Electromechanical device for continuously, rapidly and pneumatically labelling

An electromechanical equipment, labeling technology, applied in labeling, labeling machines, labels, etc., can solve the problems of low speed of manual labeling, low English level of operators, difficult and accurate alignment, etc., to achieve easy overload protection, no pollution Environment, the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

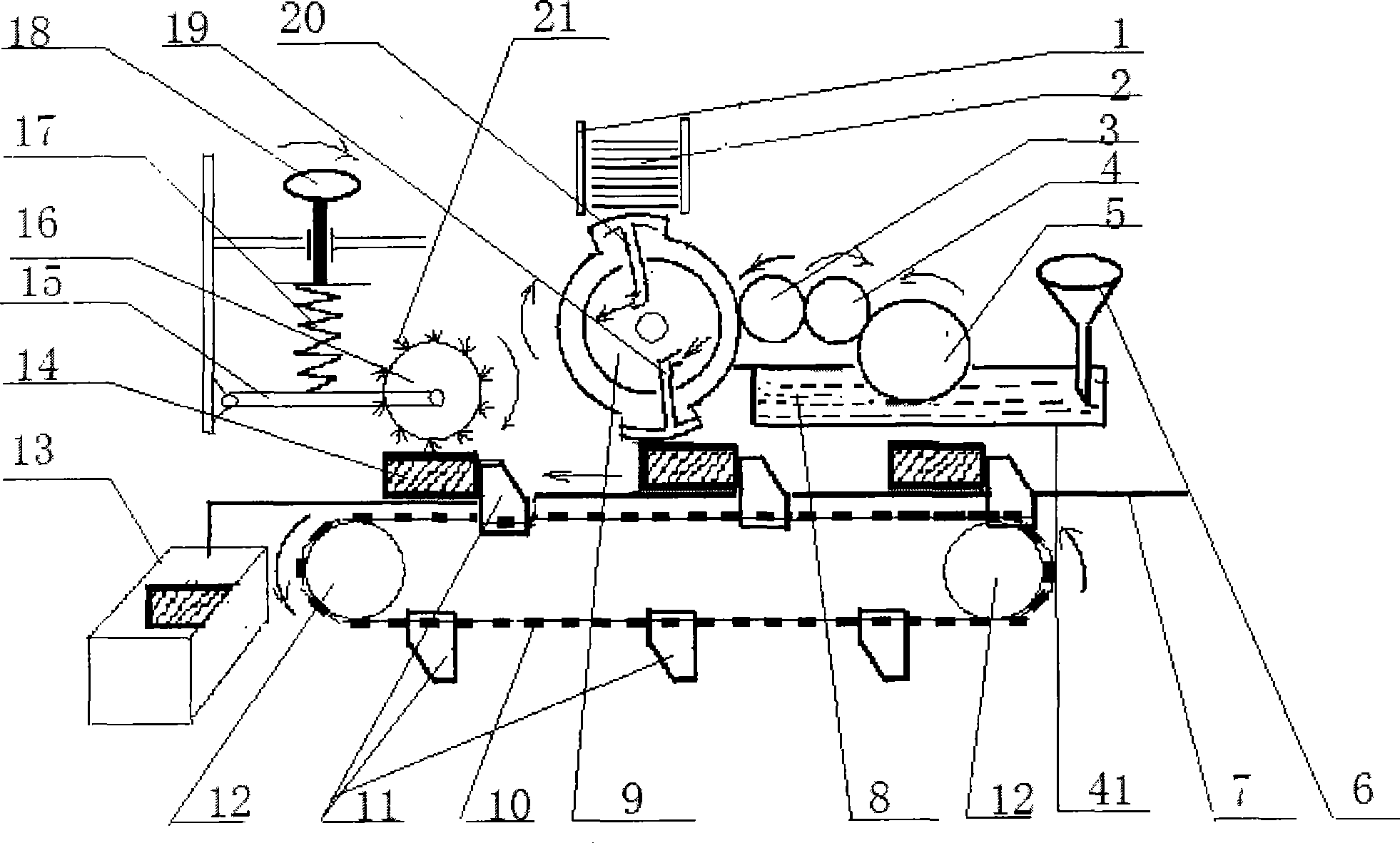

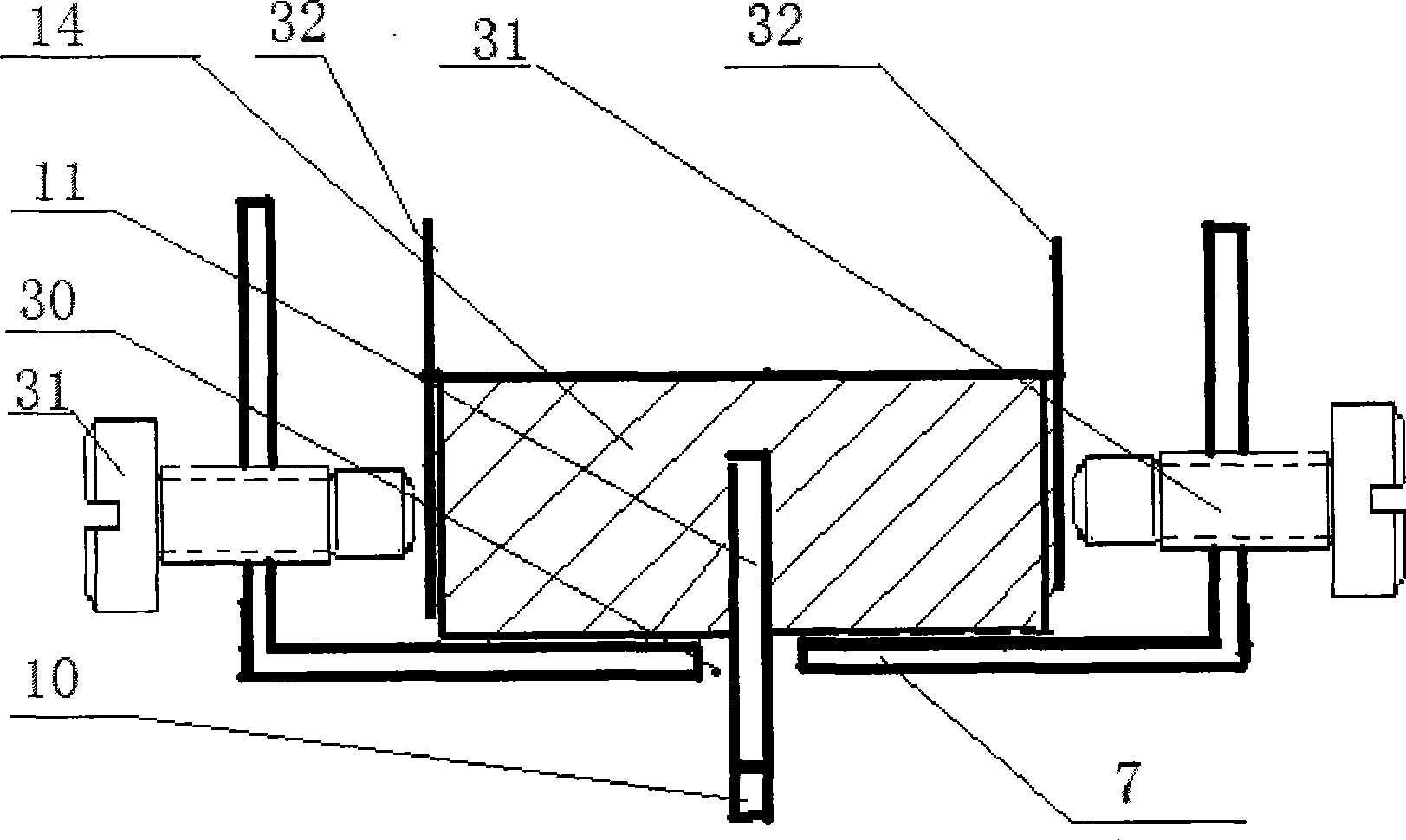

[0016] Such as figure 1 As shown, the main components of the present invention are arranged on the frame, which is mainly composed of a pneumatic suction mechanism, a pneumatic sticker mechanism, a glue application mechanism and a brush pressing and flattening mechanism. The rotating main disk (9) of the pneumatic suction mechanism There is an air suction port (20) on it, which is convenient to attract the label (2) in the box (1) where the label is stored, and the air suction port (20) is connected with the air compressor, so that the air compressor can suck air therefrom. The sticker mechanism is connected with the air compressor by the air jet port (19), so that the paper is evenly pasted on the carton surface; the glue-on mechanism has a soft rubber roller (3), a middle soft rubber roller (4), The soft rubber roller (5) of viscose glue water, funnel (6) constitute, middle soft rubber roller (4) is placed in the middle of the soft rubber roller (3) of glue glue water and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com