Multi-ring micronizer grinding cavity, multi-ring micronizer and intelligent multi-ring micronizer system

A technology of micro-powder milling and grinding chamber, which is applied in grain processing and other directions, and can solve problems such as inability to apply, waste of stone resources, failure to meet fineness requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

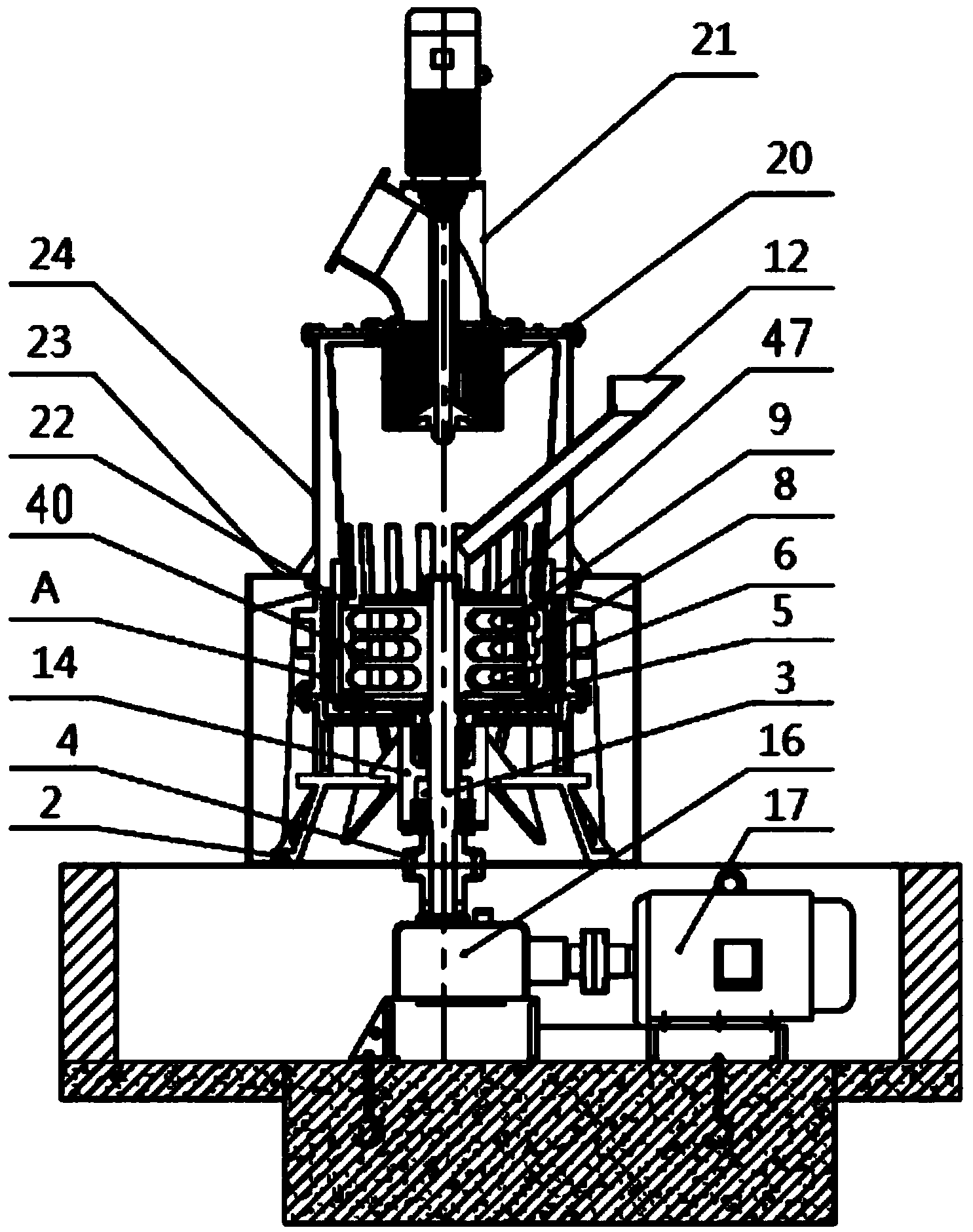

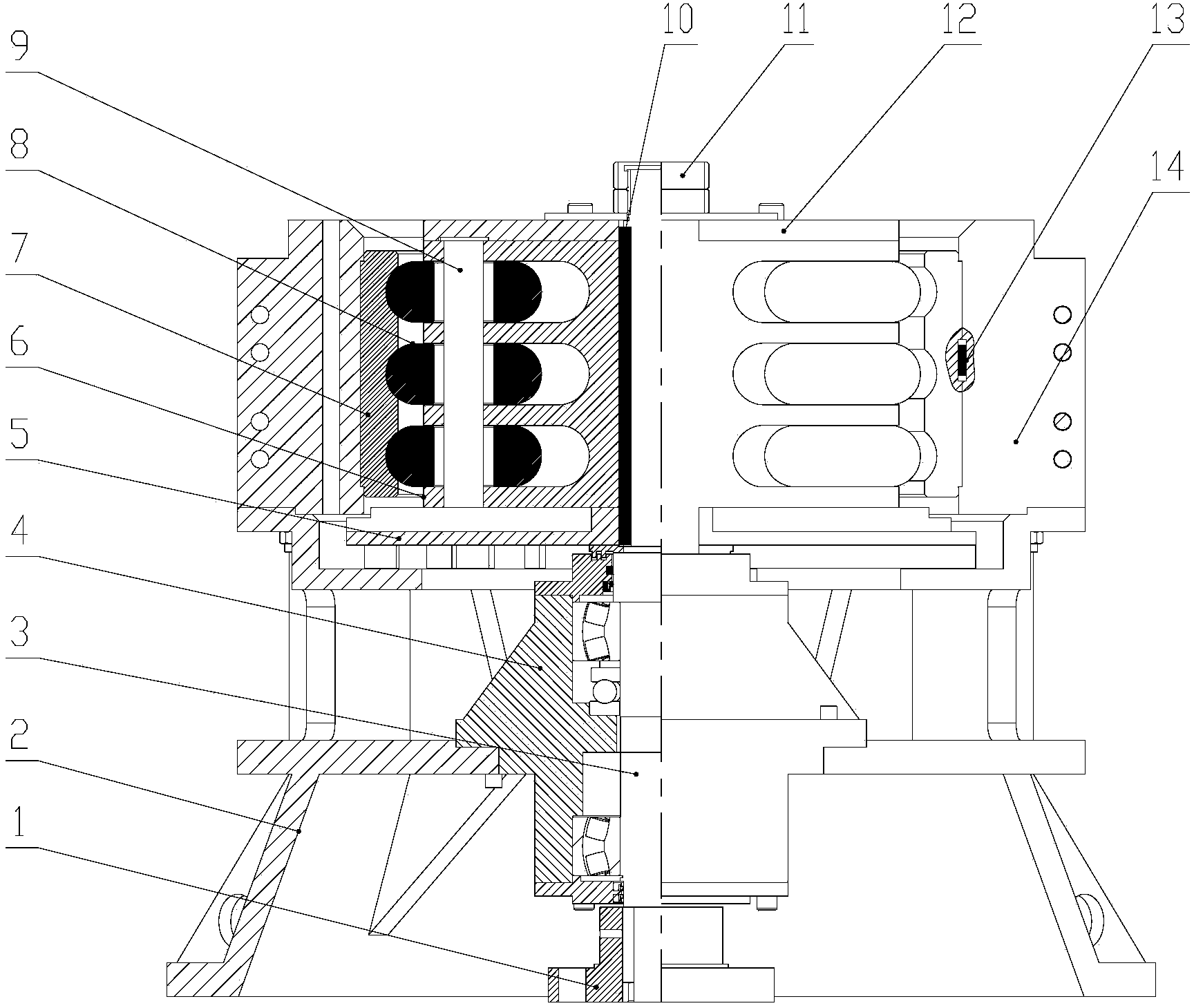

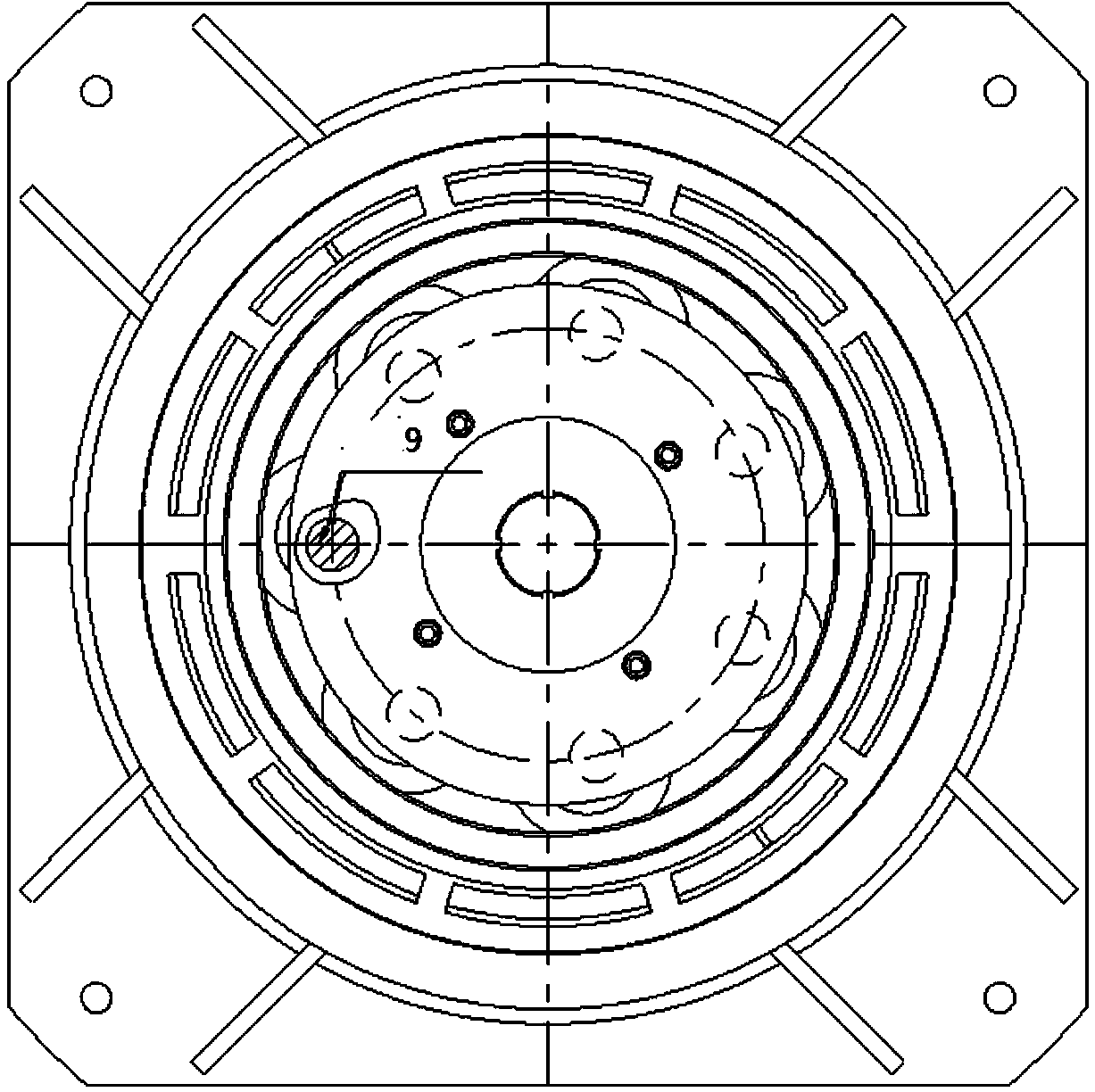

[0021] see figure 2 , 3 , which is the structural schematic diagram of the grinding chamber of the multi-ring micropowder mill of the present invention. figure 2 It includes machine base 2, coupling 1, transmission bearing cylinder 4, transmission main shaft 3, lower bulk material disc 5, multi-layer grinding disc 6, roller pin 9, combined drum-shaped grinding roller 8, inner wall with multi-layer semicircle The grinding ring 7, the grinding ring limit key 13, the upper bulk plate 12, the combined locking nut 11, the long limit key 10, the split middle casing 14, etc. Wherein: the outer shape of the drum-shaped grinding roller 8 is matched with the semicircular slideway of the grinding ring 7 with the multi-layer semicircular slideway on the inner wall.

[0022] The specific structure of the multi-ring micro-powder grinding chamber is as follows: the transmission bearing cylinder 4 is fixed in the machine base 2 by locking bolts, the coupling 1 is installed on the lower sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com