Intelligent robot capable of high-speed feeding and discharging

An intelligent robot, high-speed technology, applied in manipulators, program-controlled manipulators, chucks, etc., can solve the problems of low manual handling efficiency, easy safety accidents, easy workpiece slippage, etc. Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

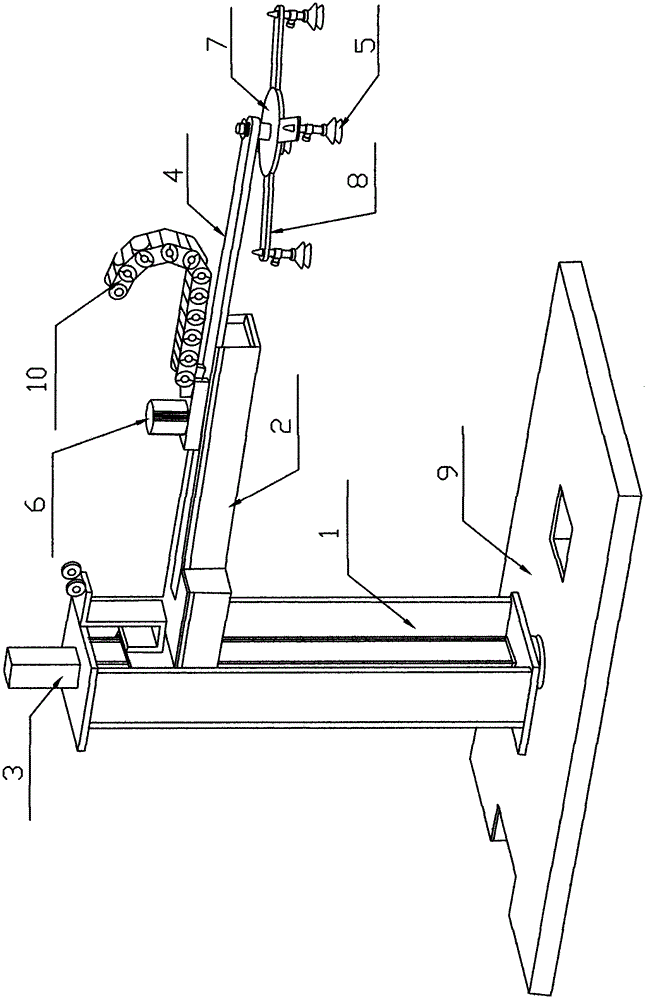

[0024] Implementation mode one: if figure 1 As shown, this high-speed loading and unloading intelligent robot includes a column 1 and a cross arm 2, wherein the column 1 is provided with a vertical linear guide rail, and the vertical linear guide rail is provided with a lifting block, and the cross arm is fixed on the lifting block. The lifting block is driven by a ball screw pair, and its lead screw is driven by a lifting servo motor 3. The screw nut is set on the lead screw and fixed together with the lifting block; There is a slider on the guide rail, and the slider is fixed with a telescopic arm 4, and the front end of the telescopic arm 4 is fixed with a suction cup frame (of course, the manipulator grabbing device can also be replaced according to the needs, the figure is omitted), and the suction cup frame is provided with a vacuum suction cup 5. The slider is driven by a ball screw pair, and its screw is driven by a telescopic servo motor 6, and its nut is set on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com