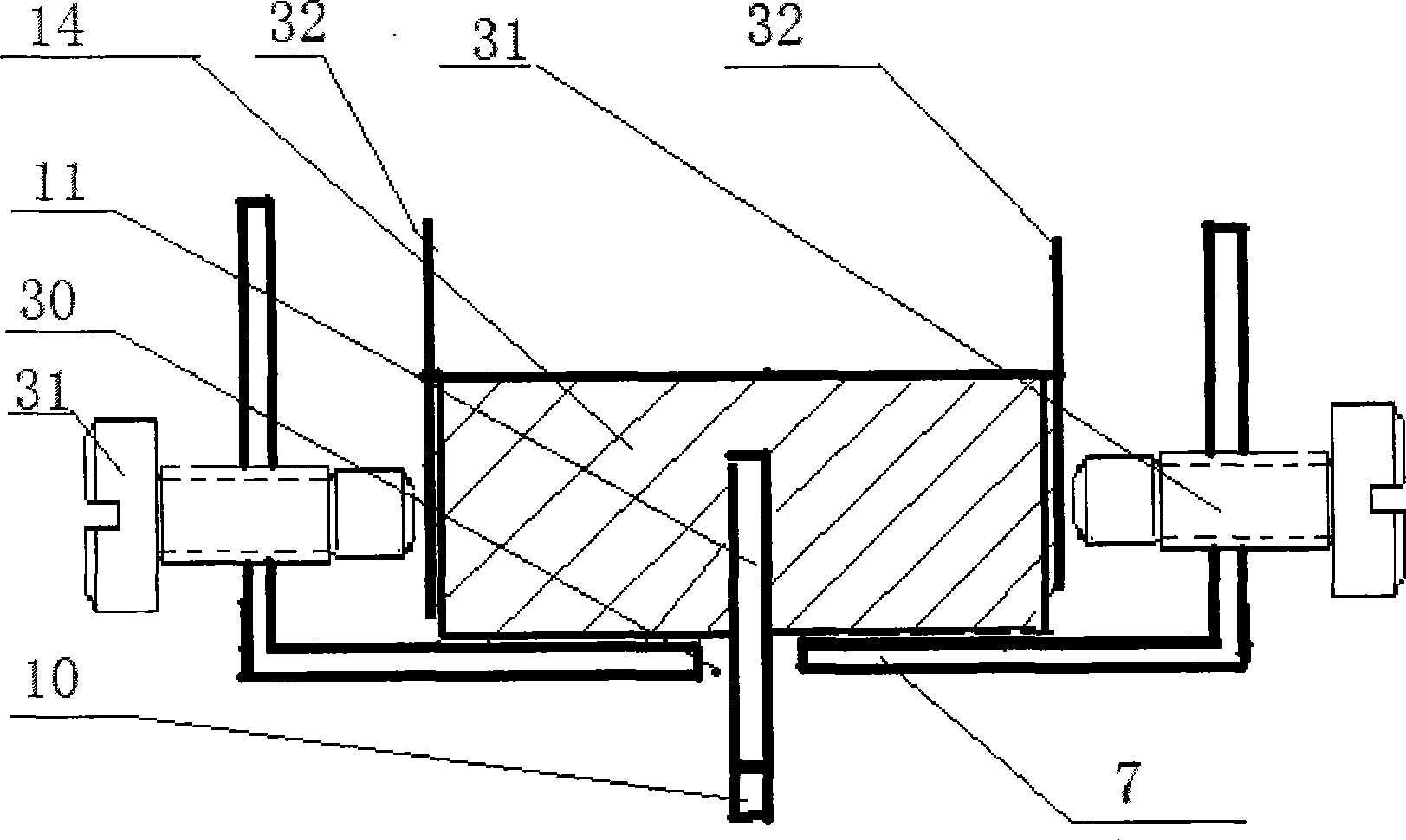

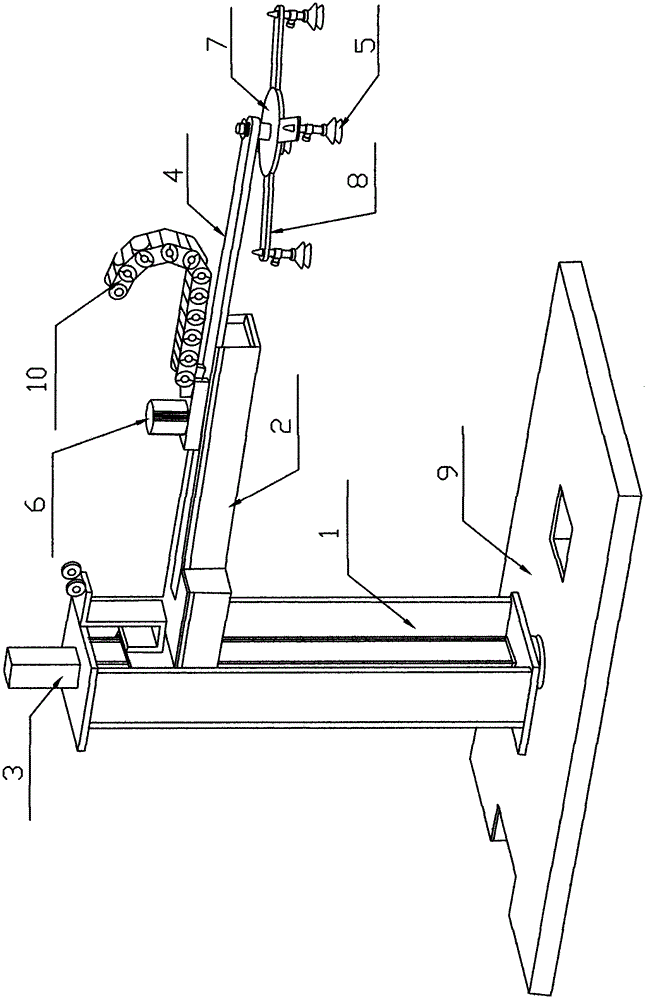

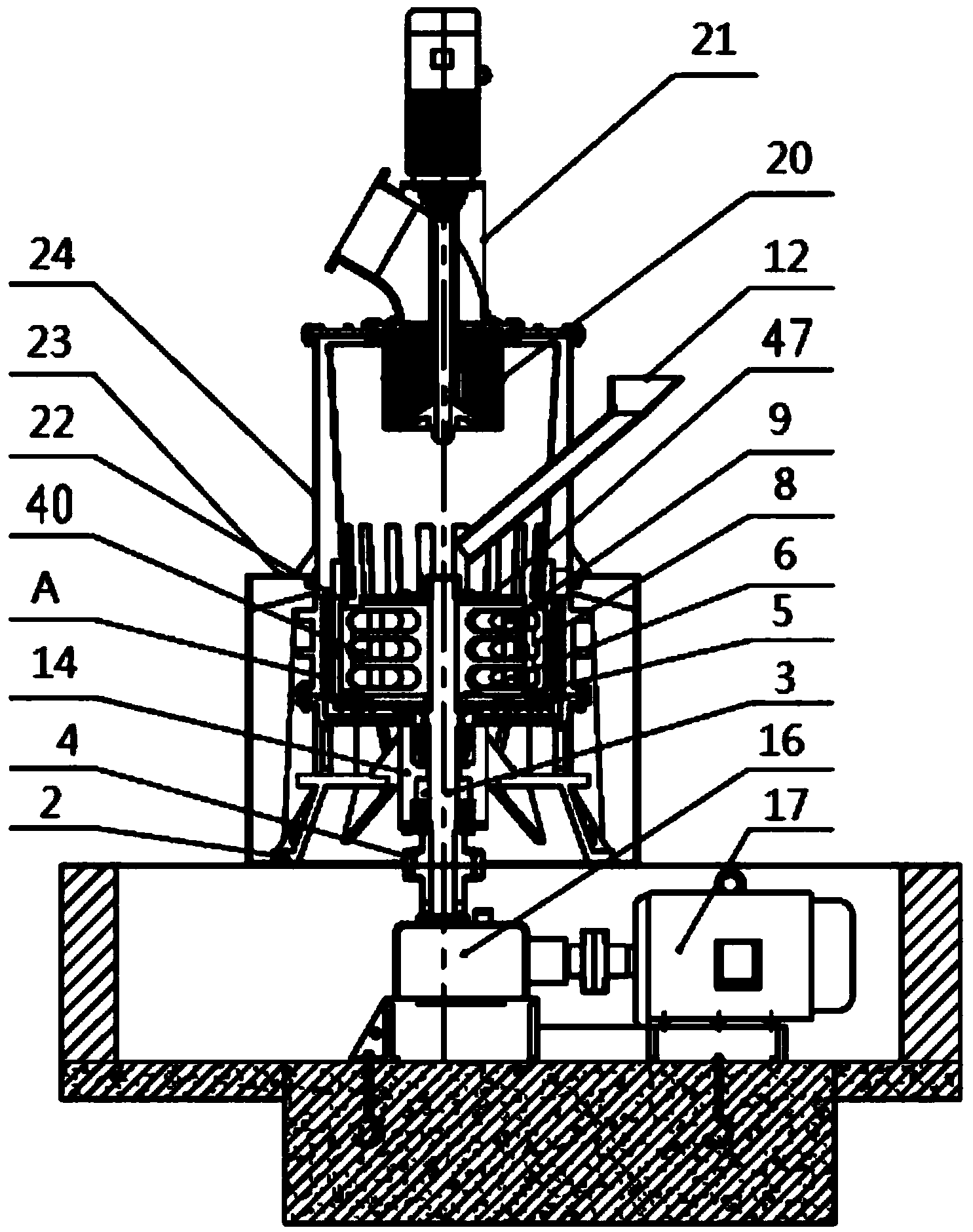

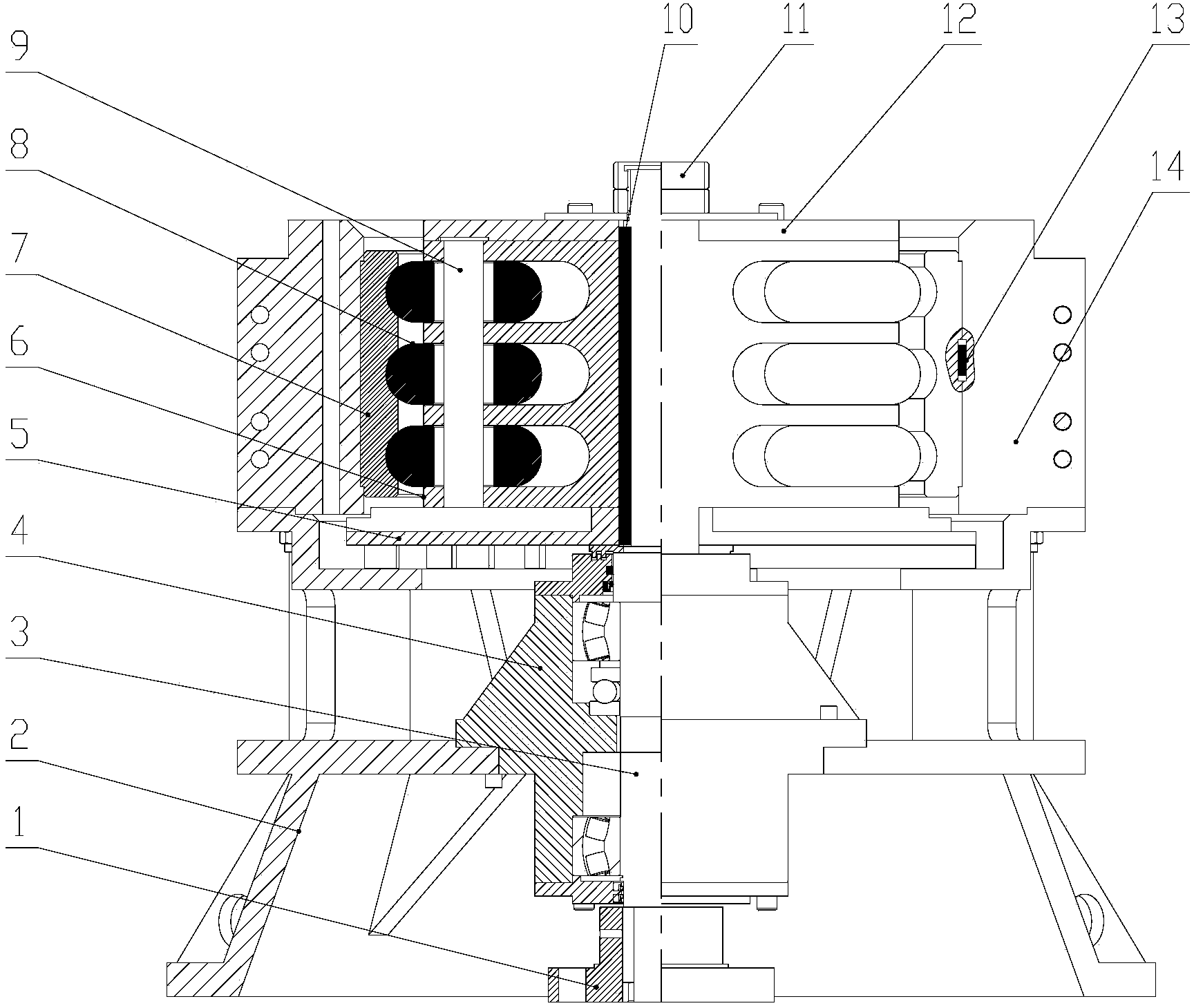

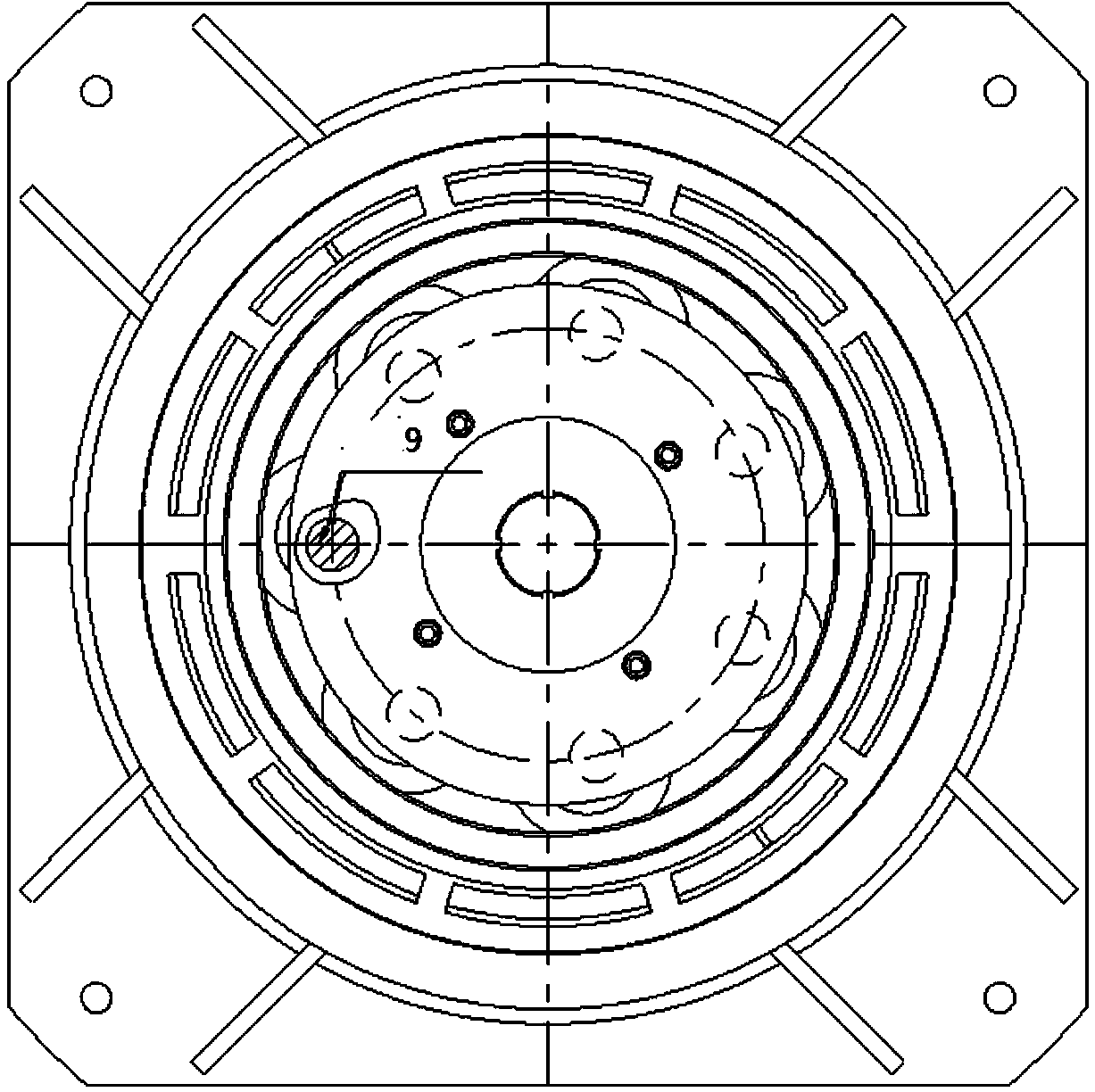

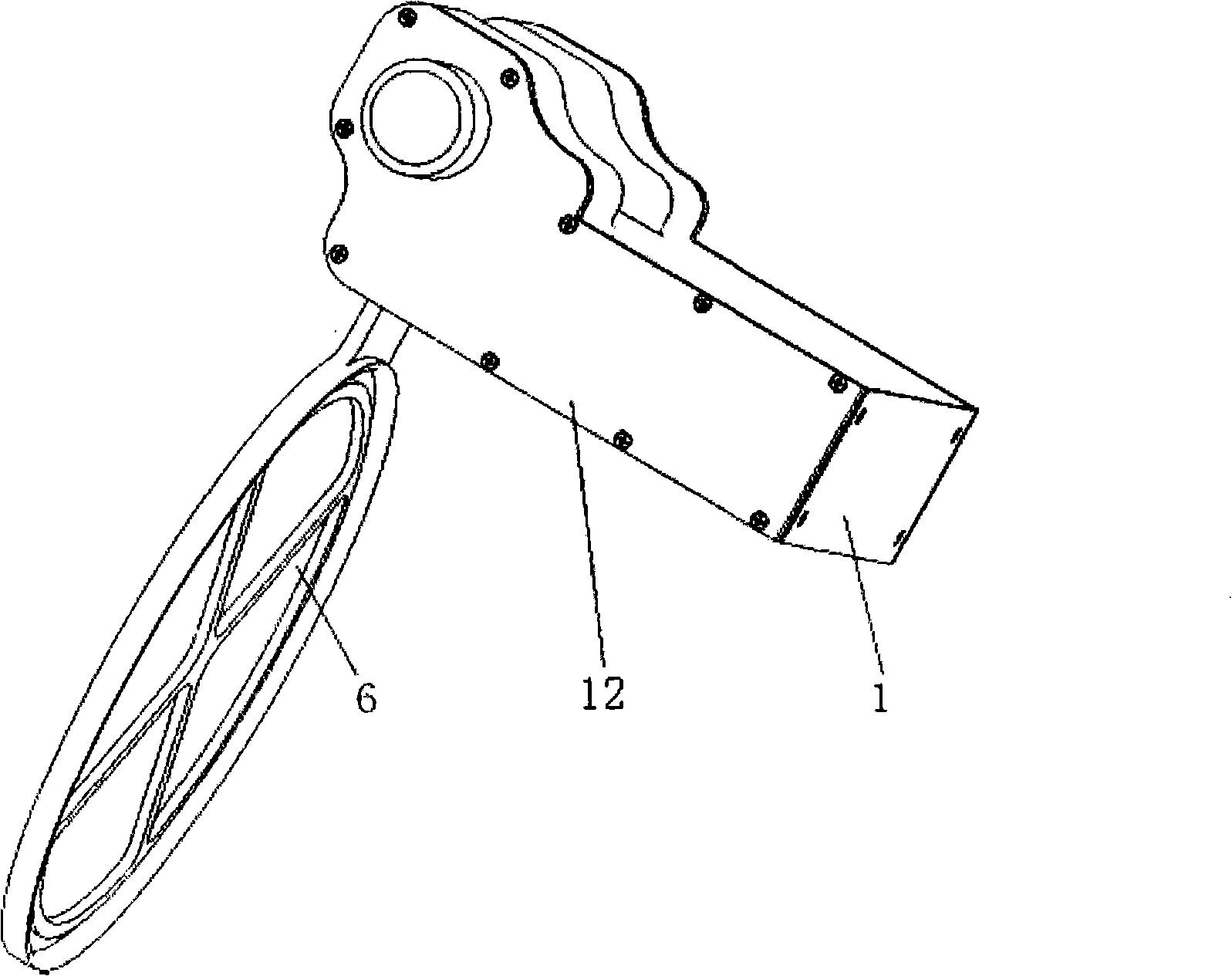

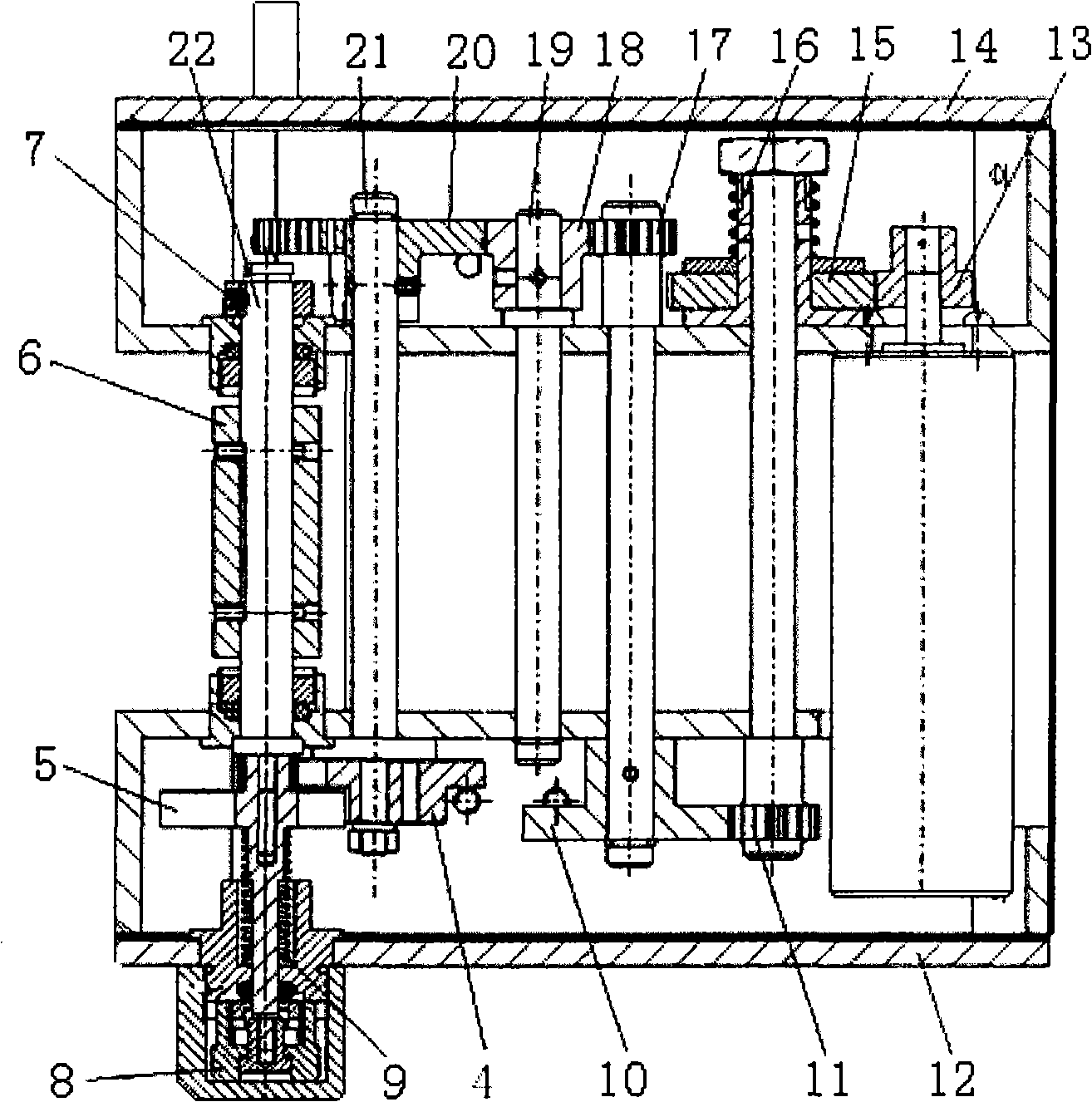

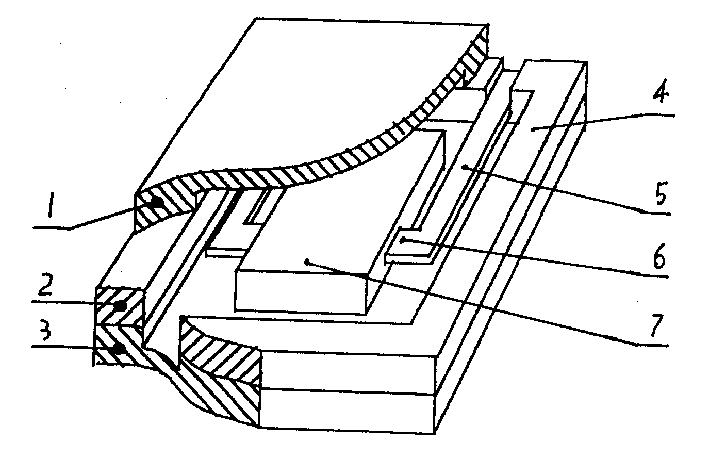

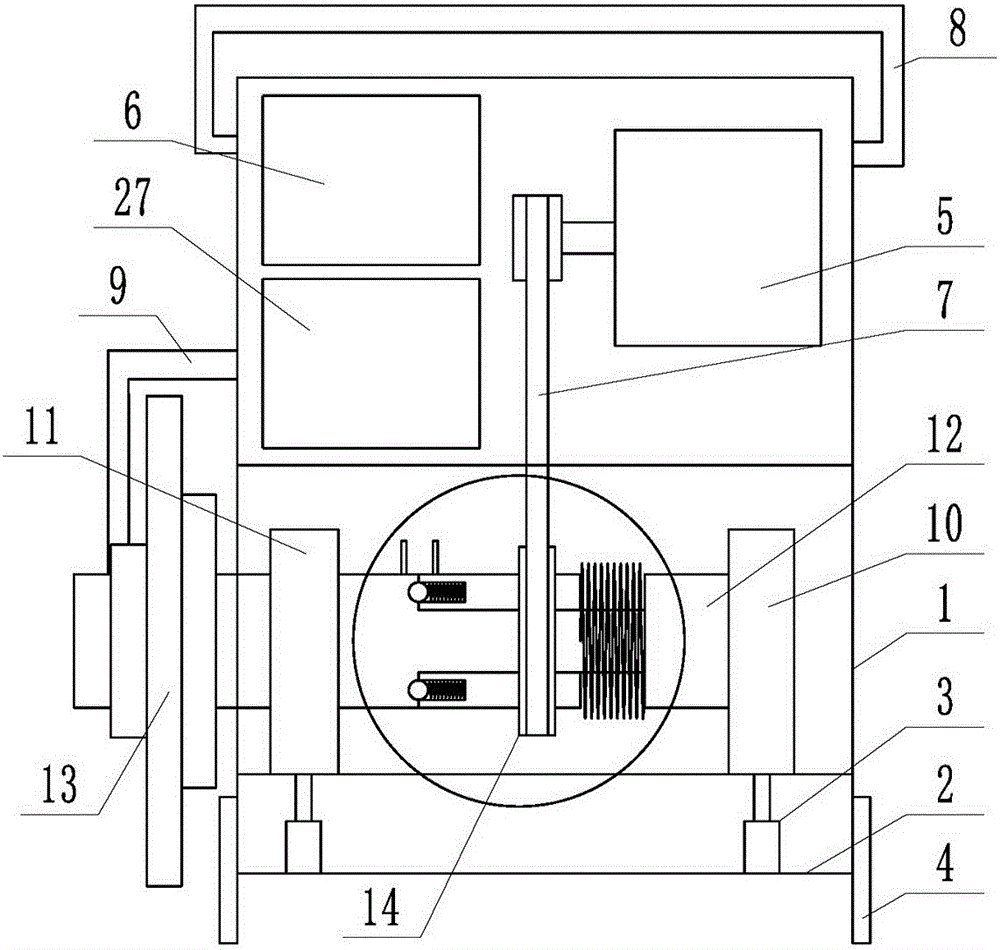

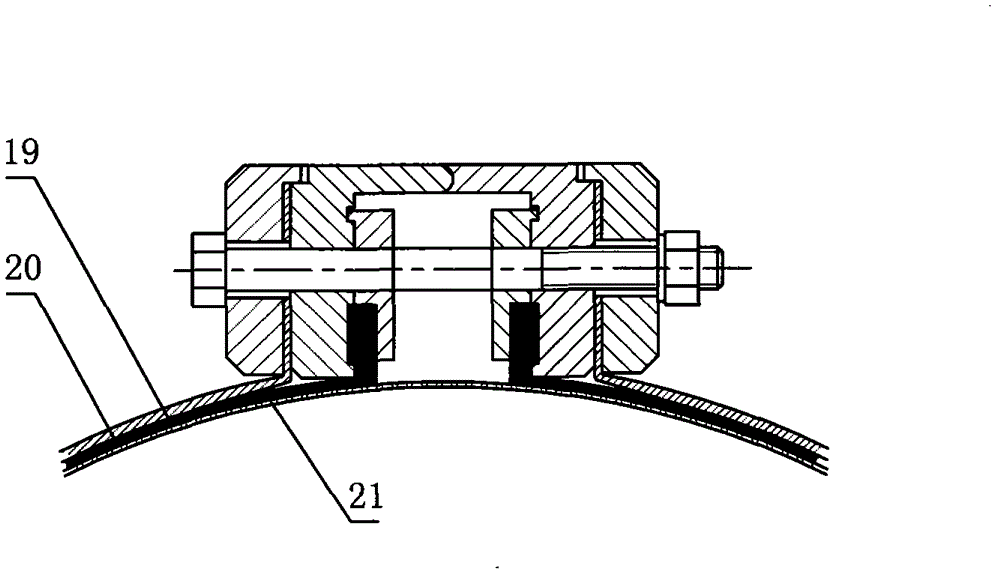

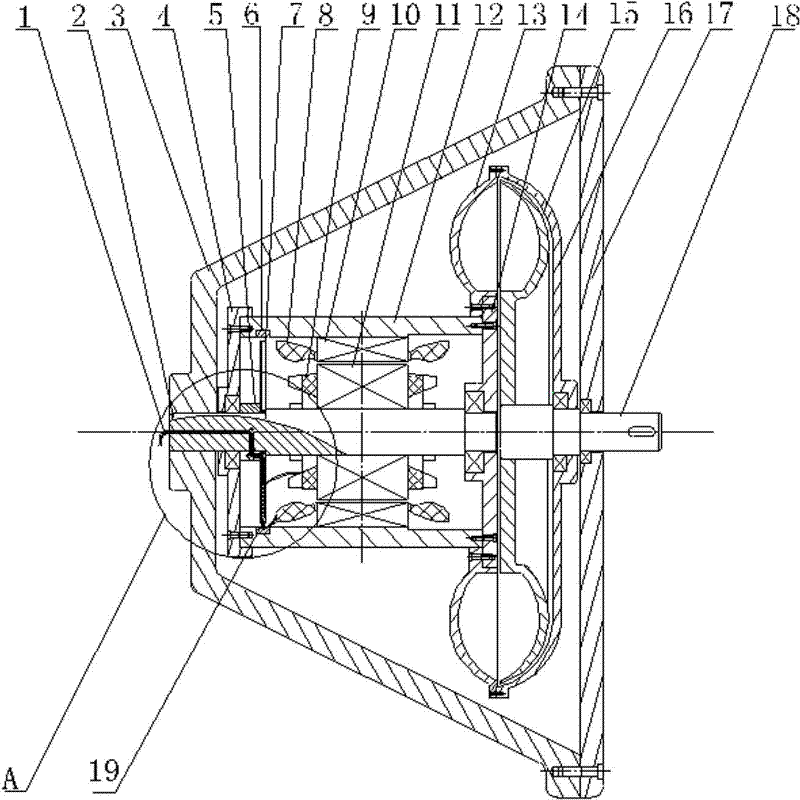

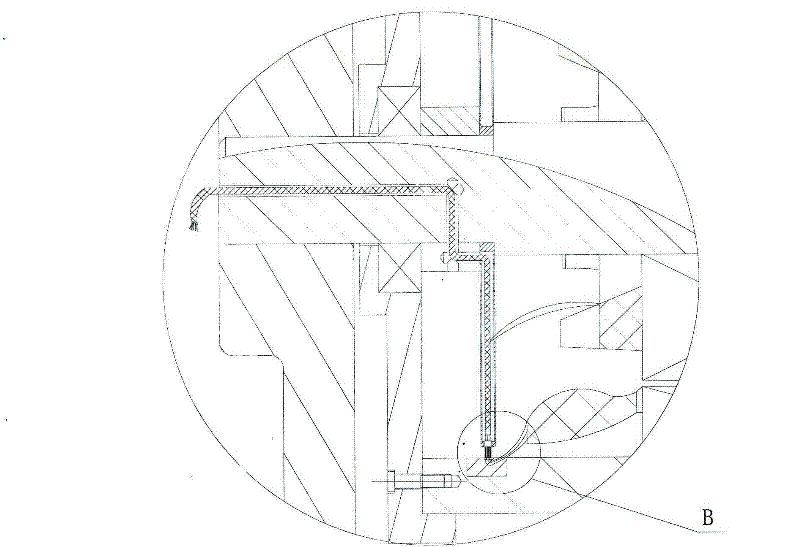

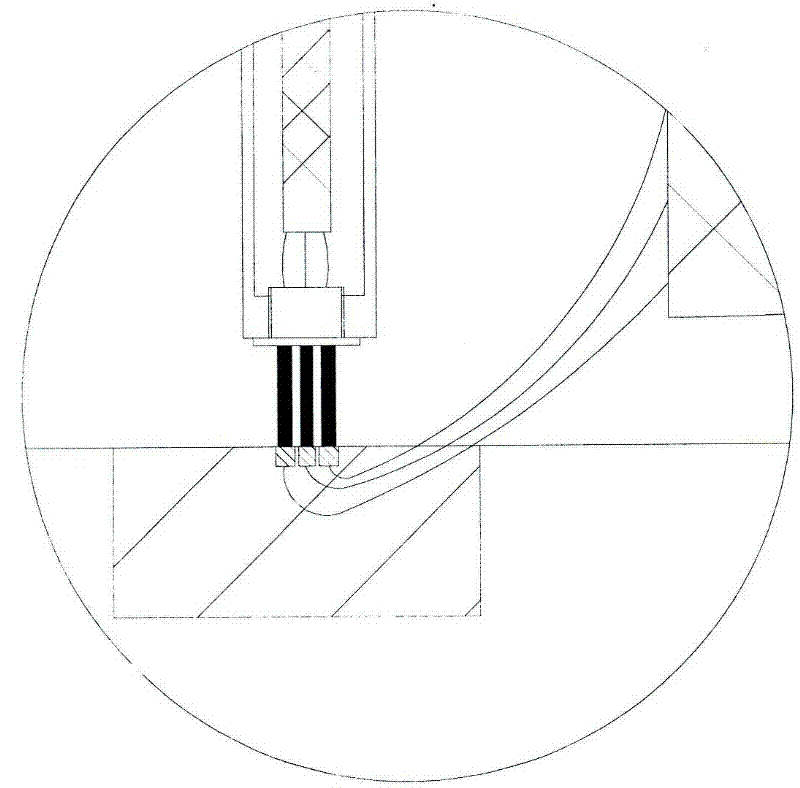

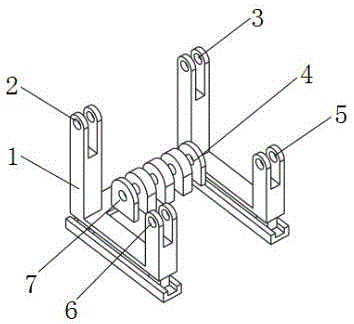

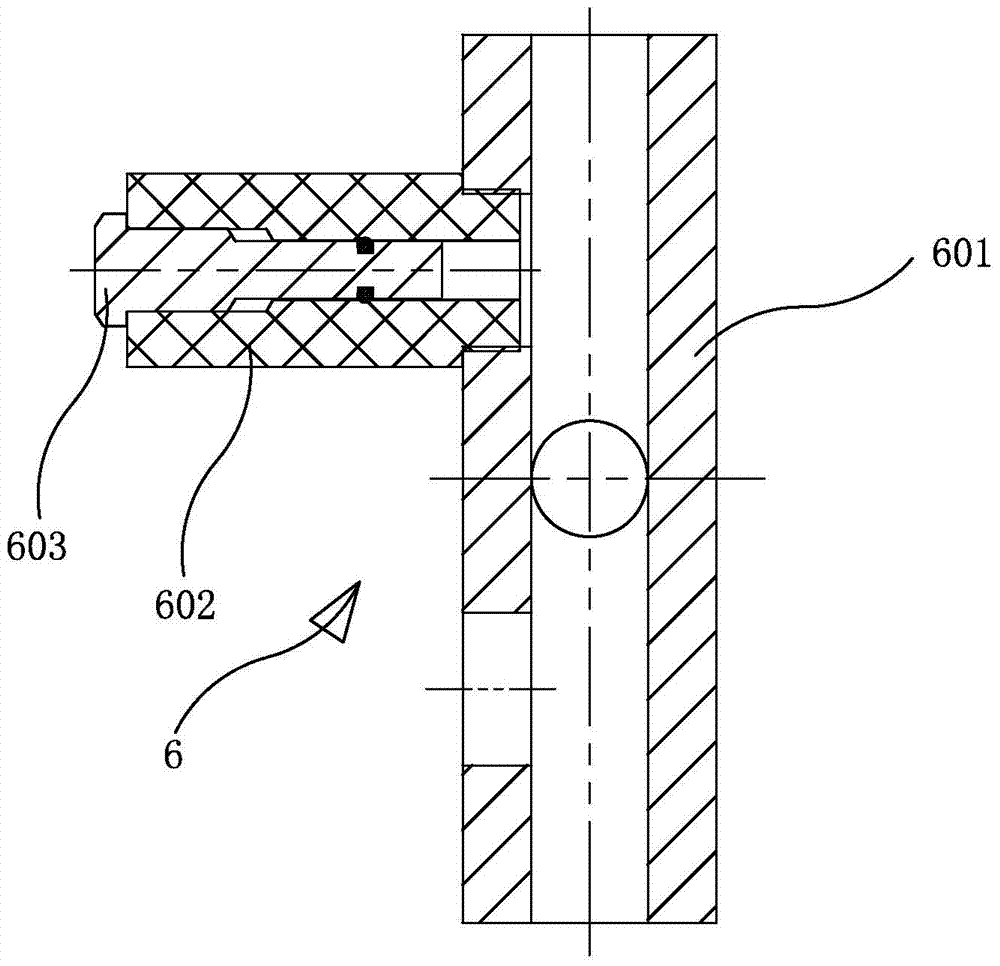

Novel upright assembling and disassembling device for upright columns of hydraulic support

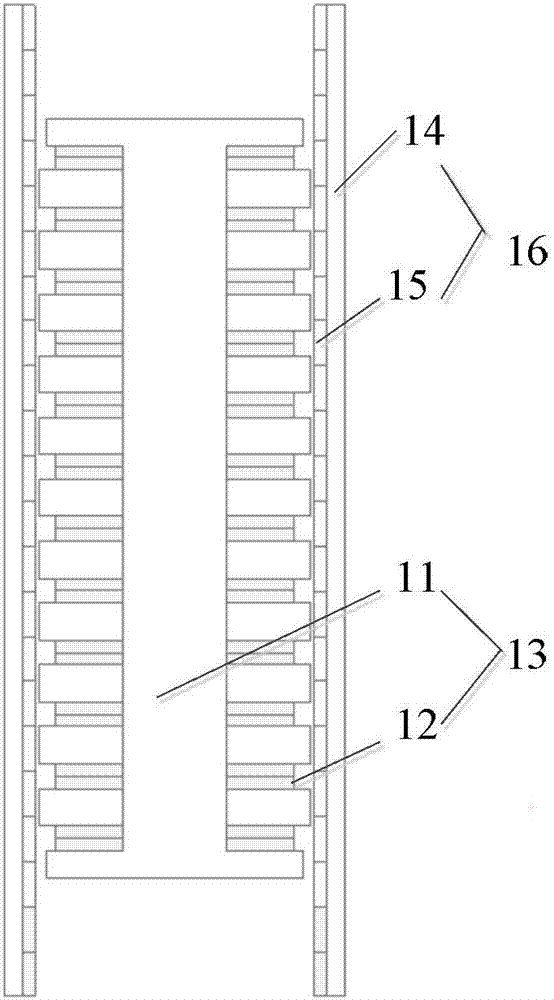

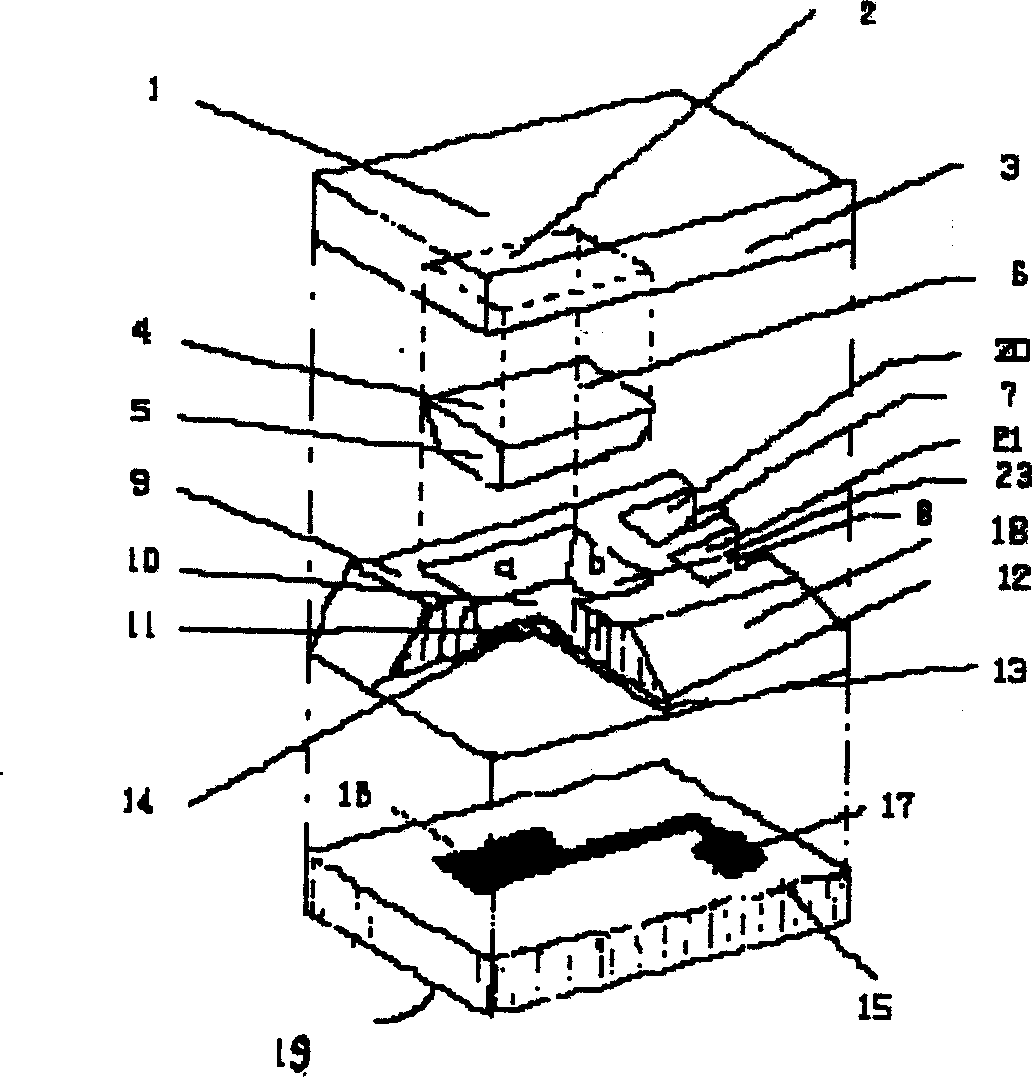

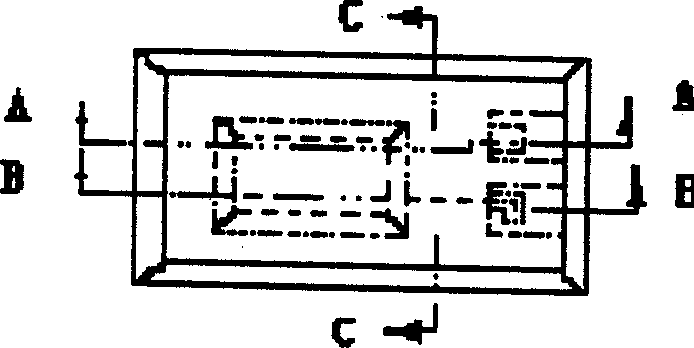

A novel upright assembling and disassembling device for upright columns of a hydraulic support consists of a body rack portion (a), a head and lifting device (b), a cylinder pressing and pushing mechanism (c), a workpiece feeding device (d), a workpiece feeding cylinder (e), a hydraulic pump station and an electrical control system. By an integrated design scheme, assembling and disassembling operations of the upright columns are finished on the device, various problems in the existing horizontal assembling and disassembling device are effectively solved, the work efficiency is improved, the labor intensity is reduced, the energy consumption is decreased, and the assembling and disassembling quality of the upright column is improved. In addition, the novel upright assembling and disassembling device has high economic benefit and high social benefit; and the popularization and application prospects of the device is wide.

