Flexible clamping device

A flexible clamping and clamping rod technology, applied in the field of manipulators, can solve the problems of complexity, high requirements for workers to operate, and a large fixture positioning mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

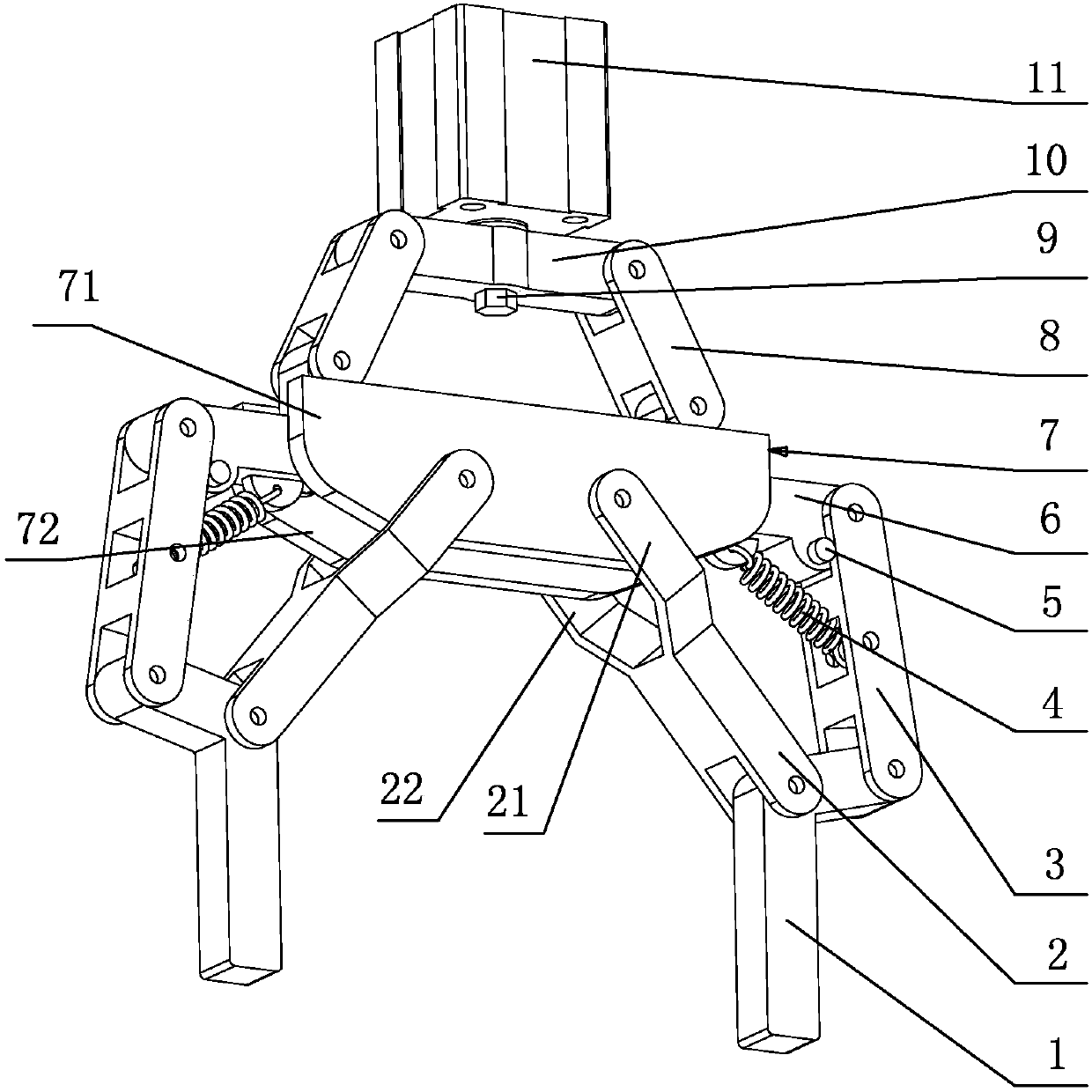

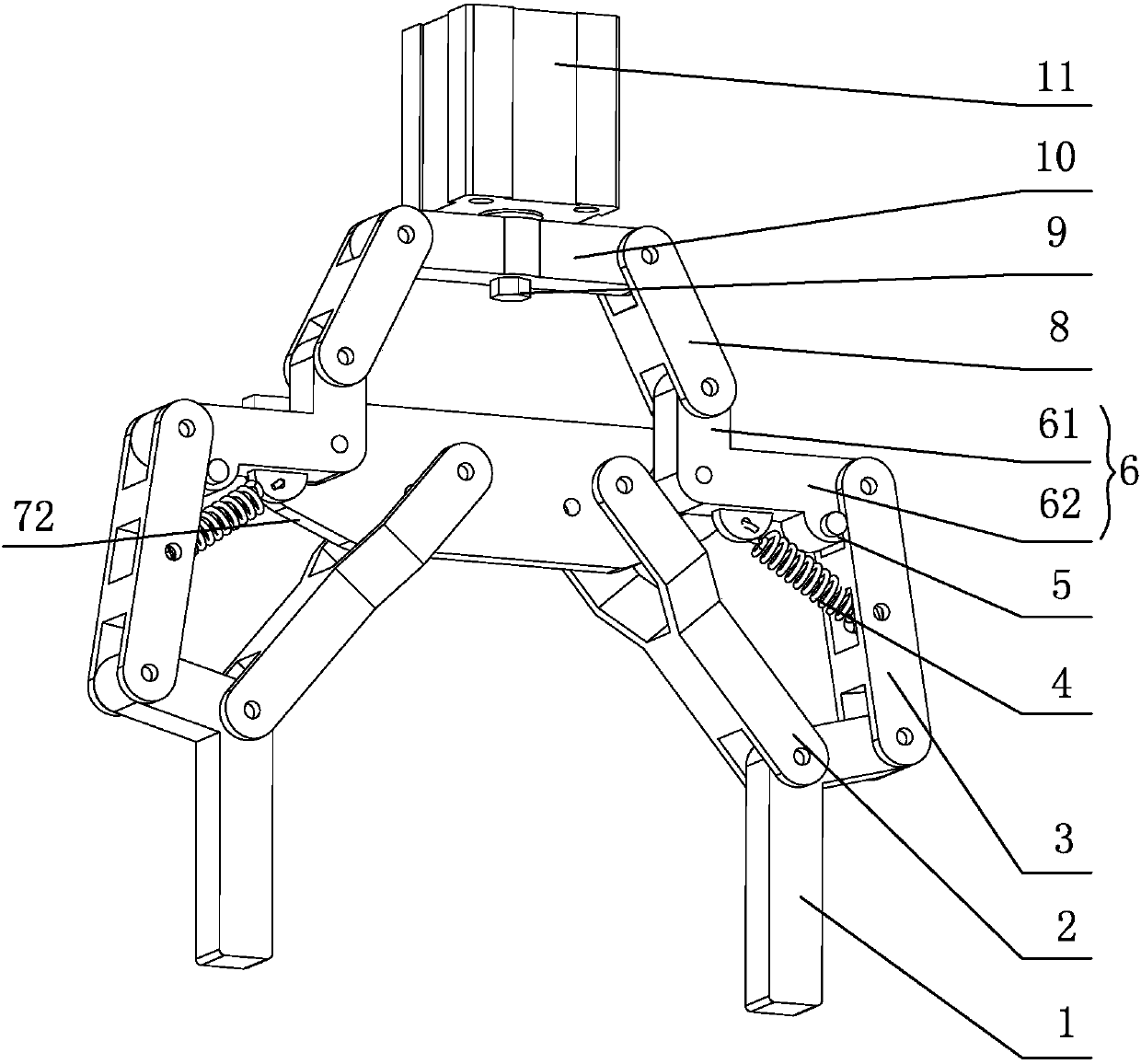

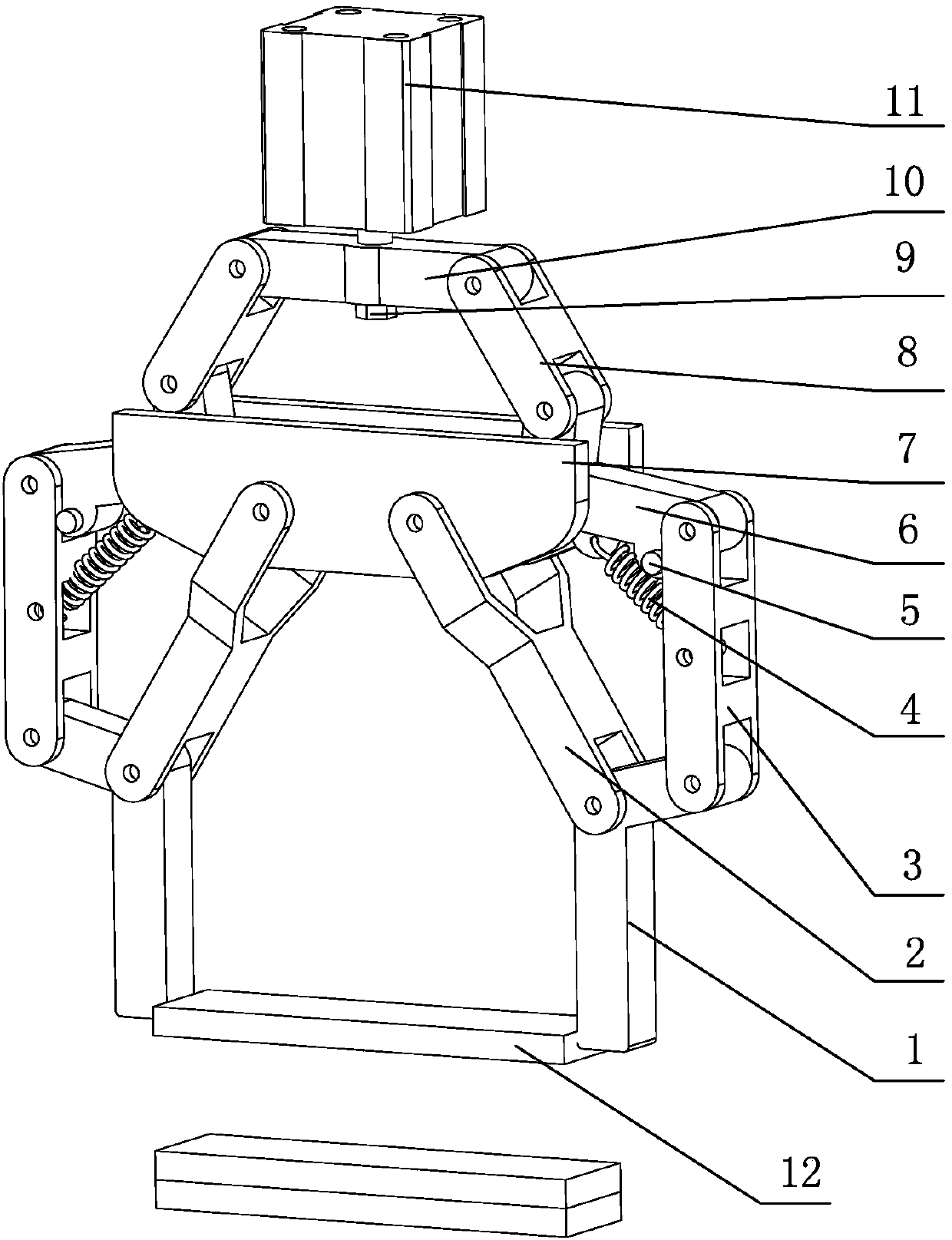

[0048] Such as figure 1 , figure 2 , Figure 9 As shown, a flexible clamping device includes a bracket 7, a driving component and a clamping component, and the driving component drives the clamping component to move;

[0049] The clamping assembly includes two drive links 6 respectively hinged to the bracket 7, two inner links 2 respectively hinged to the bracket 7, and an outer link 3 hinged to the drive link 6, and the outer link 3 is set to two , the two outer connecting rods 3 are respectively hinged to the corresponding drive connecting rod 6, and at the same time are hinged to the clamping rod 1 of the inner connecting rod 2 and the outer connecting rod 3, the clamping rod 1 is set to two, and the two clamping rods 1 are respectively hinged to the corresponding inner connecting rod 2 and outer connecting rod 3;

