Preheating control method, device and system of compressor

A preheating control and compressor technology, applied in the field of compressor control, can solve the problems of waste of preheating energy and long preheating time, and achieve the effect of reducing the preheating time and saving the preheating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] According to an embodiment of the present invention, an embodiment of a preheating control method for a compressor is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, Also, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

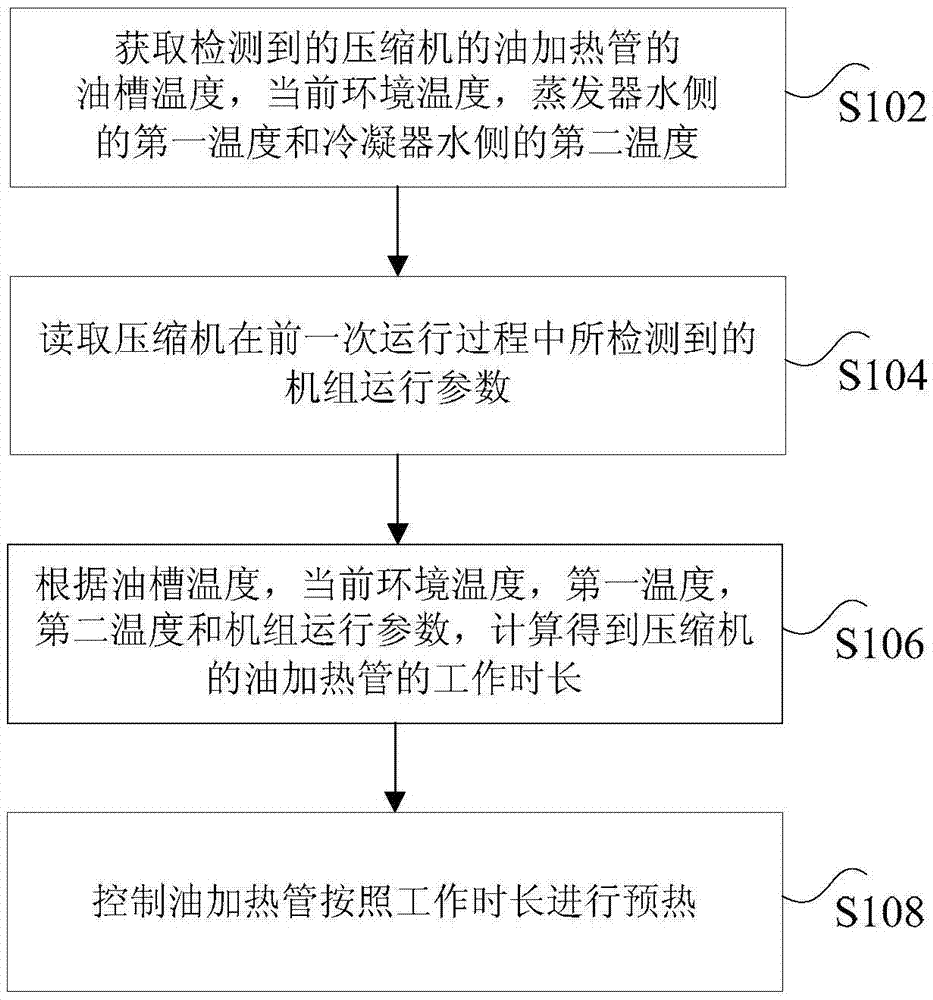

[0019] figure 1 is a flow chart of a compressor preheating control method according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0020] Step S102, acquiring the detected temperature of the oil sump of the oil heating pipe of the compressor, the current ambient temperature, the first temperature of the water side of the evaporator, and the second temperature of the water side of the condenser.

[0021] Step S104, reading the ope...

Embodiment 2

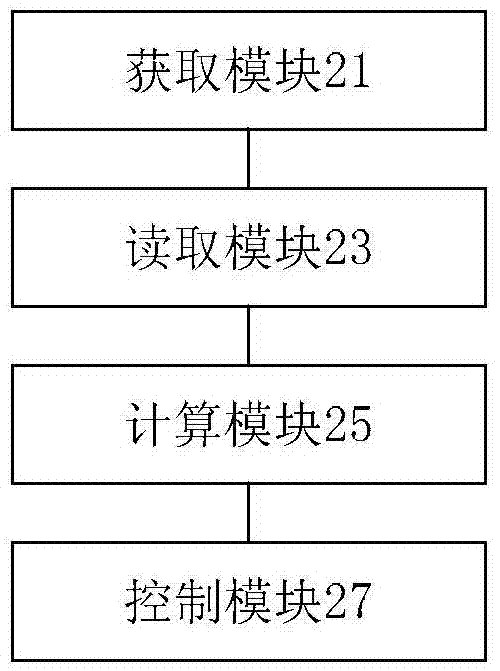

[0052] According to an embodiment of the present invention, an embodiment of a compressor preheating control device is provided, such as figure 2 As shown, the device includes: an acquisition module 21 , a reading module 23 , a calculation module 25 and a control module 27 .