Owner:焦作欣扬程煤矿设备有限公司 +2

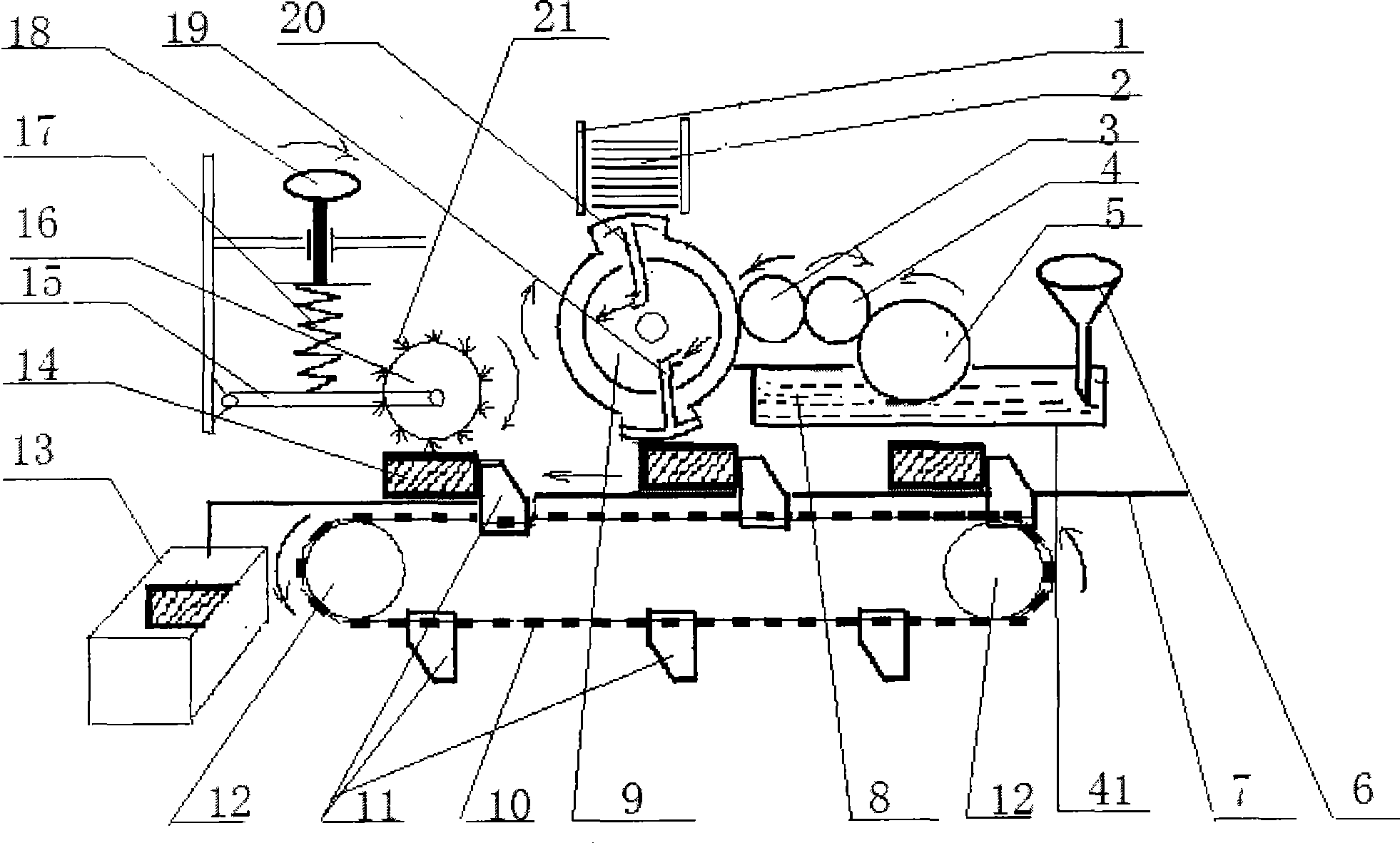

Electromechanical device for continuously, rapidly and pneumatically labelling

InactiveCN101486392AStable and reliable labelingBad labelingLabelling flat rigid surfacesLabelling machinesEngineeringAir compressor

The invention particularly relates to an electromechanical device capable of continuously, rapidly and pneumatically labelling, which consists essentially of a pneumatic suction mechanism, a pneumatic paper pasting mechanism, a glue spreading mechanism and a pressure-brushing and flat-pasting mechanism. A main rotating disc of the pneumatic suction mechanism is provided with an air suction port connected with an air compressor, an intermediate soft rubber roller is placed between a soft rubber roller coated with glue and a soft rubber roller adhered with glue, and the pressure-brushing and flat-pasting mechanism comprises a pinch roller shaft, a pinch roller, pressure-brush of kernel and a spring. A box to be printed is arranged on a middle passage of a printing box, and a toggle plate is driven by a square adjustable tooth-shaped chain. The electromechanical device is characterized by stable and reliable labeling, no malposition or bubbling of labeling, high efficiency and strong commonality; besides, the design of the pneumatic mechanisms has less pressure loss and easy overload protection, and the pneumatic mechanisms take air as medium which is easy to obtain and discharge and does not pollute the environment.

