Multilayer structure bonded seal protective capacity pressure sensor and producing method

A pressure sensor and multi-layer structure technology, which is applied in the direction of fluid pressure measurement using capacitance changes, etc., can solve the problems of poor anti-interference ability of the sensor, large temperature influence, unsatisfactory effect, etc., and achieve stable working characteristics and ideal zero pressure characteristics , good effect of overload protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

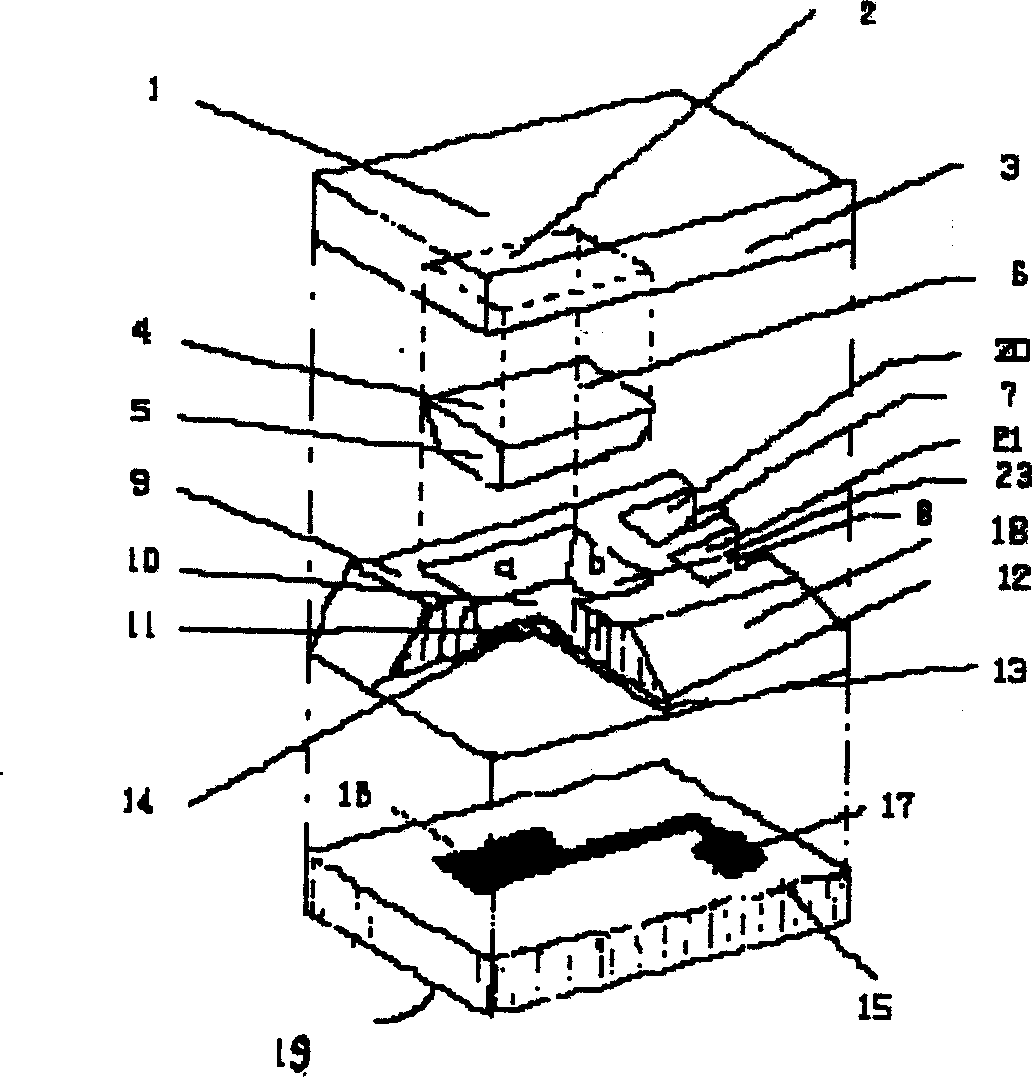

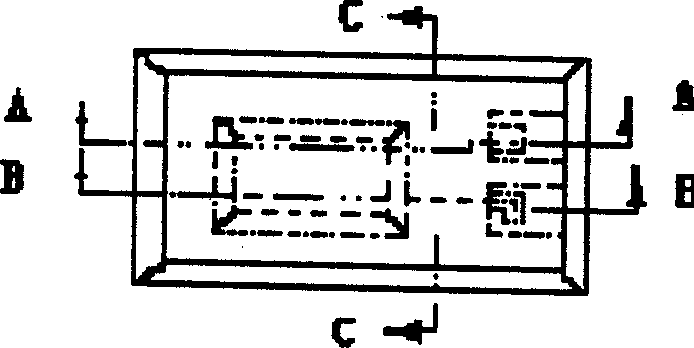

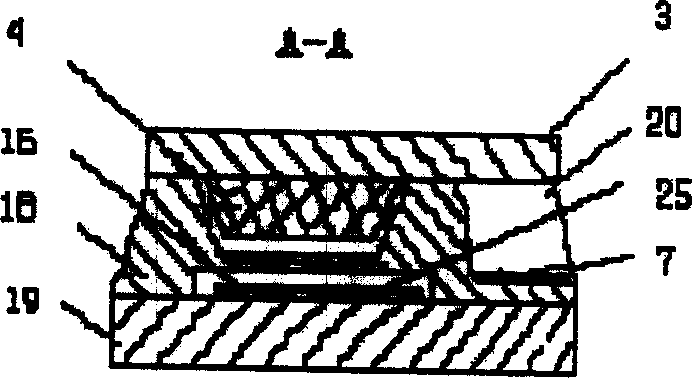

[0042] As shown in Figures 1 to 5, the multi-layer structure bonded and sealed protective capacitive pressure sensor includes a main silicon chip 18 with a pressure-sensitive membrane 10, a glass substrate 19 provided with a capacitor cavity electrode 16, and a capacitive sensor for sealing the capacitor cavity. Seal glass 1 and protect silicon wafer 4. The square silicon diaphragm or the circular silicon diaphragm 11 is made of P-type doped silicon semiconductor material utilizing P + Etching technology or PN junction chemical etching technology to form membrane or SOI (silicon on insulator) silicon wafer production. Specifically, it can be described as follows, there is a layer of P on the lower surface of the main silicon chip 18. +The diaphragm 11 is formed by etching technology or PN junction chemical etching technology or SOI (silicon on insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com