[0050] Drive assembly comprises cylinder 11, and the cylinder body of cylinder 11 and support 7 positions are relatively fixed, and the cylinder connecting ...

Embodiment 2

[0082] The main structure of this embodiment is the same as that of Embodiment 1, and the similarities will not be repeated here. The difference is that: Image 6 As shown, in order to expand and grab the inner hole object 15, the necessary condition to realize the expansion and grab is: ensure that the clamping rod 1 is vertical in any state. That is, the initial state AECD is a parallelogram. Ensure that DC does not rotate on the plane, that is, the DF rod remains vertical.

[0083] In order to achieve the optimal stable state, the following requirements are put forward for the clamping device:

[0084] Such as Figure 12 As shown, if the model in the state of pinching and grasping at the top is used for expanding grasping, F2c provides a rightward force component to the rod II, and the rod II has a clockwise rotation tendency relative to point B. At this time, the angle θ1 tends to increase, and the limiting element that limits the hinge B is the tension spring 4 .

[0...

Embodiment 3

[0088] The main structure of this embodiment is the same as that of Embodiment 1 or 2, and the similarities will not be repeated here. The difference is that: Figure 7 , Figure 8 As shown, the envelope clamps the large ball 16 and the irregular block 17. To achieve envelope clamping, the movement trend of the clamping rod 1Ⅲ is to move counterclockwise around point D. The movement trend of rod III is shown in Figure 13: when the envelope clamps the object, rod IV is held up by the object, which can be regarded as rod IV has no relative motion to the frame, which can be simplified from Figure 13(a) to Figure 13(b) is a schematic diagram of the mechanism. The mechanism has four components in total, and the corresponding instant center polygon is shown in Figure 13(c).

[0089] It can be known from the instant center polygon that P13 is represented by the common side of △123 and △153, that is, P13 should not only be on the connection line between P12 and P23, but also on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com