Owner:南通健美体育用品有限公司

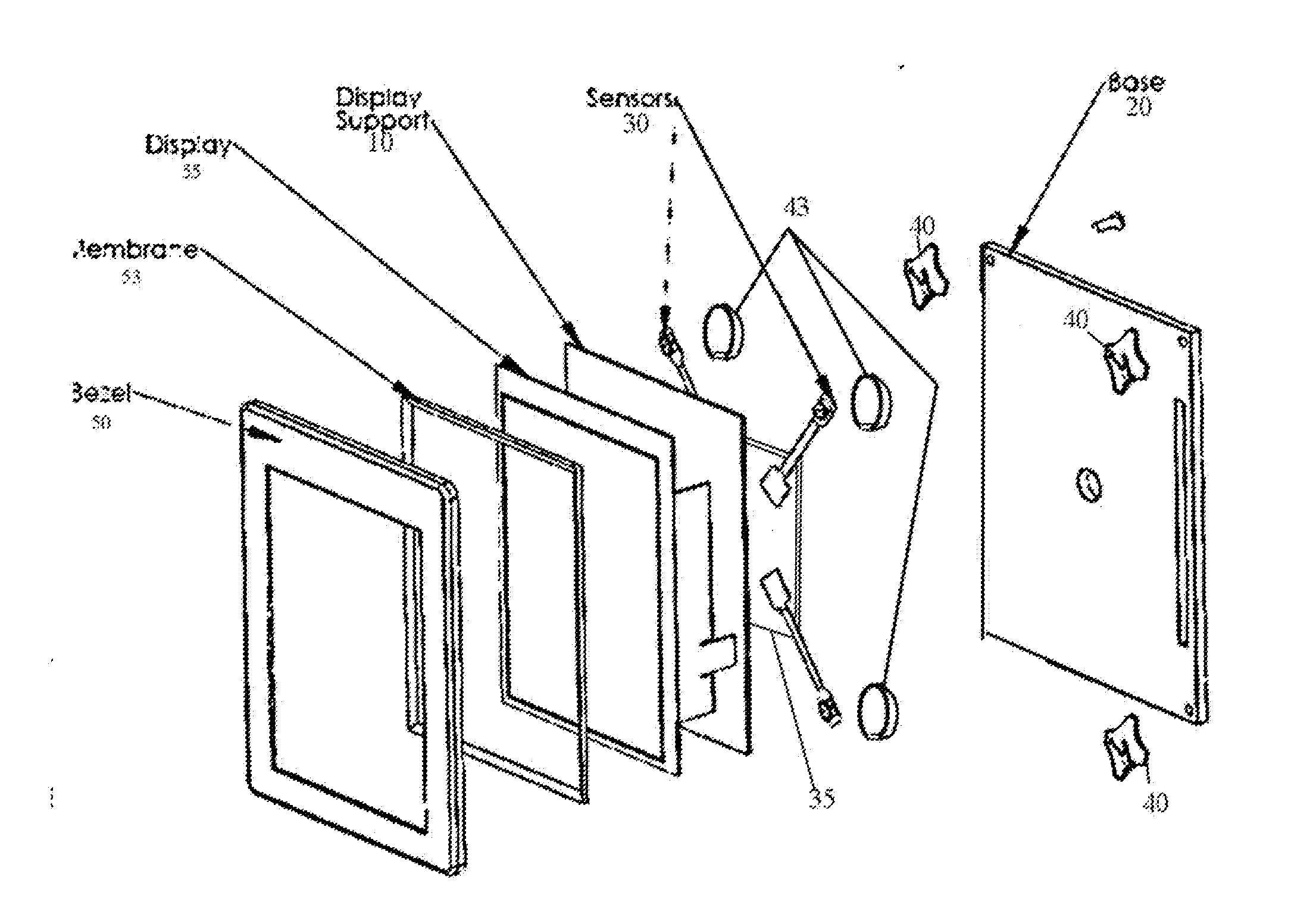

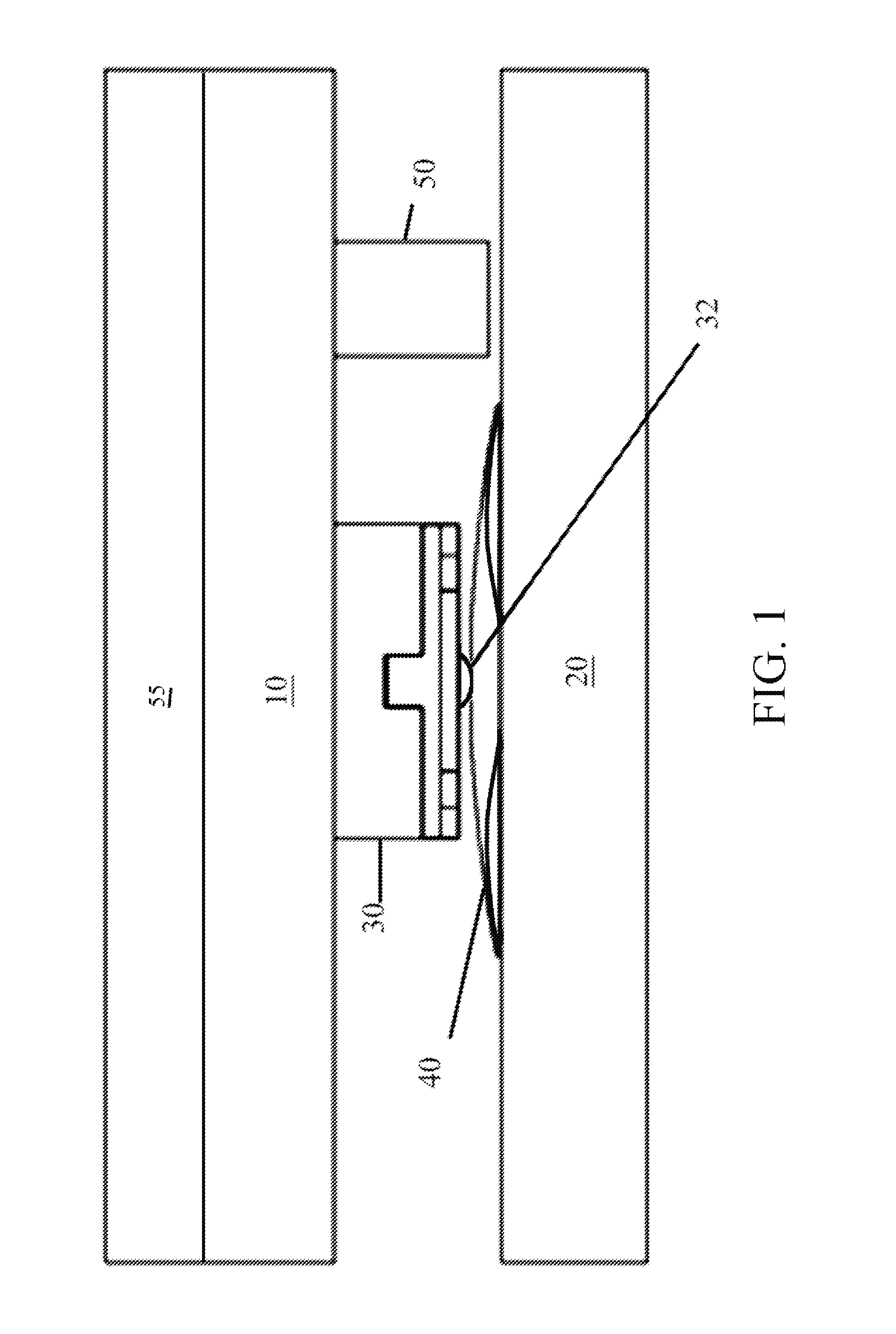

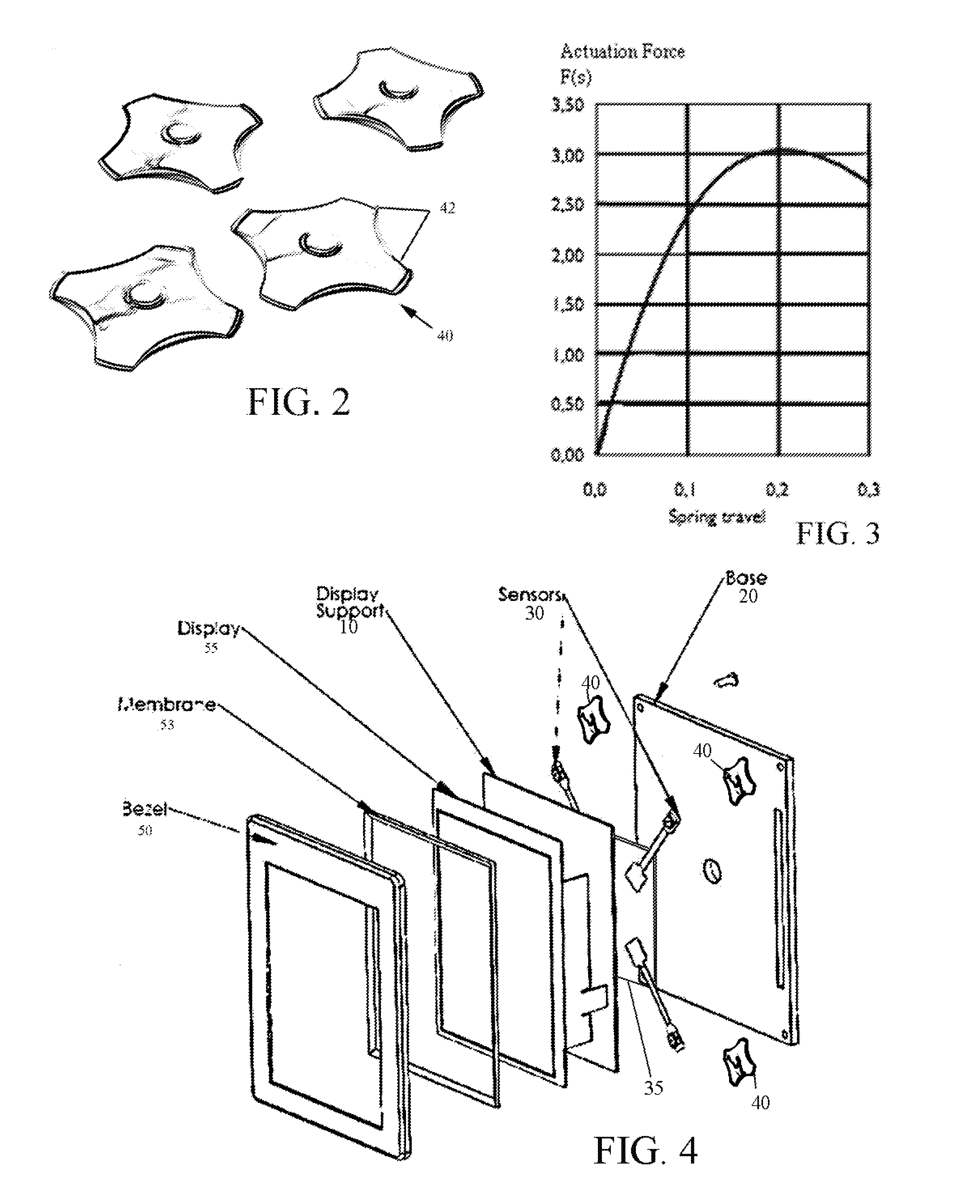

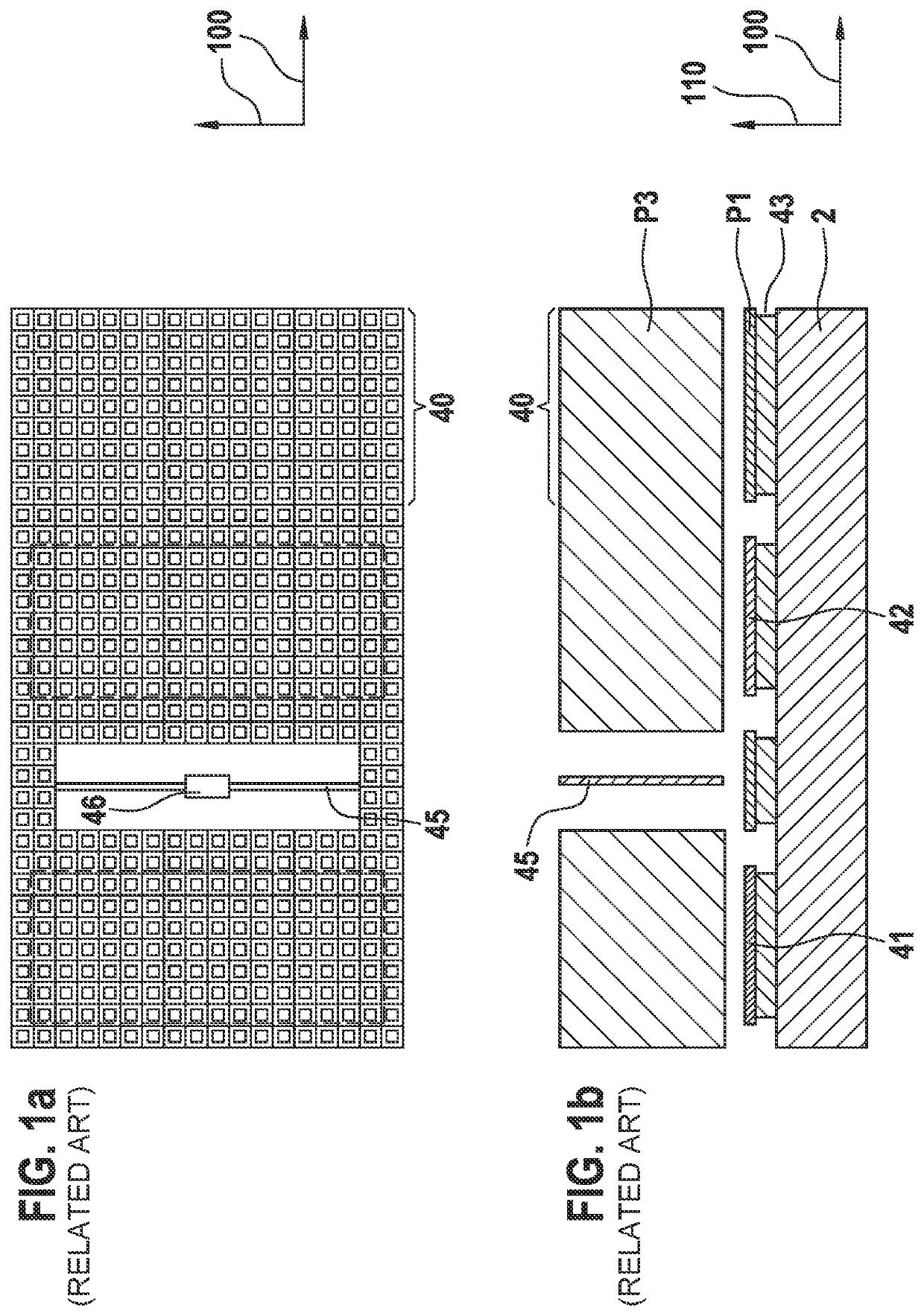

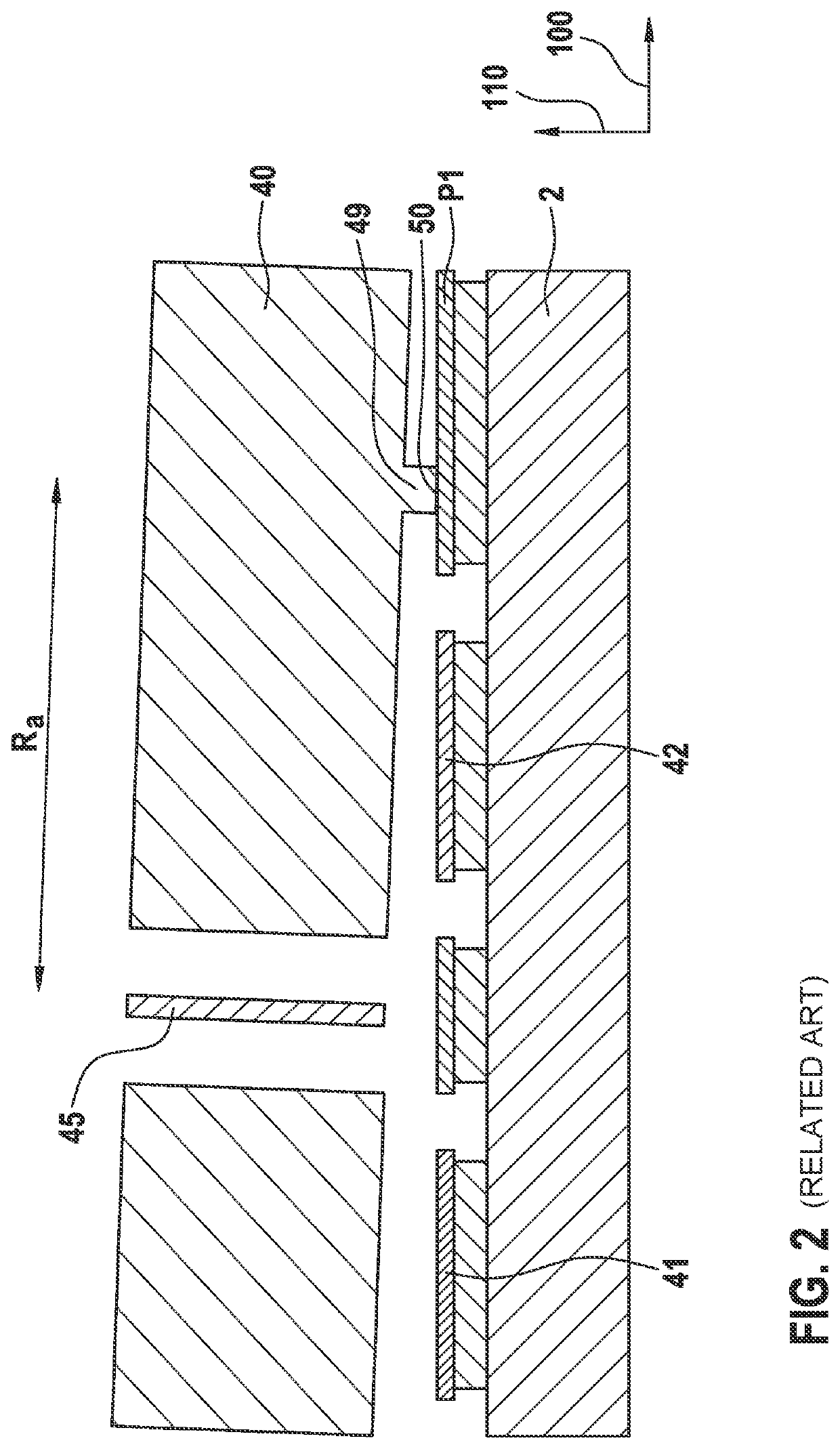

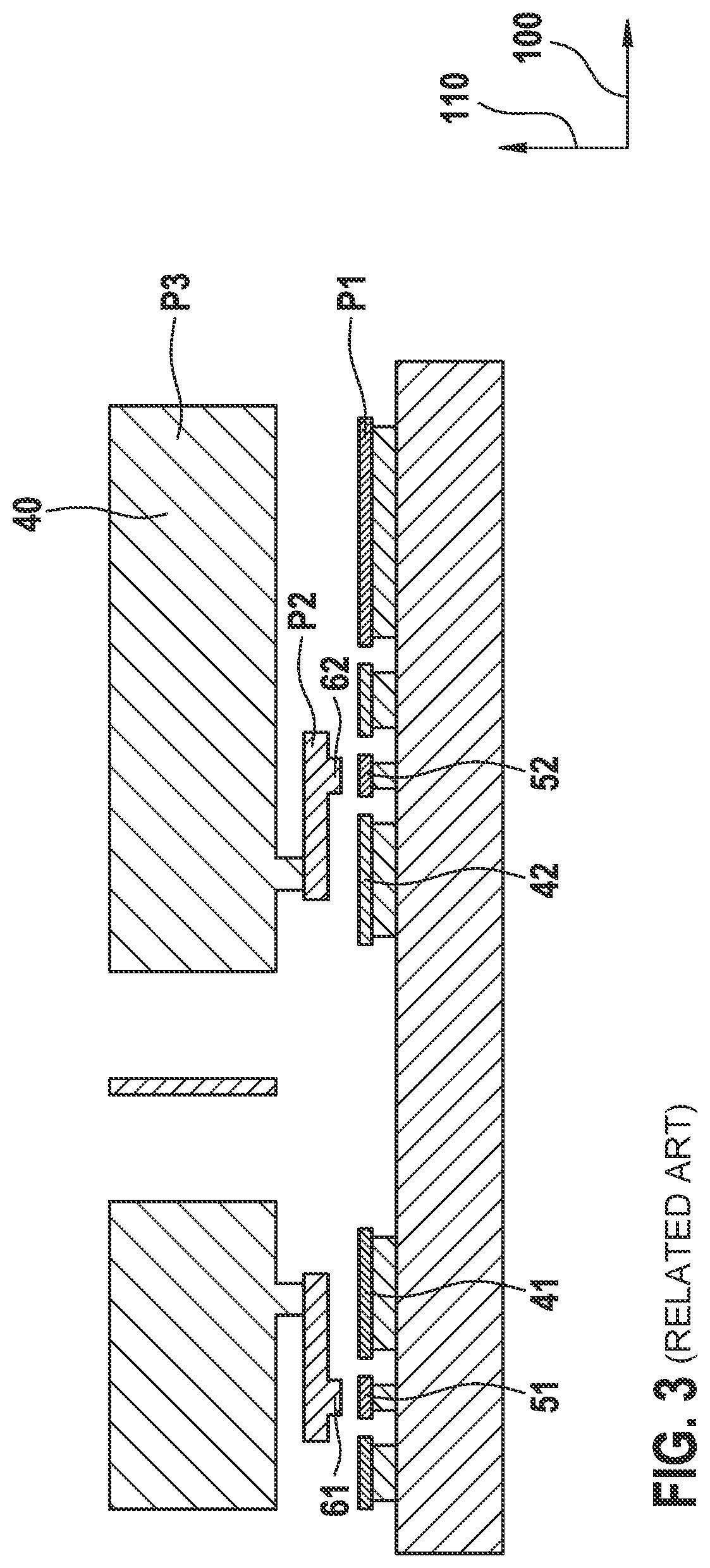

Snap domes as sensor protection

ActiveUS20120200526A1Expanding range of acceptableEasy to useEmergency actuatorsContact surface shape/structureProtection mechanismDisplay device

A protection mechanism for force-based touch sensitive input panels or displays comprising a “snap dome”, e.g., a semi-rigid pliable dome positioned over each sensor for increased overload protection. The snap dome is unidirectionally-resilient to a known point of collapse. It therefore imparts a predetermined resistance to compression over a known range of travel along the z-axis, but is unyielding along the x- and y-axis. As the touch panel is depressed toward the standoff, the snap dome resists compression until it collapses, allowing the touch panel to encounter the standoff. The standoff then imparts dead-stop overload force protection to the sensors. This allows for the placement of mechanical stops (such as stop screws) with a less exacting tolerance. Moreover, the snap domes introduce no x- or y-axis force losses / increases, and do not cause tilting of the touch panel. The touch force remains perfectly perpendicular and accuracy is preserved.

Owner:APPLE INC

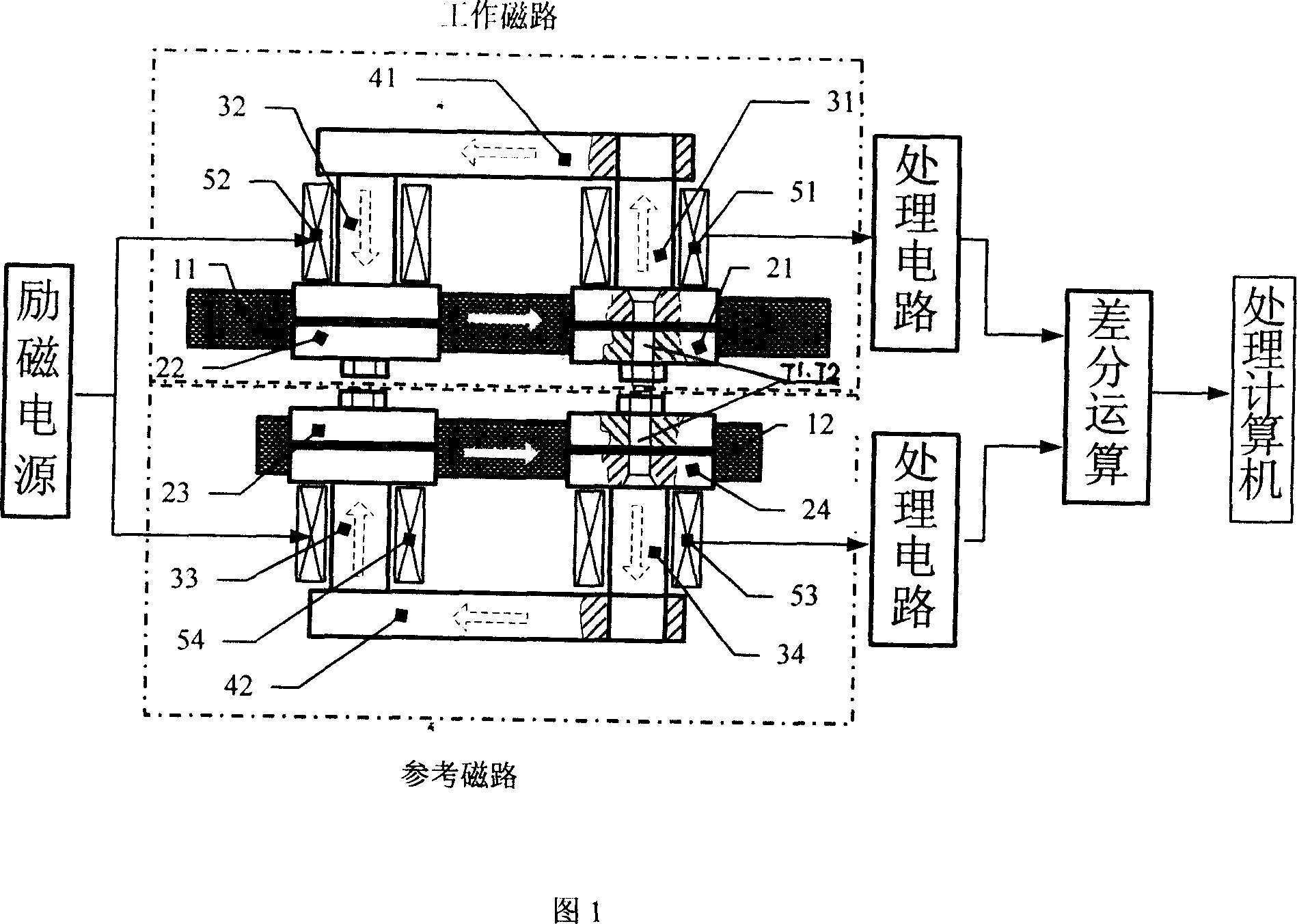

Differential and temperature compensating type on-line testing method and system for bridge cable force

InactiveCN1952635AGood dynamic responseEasy to install and debugForce measurement by measuring magnetic property varationTension measurementStress conditionsEngineering

An on line test method and test system of differential type temperature-compensating bridge rope force based on the magnetoelasticity is disclosed. The bridge rope is the ferromagnetic material and placed in the specific magnetic field, the bridge rope will be magnetized; the magnetic conductivity of bridge rope will change with the variety of stress condition and temperature. The sensor comprises operating magnetic circuit and reference magnetic circuit, in every designing of the magnetic circuit, the bridge rope is just a part of the magnetic circuit and not as the iron core of the actuating coil and the measuring coil. The reference magnetic circuit of sensor just feels the changes of temperature, but the operating magnetic circuit feels the changes of temperature and rope force, the output signal of the operating magnetic circuit and the reference magnetic circuit is differential to eliminate the temperature effect, the value of rope force can be tested with the corresponding relationship between the change of magnetic conductivity and rope force. The test method of rope force in the invention characterized in high accuracy, well dynamic response, low price of sensor, convenience of mounting and conditioning, long service life, strong overcurrent protection power, fitting for static and dynamic measurement, sampling just in time in all-weather, the testing results are free of effects of anticorrosive coating and protective plastic casing which is in surface of bridge.

Owner:CHONGQING YA PAI BRIDGE ENG QUALITY TESTING CO LTD

Intelligent robot capable of high-speed feeding and discharging

InactiveCN104440898AReduce volumeSmall inertia forceProgramme-controlled manipulatorGripping headsBall screwManipulator

The invention relates to an intelligent robot capable of high-speed feeding and discharging. An existing feeding and discharging device is complicated to operate. Accordingly, the intelligent robot capable of high-speed feeding and discharging comprises a stand column and a cross arm, wherein the stand column s provided with a vertical linear guide rail, a lifting block is arranged on the vertical linear guide rail, the cross arm is fixed to the lifting block, the lifting block is driven by a ball screw pair, lead screws of the ball screw pair are driven by a lifting servo motor and sleeved with nuts of the ball screw pair, and the nuts and the lifting block are fixed together. The cross arm is provided with a horizontal linear guide rail provided with a slide block, a telescopic arm is fixed to the slide block, a sucker rack or a manipulator grabbing device is fixed to the front end of the telescopic arm, the slide block is driven by a ball screw pair, lead screws of the ball screw pair are driven by a telescopic serve motor and sleeved with nuts of the ball screw pair, and the nuts and the slide block are fixed together. The intelligent robot has the advantages of being convenient to use, safe and efficient, thereby being suitable for various production enterprises needing workpiece carrying.

Owner:范克健

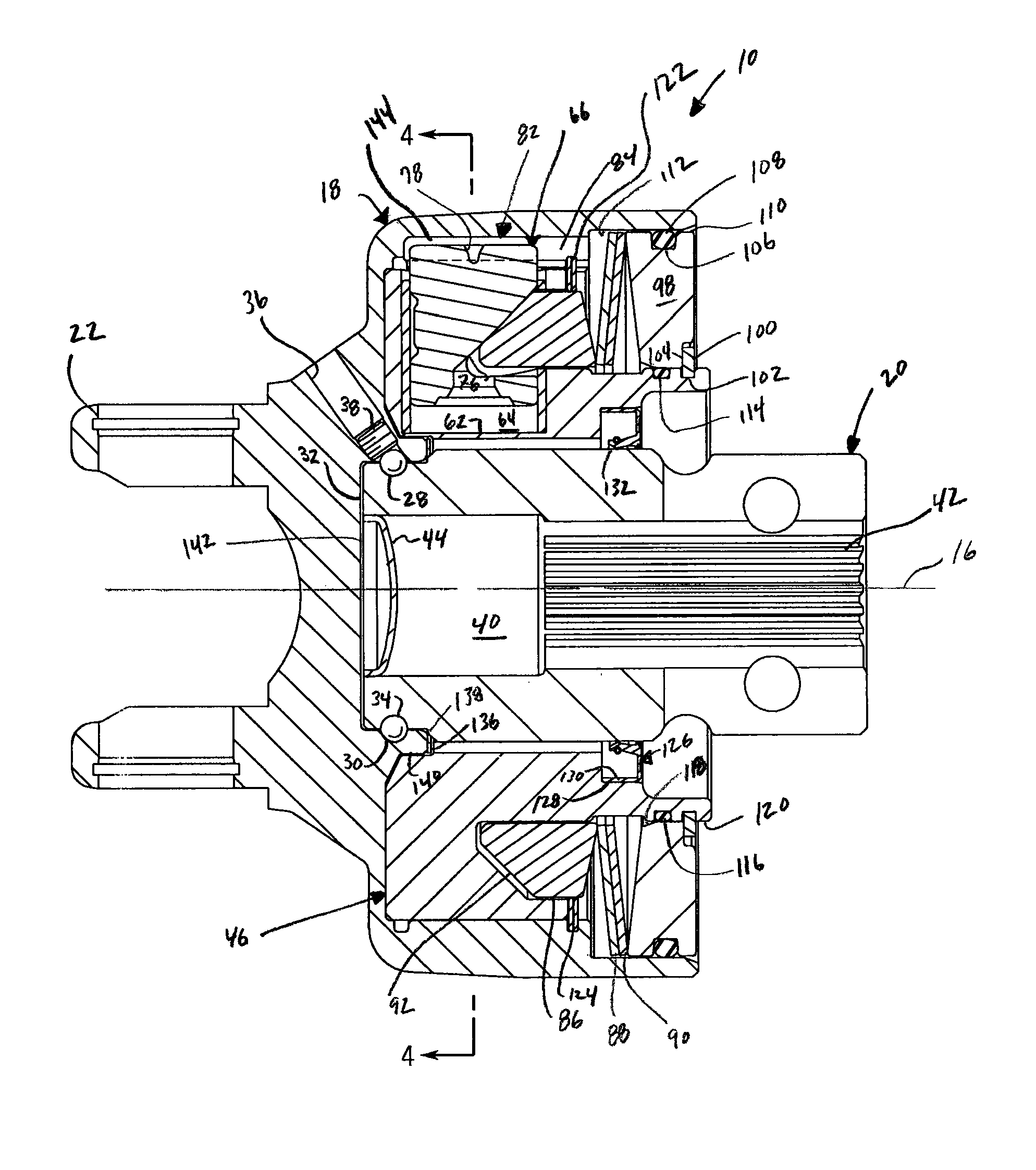

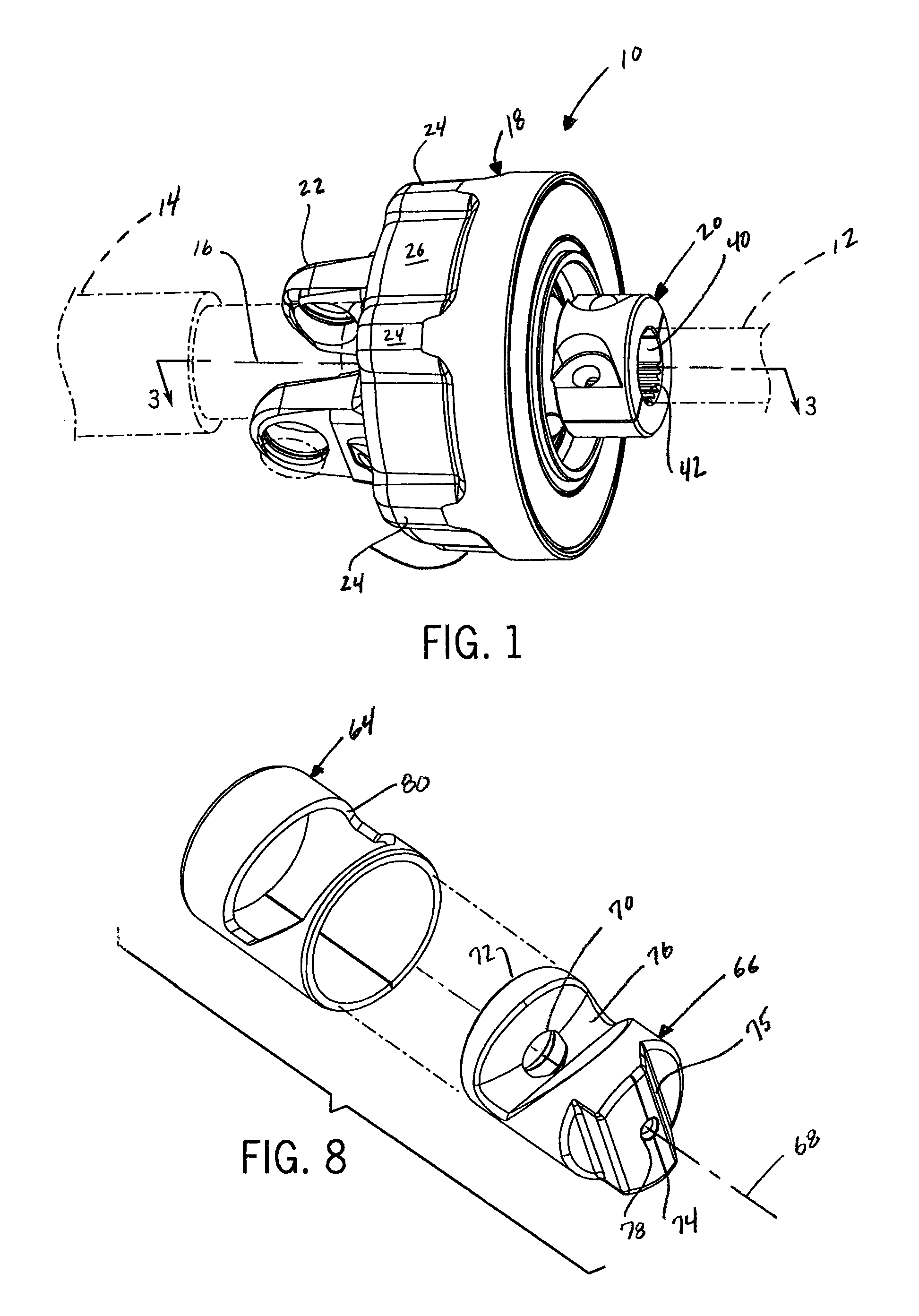

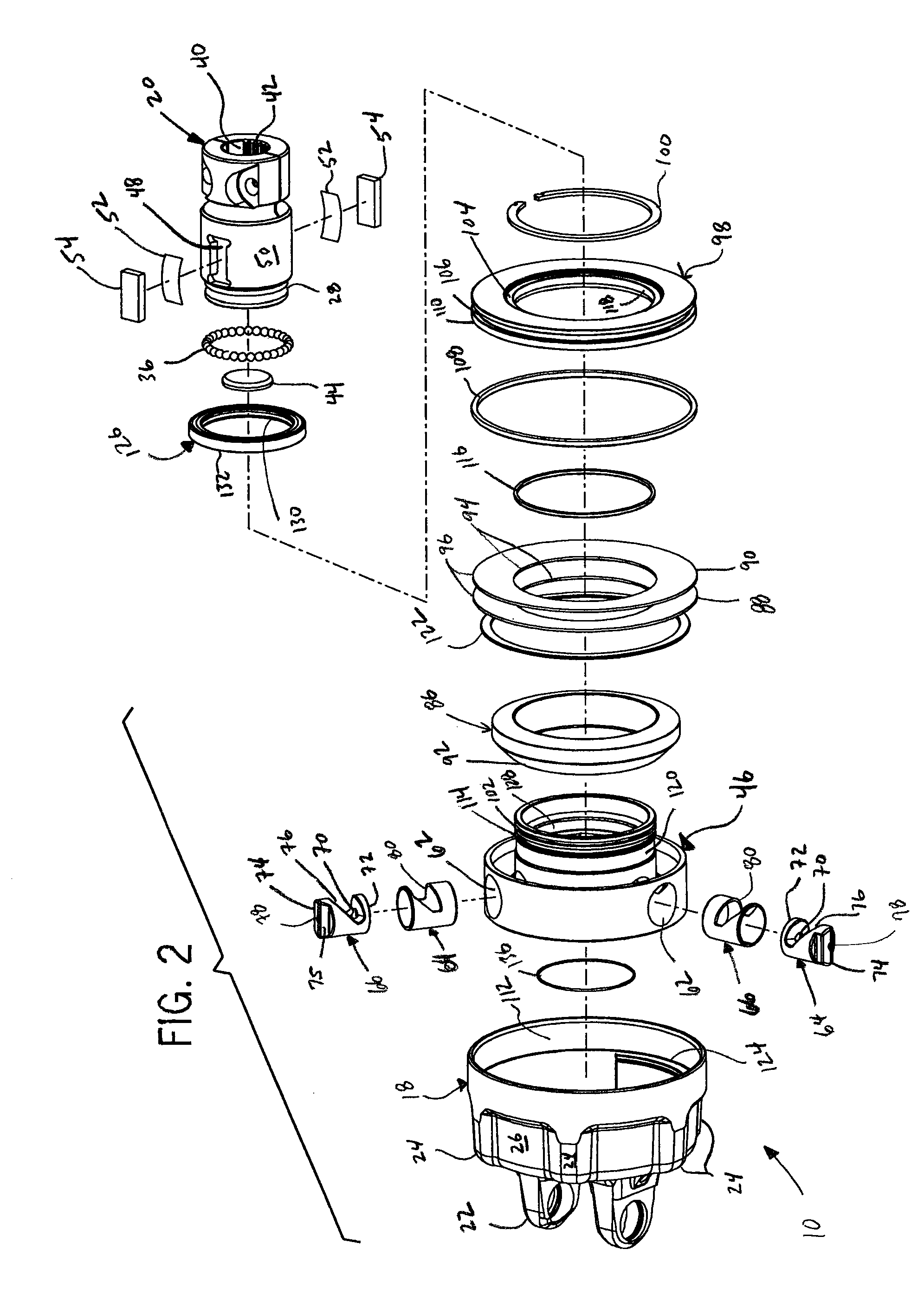

Automatic torque overload clutch

A torque overload clutch comprises outer and inner members. A recess is formed in the outer member and a radial opening is formed in the inner member. A driving member is slideably captured in the opening to move between an extended, engaged position with the recess and a retracted, disengaged position. An actuator ring is urged by a spring into engagement with the driving member to bias the driving member toward the engaged position. An end of the driving member may engage the recess to define an engagement angle that is approximately between thirty-four and seventy degrees relative to a radially oriented reference. The driving member may be slideably captured in a liner seated in the opening, and one or both may be impregnated with a lubricant. A bearing may be positioned between the inner and outer members to inhibit relative movement along the clutch axis.

