Patents

Literature

88results about How to "Reduce the gap width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

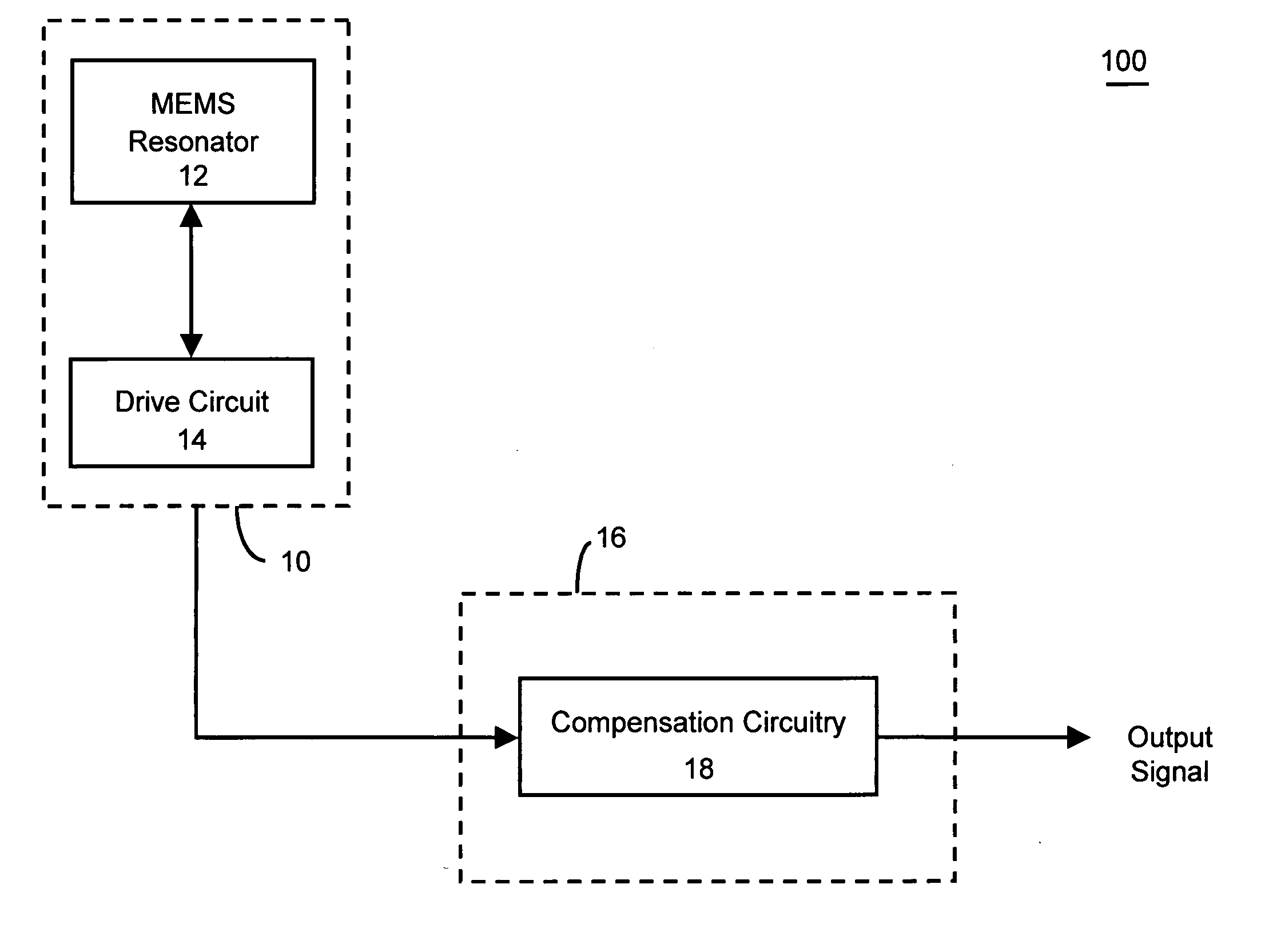

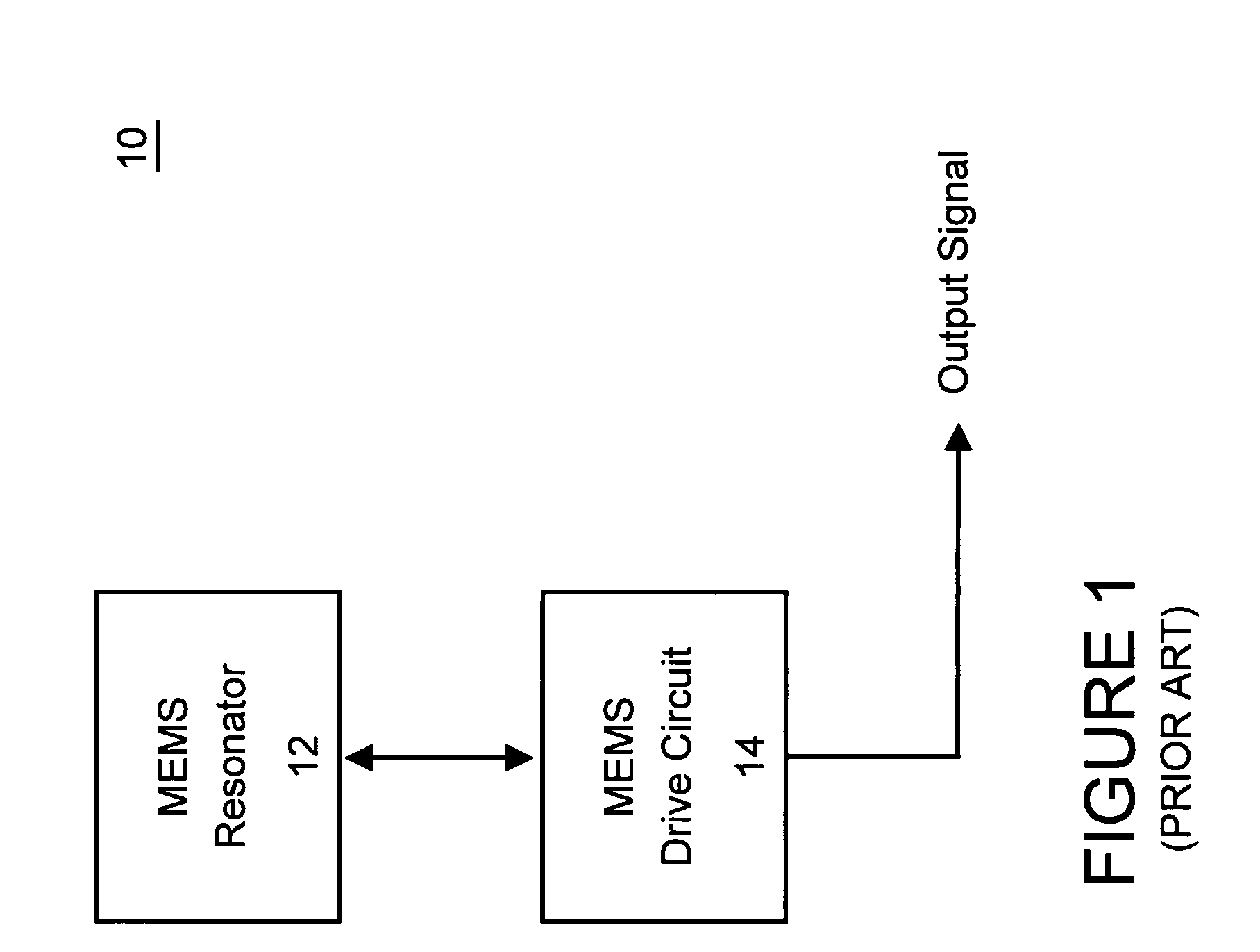

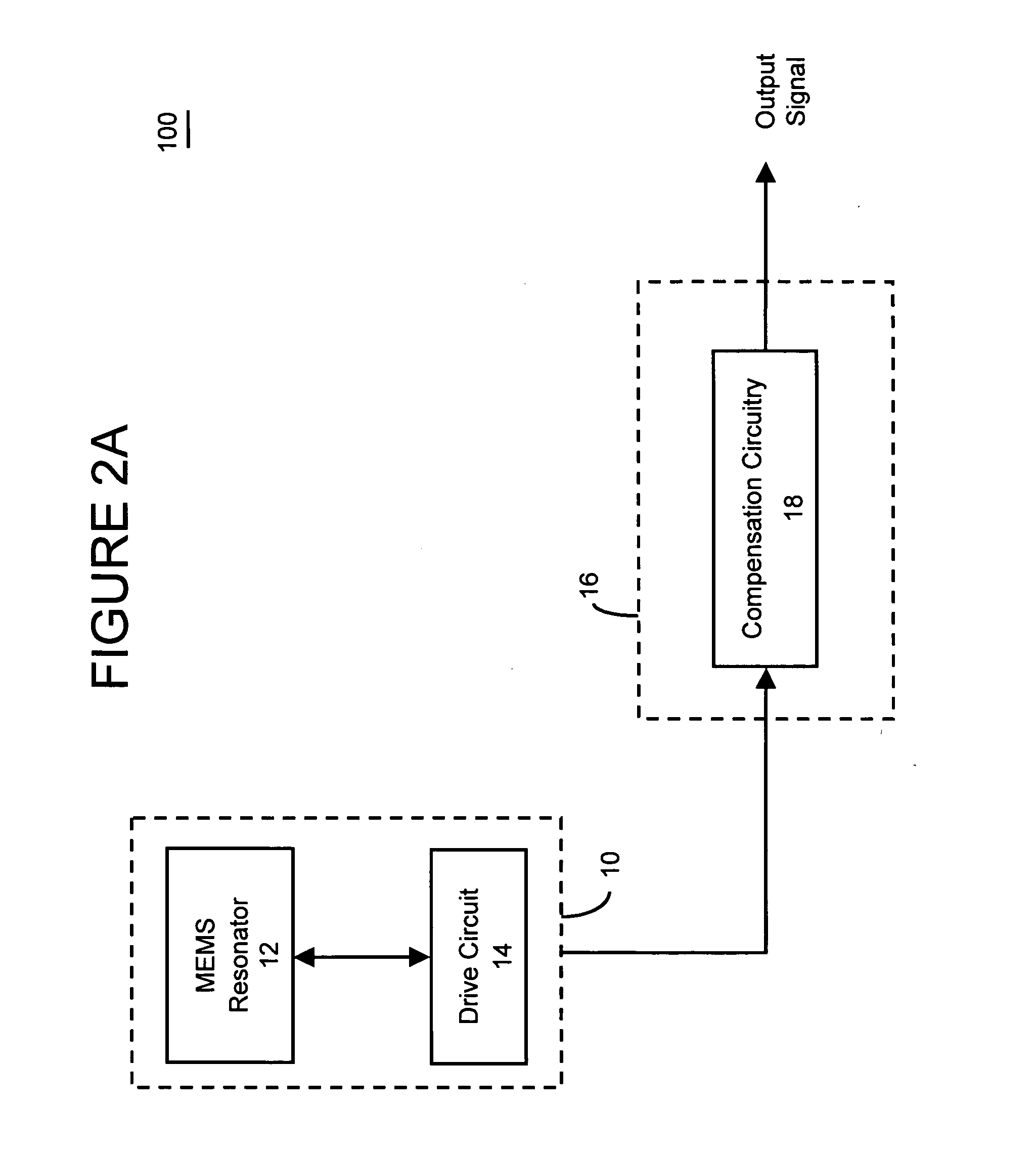

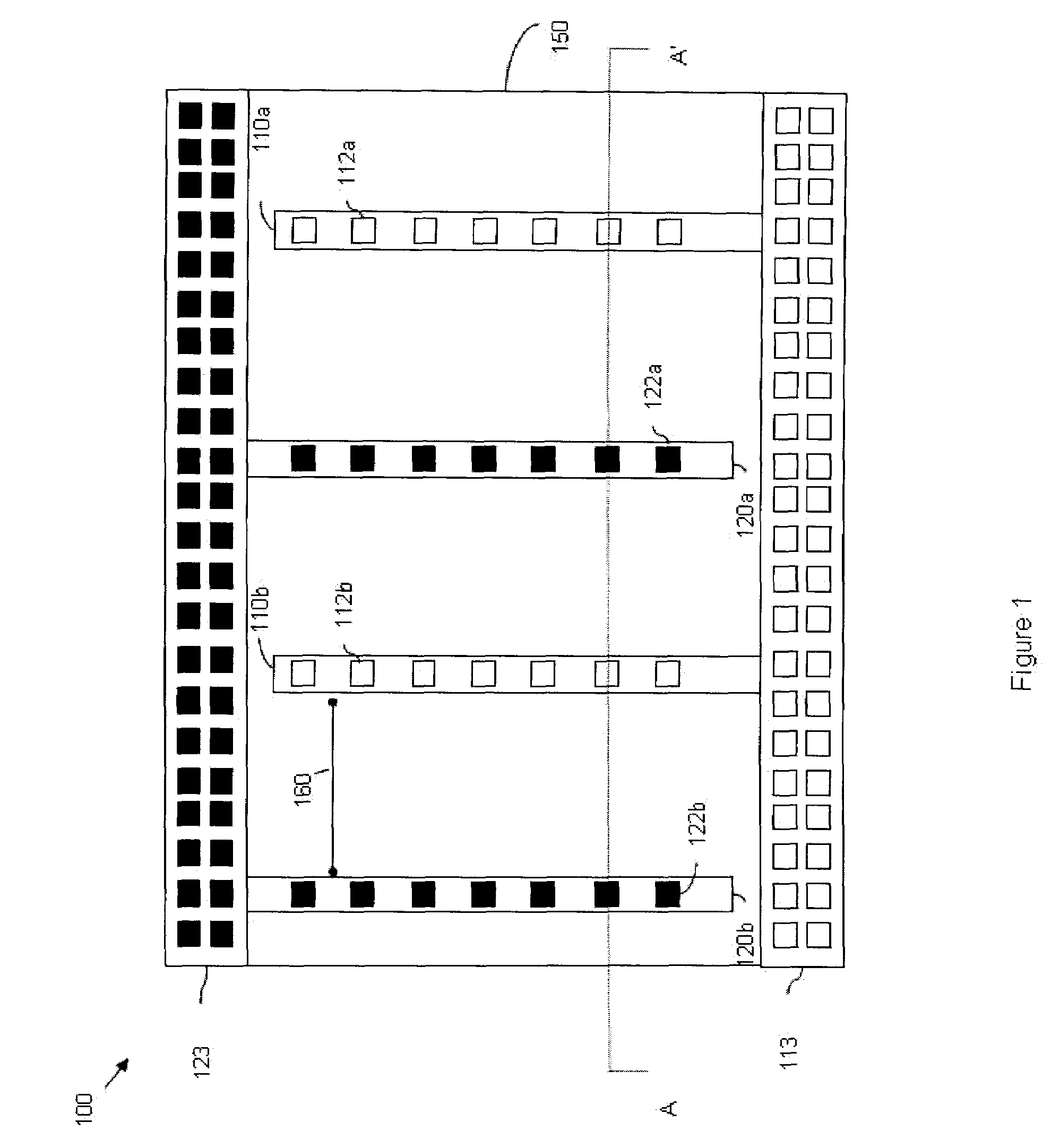

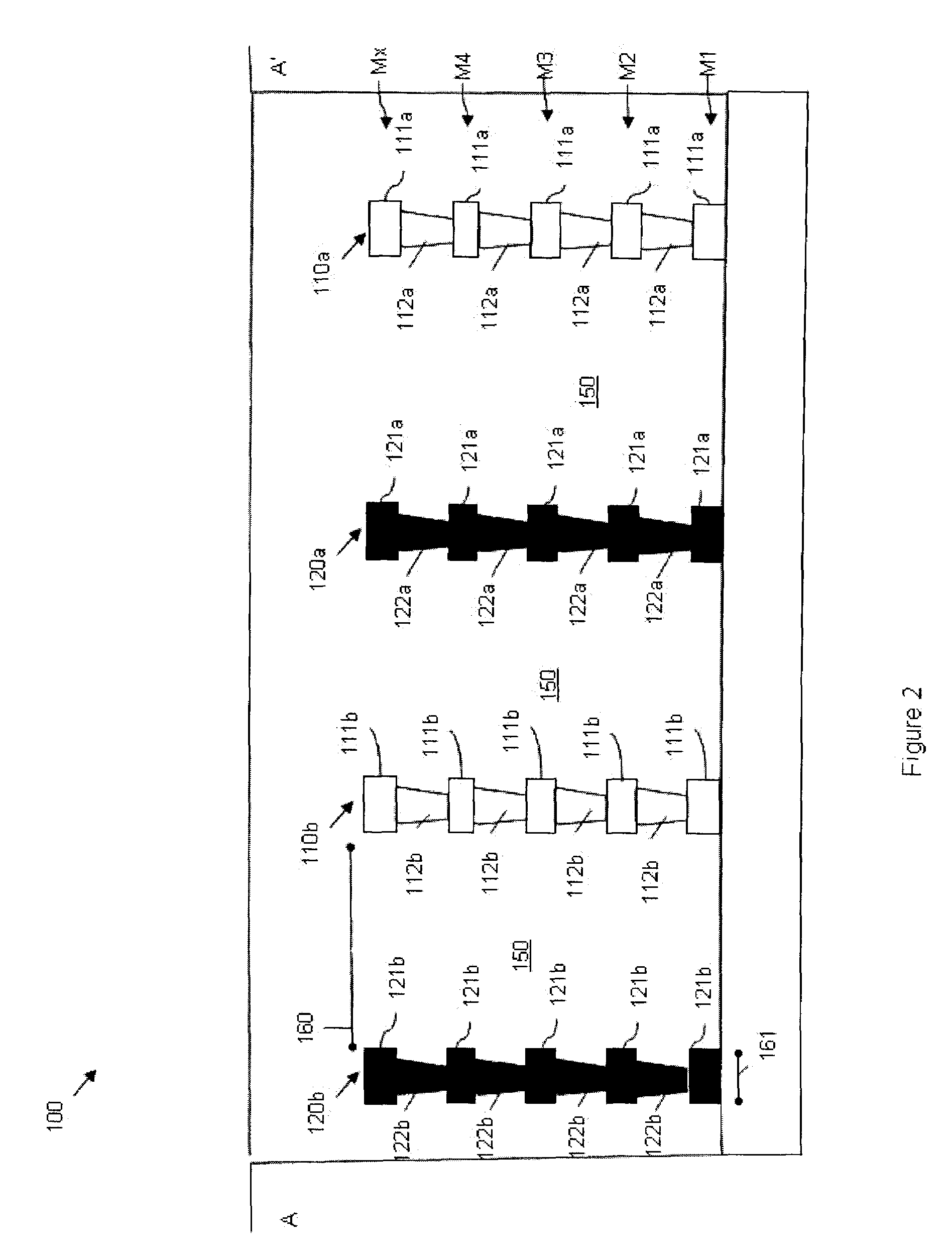