[0053] Wherein, the acquiring module 21 is used to acquire the detected temperature of the oil tank of the oil heating pipe of the compressor, the current ambient temperature, the first temperature of the water side of the evaporator and the second temperature of the water side of the condenser.

[0054] The reading module 23 is used to read the operating parameters of the unit detected during the previous operation of the compressor.

[0055] Specifically, the above-mentioned unit operating parameters may be operating data of the unit itself.

[0056] The calculation module 25 is used to calculate the working time of the oil heating pipe of the compressor according to the temperature of the oil tank, ...

Embodiment 3

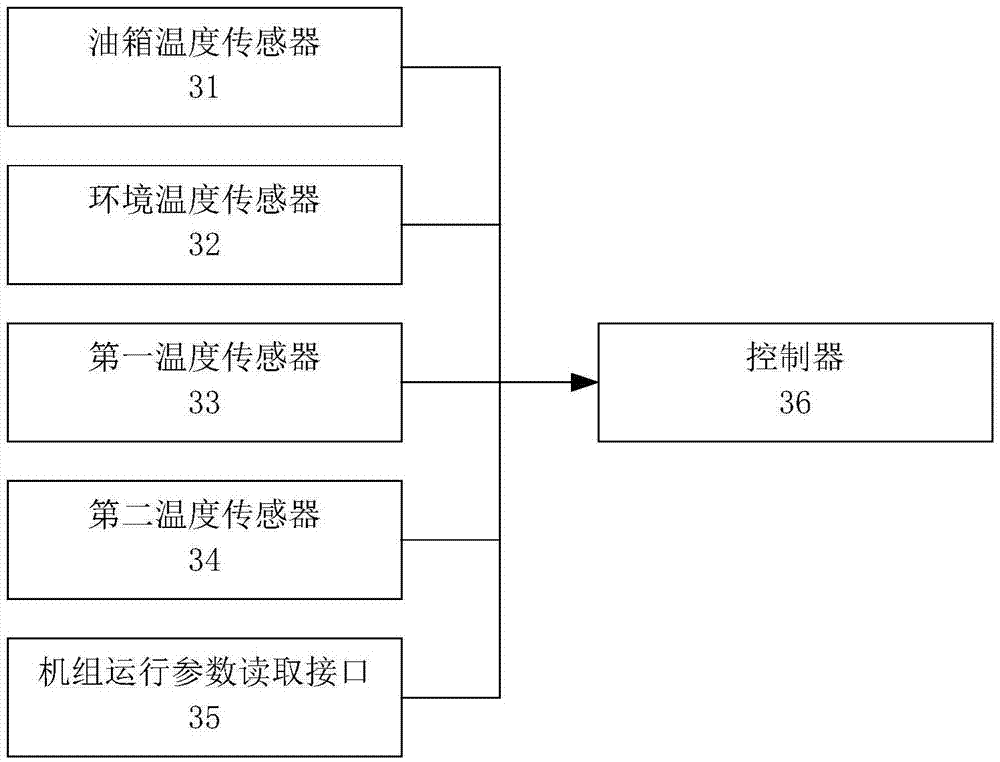

[0085] According to an embodiment of the present invention, an embodiment of a compressor preheating control system is provided, such as image 3 As shown, the system includes: a fuel tank temperature sensor 31 , an ambient temperature sensor 32 , a first temperature sensor 33 , a second temperature sensor 34 , a unit operating parameter reading interface 35 and a controller 36 .

[0086] Wherein, the oil tank temperature sensor 31 is used to detect the oil tank temperature of the oil heating pipe of the compressor.

[0087] The ambient temperature sensor 32 is used to detect the current ambient temperature.

[0088] The first temperature sensor 33 is used to detect the first temperature of the water side of the evaporator.

[0089] The second temperature sensor 34 is used to detect the second temperature of the water side of the condenser.

[0090] The unit operating parameter reading interface 35 is used to detect and obtain the unit operating parameters of the compressor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com