Owner:WEASLER ENG

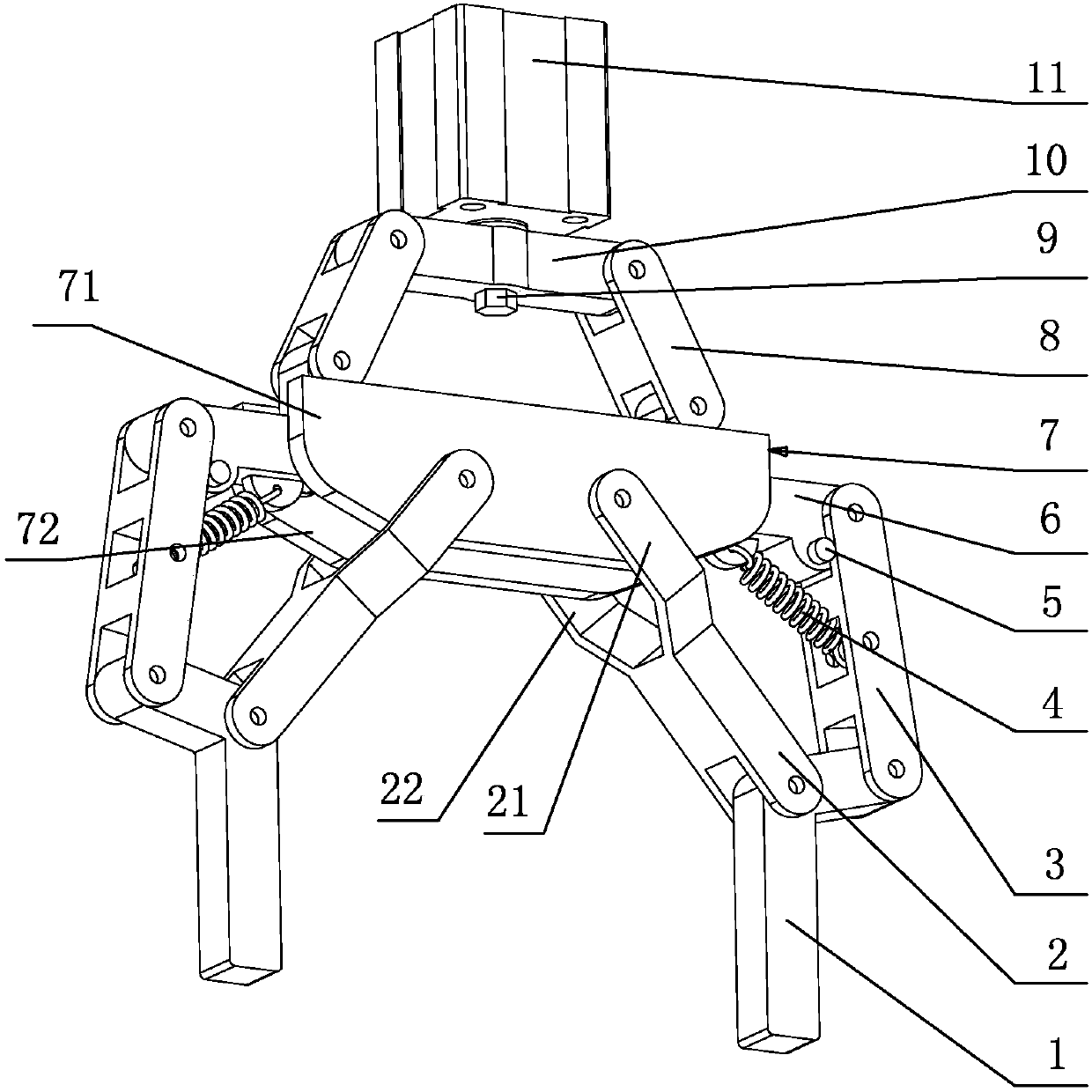

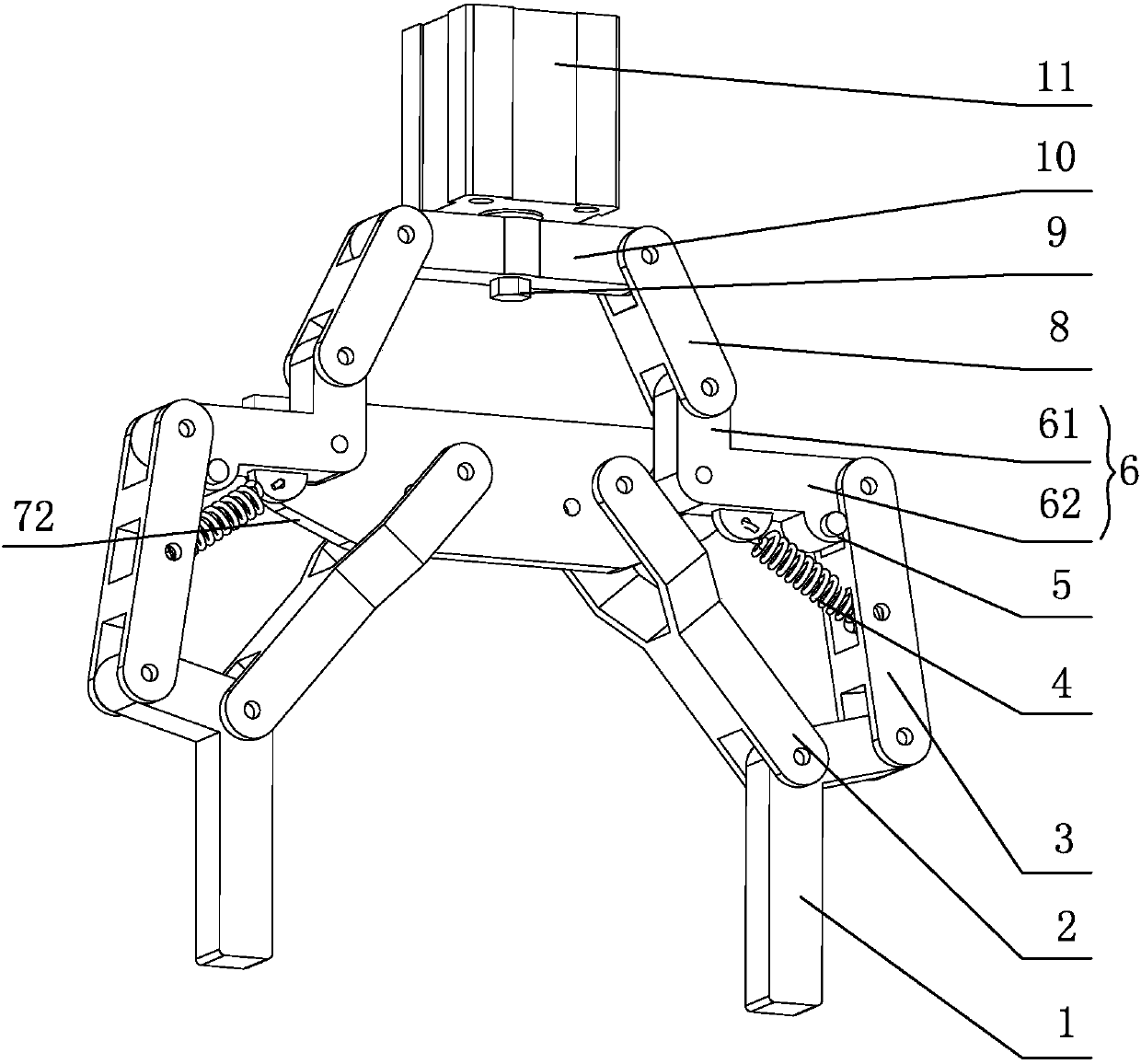

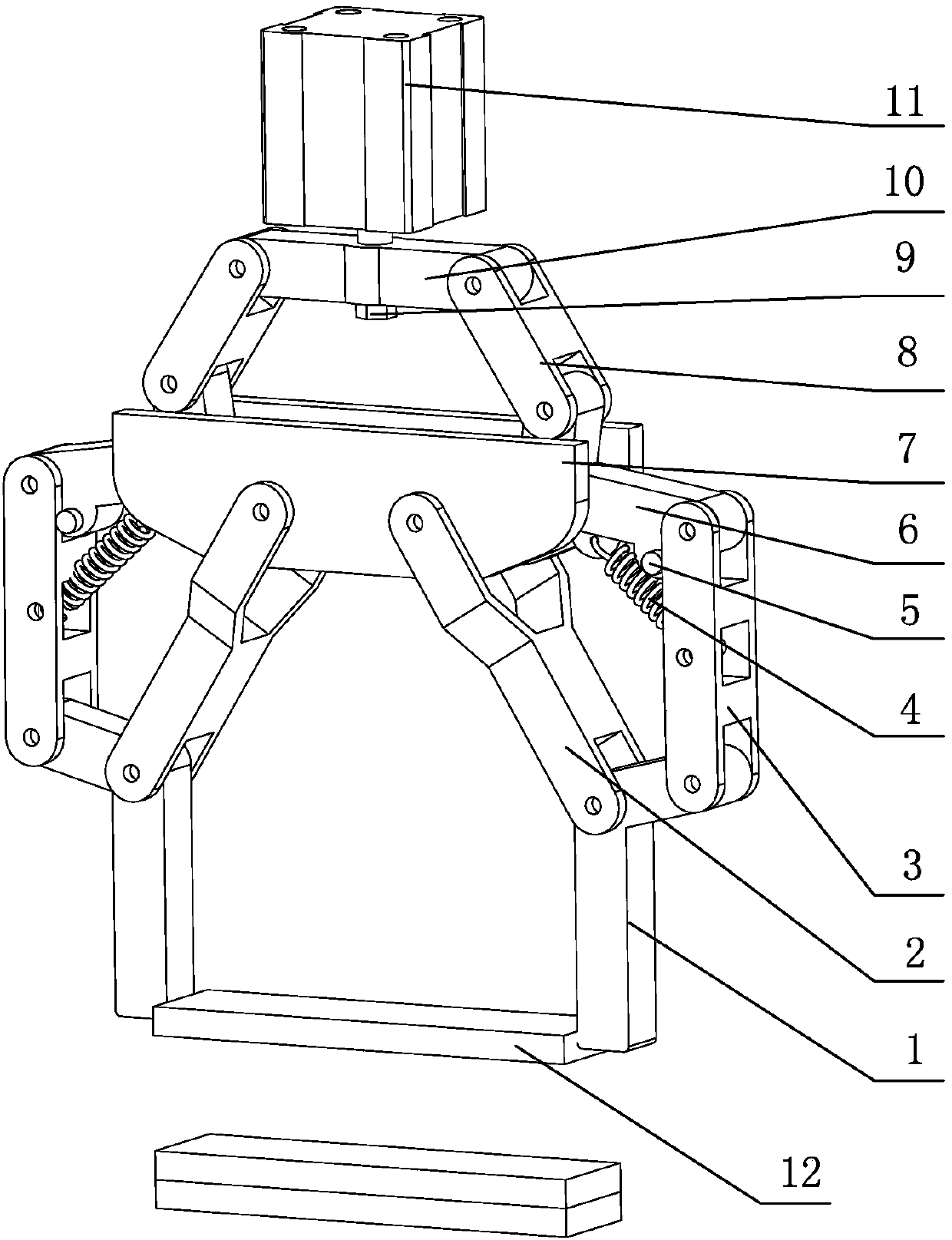

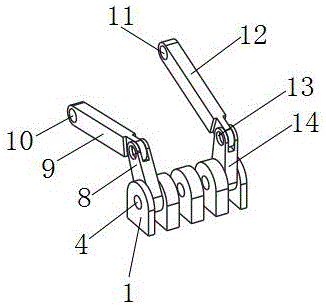

Flexible clamping device

The invention relates to a flexible clamping device. The flexible clamping device comprises a support, a driving assembly and a clamping assembly, wherein the driving assembly drives the clamping assembly to move; the clamping assembly comprises two driving connecting rods hinged to the support, two inner connecting rods hinged to the support, outer connecting rods hinged to the driving connectingrods, and clamping rods hinged to the inner connecting rods and the outer connecting rods; the two outer connecting rods are arranged; the two outer connecting rods are hinged to the corresponding driving connecting rods respectively; the two clamping rods are arranged; and the two clamping rods are hinged to the corresponding inner connecting rods and the corresponding outer connecting rods respectively. The flexible clamping device is composed of under-actuated connecting rods, namely, after driving elements are added, a single-side connecting rod set composed of the driving connecting rod,the outer connecting rod, the inner connecting rod and the clamping rod at any side still has two degrees of freedom; the under-actuated connecting rods are provided with self-adaptability; and underthe process of clamping objects and making contact with the objects, the under-actuated connecting rods form a shape for enveloping the objects under the action of external force.

Owner:FOSHAN UNIVERSITY

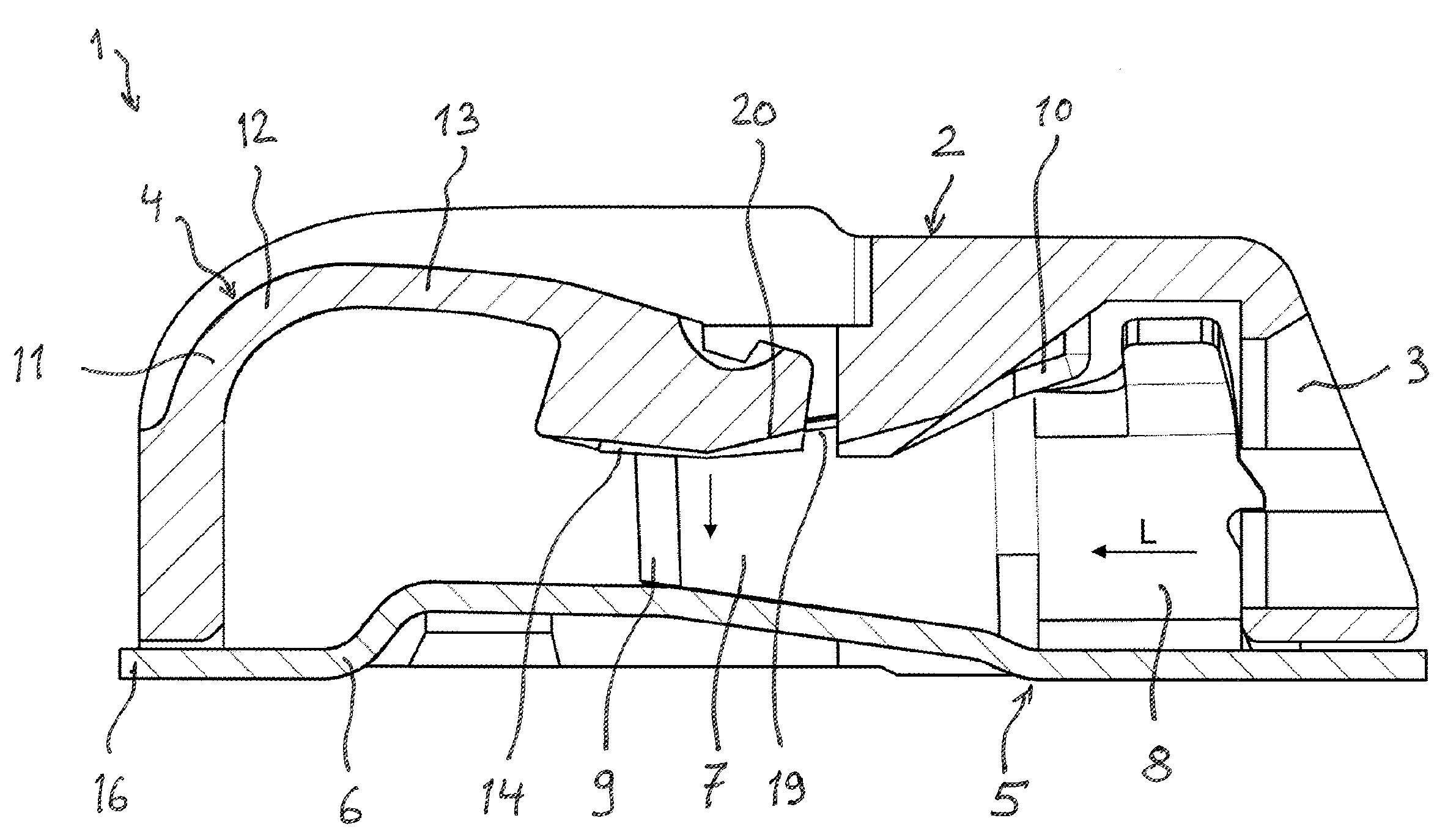

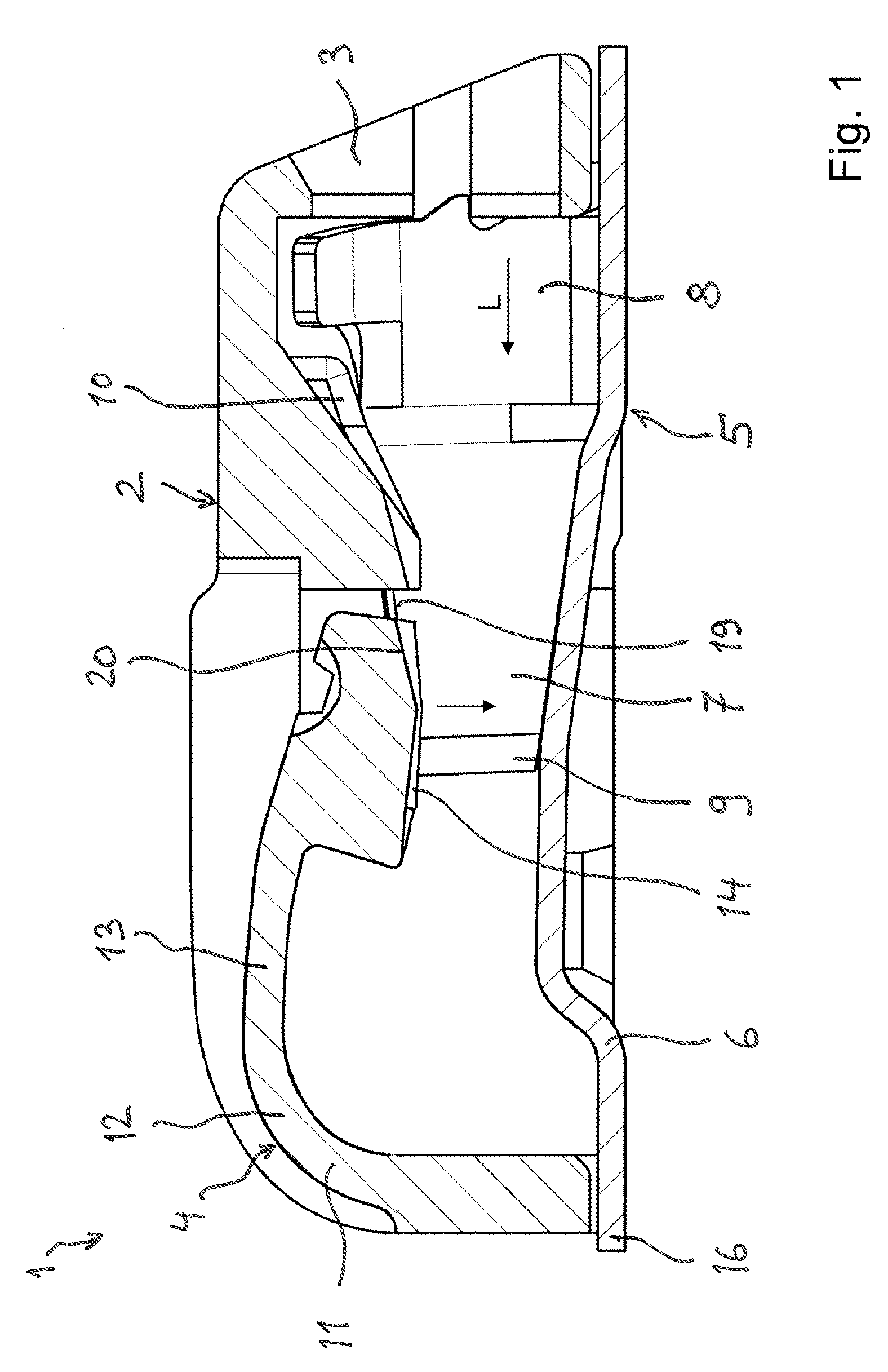

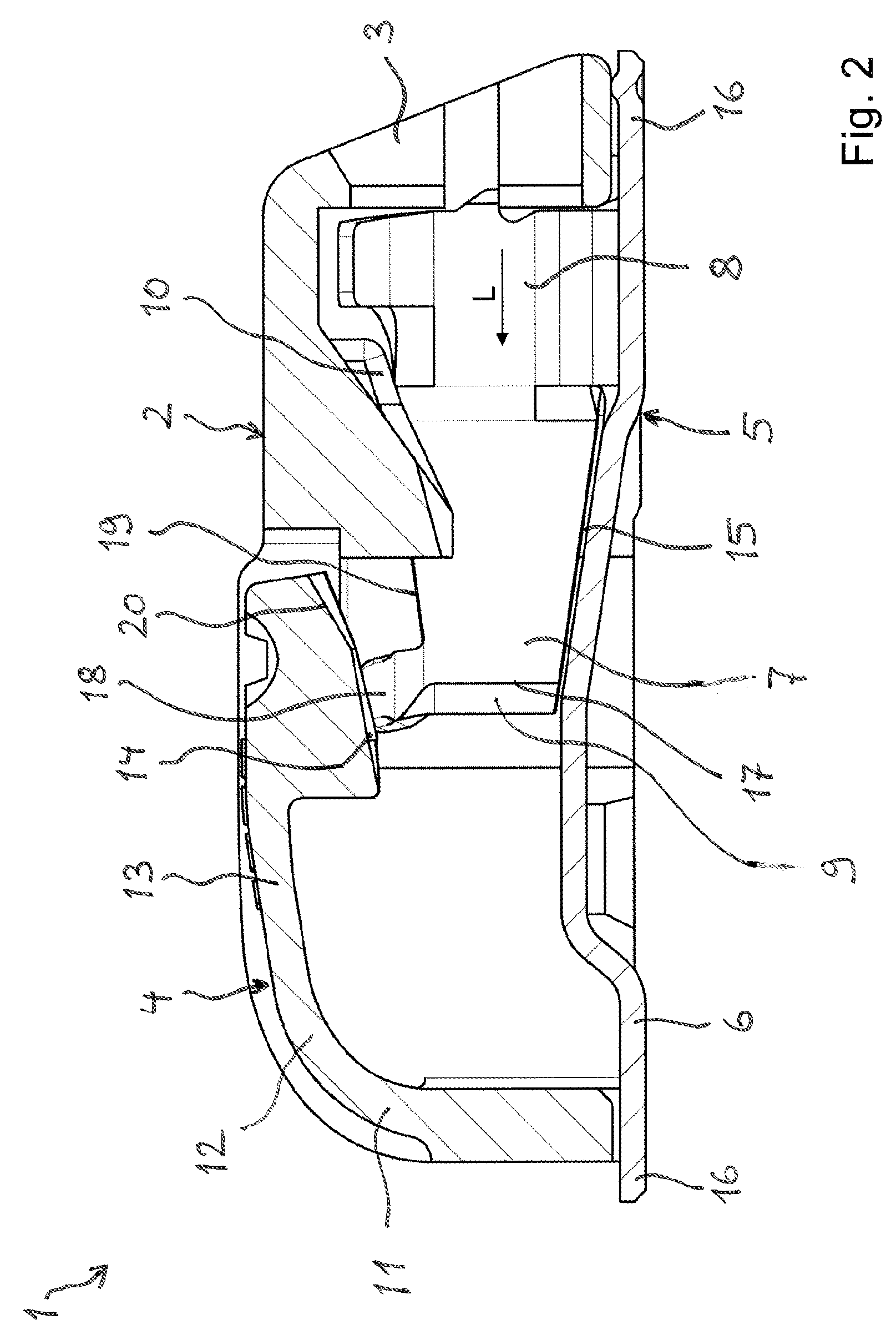

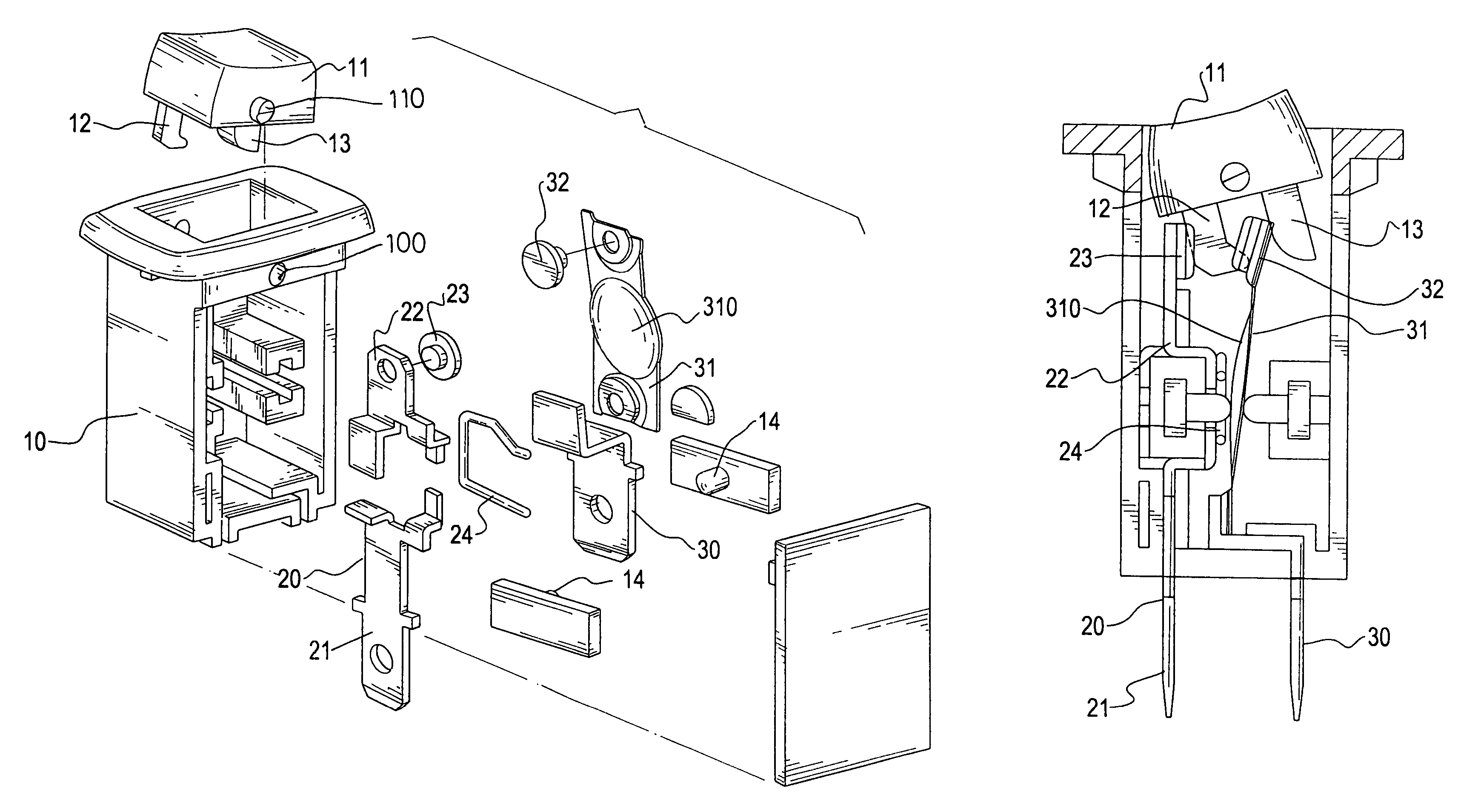

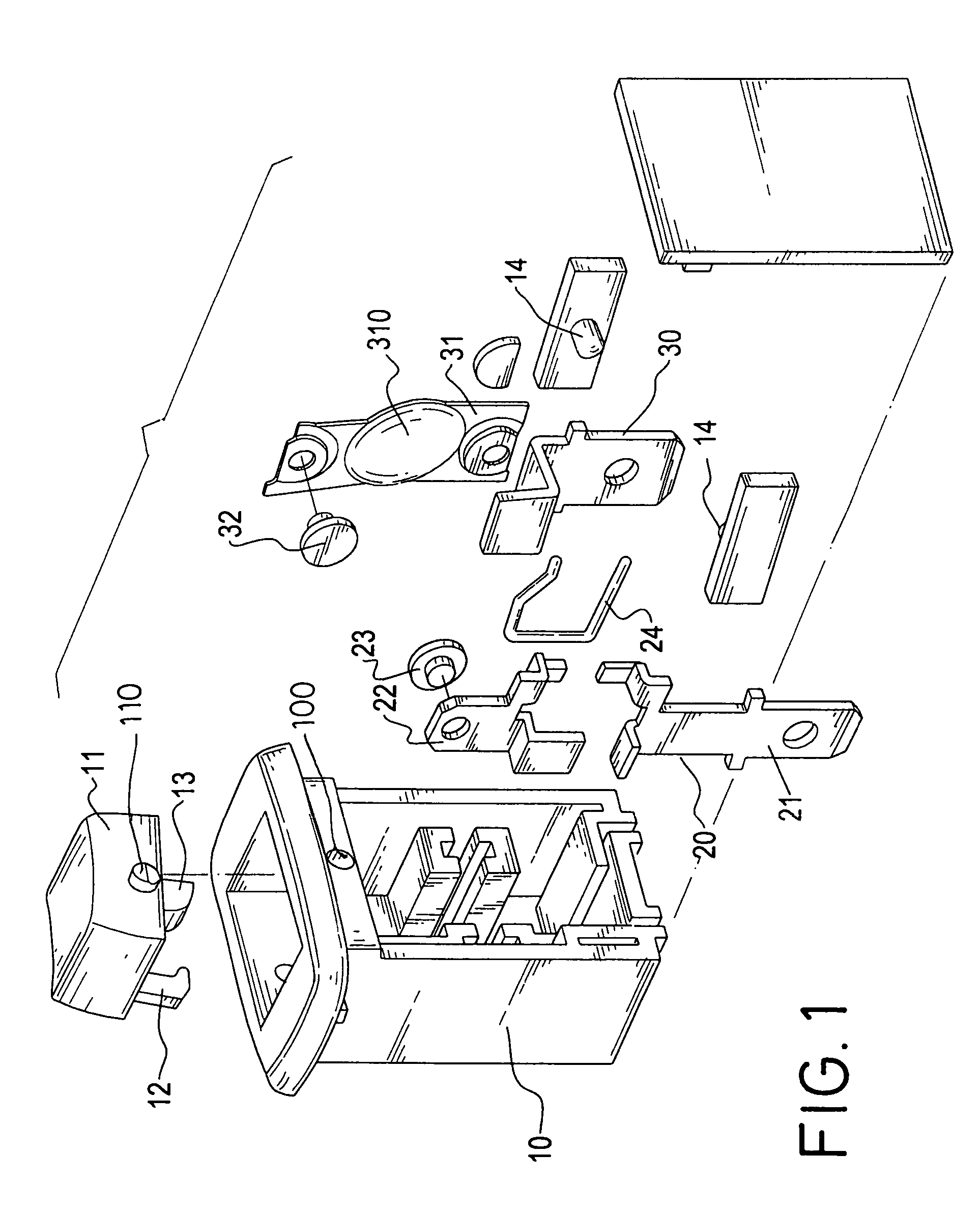

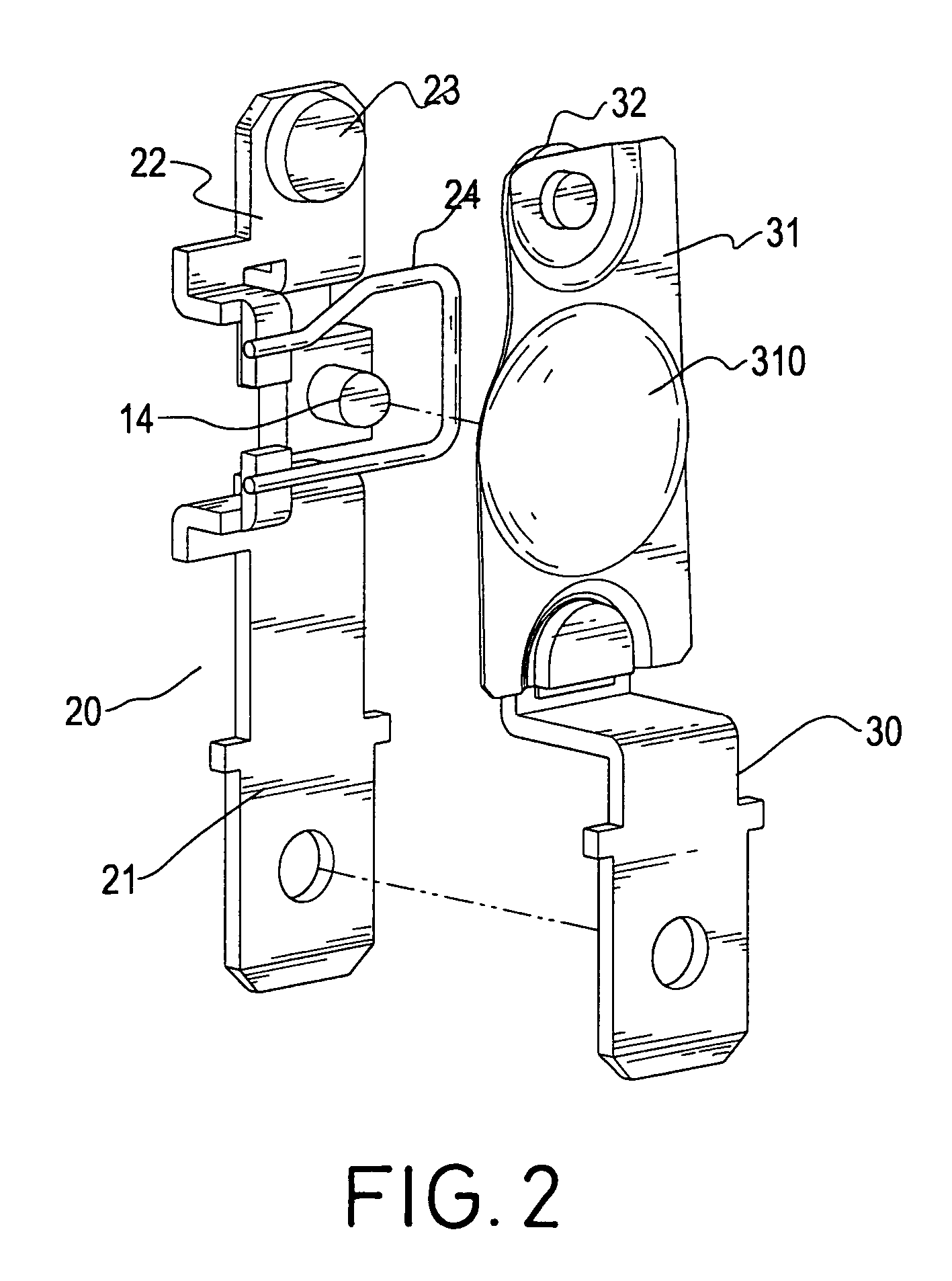

Conductor connection terminal having improved overload protection

ActiveUS9209530B2Reduce the gap widthClearly noticeableElectric discharge tubesCoupling contact membersElectrical conductorSpring force

A conductor connection terminal (1) comprising an insulating housing (2) and comprising at least one spring-force clamping connection (5) in the insulating housing (2) for making the terminal connection of an electrical conductor is described. The spring-force clamping connection (5) has a base plate (6) and at least one spring tongue (7), which is at an angle to the base plate (6), is connected in a root region (8) to the base plate (6) and extends with its tongue end (9), which is movable in spring-elastic fashion, in a conductor plug-in direction (L). The free tongue end (9) is spaced apart from the base plate (6) by a gap (15). The insulating housing (2) has at least one actuating pushbutton (4), which interacts with the tongue end (9) opposite the base plate (6) and has an actuating section (14), which extends in the direction towards the base plate (6), for deflecting the spring tongue (7) transversely to the direction of extent of the spring tongue (7). The actuating pushbutton (4) has at least one resting section (20), which is designed in each case at an associated tongue end (9) to rest on a lateral peripheral edge (19) of the associated tongue end (9) and to shift the tongue end (9) in the direction of the base plate (6) whilst reducing the width of the gap (15) when the actuating pushbutton (4) is shifted in the direction of the base plate (6) so as to open a clamping connection formed by the spring tongue (7) for an electrical conductor of which a terminal connection is intended to be made.