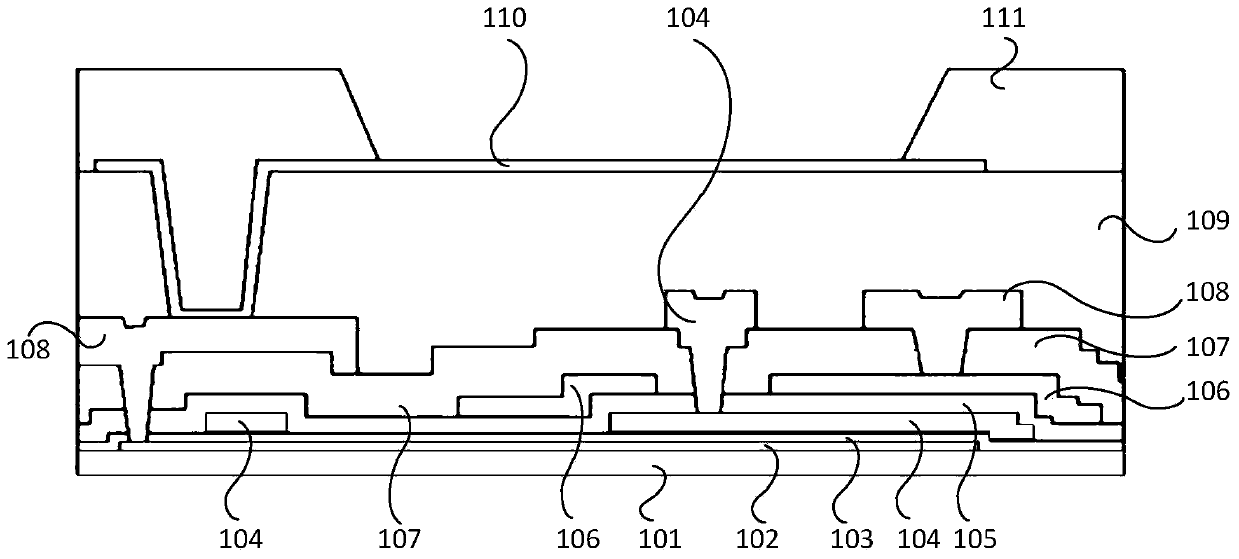

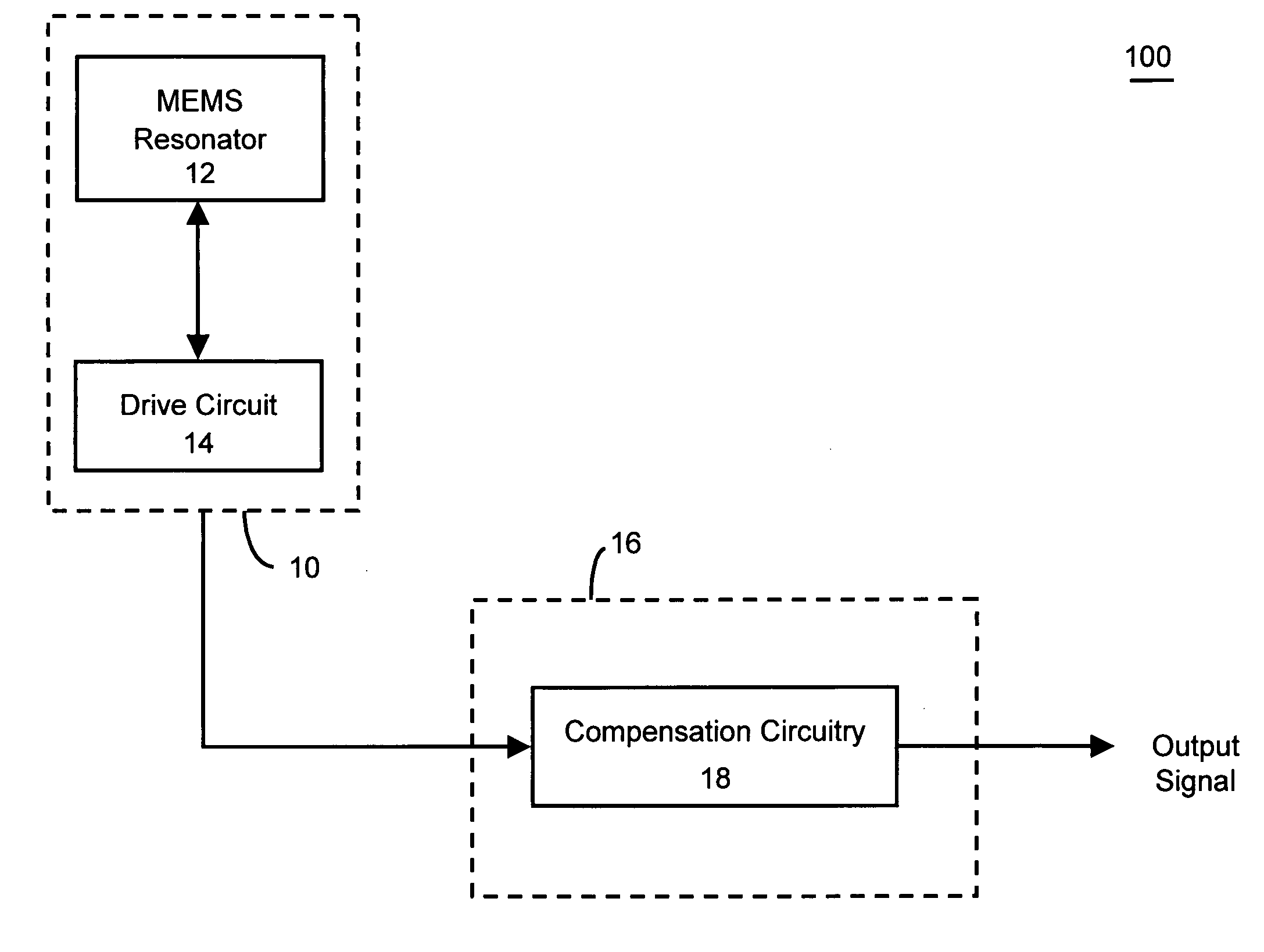

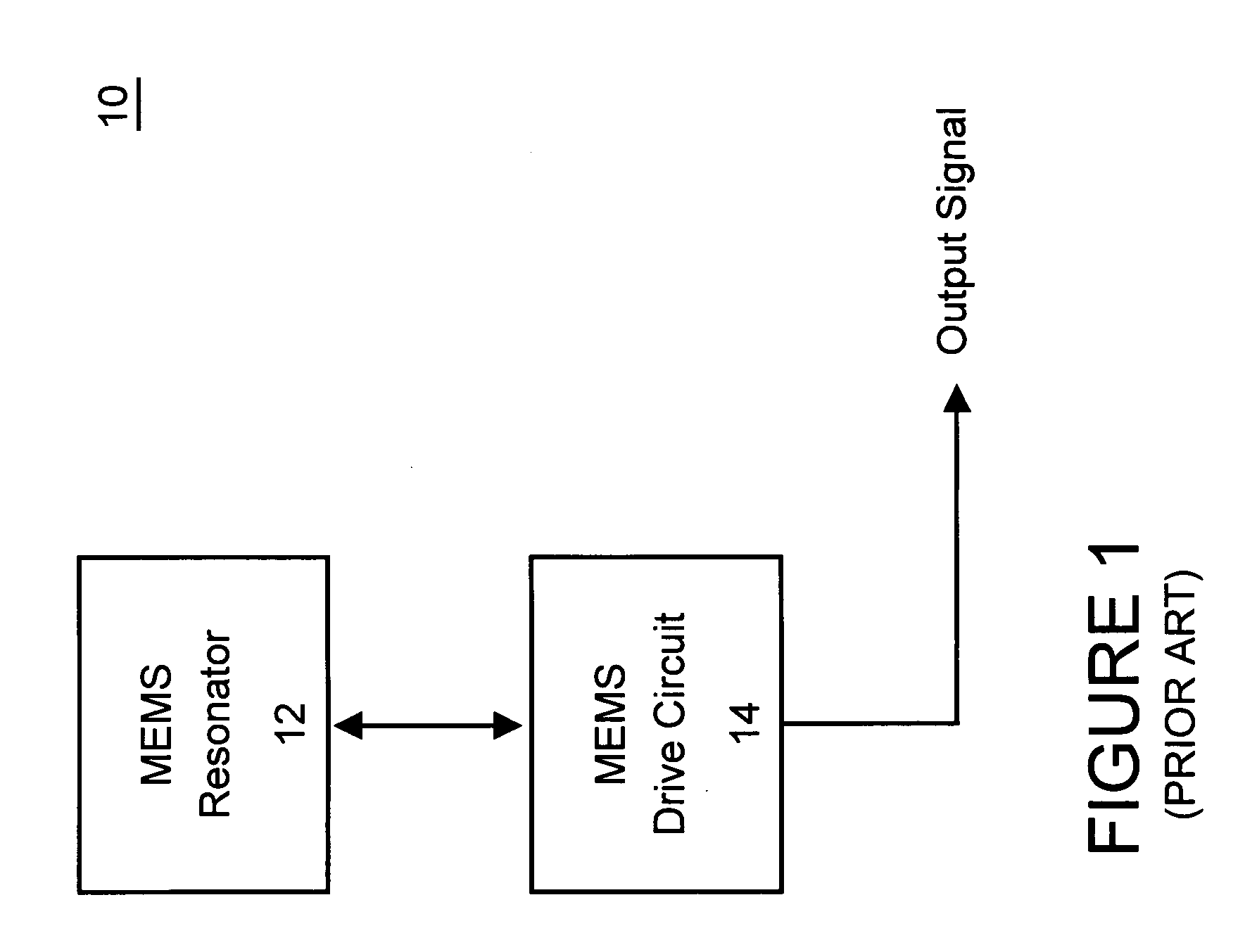

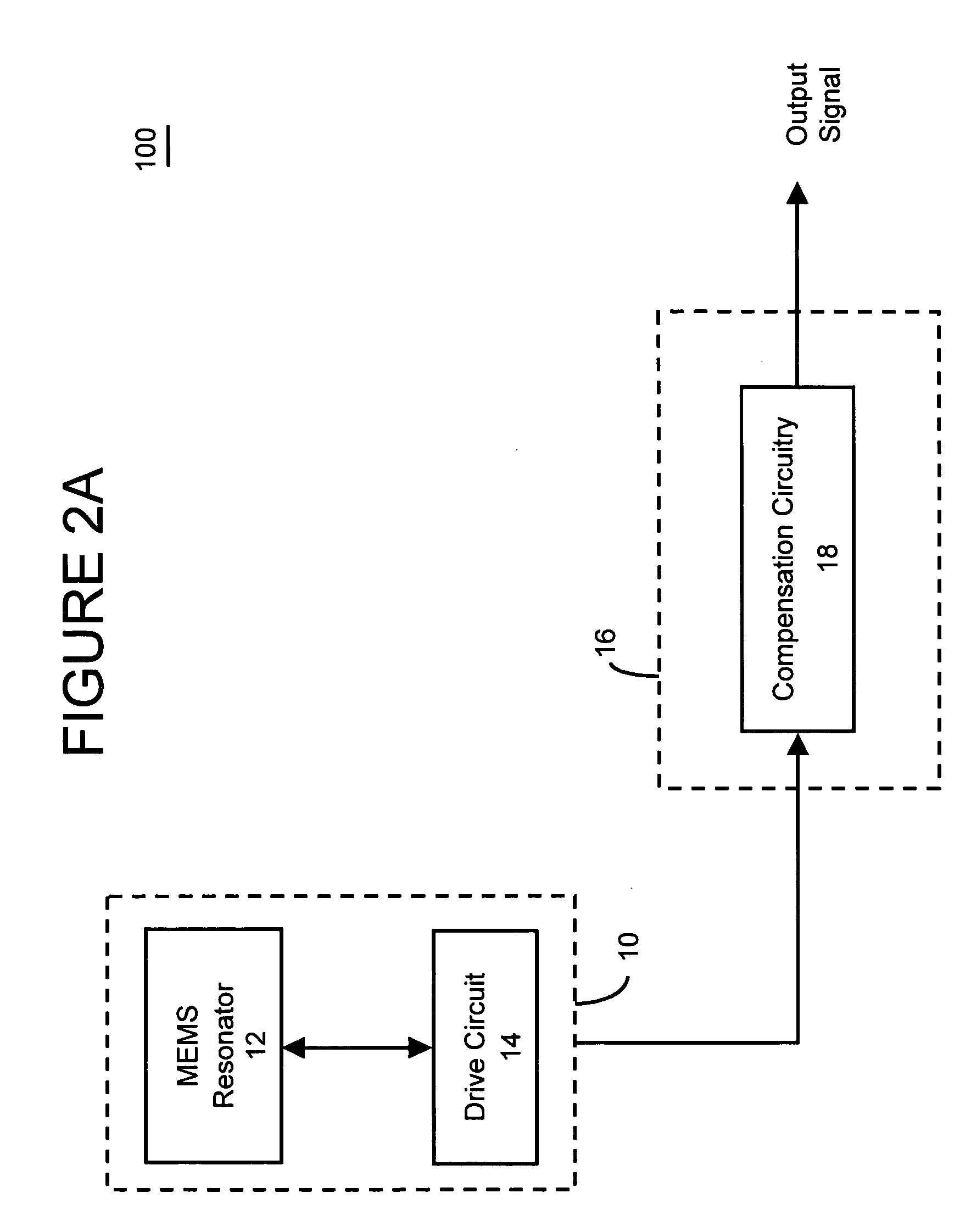

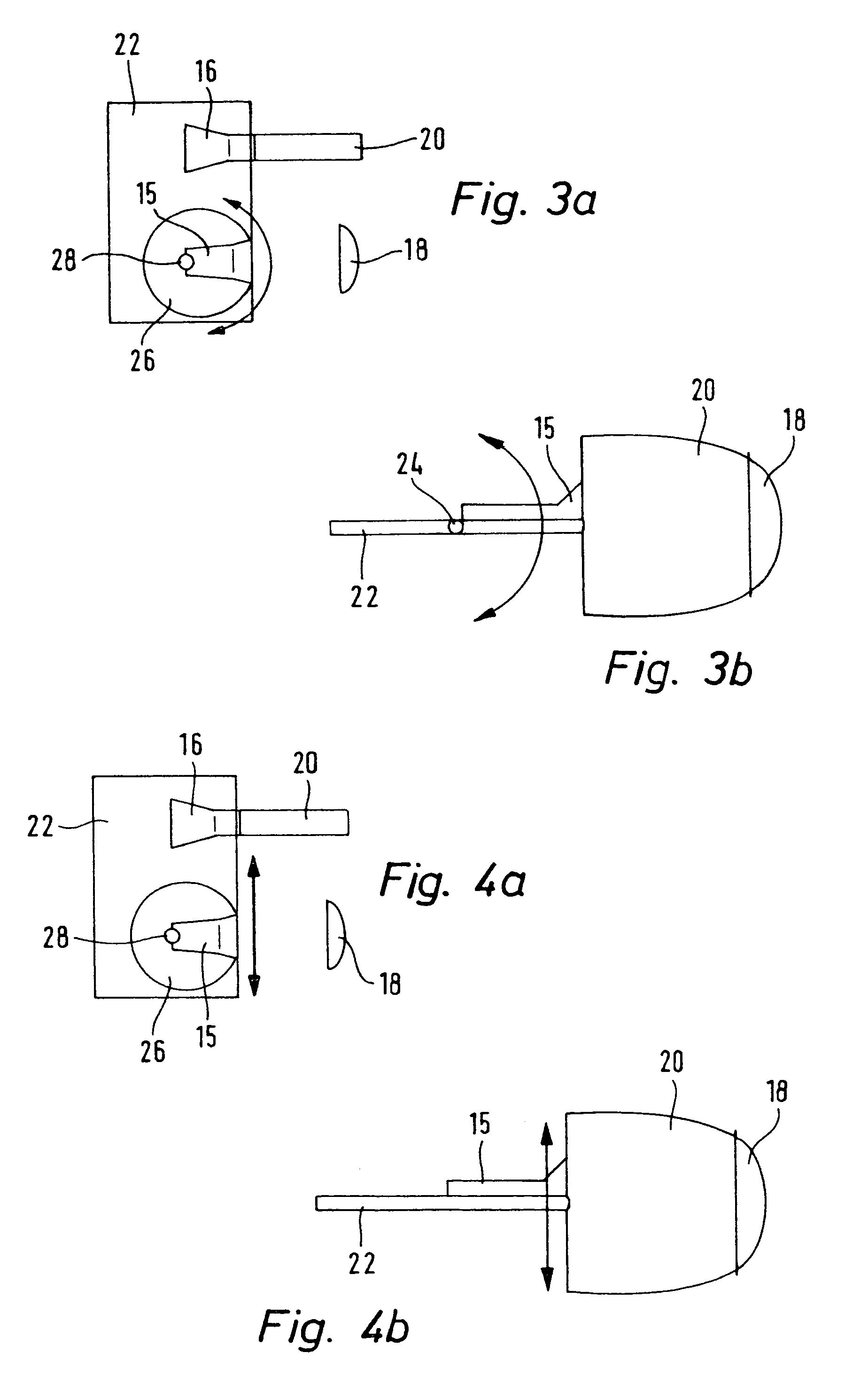

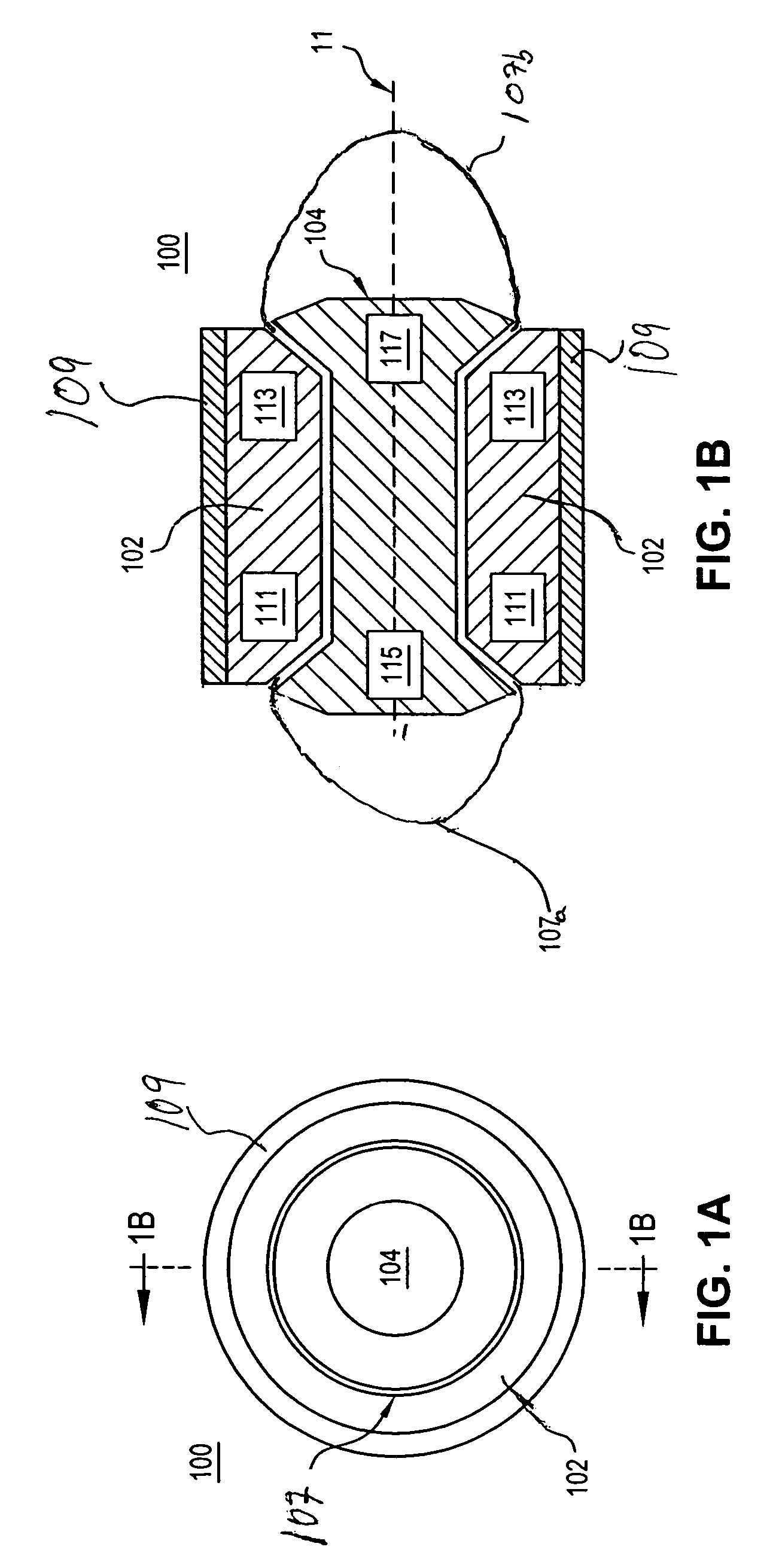

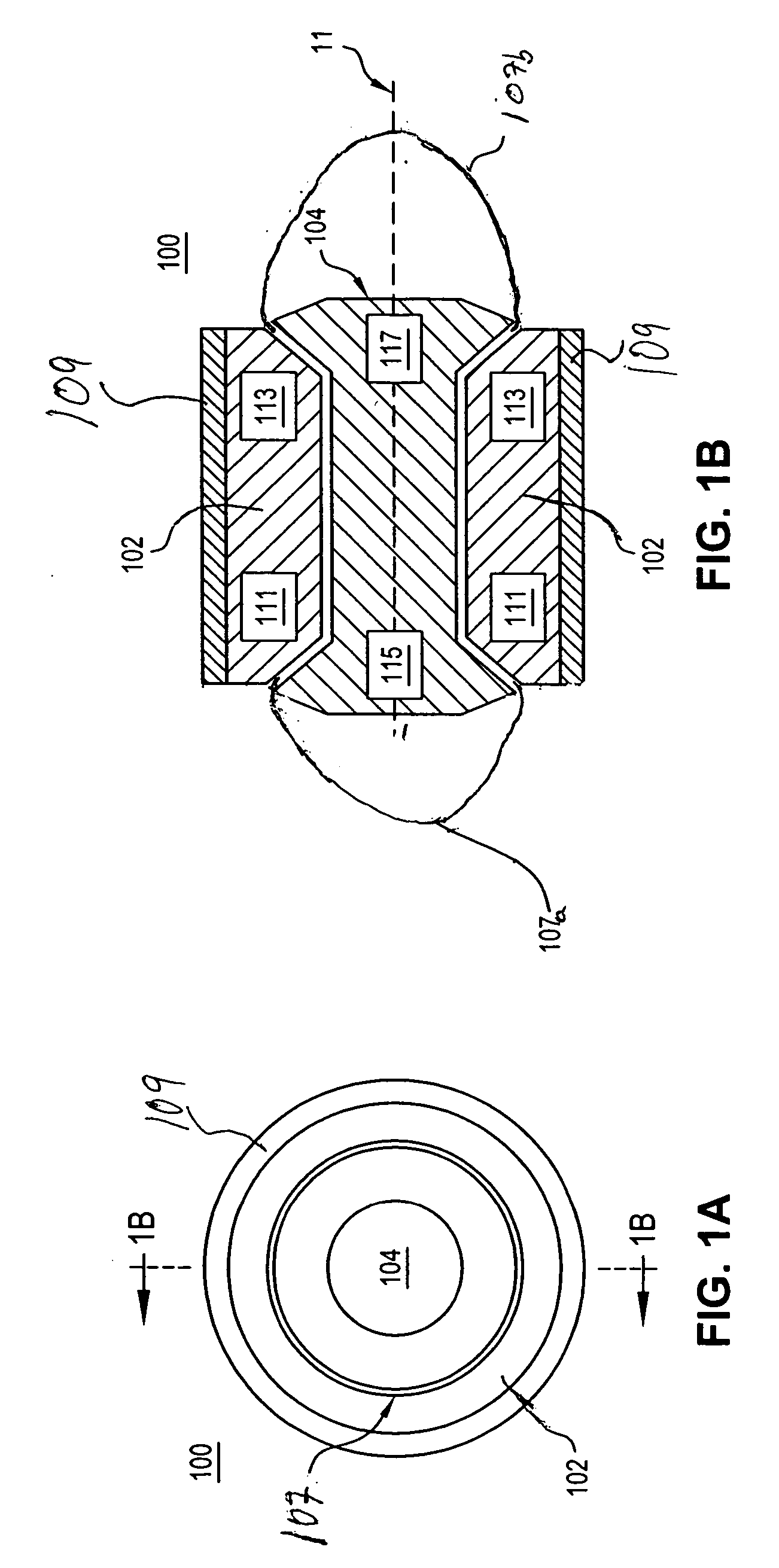

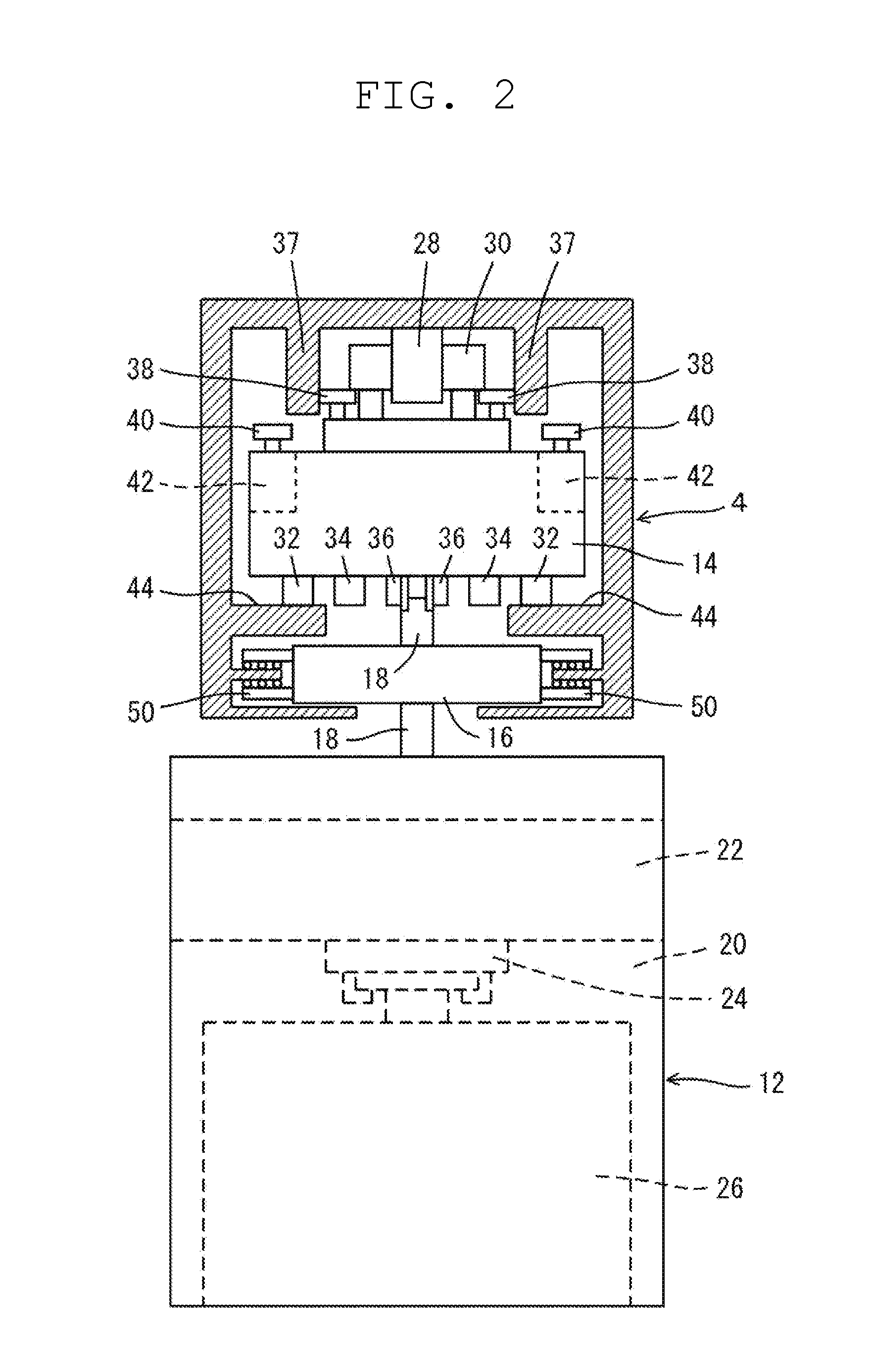

