Mine water pump pressure relief device

A technology of pressure relief device and water pump, which is applied in the direction of valve device, parts of pumping device for elastic fluid, pump components, etc. It can solve the problems of damage to water supply equipment, motor burnout, motor heating, etc., and prevent overload operation , Reduce maintenance costs, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

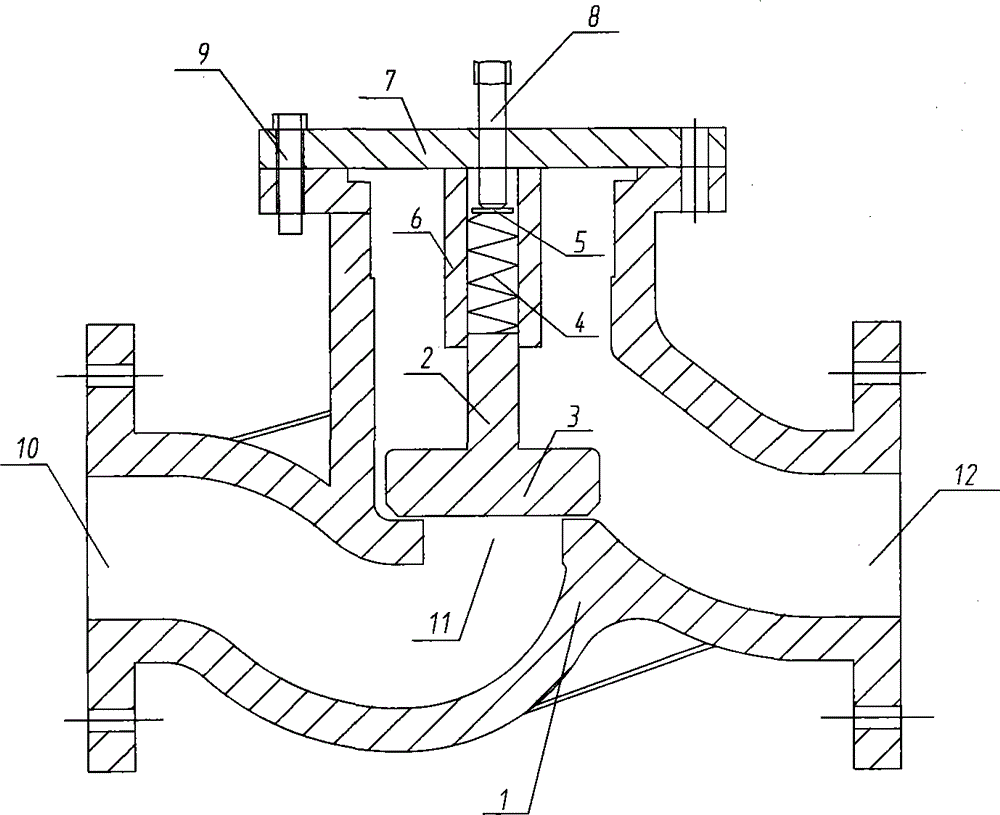

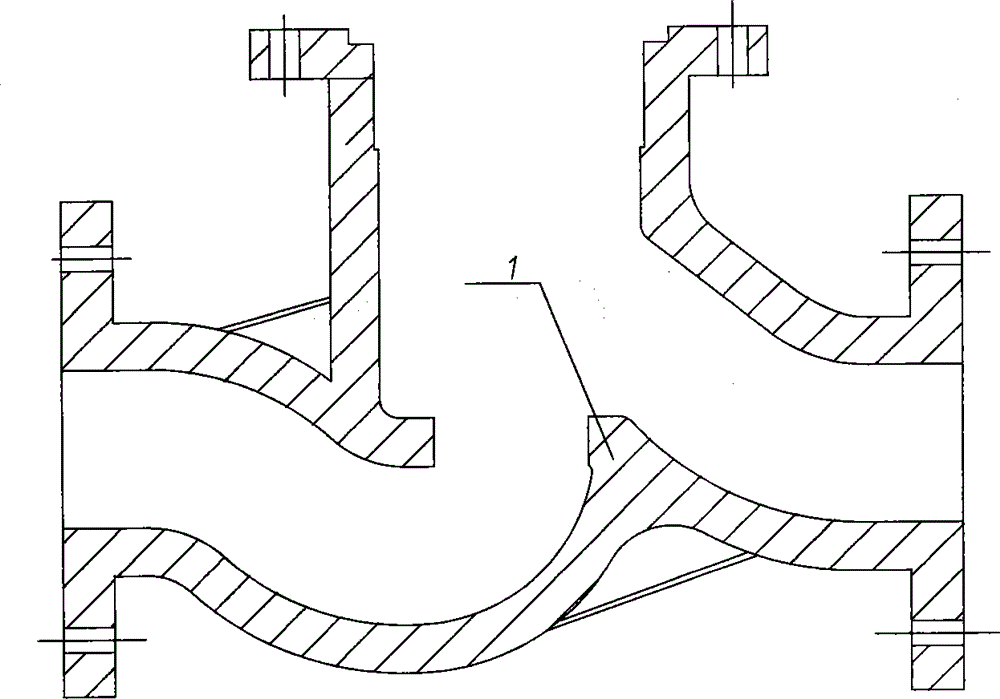

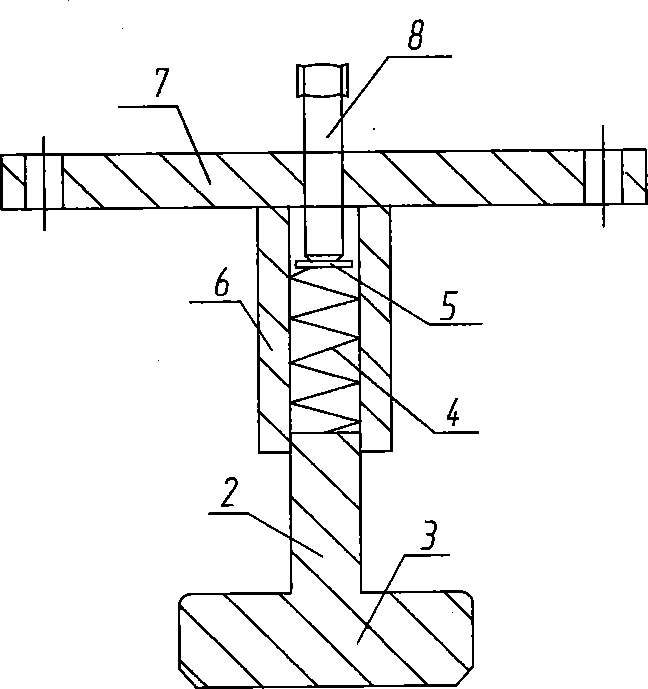

[0010] Below in conjunction with accompanying drawing, the present invention will be further described, as figure 1 , figure 2 , image 3 Shown: The mine water pump pressure relief device includes valve body 1, valve disc 2, valve disc head 3, spring 4, baffle plate 5, cylinder 6, valve cover 7, screw rod 8, bolt 9, water inlet 10, center Hole 11, water outlet 12.

[0011] Such as figure 1 , figure 2 , image 3 As shown, the valve body 1 is cast, the diameter of the water inlet 10 and the water outlet 12 is 50mm, the diameter of the middle hole 11 is 30mm, the valve disc 2 is processed into a convex shape with a length of 30mm, and the valve disc head 3 The diameter is 60mm and the height is 10mm. The diameter of the bonnet 7 is 123mm and the height is 10mm. Four M14 threaded holes are evenly processed on its circumference, and one M12 threaded hole is processed in the middle. The cylinder 6 is welded on the center of the bonnet 7 , the inner diameter of the cylinder 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com