Owner:WAGO VERW GMBH

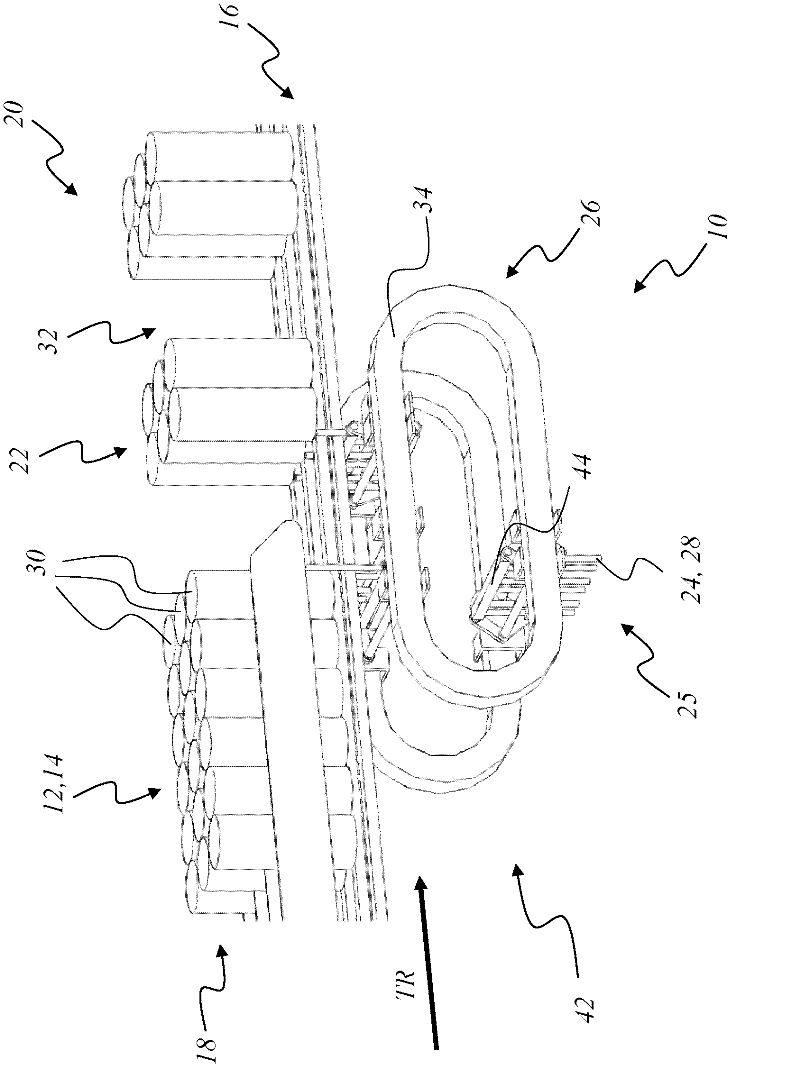

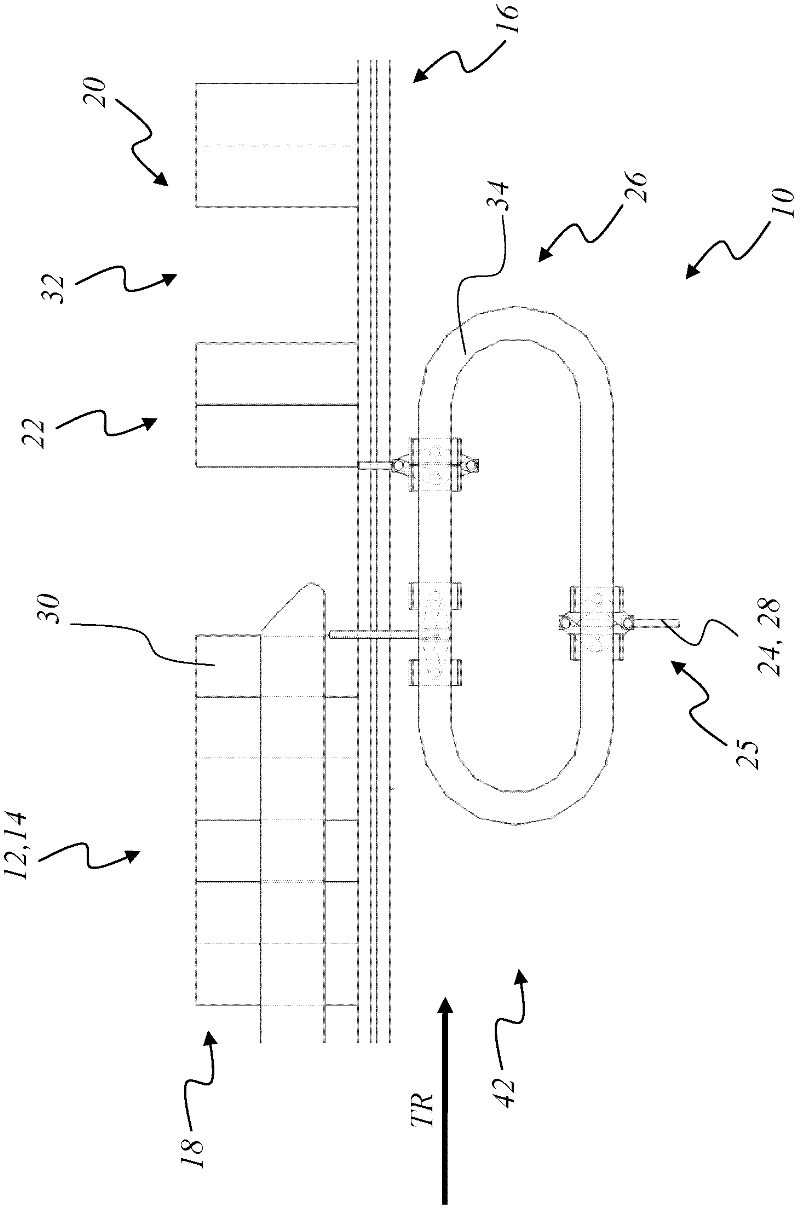

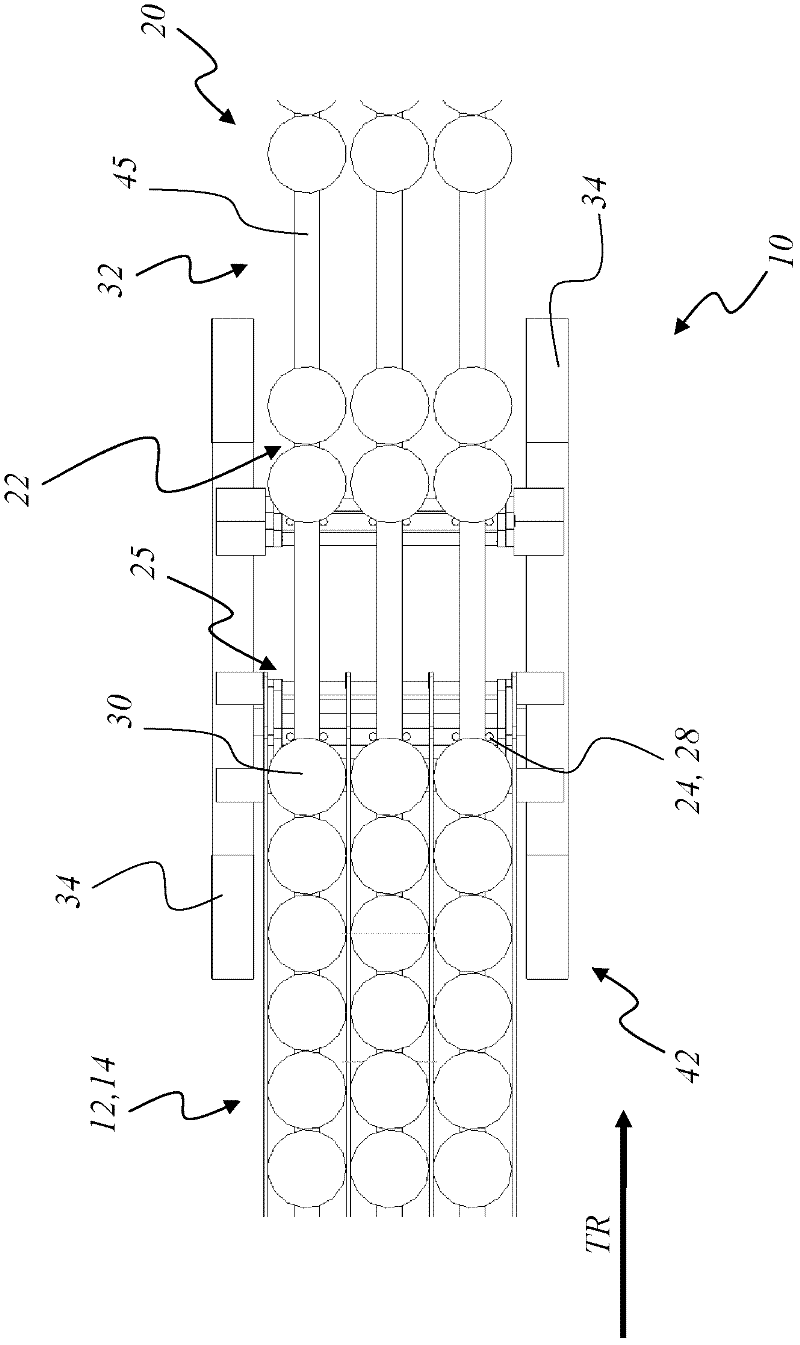

Device and method for grouping bulk material

ActiveCN102673995AIncrease exerciseReduce in quantityNon-mechanical conveyorsConveyor partsEngineeringOrbit

Provided is a device and method for grouping bulk material. Bulk material are delivered in a substantially closed transmission path (18) by means of a transporting device (16) to pass a transportation section (20). The device (10) has movable distributor elements (24) located transversely in a transport direction (TR) during the feed stream (18) and used for forming gaps (32) between successive bulk materials. The movable distributor elements (24) are distributed to distribution devices (25) which possess transmission-free and direct driving and winds along a closed transport trajectory (26) which is partially parallel with the transportation section (20). A plurality of single distribution devices and each of the distributed distributor elements can change and be individually controlled according to feed movement and feed speed of movement orbits. According to the invention, dimension of form to be processed and individuation control of the distributor elements can be changed greatly at a high processing speed.

Owner:KRONES AG

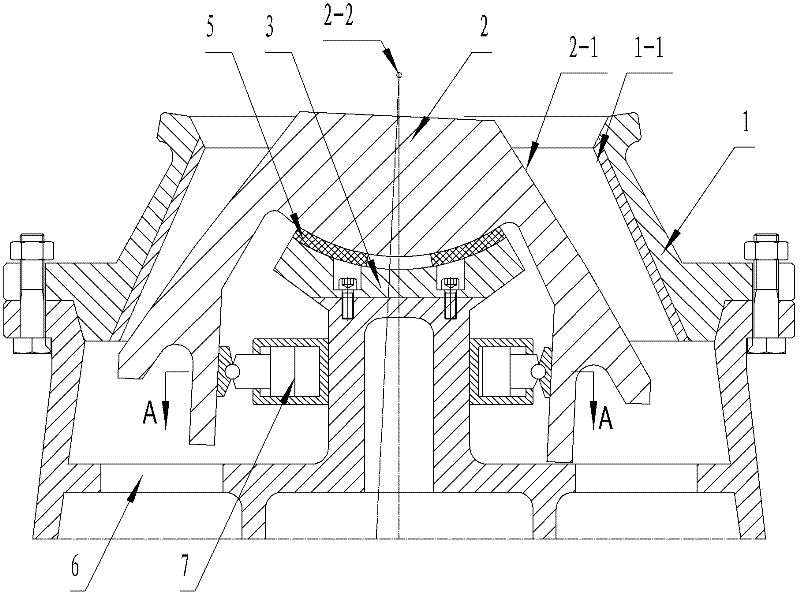

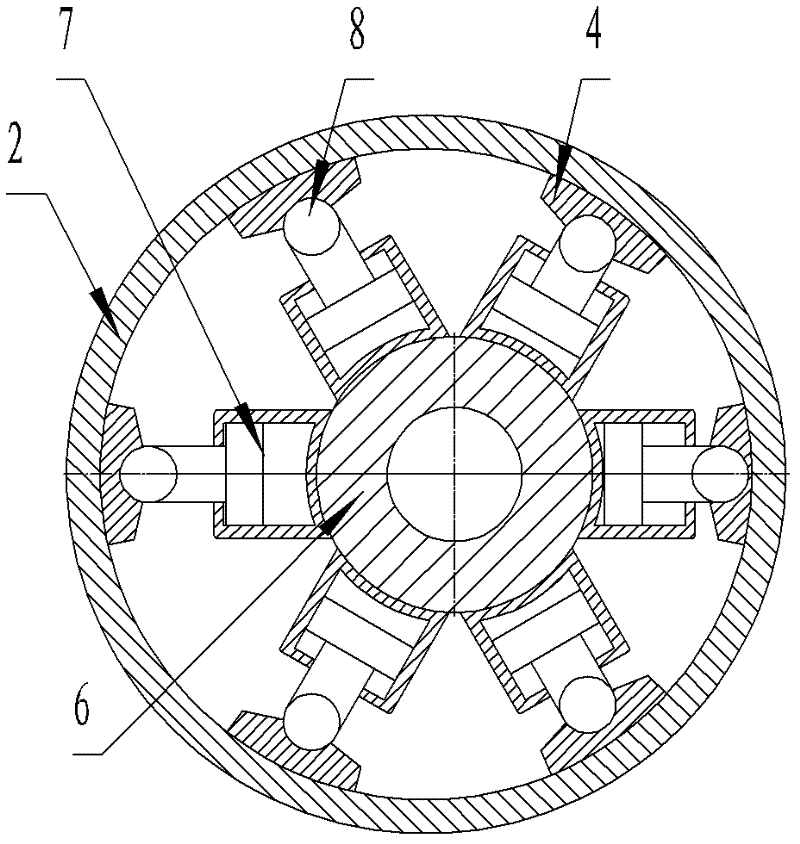

Conical crusher

InactiveCN102327791AIncrease exercise frequencyIncrease productionGrain treatmentsCrushed stoneEngineering

The invention relates to a crusher for crushing stones. The technical problem to be solved is that the crusher has the characteristics of high production efficiency, simple structure and small volume, and can be started in a full-load mode and subjected to stepless regulation. In the technical scheme, the conical crusher comprises a fixed cone which is provided with an inner conical roll compacting surface and is fixed to a machine frame, a movable cone which is provided with an outer conical roll compacting surface and can be positioned on a spherical support in a sliding mode and a hydraulic power system for driving the movable cone to move, wherein the roll compacting surface of the movable cone is encircled by the roll compacting surface of the fixed cone, and keeps a certain roll compacting interval with the roll compacting surface of the fixed cone. The conical crusher is characterized in that the hydraulic power system comprises a plurality of oil cylinders for pushing the movable cone to move, an oil distributor for controlling the oil cylinders to move sequentially and an oil pump for conveying hydraulic oil to the oil cylinders and the oil distributor by an oil passage; and a plurality of oil cylinders are positioned between the movable cone and the machine frame radially and regularly.

Owner:来军剑

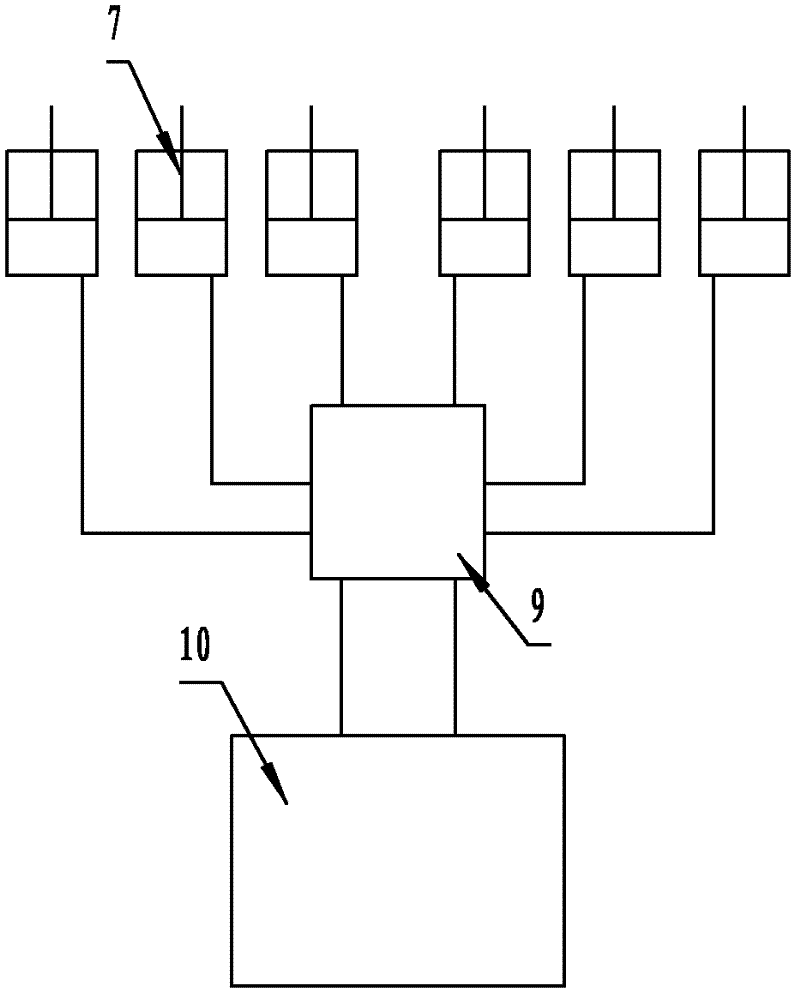

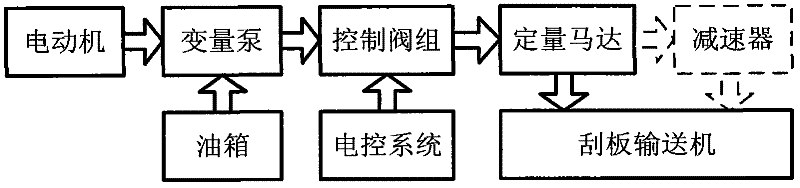

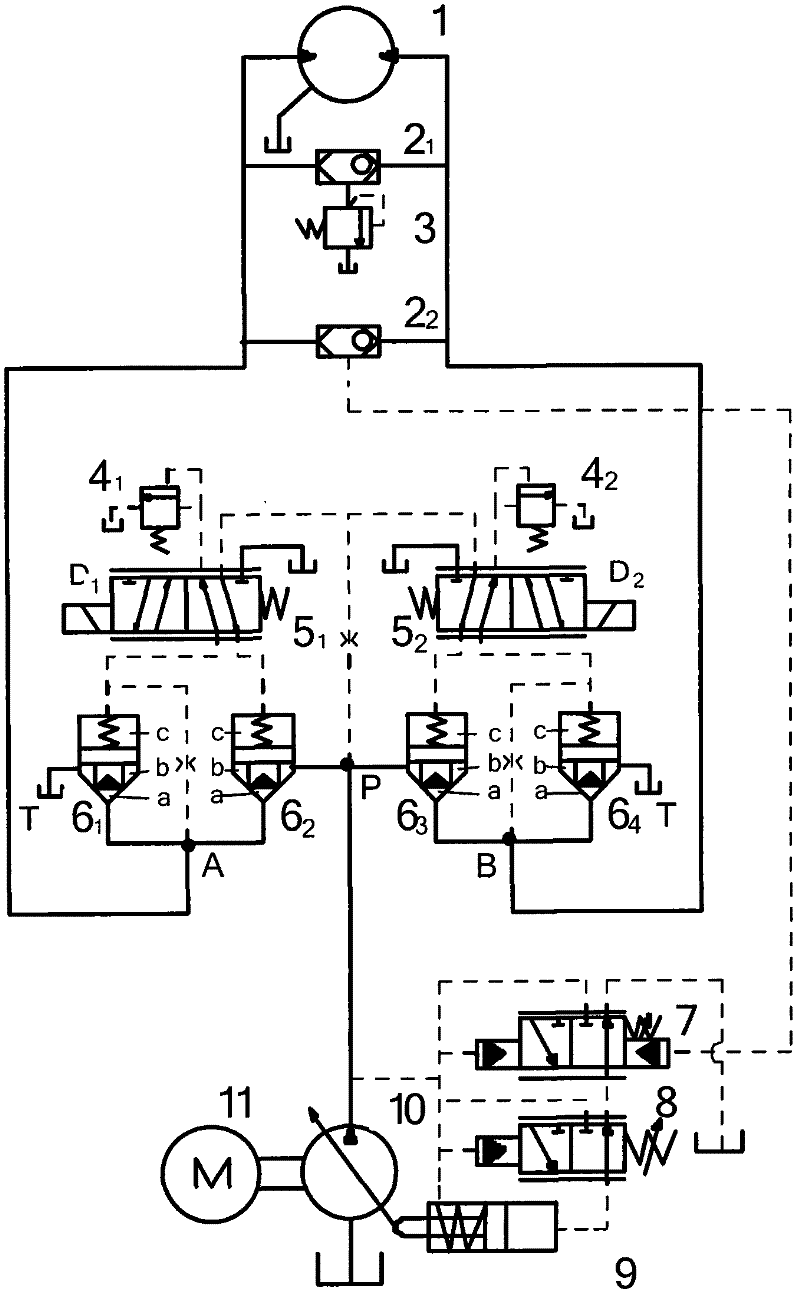

Novel hydraulic driving system for scraper conveyer

The invention relates to a hydraulic driving system, in particular to a novel hydraulic driving system for a scraper conveyer, which aims to the overcome the defect that as the existing scraper conveyer is commonly driven by a two-speed motor, a single speed motor plus a hydraulic coupling, a variable-frequency motor and the like, when a motor, a transmission device and a chain wheel are connected with one another, the tail part is suspended, resulting in easy generation of vibration, abrasion, invalid sealing and the like. The novel hydraulic driving system consists of a hydraulic motor, a shuttle valve, a safety valve, an overflow valve, a proportional reversing valve, a flow type cartridge valve, a load sensing valve, a pressure cutoff valve, a variable piston, a variable pump and a motor. The novel hydraulic driving system has the beneficial effects that the soft start of the scraper conveyer is realized by applying a load sensing system, a variable pump-quantitative motor type volume speed control circuit and a flow type proportional cartridge valve control element; the rotating speed of the hydraulic motor can be controllable, can also be subjected to stepless speed regulation within a certain scope and is not affected by load change and motor rotating speed fluctuation; and the working requirements on high pressure and large flow rate of the system are satisfied, and equipment operation and braking are ensured to be stable and reliable.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

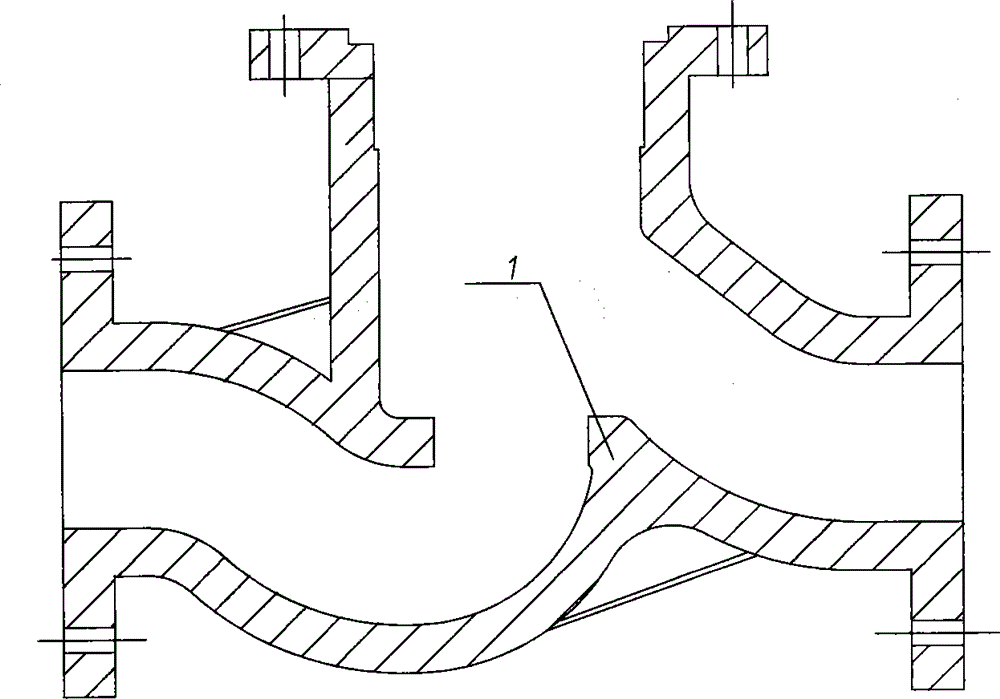

Multi-ring micronizer grinding cavity, multi-ring micronizer and intelligent multi-ring micronizer system

ActiveCN103861695ASolve wasteful technical problemsImprove grinding efficiencyGrain treatmentsIntelligent lightingCoupling

The invention relates to a multi-ring micronizer grinding cavity, a multi-ring micronizer and an intelligent multi-ring micronizer system. The multi-ring micronizer grinding cavity comprises a rotating grinding device connected with a transmission main shaft, wherein the rotating grinding device is composed of multiple layers of grinding discs, coupling drum-shaped grinding rollers and a roller shaft pin; the roller shaft pin is arranged in multiple layers of grinding discs, the coupling drum-shaped grinding rollers take a single grinding roller inner through hole as a standard and can be positioned by depending on the roller shaft pin, and the coupling drum-shaped grinding rollers are arranged at interval regions of the multiple layers of grinding discs according to groups; a shell of the outer side of the rotating grinding device is provided with a grinding ring, wherein the inner wall of the grinding ring is provided with multiple layers of half round sliding channels, and horizontal centers of the half round sliding channels of the grinding ring and a horizontal center of a grinding roller of a corresponding layer arranged on a rotating grinding roller assembly are horizontally arranged on a line. The multi-ring micronizer with the multi-ring micronizer grinding cavity and the system mainly solve the technical problem that the broken stones and mountain flour in a stone exploitation process can not achieve a fineness requirement, the application is not performed, a stone resource is wasted, the stone waste is recycled through a manufacture processing system, and an environment energy-saving environment-friendly requirement is achieved in a productive process.