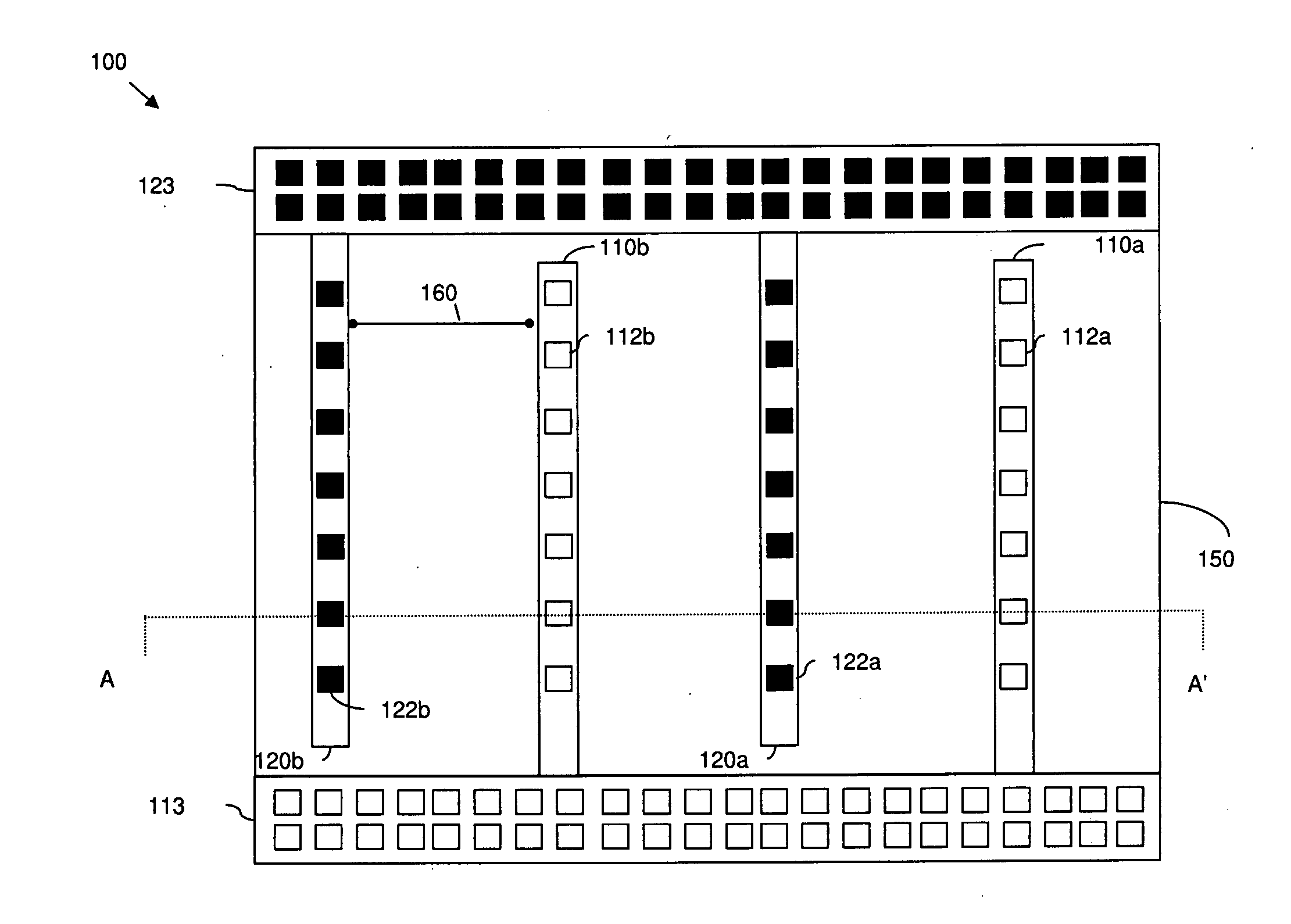

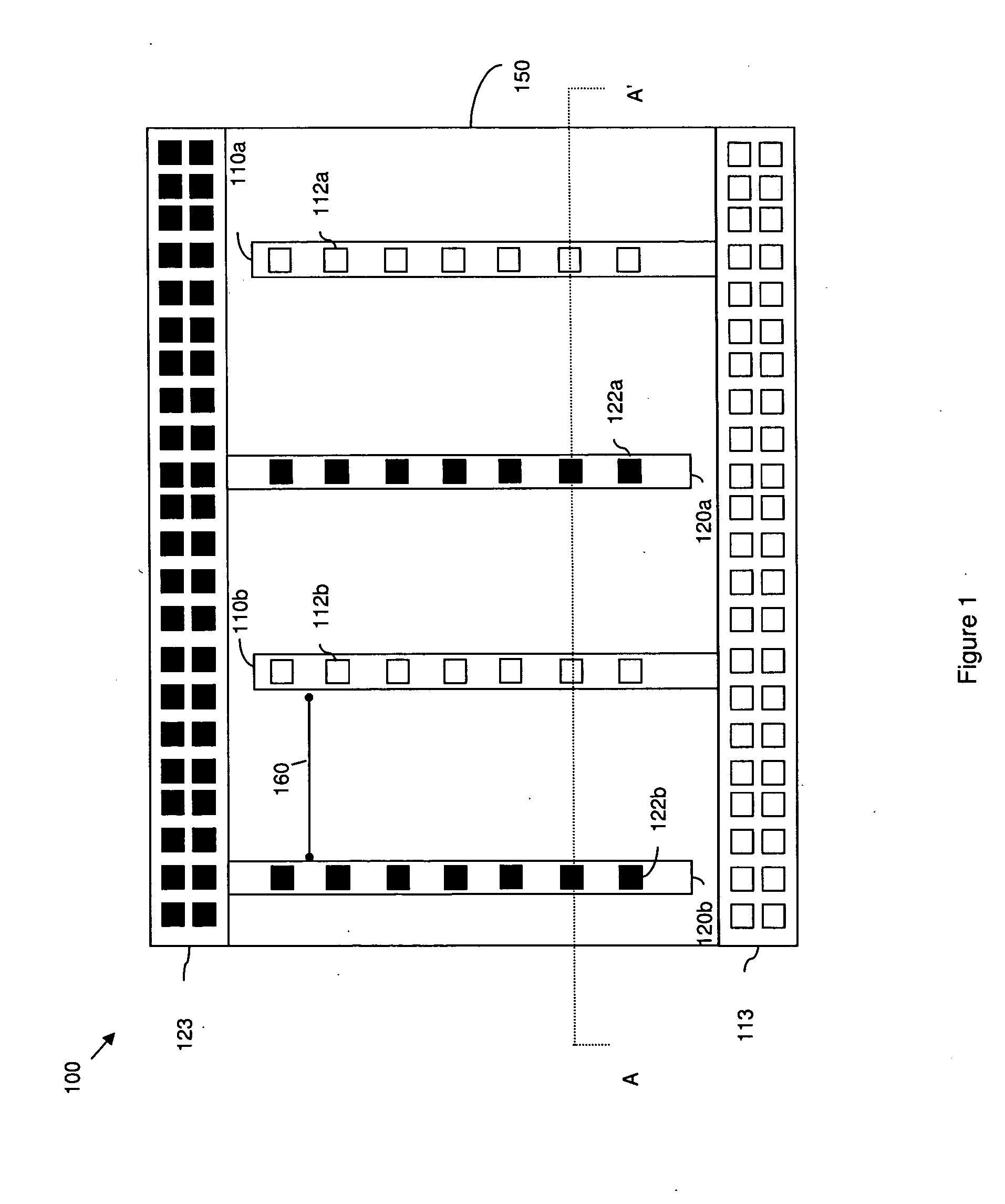

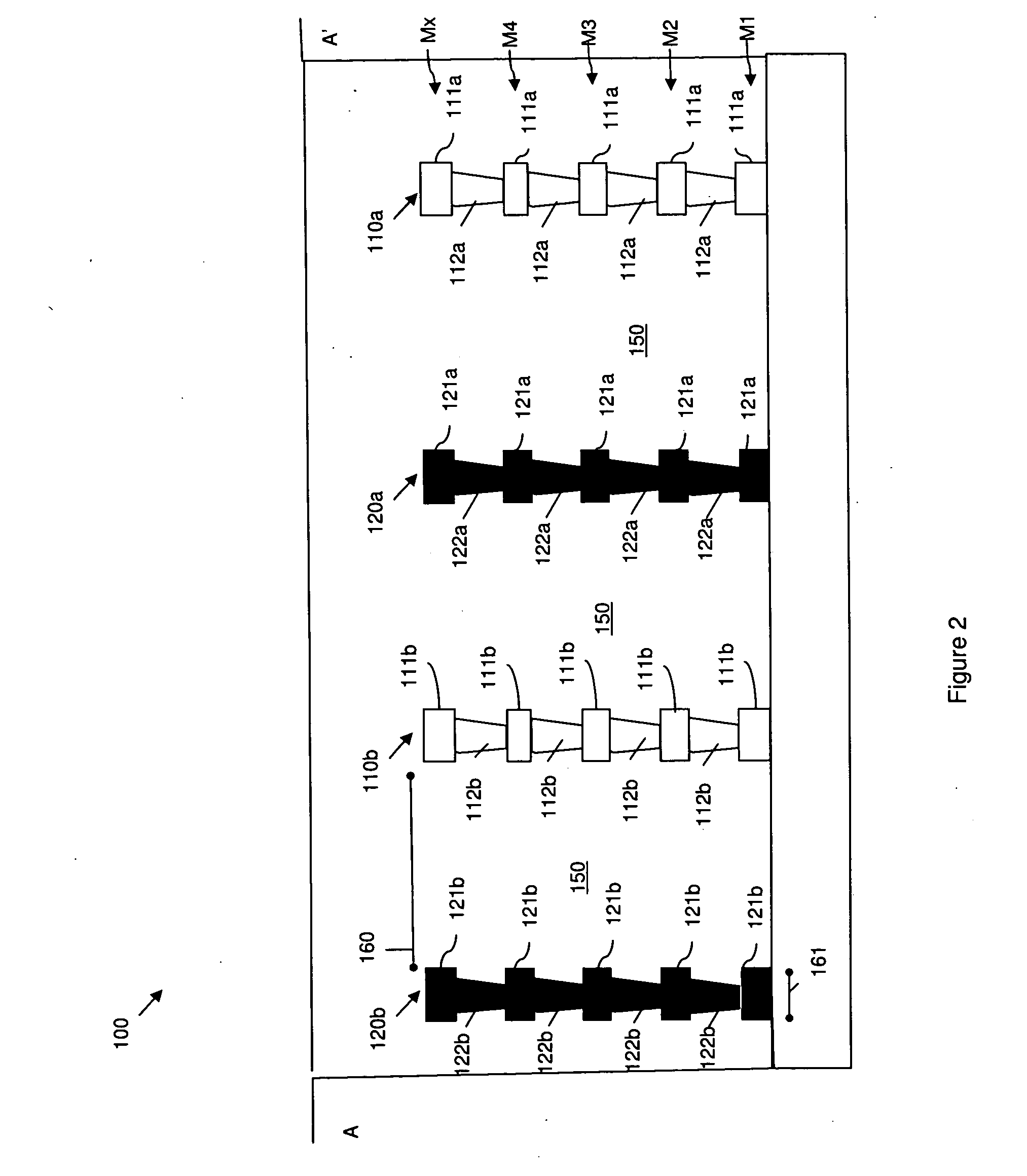

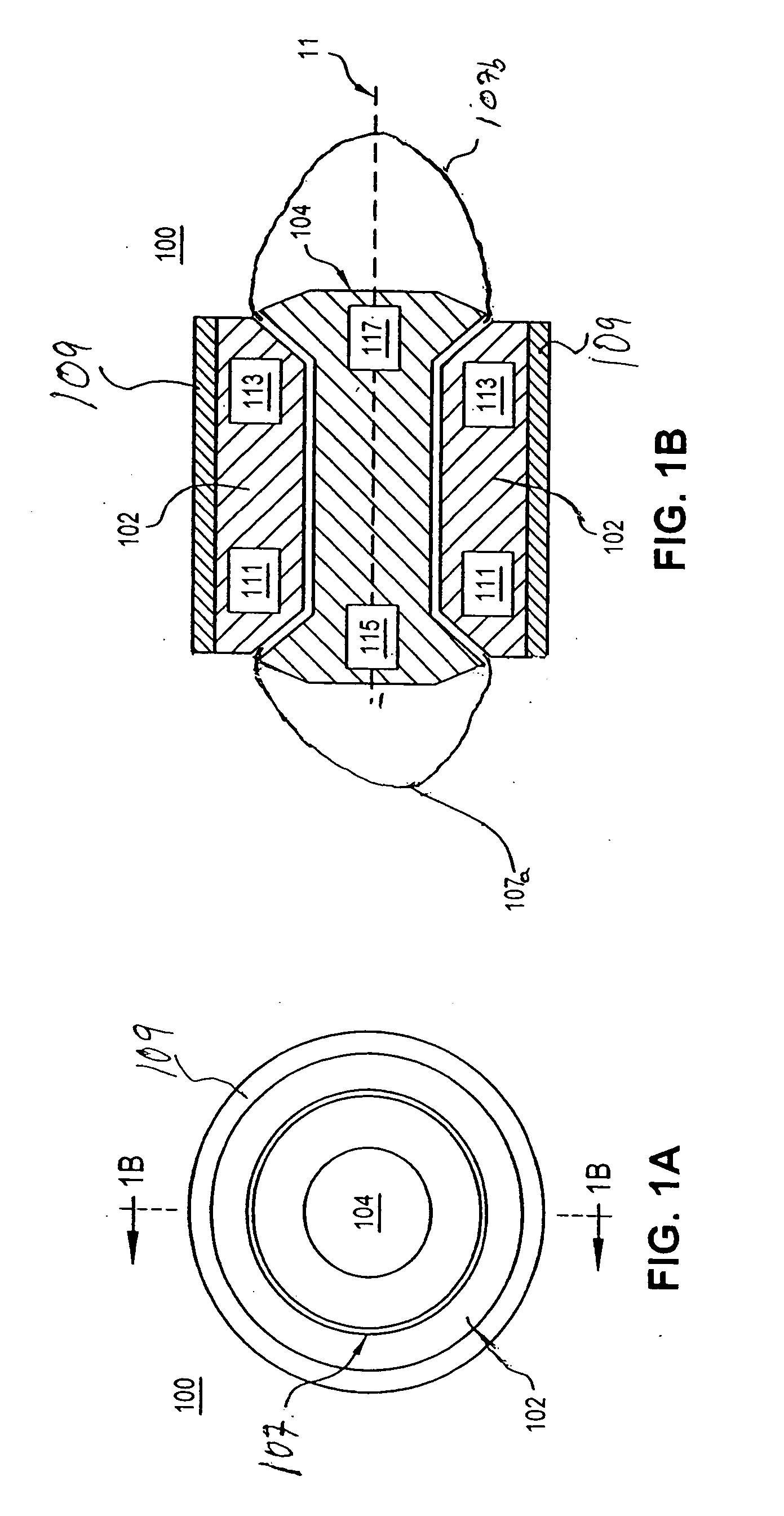

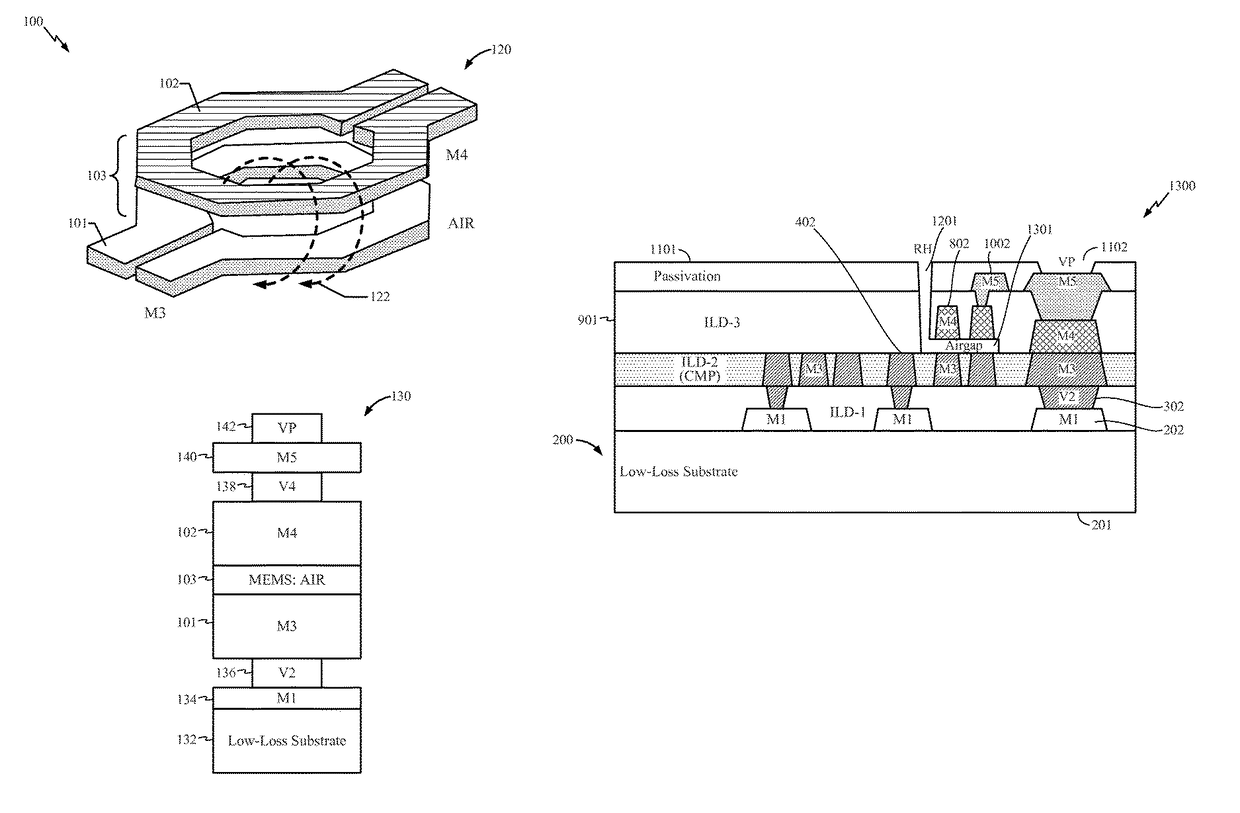

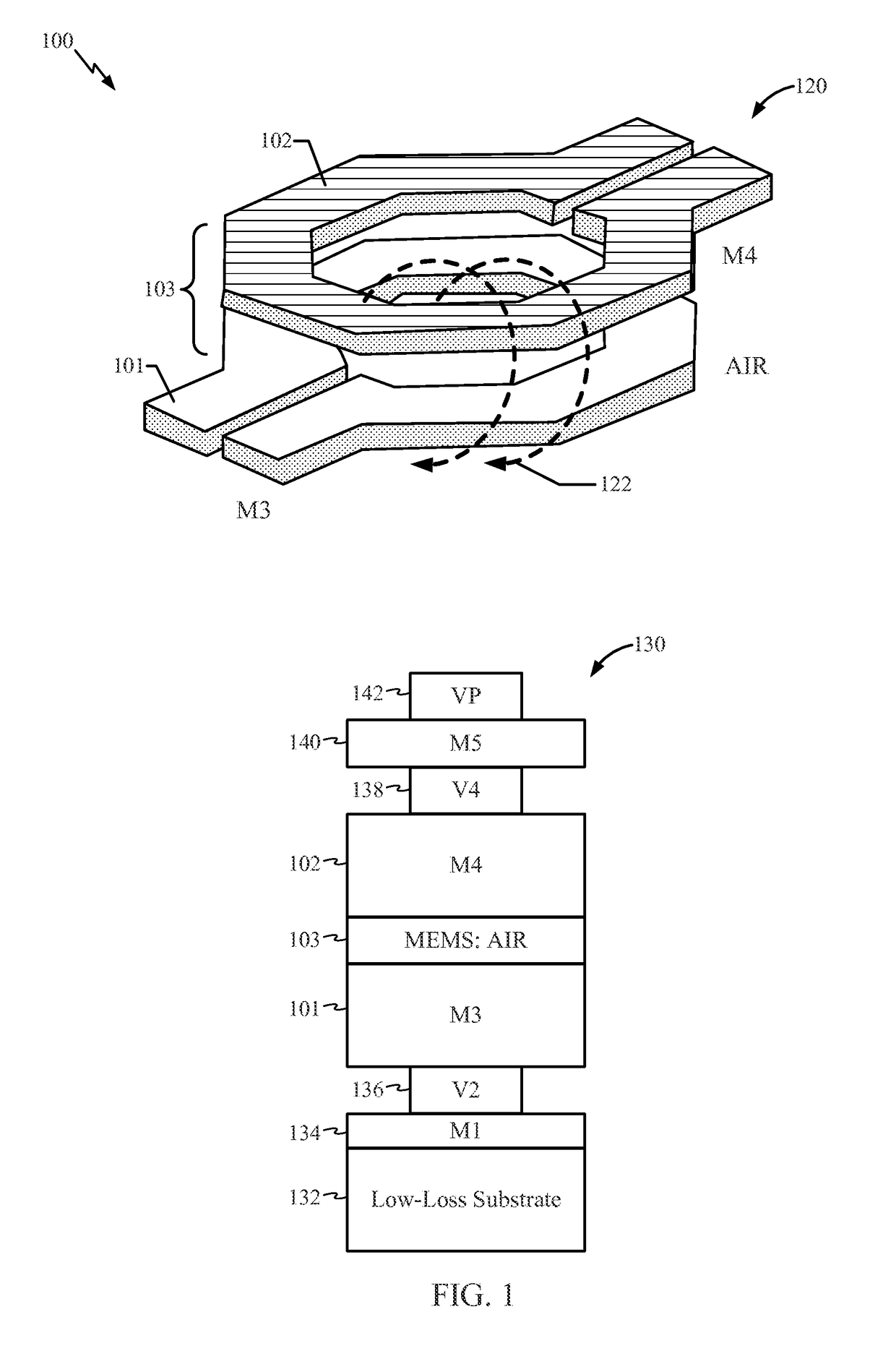

Frequency and/or phase compensated microelectromechanical oscillator

ActiveUS20050151592A1Reduce the gap widthIncreasing available voltage to applyRadiation pyrometryPulse automatic controlFrequency synthesizerFrequency multiplier

There are many inventions described and illustrated herein. In one aspect, the present invention is directed to a compensated microelectromechanical oscillator, having a microelectromechanical resonator that generates an output signal and frequency adjustment circuitry, coupled to the microelectromechanical resonator to receive the output signal of the microelectromechanical resonator and, in response to a set of values, to generate an output signal having second frequency. In one embodiment, the values may be determined using the frequency of the output signal of the microelectromechanical resonator, which depends on the operating temperature of the microelectromechanical resonator and / or manufacturing variations of the microelectromechanical resonator. In one embodiment, the frequency adjustment circuitry may include frequency multiplier circuitry, for example, PLLs, DLLs, digital / frequency synthesizers and / or FLLs, as well as any combinations and permutations thereof. The frequency adjustment circuitry, in addition or in lieu thereof, may include frequency divider circuitry, for example, DLLS, digital / frequency synthesizers (for example, DDS) and / or FLLs, as well as any combinations and permutations thereof.