Owner:上海建冶路桥机器设备有限公司

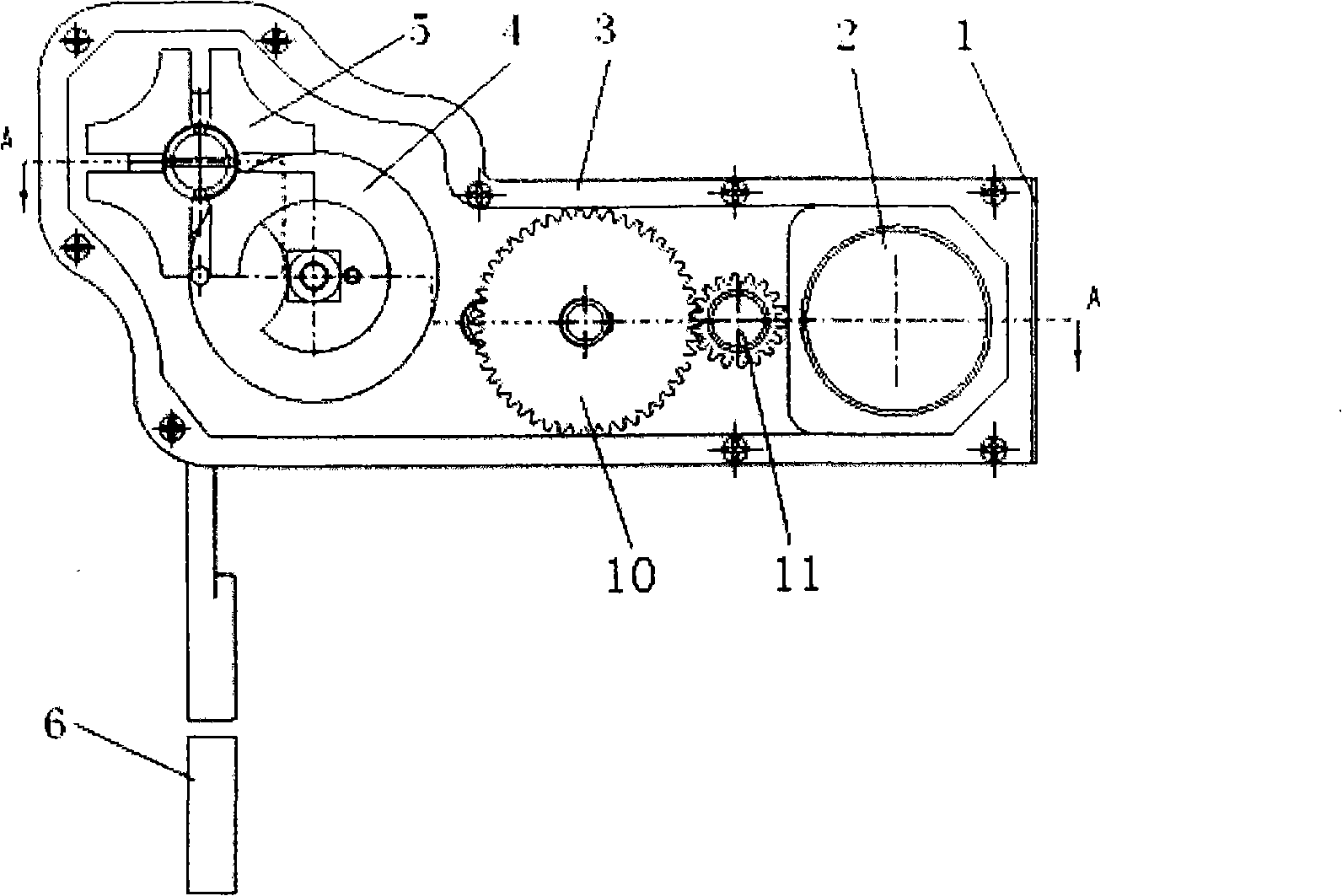

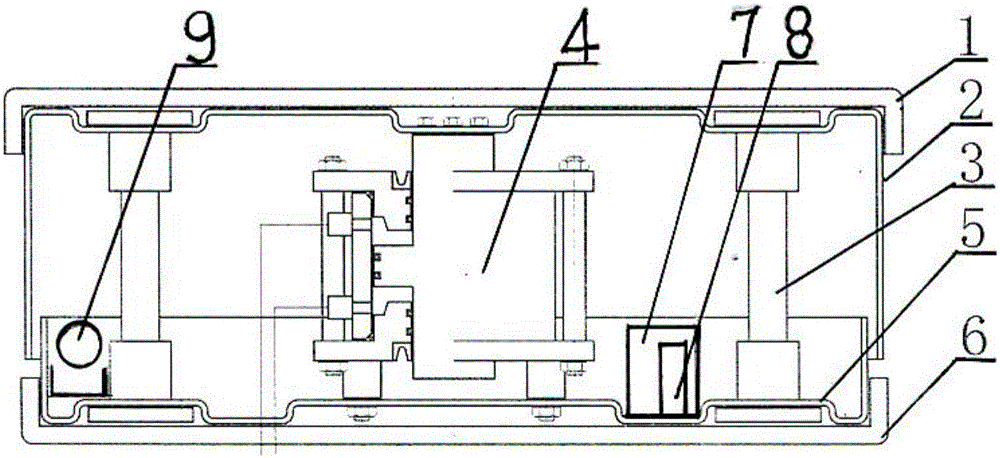

Electric control lens cap with self-locking function

InactiveCN101299128AAvoid accessStrong self-locking functionToothed gearingsCamera filtersCamera lensElectric machine

The present invention relates to an electric-controlled lens cover which is used in the field of optical device and has a self-locking function. The electric-controlled lens cover comprises a lens cover and a driving cabinet. The lens cover is connected with the output axis of the driving cabinet through a rock arm. The difference is that the driving cabinet comprises a cabinet and a self-locking driving device provided in the cabinet. The self-locking driving device comprises a grooved pulley pin self-locking mechanism which is connected with the output axis. The driving input end of the grooved pulley pin self-locking mechanism is connected with the driving motor through the transmission chain. The electric-controlled lens according to the invention has the following beneficial effects: 1. switching and self-locking realized by the electric-controlled cover of grooved pulley pin self-locking mechanism, resistance to the strong exterior shake, strong self-locking function, high using reliability, effective prevention for the entering of wind, rain, sand and dust into the lens when the lens cover is closed, lens protection; 2, simple and compact structure, reasonable arrangement, facility for matching with the optical camera-shooting device and the photograph-taking device; and 3. excellent overload protection function.

Owner:NO 717 INST CHINA MARINE HEAVY IND GRP

Acceleration earthquake sensor

InactiveCN1538192AImprove linearityIncrease temperatureSeismic signal receiversCantilevered beamFixed frame

An ecceleration-type earthquake sensor is composed of upper and lower electrode with recess, and an intermediate electrode, which is composed of fixing frame, mass block, cantilever beam and transverse beam and can be horizontally moved between two fixed electrodes. Its advantages are high linearity and temp drift and compensation, and small size.

Owner:WEIHAI SUNFULL GEOPHYSICAL EXPLORATION EQUIP

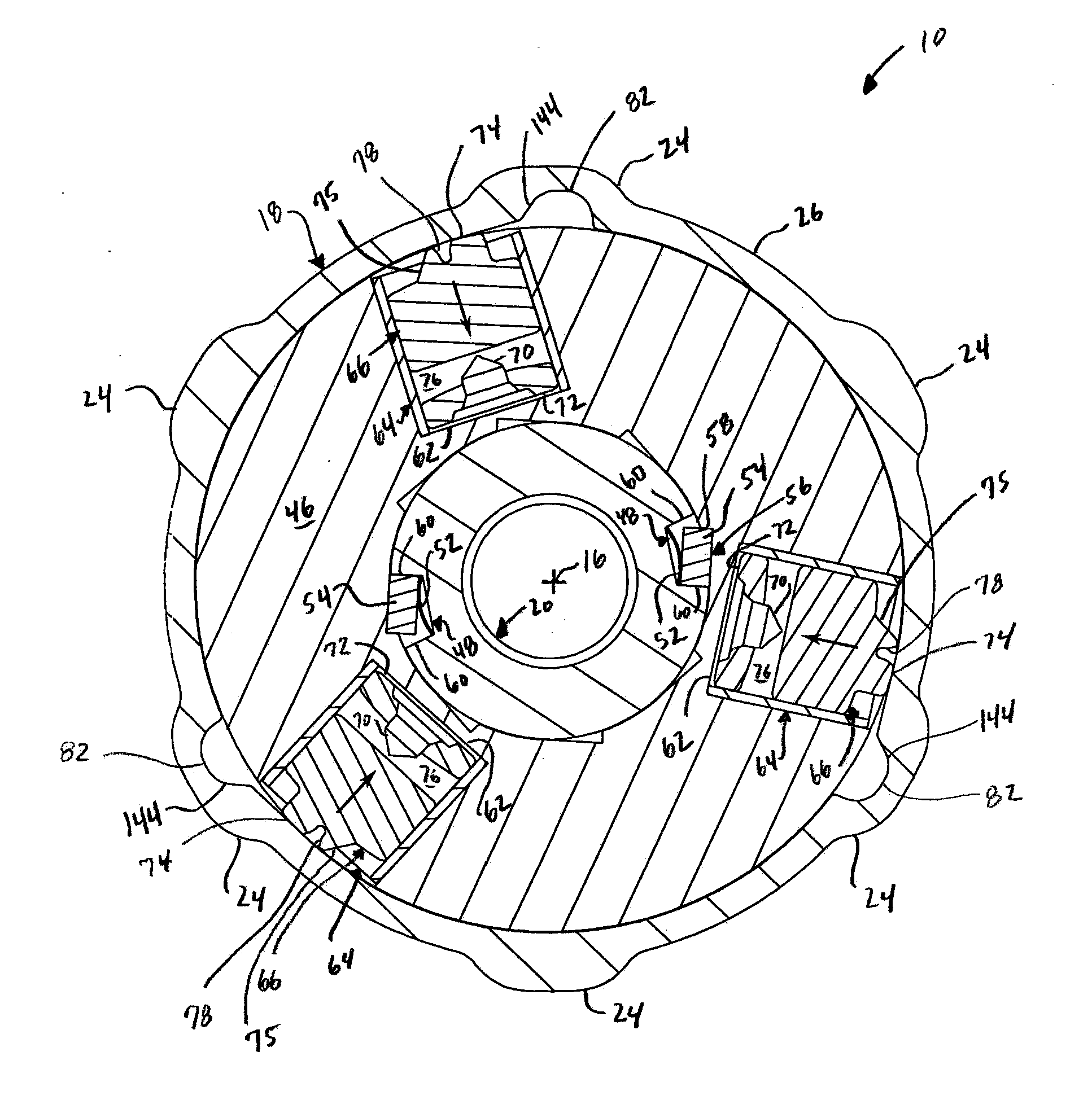

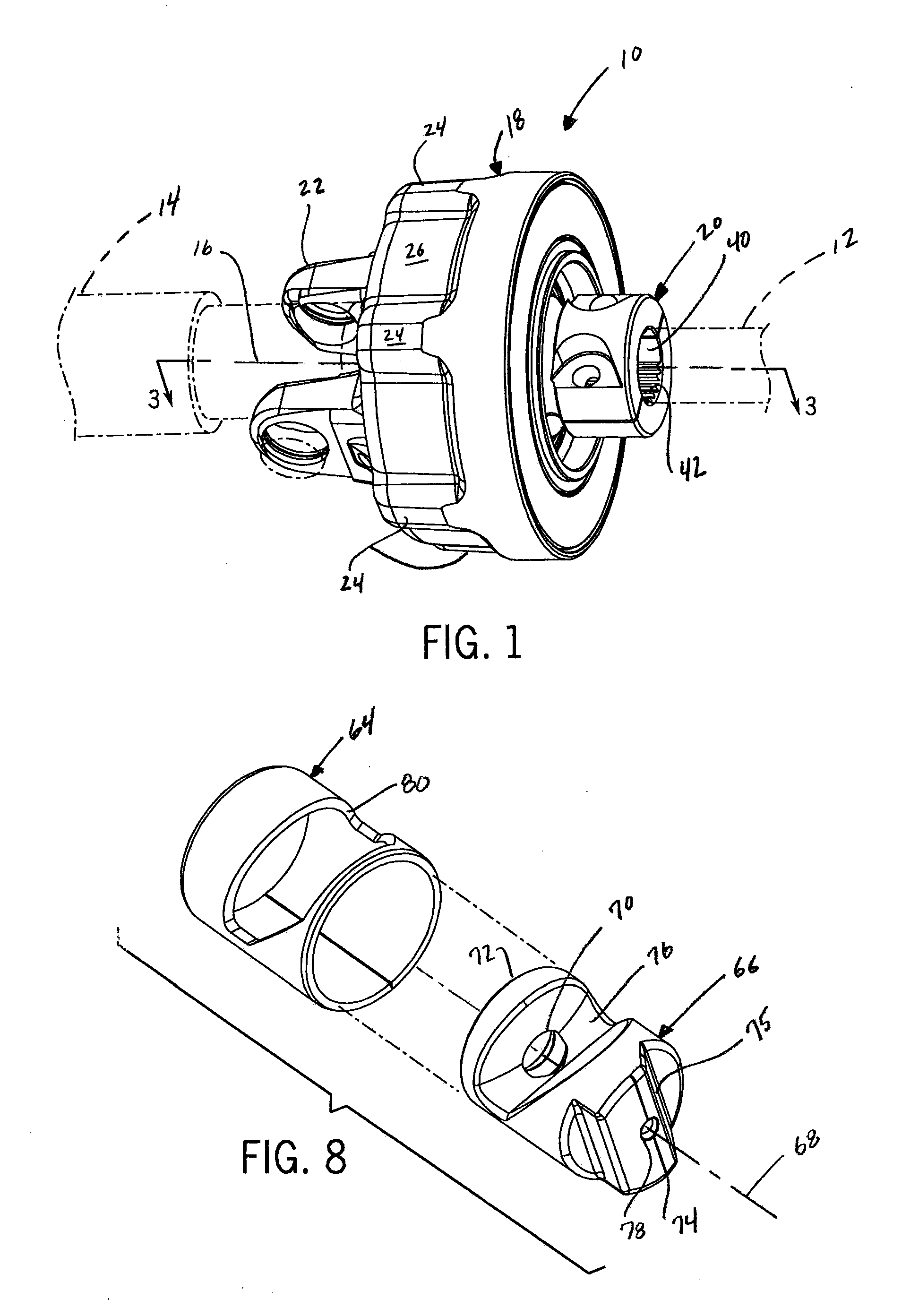

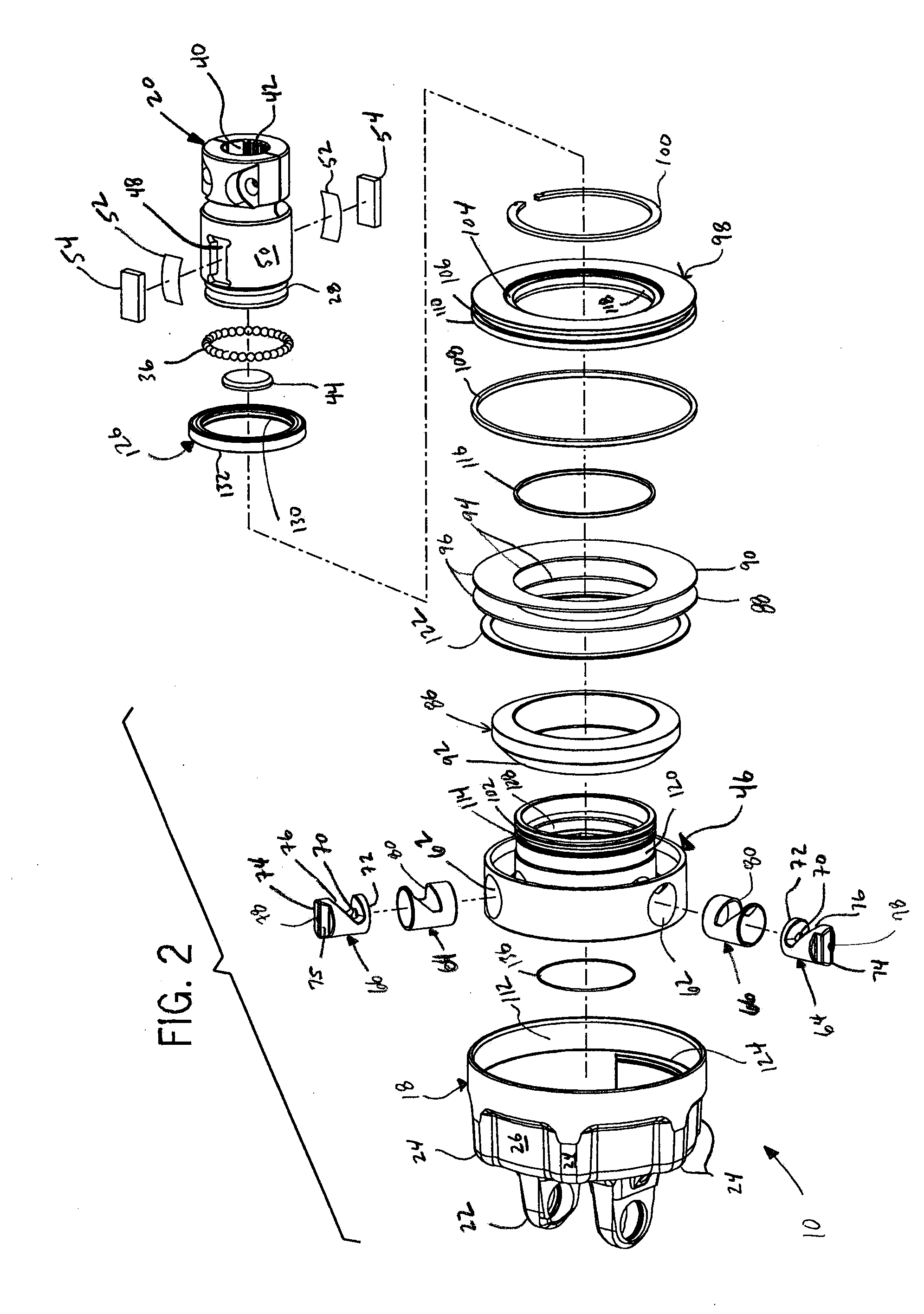

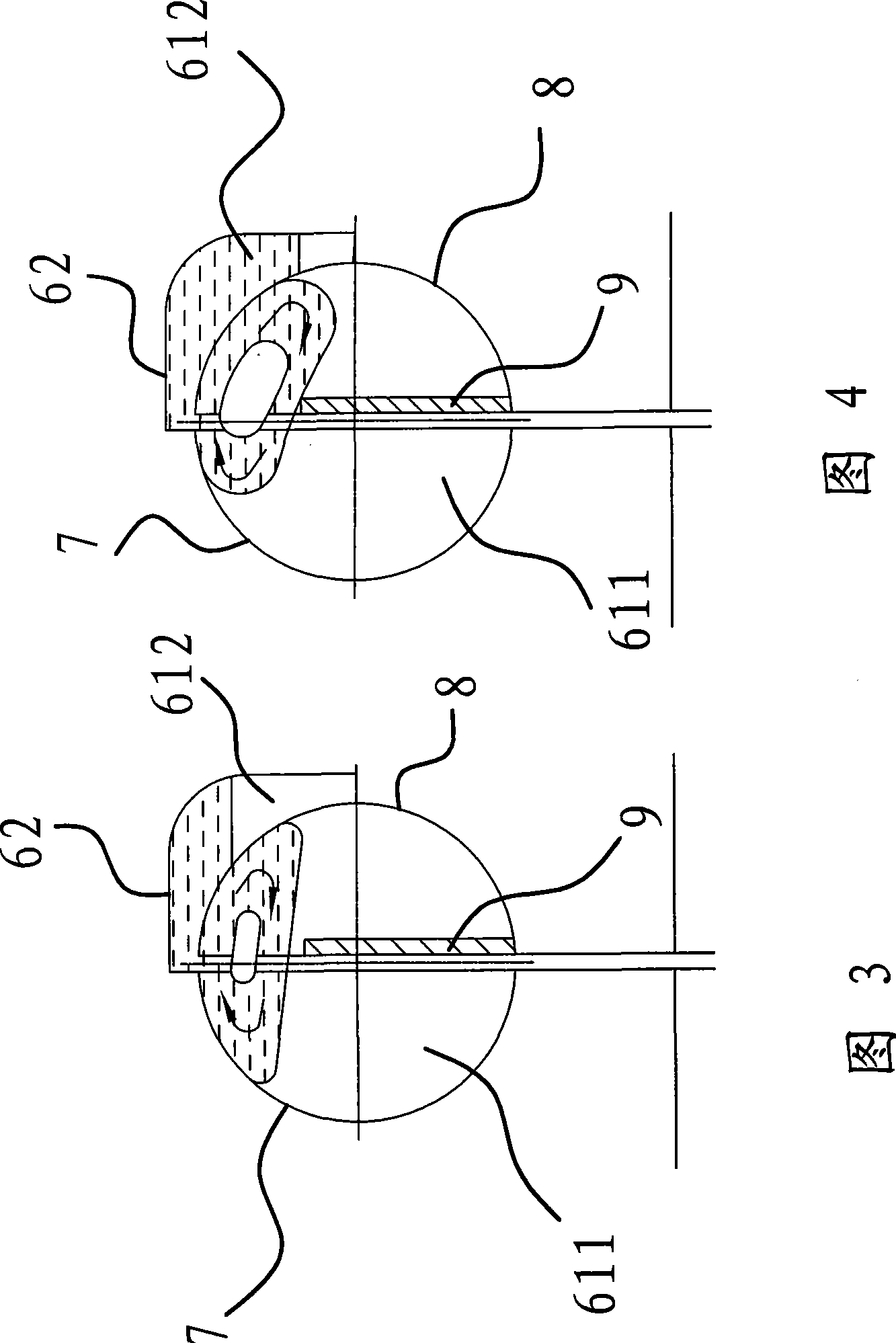

Automatic Torque Overload Clutch

InactiveUS20120073928A1Easy overload protectionSlip couplingFriction clutchesRelative motionActuator

A torque overload clutch, in one form, comprises outer and inner members. A recess is formed in the outer member and a radial opening is formed in the inner member. A driving member is slideably captured in the opening to move between an extended, engaged position with the recess and a retracted, disengaged position. An actuator ring is urged by a spring into engagement with the driving member to bias the driving member toward the engaged position. An end of the driving member may engage the recess to define an engagement angle that is approximately between thirty-four degrees and seventy-degrees relative to a radially oriented reference. The driving member may be slideably captured in a liner seated in the opening, and one or both may be impregnated with a lubricant. A bearing may be positioned between the inner and outer members to inhibit relative movement there between along the clutch axis.

Owner:WEASLER ENG

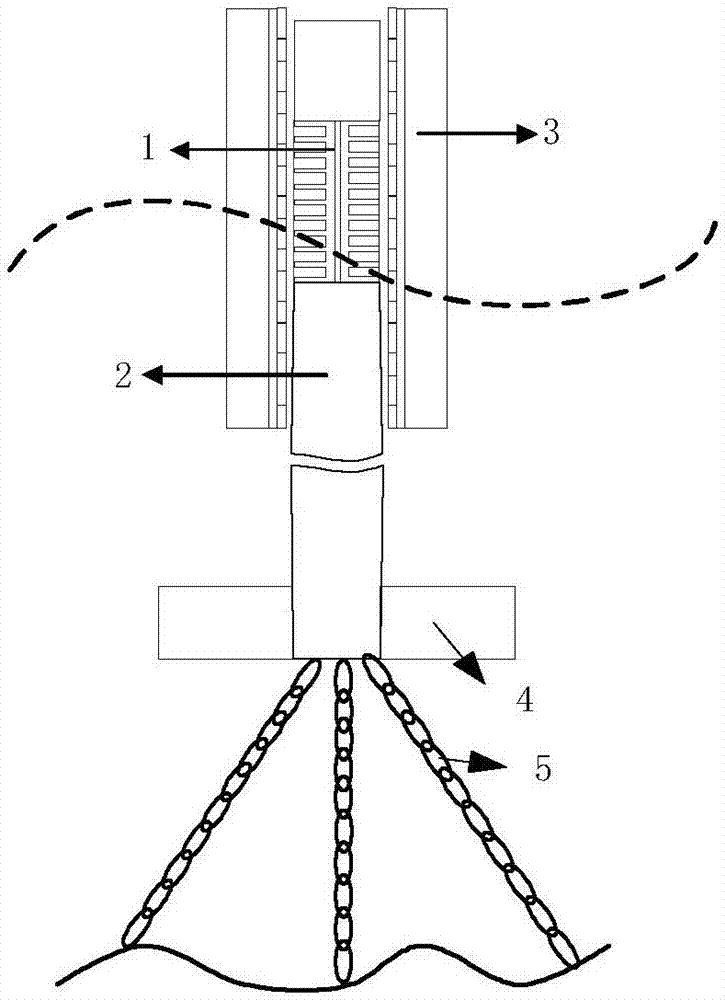

Dual-floater direct-drive type wave power generation system based on speed-increasing type linear permanent magnet generator

InactiveCN106953494ACompact structureImprove power generation efficiencyMachines/enginesEngine componentsWave power generationHigh energy

The invention discloses a dual-floater direct-drive type wave power generation system based on a speed-increasing type linear permanent magnet generator. The dual-floater direct-drive type wave power generation system comprises the speed-increasing type linear permanent magnet generator, an inner floating cylinder, an outer floating cylinder, a damping plate, anchor chains and the like; the whole set of the apparatus adopts a dual-floater structure, and is fixed on the seafloor through the anchor chains to form a floating type system; the inner floating cylinder and a stator of the speed-increasing type linear permanent magnet generator are connected integrally; a stator iron core and armature windings of the motor are mounted in the inner floating cylinder; the outer floating cylinder and a mover of the speed-increasing type linear permanent magnet generator are connected integrally; the outer floating cylinder is arranged outside the inner floating cylinder in a sleeving manner; and the damping plate provides enough buoyancy force to maintain a circular rod which is connected with the stator at a static state. The wave power generation system based on the speed-increasing type linear permanent magnet generator provided by the invention has the advantages of no need of an extra huge speed increasing apparatus, relatively small size, high energy capture and power generation efficiency, and convenience in designing, debugging and maintaining of an electrical control system by virtue of the overall floating suspension structure, and the like.

Owner:SOUTHEAST UNIV

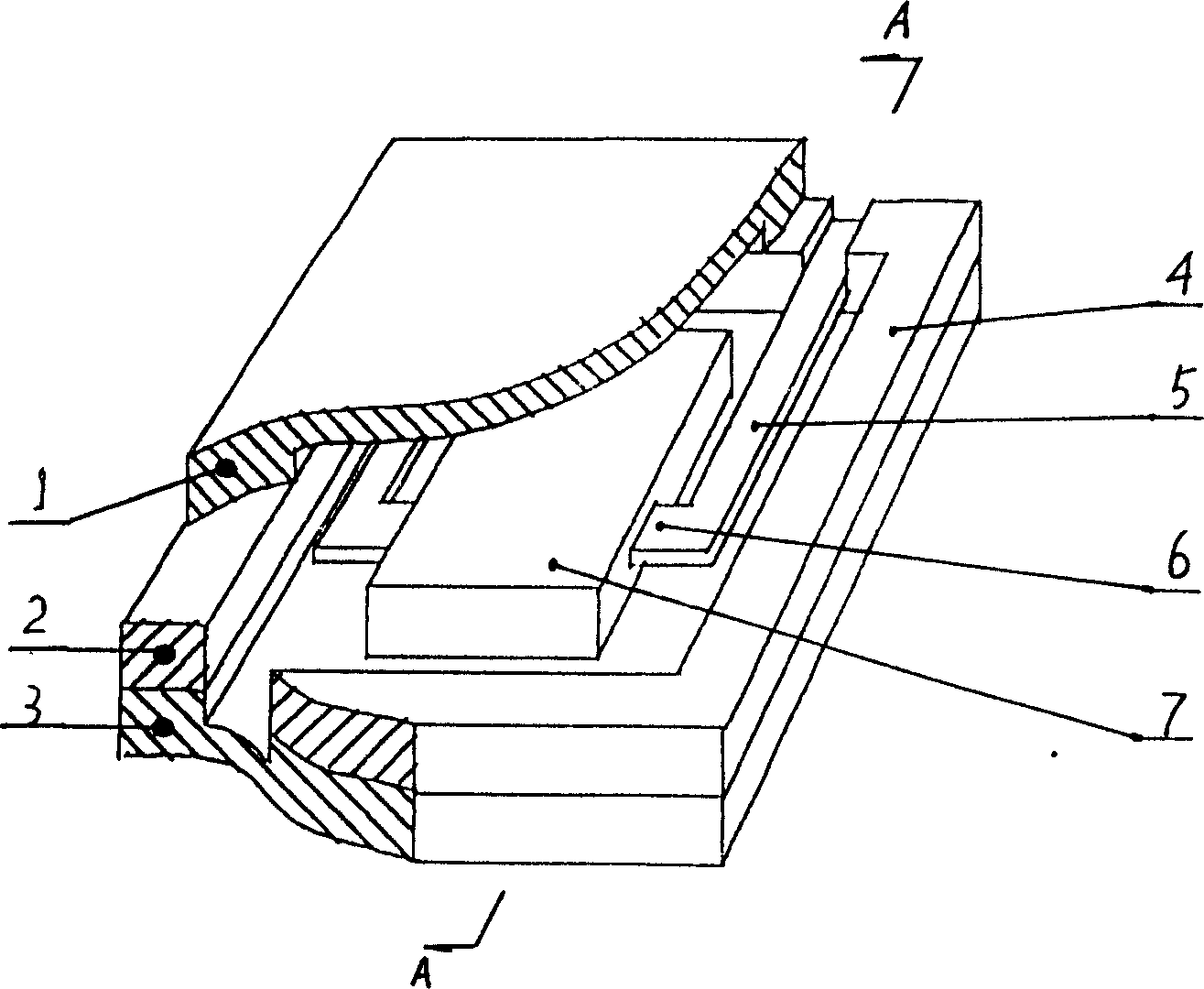

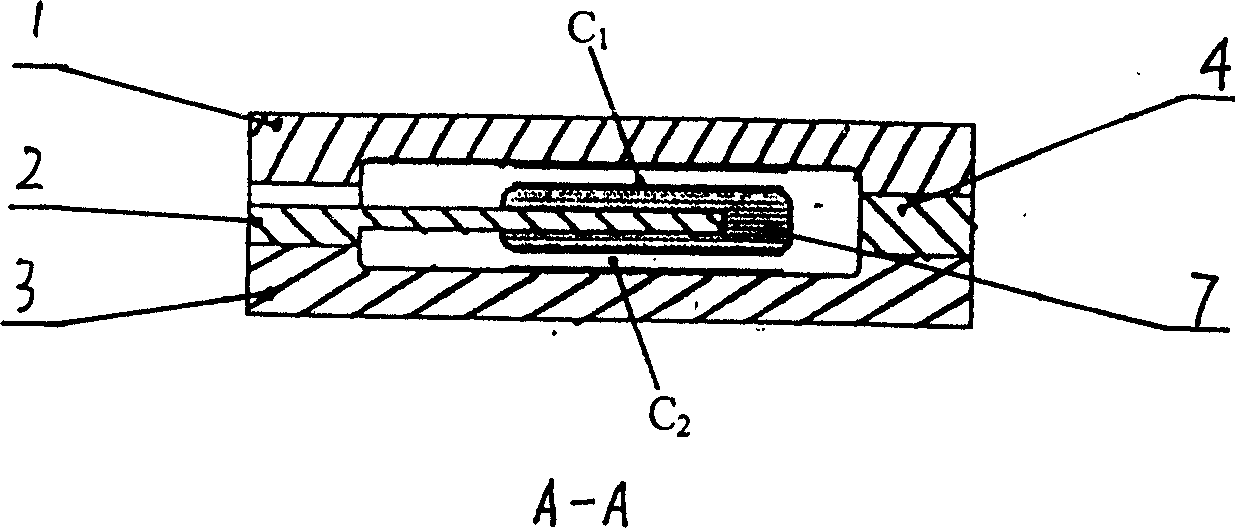

Multilayer structure bonded seal protective capacity pressure sensor and producing method

InactiveCN1587939ACapacitor chamber sealing characteristics are goodStable working characteristicsFluid pressure measurement using capacitance variationCapacitanceMetal

Multi-structure linkage enclosed protecting capacitance pressure sensor and its manufacturing method relate to a pressure sensor, supplying sensor with good hermetical characteristic, stable performance, excellent bearing capacity, high linearity and sensibility, and technical method with good versatility and low manufacturing cost, having prime silicon slice, glass substrate, enclosed glass, silicon film electron and capacitance cavity electron. Wash, dry, oxidize the prime silicon slice, erode capacitance cavity, then spread to form P+layer or PN node of film, creating metal electron; isolation glass is made on metal electron, prime silicon slice and glass slice is linked; dual-plane polishing glass slice used for enclosing glass is linked with protecting silicon slice; enclosing glass is isolation wall has static electricity linkage with enclosing glass. Use linkage structure of two pieces of silicon and two pieces of glass, and multi-structure static electricity linkage technique enclosing capacitance cavity, to produce capacitance cavity type micro pressure sensor, avoiding effectively the problem of capacitance cavity enclosing linkage.

Owner:XIAMEN UNIV

Overload protection switch

ActiveUS6992559B2Speed up deformationEasy overload protectionElectrothermal relaysEmergency protective arrangements for automatic disconnectionElectrical conductorEngineering

An overload protection switch has a conductor interconnecting the first primary leg and a second primary leg so that when current passes through the switch, the current not only raises the temperature of the bi-metal plate, but also raises the temperature of the conductor to enhance the deformation of the bi-metal plate such that the electrical appliance connected to the switch and having an ampere tolerance lower than that of the bi-metal plate is protected.

Owner:HUANG ALBERT

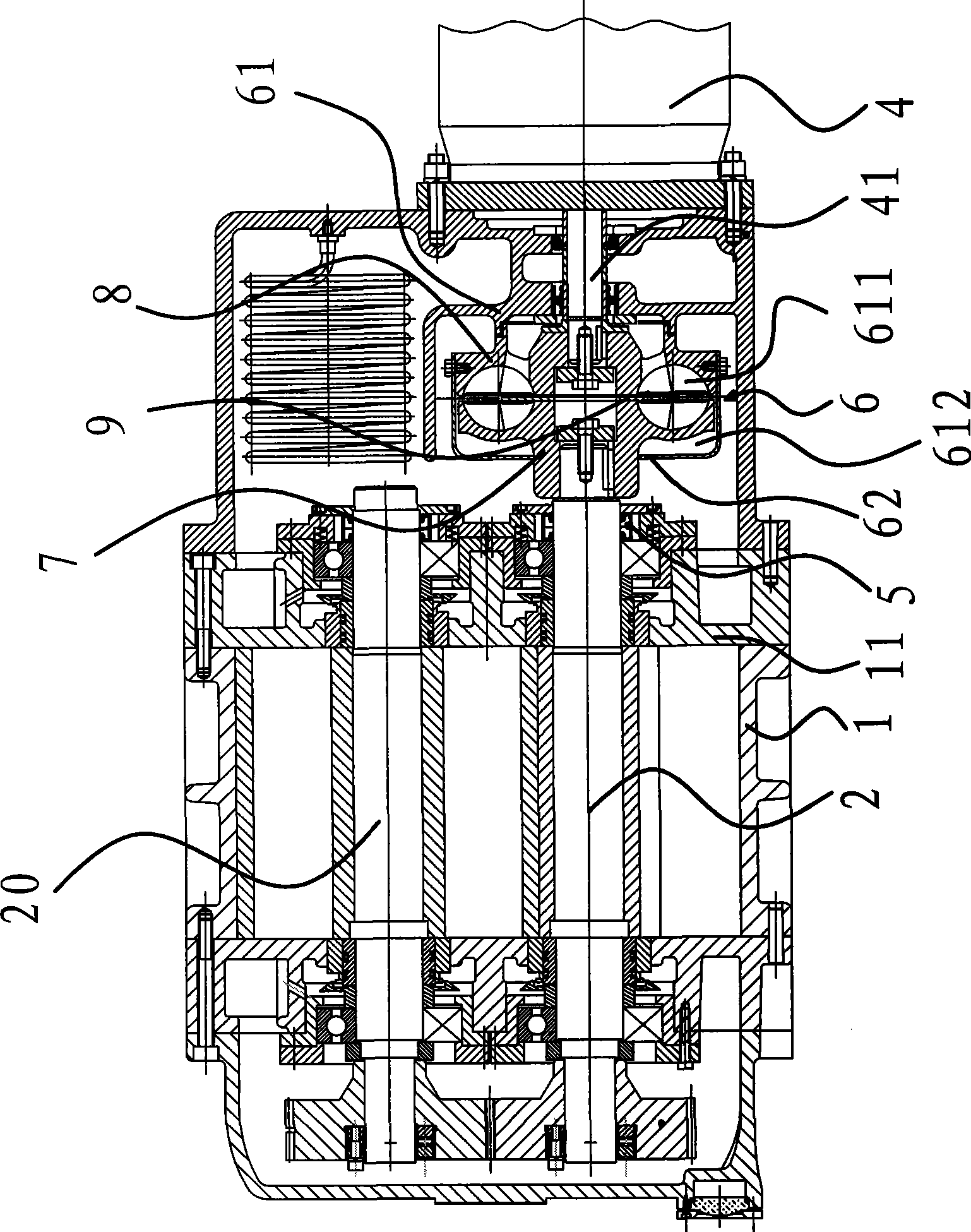

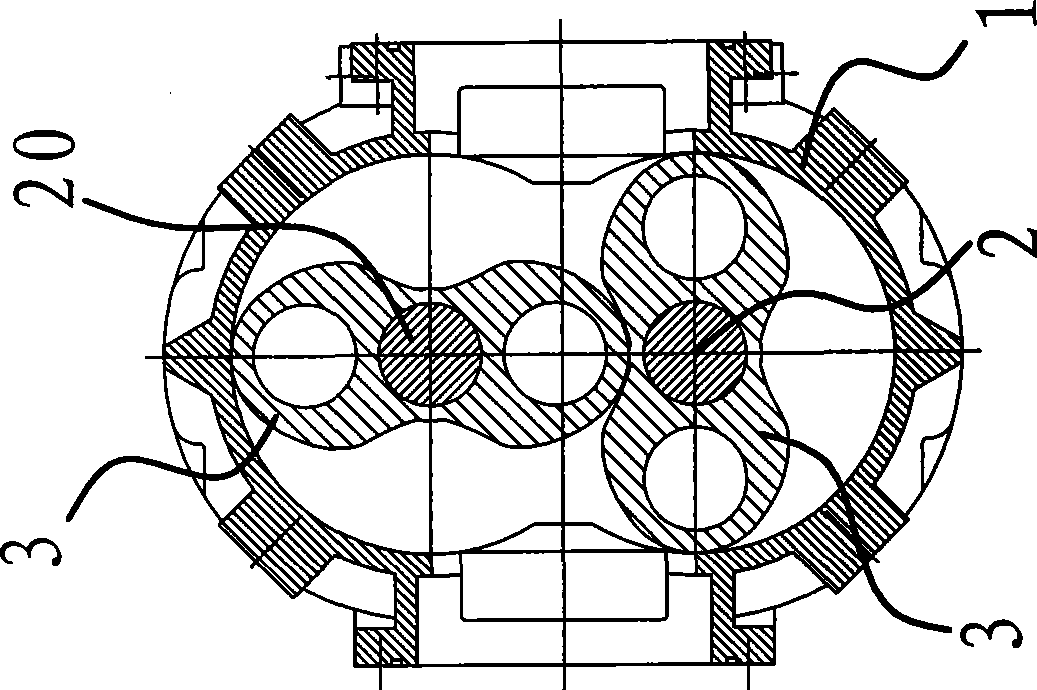

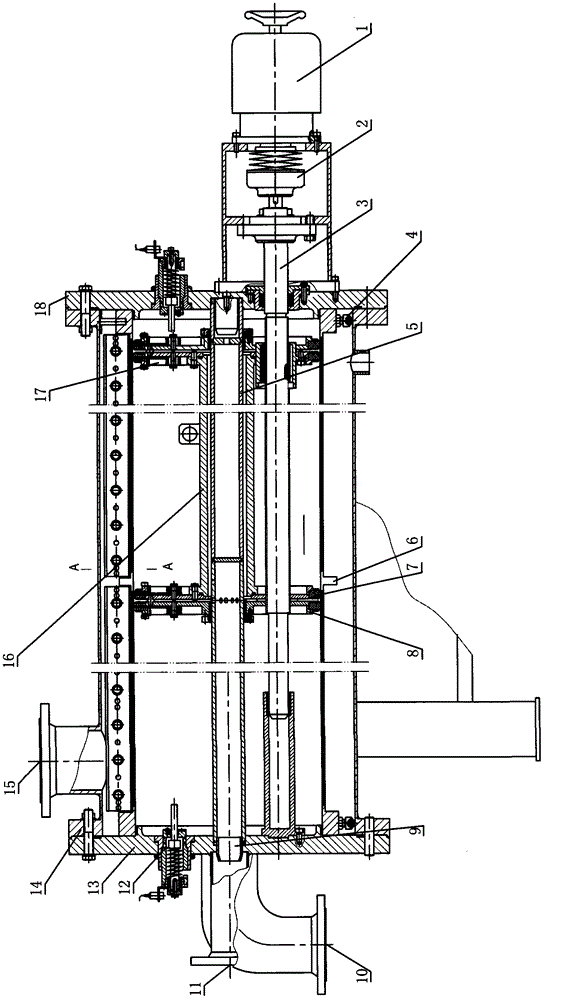

Roots vacuum pump

InactiveCN101463816ALow ultimate pressureReduce pumping timeRotary piston pumpsRotary piston liquid enginesPower gridEngineering

The invention provides a Roots vacuum pump, which belongs to the technical field of machinery and solves the technical problems of hard load start, high starting current, high impact on an electricity grid, high bearing impact, and the like of the existing Roots vacuum pump. The Roots vacuum pump comprises a pump body and a long pump shaft and a short pump shaft arranged in the pump body, wherein, rotors are respectively connected on the long pump shaft and the short pump shaft, the long pump shaft and the short pump shaft are connected with each other by a pair of engaged driver gears, one end of the long pump shaft extends out of the pump body on which an electric motor is arranged, and a rotating shaft of the electric motor and the pump shafts are connected by hydraulic driving mechanisms. The Roots vacuum pump has the advantages of favorable overload protection, low starting current, easy load start, short air suction time, etc.

Owner:ZHEJIANG VACUUM EQUIP GROUP

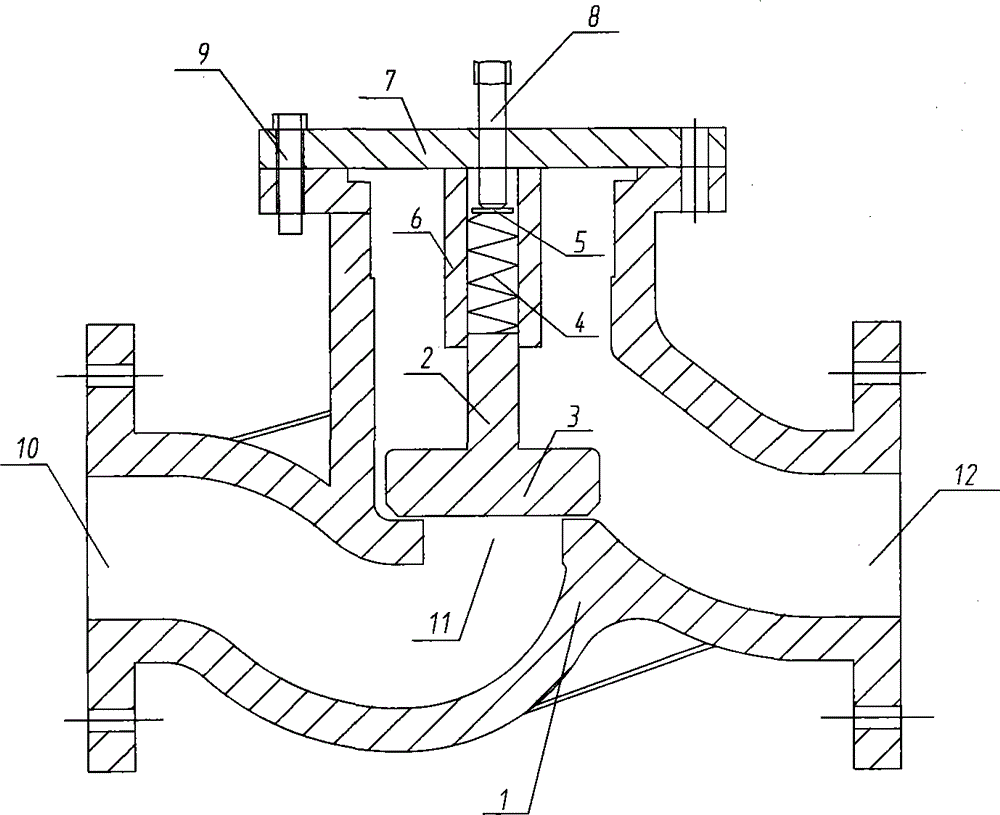

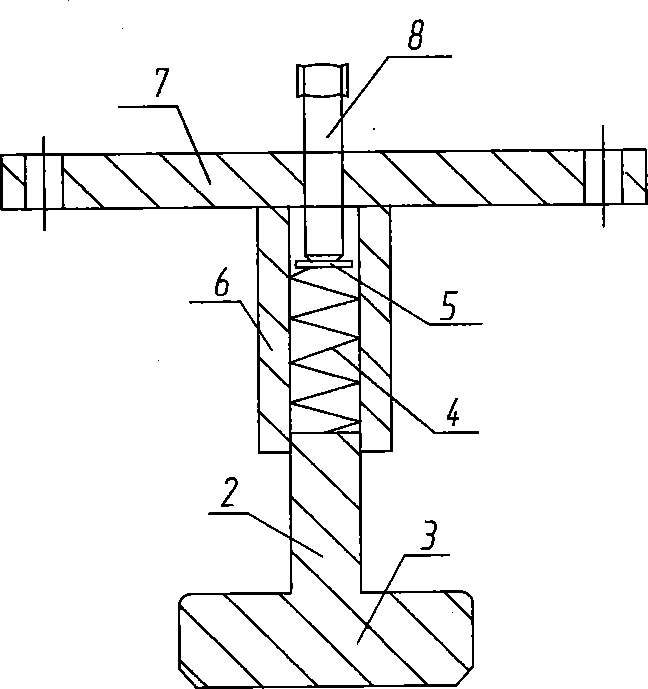

Mine water pump pressure relief device

InactiveCN104482230ASimple structureEasy overload protectionPositive displacement pump componentsEqualizing valvesWorking pressureEngineering

The invention discloses a mine water pump pressure relief device, including a valve body, a valve disk, a valve disk head, a spring, a baffle, a cylinder, a bonnet, a lead screw, a bolt, a water inlet, a mesopore and a water outlet, wherein the cylinder is welded onto the bonnet; the spring is installed in the cylinder as a motion track of the valve disk; the valve disk head of the valve disk is pressed on the mesopore; the bonnet is fixedly connected to the valve body by the bolt; the lead screw is screwed into a central threaded hole in the bonnet to be pressed against the baffle; the pressure of the spring is adjusted by the screwing stroke of the lead screw; the valve disk is set with a rated working pressure to be tightly pressed against the mesopore to block a channel; when water pressure in a water outlet pipe is more than the rated working pressure of the valve disk, the valve disk is pushed by the water pressure to move upwards to open the mesopore channel and communicate the water inlet with the water outlet, and thereby achieve pressure relief of a water pump. The mine water pump pressure relief device has the advantages of being simple in structure, achieving good overload protection, effectively avoiding the device from overload operation, improving the service life of the device, and reducing the maintenance cost of the device.

Owner:SICHUAN HUAYINGSHAN COAL IND CO LTD LIZIYA MINE

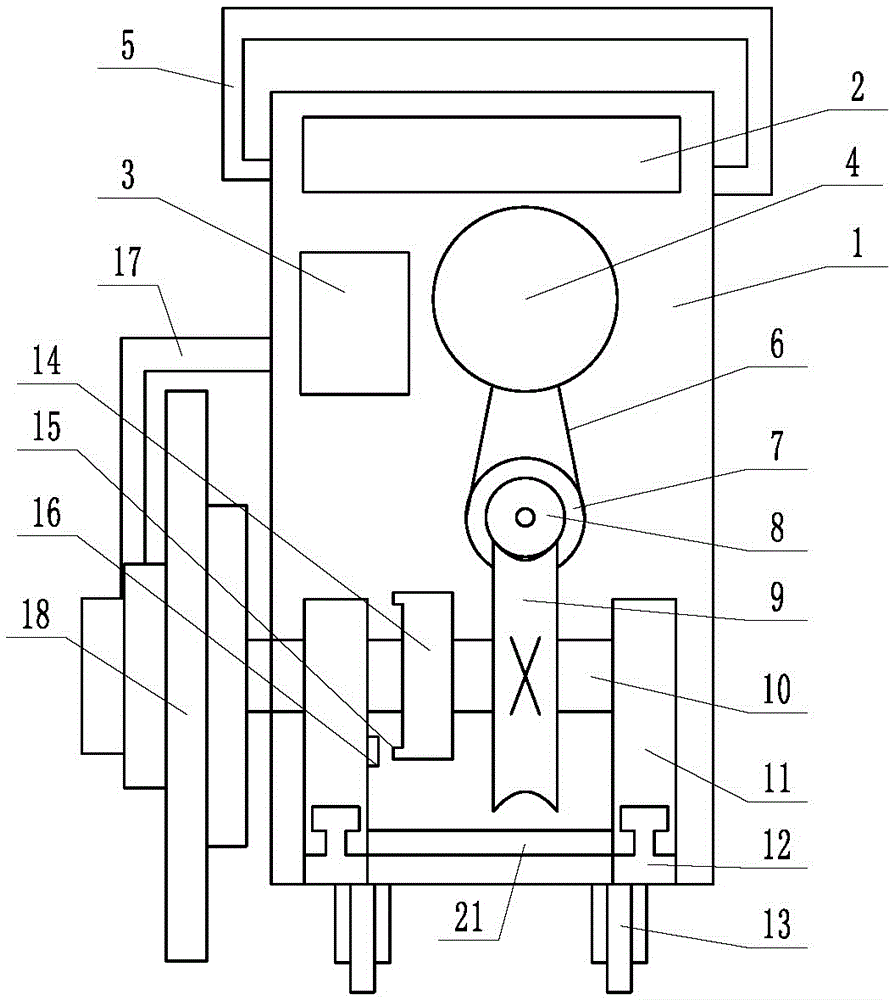

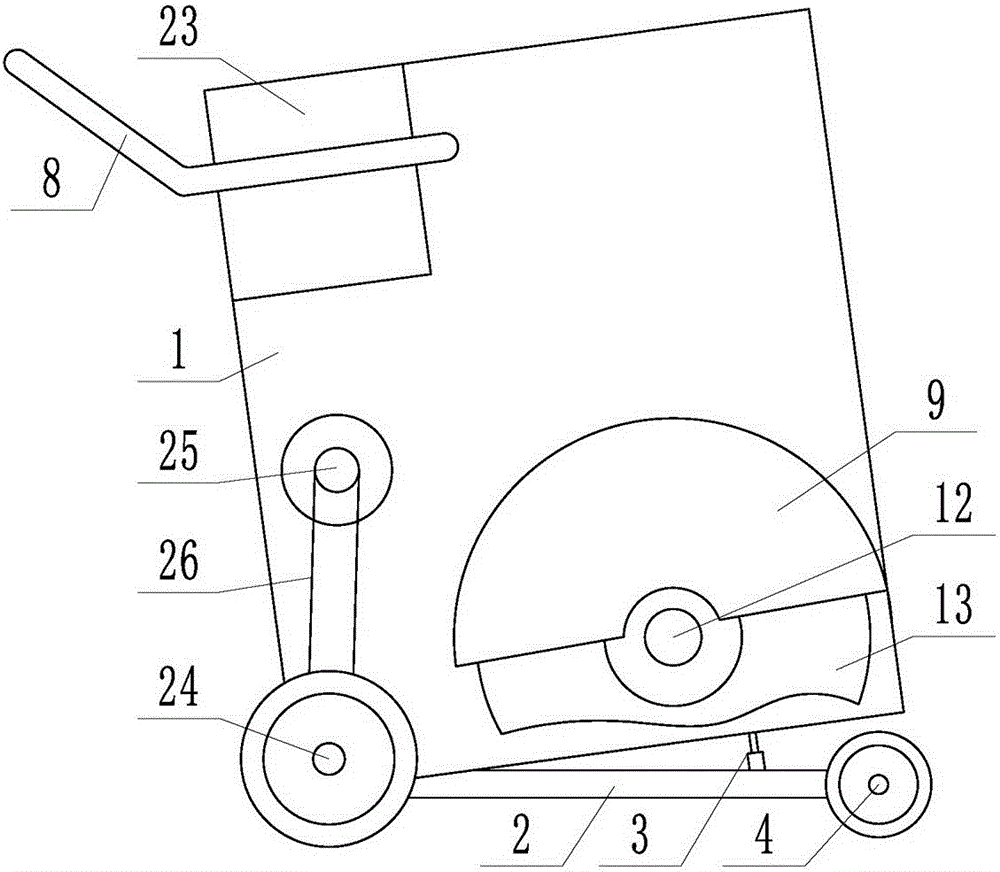

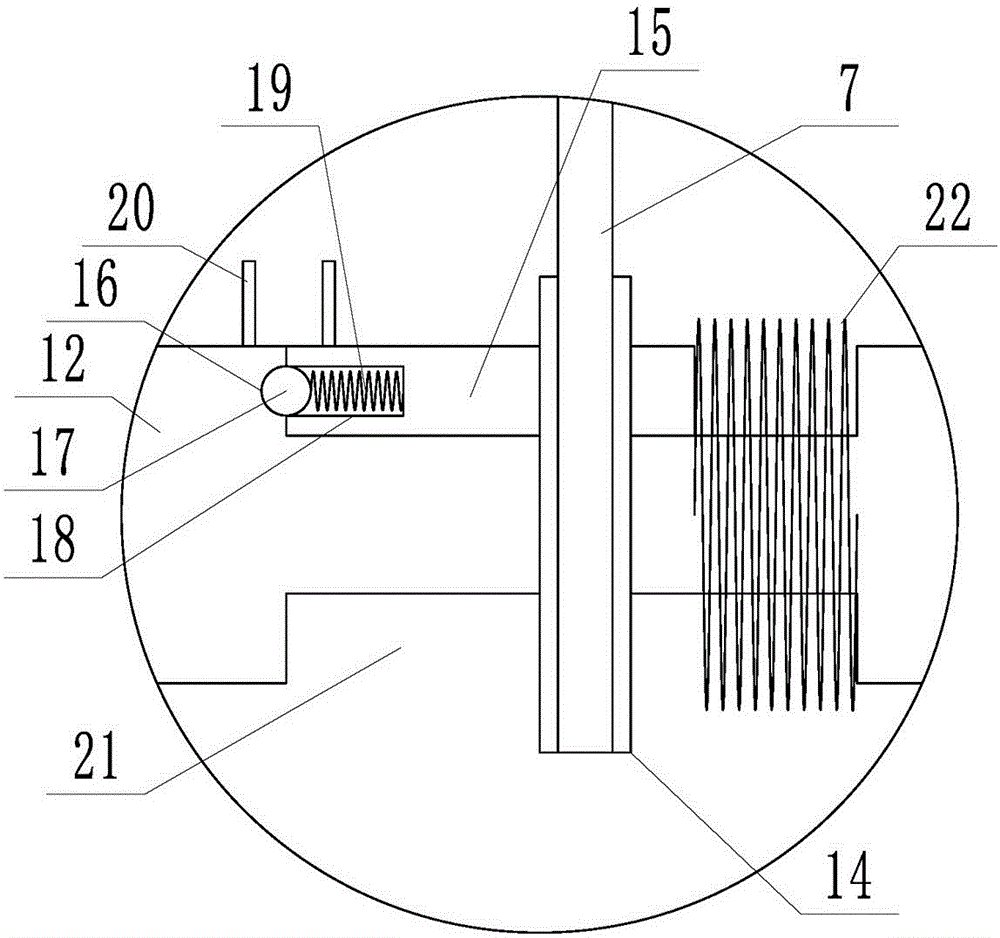

Cutting machine with overload protection function

ActiveCN106192709AAvoid deformation damageSimple structureRoads maintainenceHydraulic motorControl system

Disclosed is a cutting machine with the overload protection function. The problems that excessive road cutting is performed, incomplete cutting is performed and a cutting machine does not have the overload protection function due to the fact that the depth is artificially set in the cutting process of a cutting machine are effectively solved. The construction time can be shortened, the construction progress can be accelerated, the technical requirement of operators is lowered, the operators and a cutting machine body are protected, and the cutting machine has generalization; the cutting machine comprises a machine frame, a pushing handle, wheels, a cutting piece, a small hydraulic station, a control system and a hydraulic motor. The cutting machine is simple and reasonable in structure, vertical motion of the cutting piece can be controlled while cutting is performed, it is ensured that a cut road can be completely separated from a soil matrix, secondary construction is avoided, the overload protection function is added while cutting is performed, the hydraulic motor is adopted as power, the protection effect can be achieved when the stress of the cutting piece changes suddenly, and the cutting piece and a transmission element are prevented from being deformed or damaged by excessive strength.

Owner:长沙县海逸凯达汽车配件有限公司

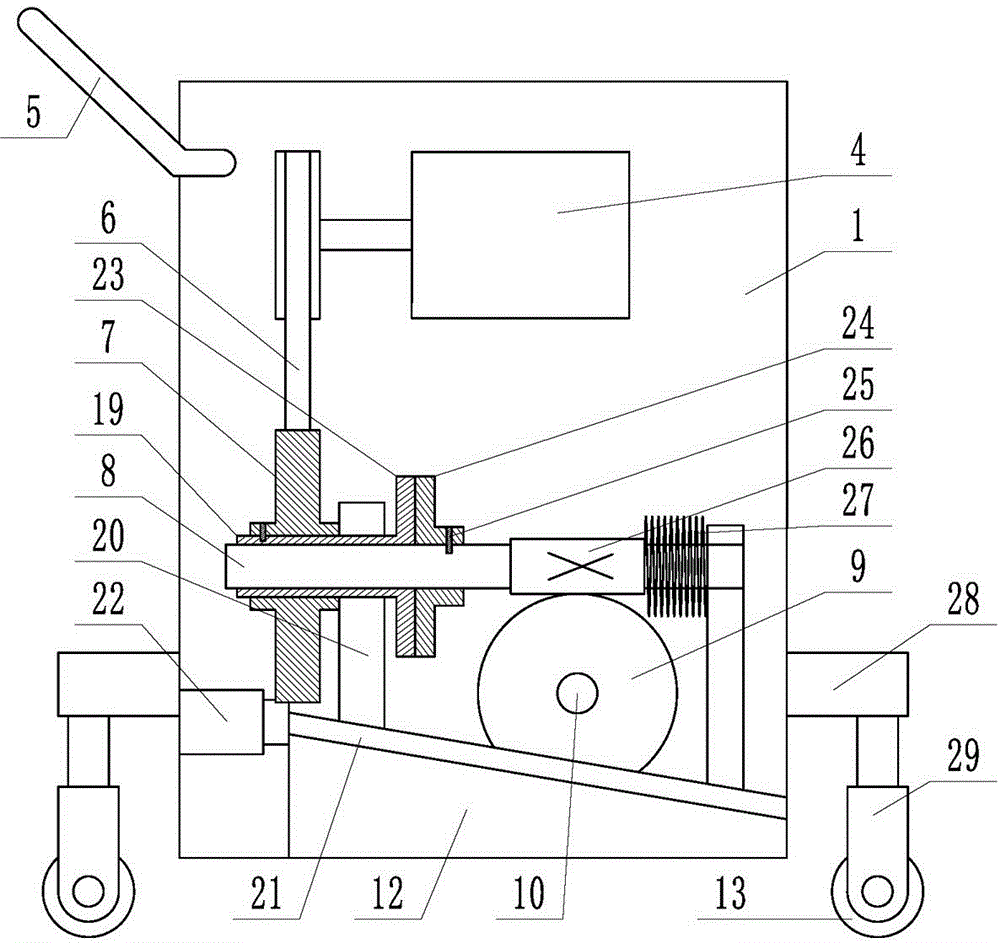

Automatic control cutter with overload protection function

The invention discloses an automatic control cutter with an overload protection function. The problems of incapability of a cutter in complete cutting of concrete, no overload protection function of the cutter and the like are effectively solved. The automatic control cutter comprises a rack, and is characterized in that a bottom plate is hinged to the lower end of the rack, wherein electric pushrods are connected between the bottom plate and the rack; a first fixed frame and a second fixed frame are fixedly arranged on the inner lower part of the rack; a rotating shaft is arranged in the first and second fixed frames in a penetration manner; a mounting section of the which the diameter is smaller than that of the rotating shaft is arranged on the middle section of the rotating shaft; a shaft sleeve is arranged on the mounting section in a sleeving manner; a chain wheel is fixedly arranged outside the shaft sleeve, and is connected with an engine through a chain; a reset spring pressed against one end of the shaft sleeve is connected to the rotating shaft in the sleeving manner; a first groove is formed in the other end of the shaft sleeve; a steel ball is connected in the first groove through a spring; a second groove capable of accommodating the steel ball is formed in the rotating shaft. The automatic control cutter is simple and reasonable in structure, a cut road can be completely separated from an earth foundation to avoid secondary construction, and overload protection is added at the same time of cutting to prevent a cutting disk from being stressed, deformed and damaged.

Owner:山东沂蒙工具有限公司

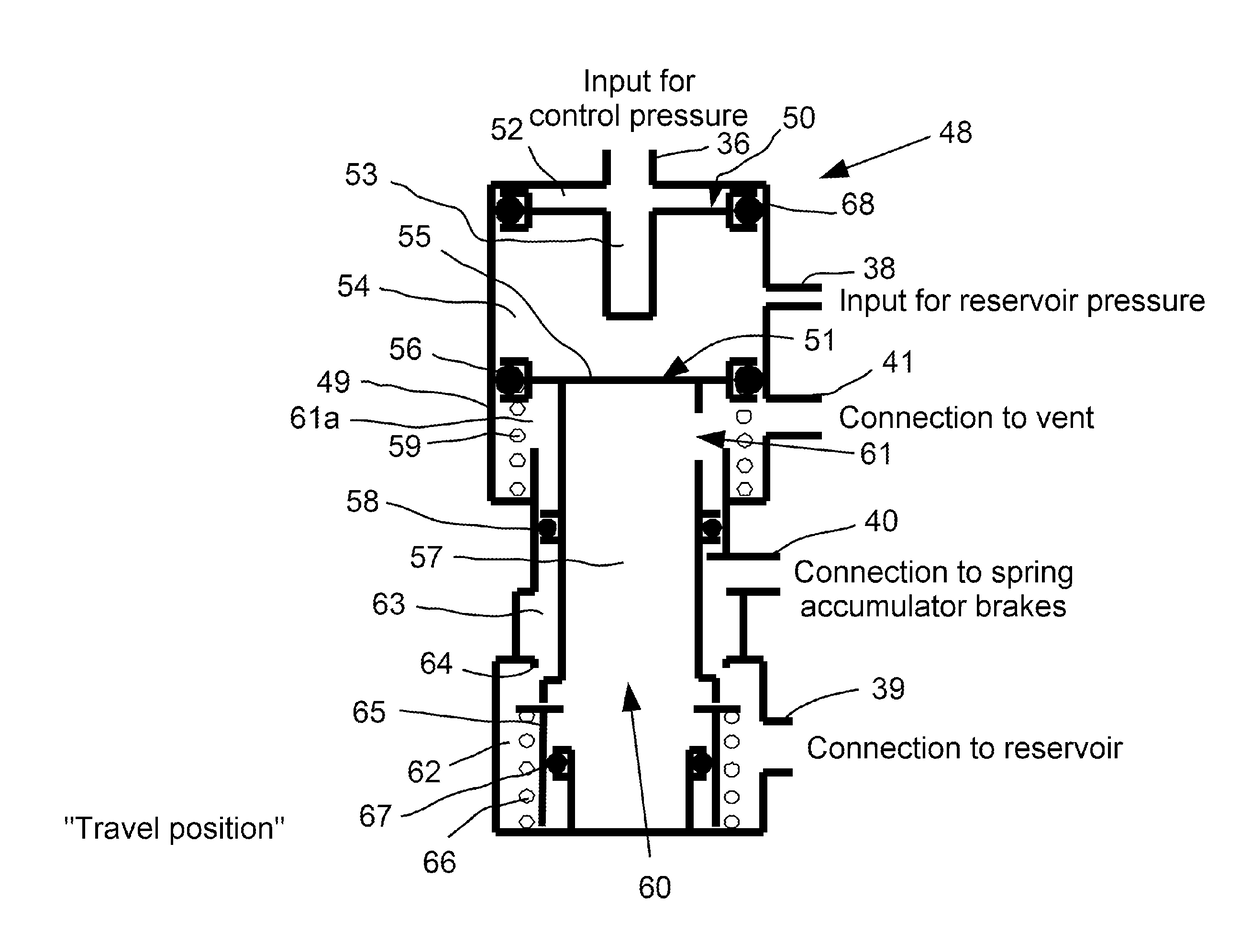

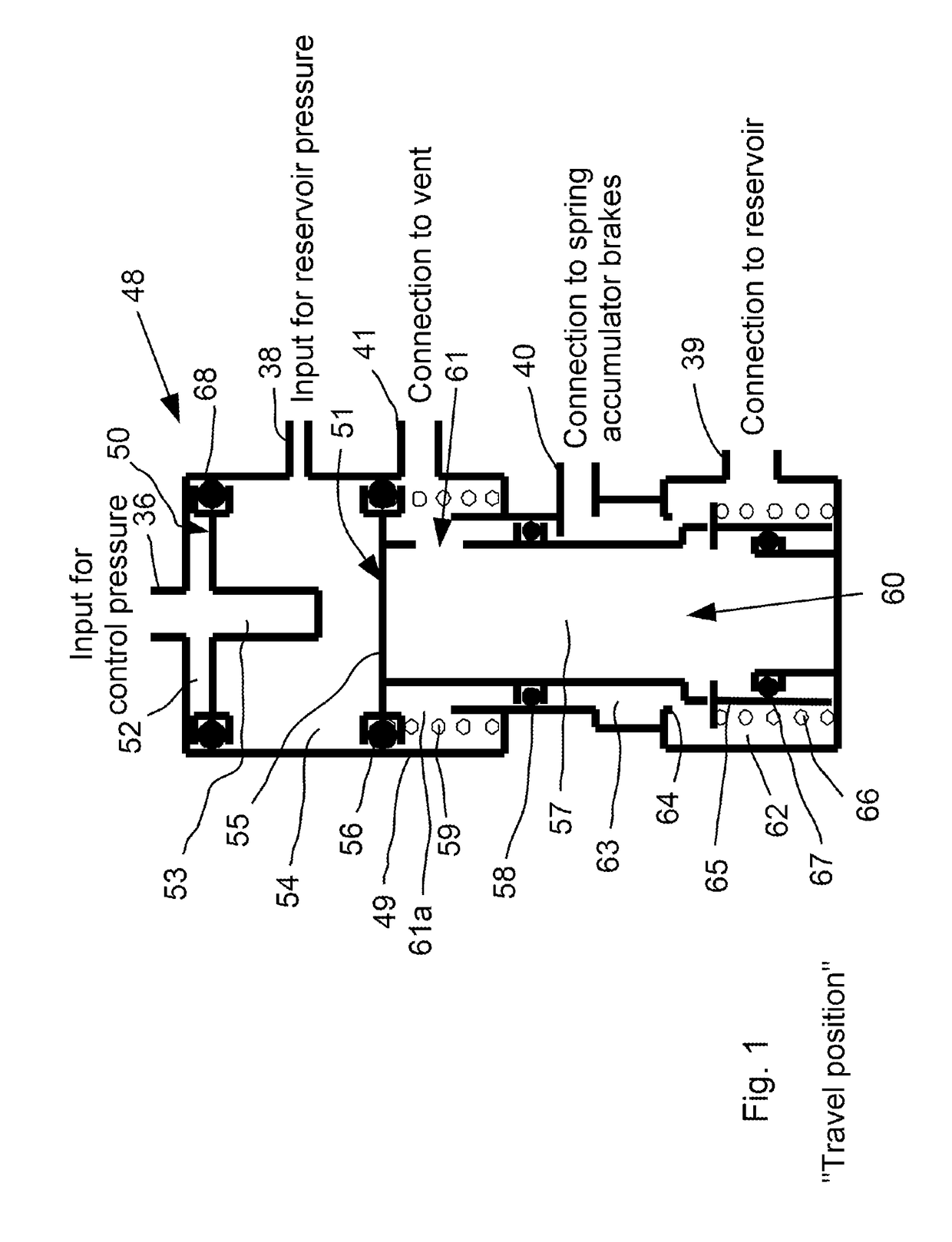

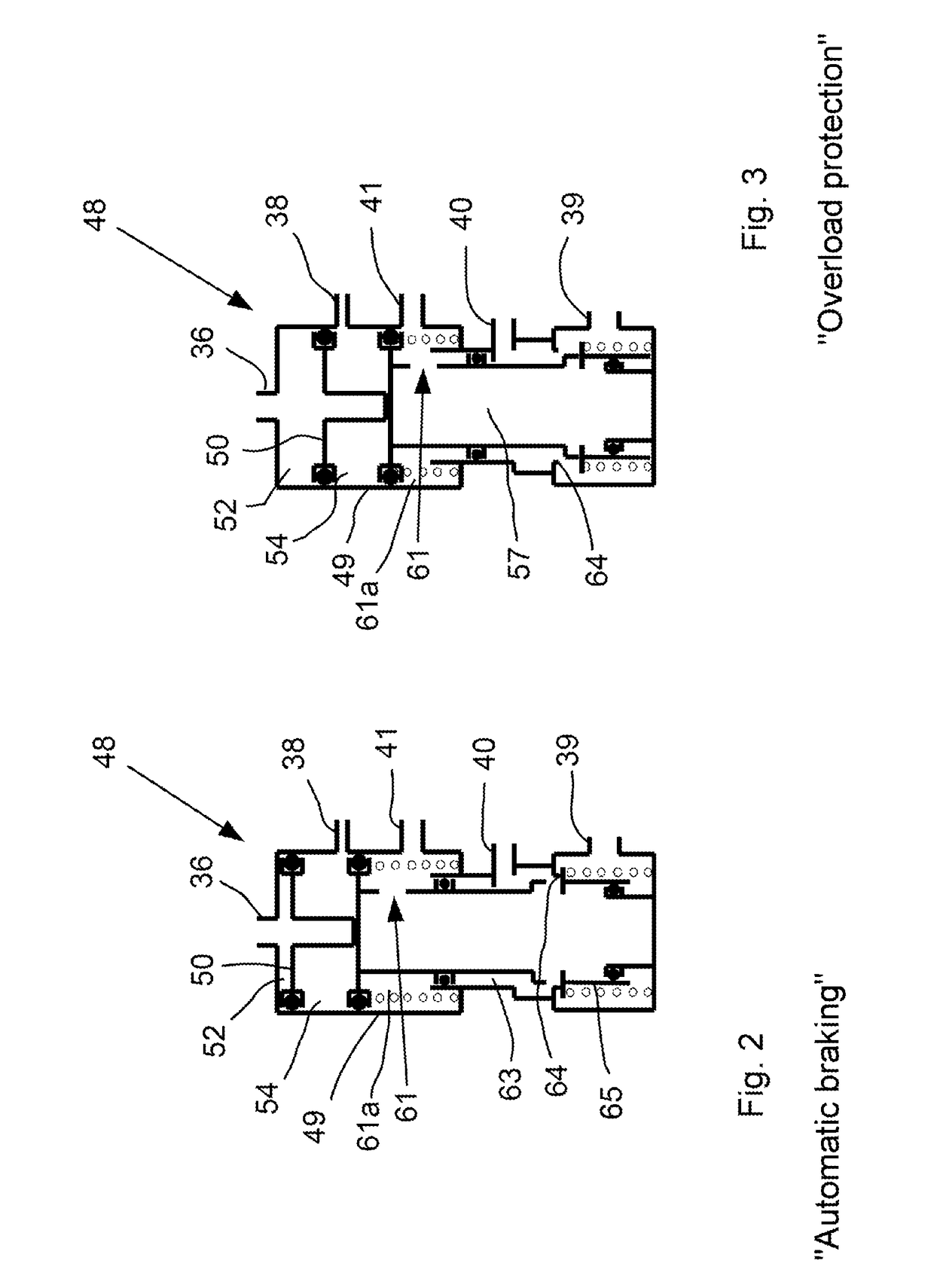

Pneumatic braking system for a trailer vehicle

ActiveUS20180229708A1Easy overload protectionEasy to controlBraking action transmissionAutomatic initiationsLine tubingBraking system

Disclosed is a valve arrangement for aerating spring accumulator brake cylinders in a trailer vehicle with a pneumatic braking system, the valve arrangement having a first connection for a line connected to a reservoir of the trailer vehicle, a second connection for a line leading to the spring accumulator brake cylinders, and a first pneumatic control input, wherein the first connection can be connected to the second connection depending on the pressure on the first pneumatic control input. The first control input is connected to a line connected to a control connection of the trailer vehicle or to a line connected to the reservoir. A valve unit, a pneumatic braking system, a method of operating the same, and a trailer vehicle including the same are also disclosed.

Owner:ZF CV SYST EURO BV

Hydraulic-driven bone density increase device

The invention belongs to equipment for increasing human bone density, and is a hydraulically driven bone density increaser. The disadvantages of the prior art are that the drug treatment for improving bone density is expensive, has side effects, and has no obvious effect. The bottom plate (5) of the present invention is placed on the upper part of the lower rubber shock absorber (6), and columns (3) are respectively connected on both sides between the vibration plate (2) and the bottom plate (5); An oil pump (9), a hydraulic oil cylinder (4) and a controller (7); the controller (7) is provided with a 2D electro-hydraulic control valve (8). The advantages of the present invention are: small size, light weight; stable and automatic frequency adjustment; easy direction change, which can conveniently realize the conversion of linear reciprocating motion; oil is used as the working medium, and the relative moving surfaces of the components can be self-lubricated and wear-resistant. Small size, long service life; easy operation and control, high degree of automation; no drugs, no side effects.

Owner:上海愿航医疗器械有限公司

Automatic backwashing viscose filter

InactiveCN103055570AControl center locationOvercome the defect of easy deformationStationary filtering element filtersAutomatic controlProgrammable logic controller

The invention discloses an automatic backwashing viscose filter, belonging to filtering machinery. A rack is provided with a cylindrical filter drum body; two ends of the filter drum body are respectively provided with a front drum body end cover and a rear drum body end cover which are respectively and fixedly provided with an ejecting rod component; the filter drum body is provided with a viscose outlet near the rear drum body end cover; a waste viscose outlet and a viscose inlet are arranged at the rear drum body end cover; a mesh cage is arranged inside the filter drum body; the two ends of the mesh cage are connected with the front drum body end cover and the rear drum body end cover; a protective mesh is fixed on the surface of the mesh cage by a clamping plate and a hoop; a filtering mesh is wrapped and clamped between a lining mesh and the protective mesh; the lining mesh is wrapped and clamped between the mesh cage and the filtering mesh; two ends of a center pipe are respectively inserted in hole slots in the central parts of the front drum body end cover and the rear drum body end cover; a backwashing piston is located inside the mesh cage and sleeved on the center pipe; a safety coupler is connected with a speed reducer; and the speed reducer is connected with a motor. For the filter, an automatic filtering system is designed according to an osmosis filtration principle, and a PLC (Programmable Logic Controller) technology is adopted, so that the automatic backwashing viscose filter can achieve automatic control, continuous work, automatic backwashing and automatic residue discharge.

Owner:YANCHENG XINGHUO VALVE IND MFG CO LTD

Hydraulic motor integrated transmission device

InactiveCN102545506ASolve processing problemsImprove powerAsynchronous induction motorsHydraulic motorFluid coupling

The invention relates to a hydraulic motor integrated transmission device, which comprises a machine base, an outer rotor motor and a hydraulic coupler and is characterized in that the machine base is composed of a machine base end cover and a machine base casing, the outer rotor motor and the hydraulic coupler are installed in the machine base, pump impeller blades of the hydraulic coupler are directly and fixedly connected with outer rotors of the outer rotor motor, an inner stator shaft of the outer rotor motor is concentric with an output shaft of the hydraulic coupler, the shaft end of the inner stator shaft of the outer rotor motor is fixed on the machine base casing, and the output shaft of the hydraulic coupler extends out of the machine base end cover. The hydraulic motor integrated transmission device has the advantages of being capable of absorbing impact and vibration brought by outer load, being so good in overload protection performance that a power source can still rotate without being damaged even when the output shaft is clamped, and being good in loaded start-up performance and power performance and capable of achieving automatic speed changing.

Owner:YANSHAN UNIV

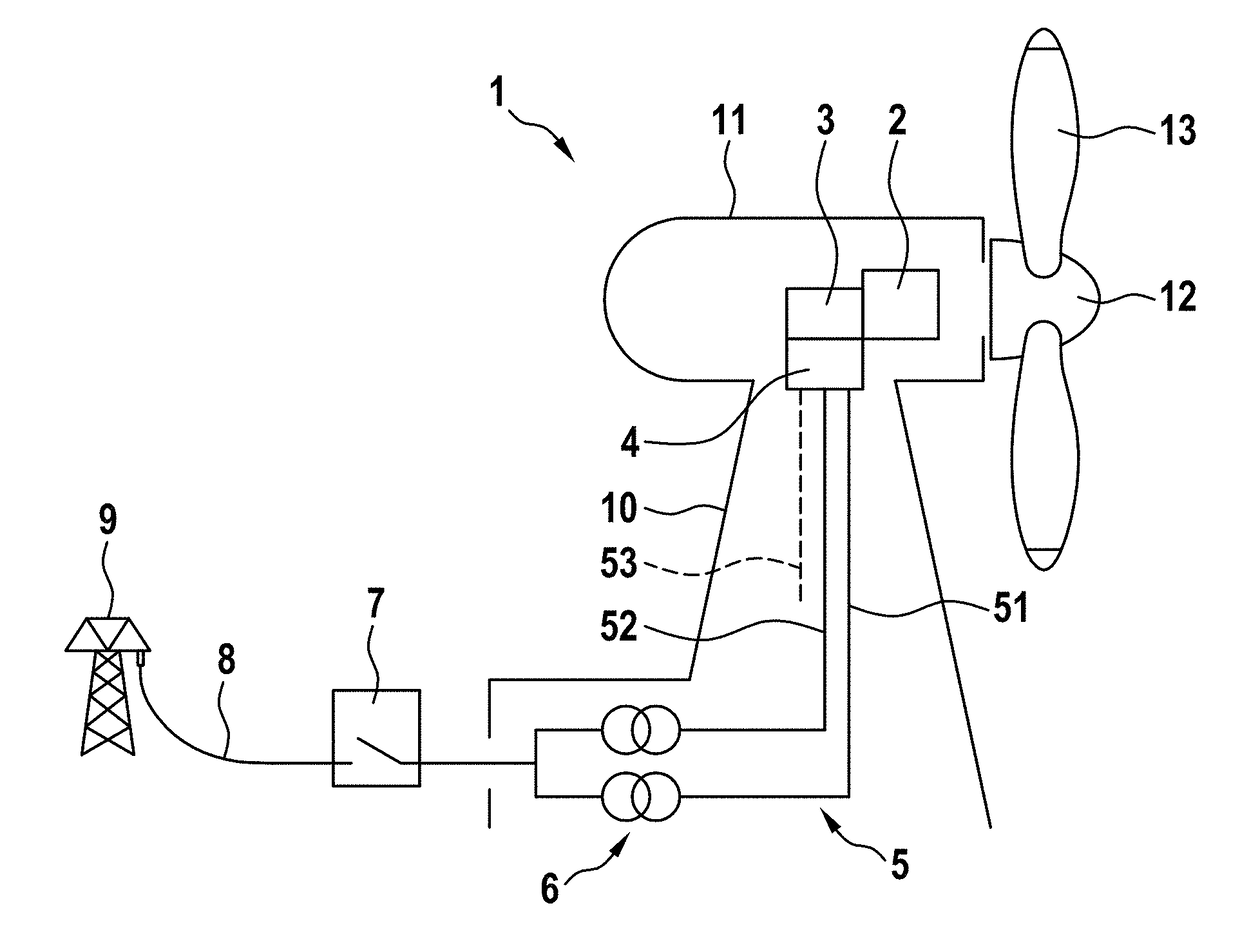

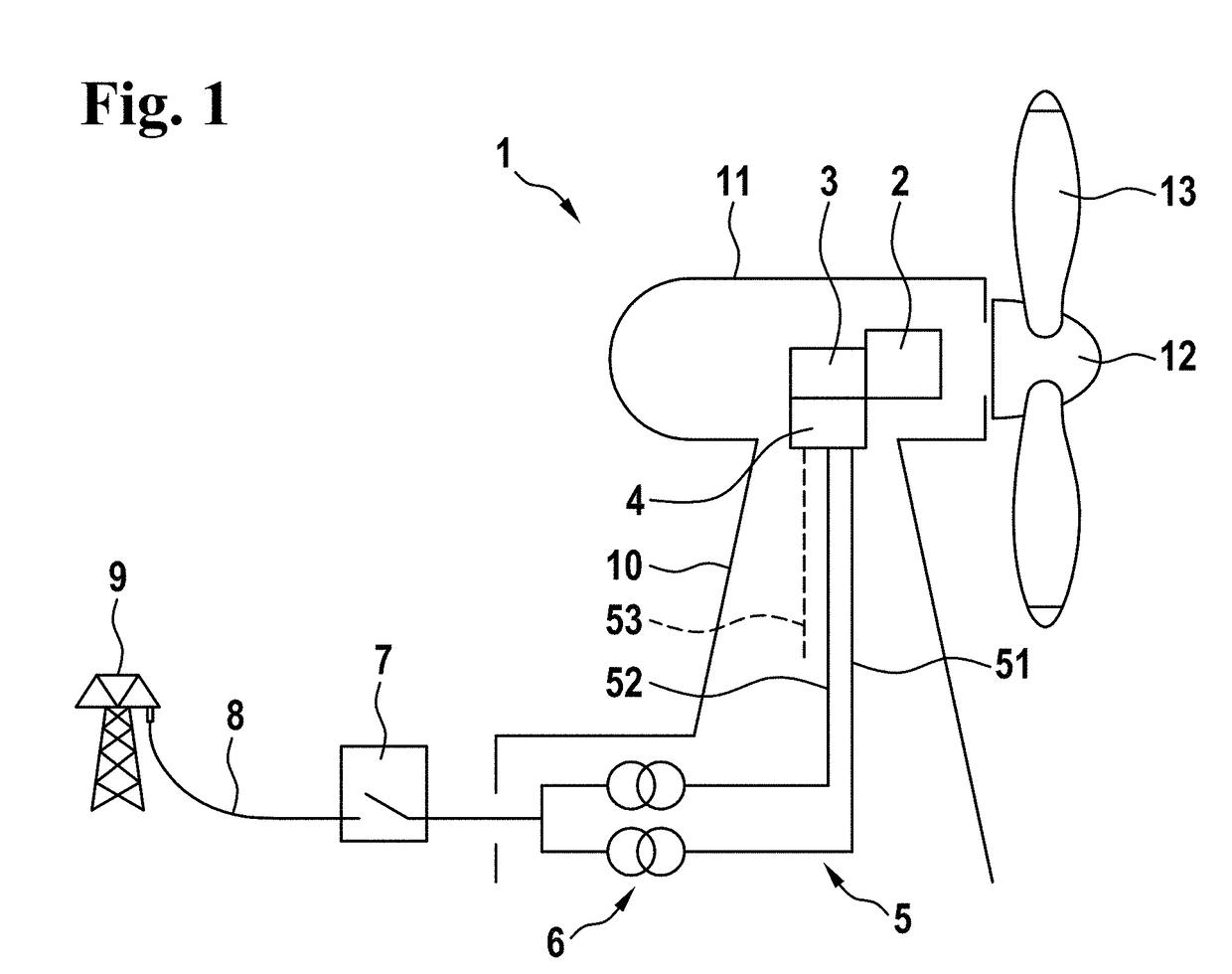

Wind turbine with feed line

ActiveUS20180287369A1Cost-saving configurationIncrease redundancyEmergency protective circuit arrangementsSingle network parallel feeding arrangementsLow voltageElectric power system

A wind turbine includes a wind rotor, a generator, and a converter. The generated electric power is fed from the converter by means of a feed to a turbine transformer for delivery to a grid. The feed is designed as a double branch including a power-branched power circuit breaker unit having a first feed line and a second feed line connected in parallel, wherein a separate low-voltage winding of the turbine transformer and a separate power circuit breaker at the connector of the converter is associated with each feed line.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

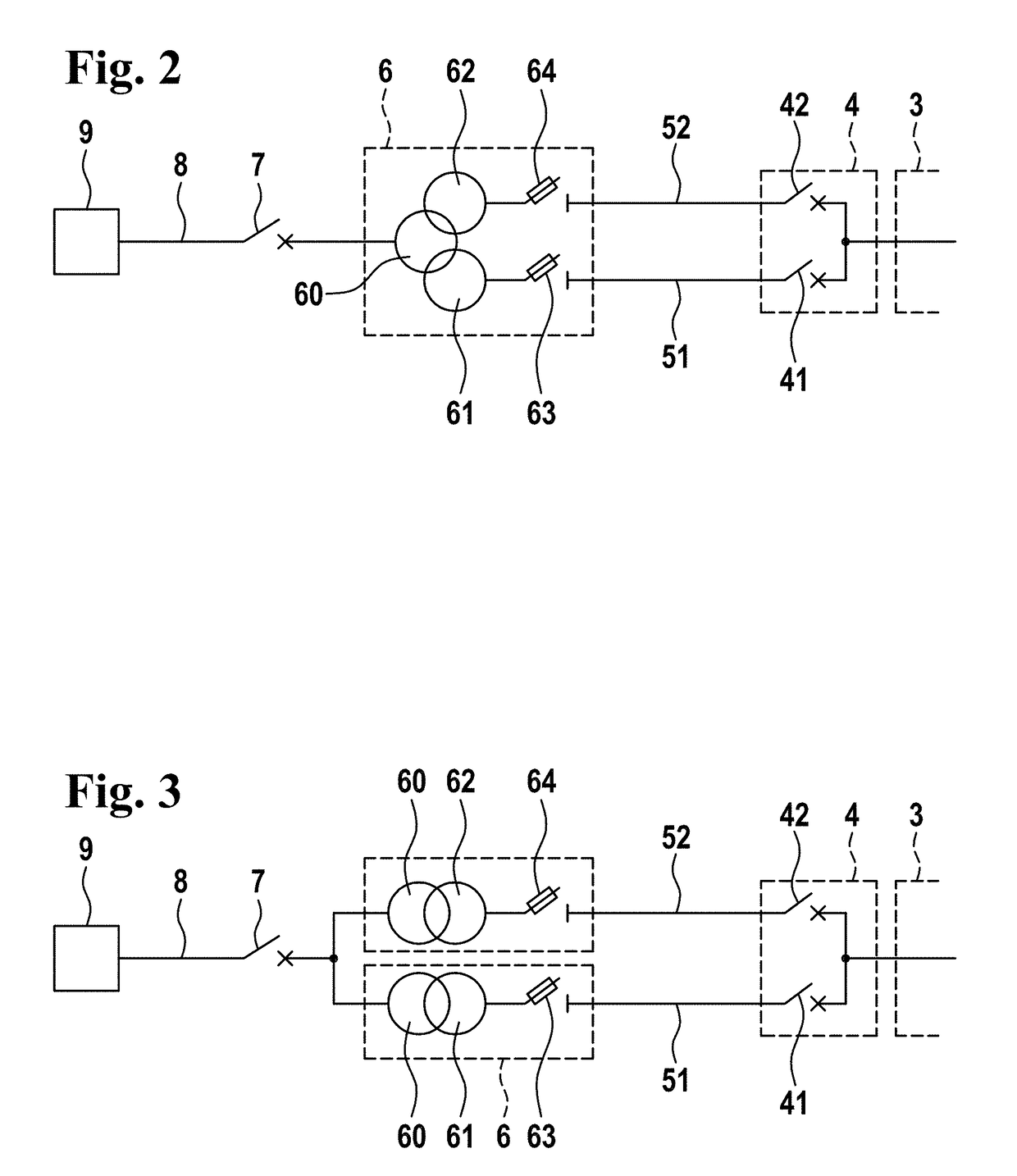

Planar controllable slippage type wood forklift with multi-unit connection rod driving function

InactiveCN106081932AImprove mechanical propertiesImprove rigidityFluid-pressure actuator safetyLoad-engaging elementsHydraulic cylinderMulti unit

A planar controllable slippage type wood forklift with a multi-unit connection rod driving function comprises a multi-unit connection rod driving mechanism, a movable arm lifting mechanism, a fork bucket control mechanism and the like. Under control of a computer, the multi-unit connection rod driving mechanism achieves driving of multiple small-power motors and high-power and high-torque power output, and meets the power requirement of high-load operation of the slippage type wood forklift. A hydraulic cylinder is applied to the configuration design of the wood forklift as a connection rod on the basis of the Pascal principle, the problem that in the prior art, stress on two driving chains for lifting a movable arm is unbalanced is effectively solved, and the bearing stability is improved. The slippage type wood forklift not only has the characteristics of being high in transmission efficiency, high in response speed, high in motion precision, good in controllability, capable of saving energy, environmentally friendly and the like as a controllable mechanism, but also has better bearing performance and shock resistance through introduction of the multi-unit connection rod driving mechanism and a hydraulic element, can achieve the overload protection function easily and has great engineering application prospects and development potential.

Owner:SHANDONG JIAOTONG UNIV

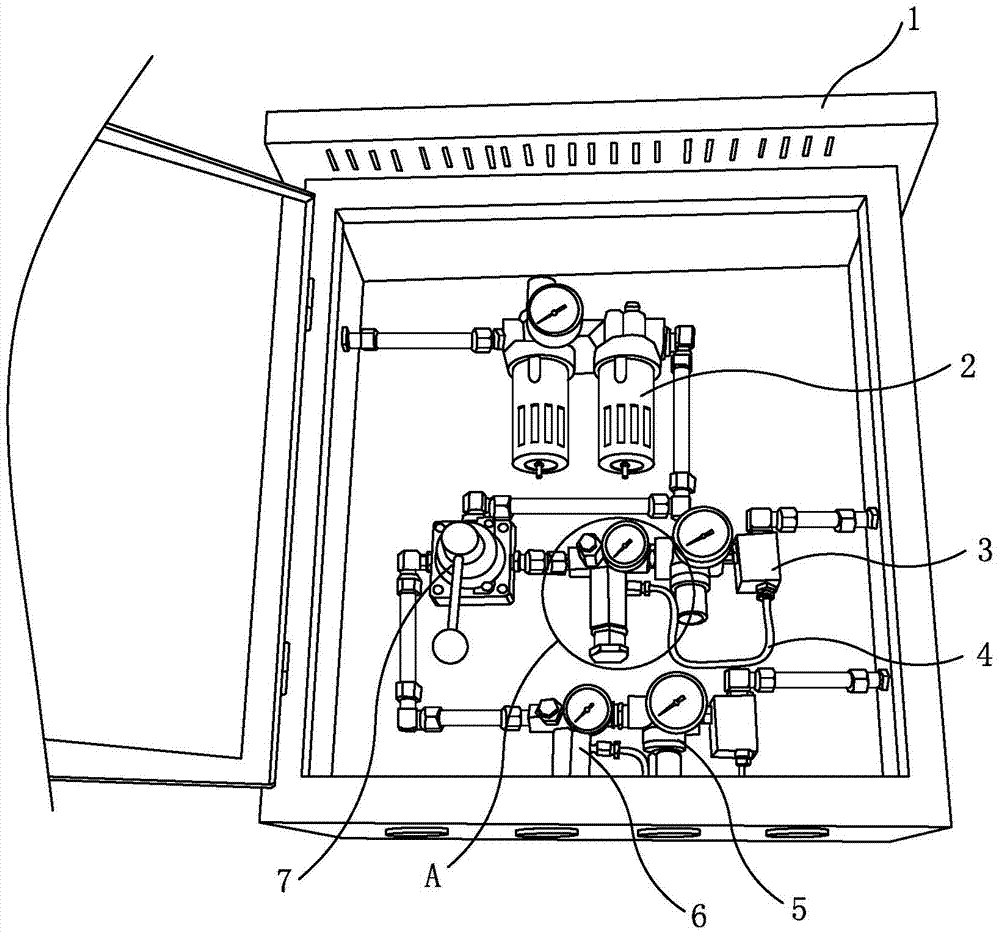

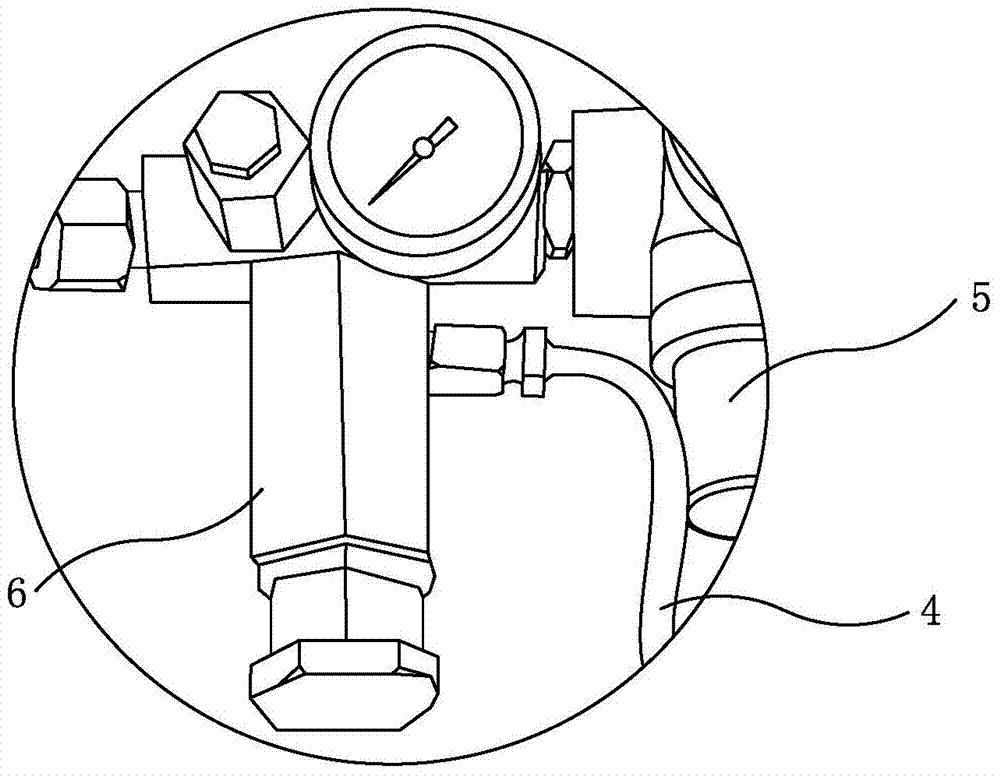

Overload protection device and overload protection method for valve actuator

InactiveCN103697201ASimple structural designEasy to useFluid-pressure actuator safetyOperating means/releasing devices for valvesValve actuatorOil water

The invention relates to an overload protection device and an overload protection method for a valve actuator and aims to solve the problem that a conventional like product is not good enough in structural design. The overload protection device is characterized in that after an oil-water filter and a manual bi-directional valve inside the tank body of the overload protection device are connected in sequence, the manual bi-directional valve is respectively connected with forward and reversal rotating overload protecting components through two pipelines, and a pressure control valve, a flow adjusting valve and a three way switch valve inside the each set of the overload protecting component are connected in sequence, one pipeline of the pressure control valve is connected with one pipeline of the three-way switch valve through an auxiliary gas pipe, and the pressure control valve and the flow adjusting valve are respectively provided with a control pressure gauge and a flow pressure gauge, and the oil-water filter is provided with a filtering pressure gauge and a pressure regulating valve. The two ends of the connecting seat of the pressure control valve are respectively connected with the flow adjusting valve and the manual bi-directional valve through air pipes of the pipelines, three through holes are formed in the seat body of the connecting seat, and are respectively connected with the control pressure gauge, a voltage-stabilizing valve and the flow adjusting valve. The overload protection device provided by the invention is suitable for being used as an overload protecting device for an air actuator in a pneumatic valve.

Owner:宁波市镇海晴鑫石化机械设备有限公司

Micromechanical sensor system, method for using a micromechanical sensor system

ActiveUS20210341510A1Easy overload protectionReduce riskAcceleration measurement using interia forcesFlexible microstructural devicesEngineeringMicromachinery

A micromechanical sensor system, in particular, an acceleration sensor, including a substrate having a main extension plane, the sensor system including a first mass and a second mass. The first and second masses are each designed to be at least partially movable in a vertical direction, perpendicular to the main extension plane of the substrate. The first mass includes a stop structure, wherein the stop structure has an overlap with the second mass in the vertical direction.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com