Owner:ROBERT BOSCH GMBH

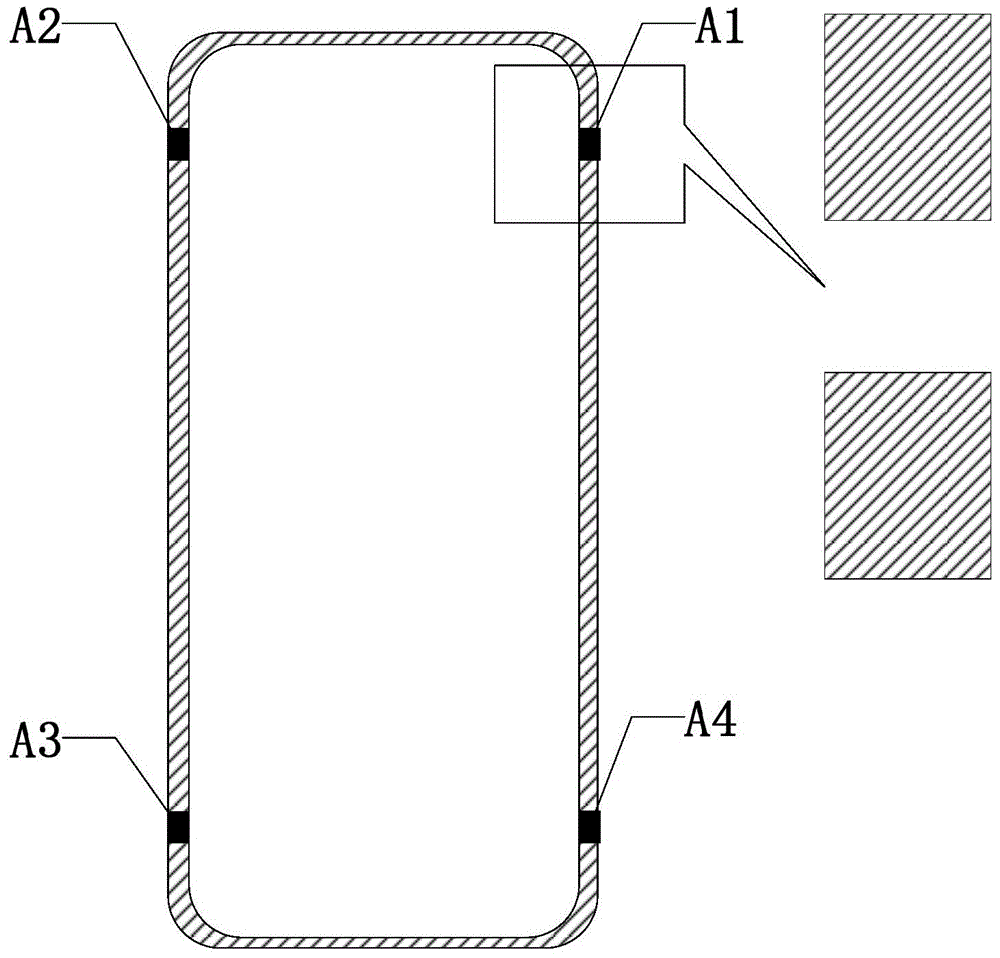

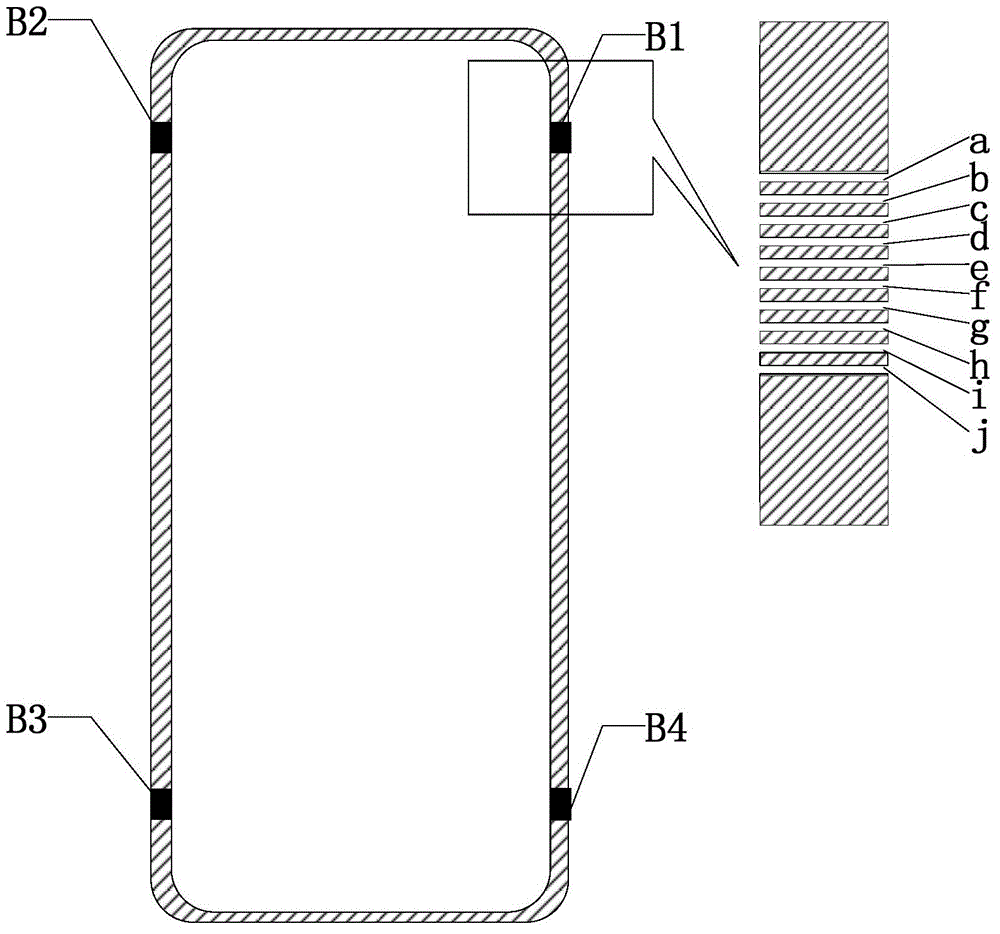

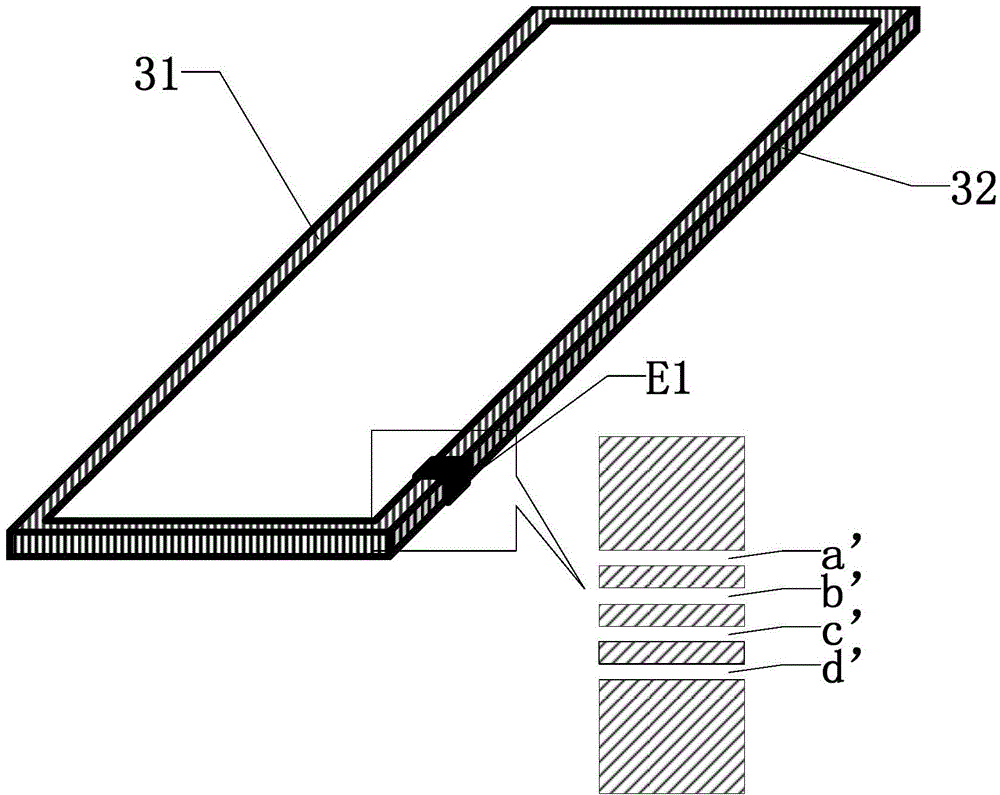

Metal shell, mobile terminal and manufacturing method

ActiveCN104640391AReduce the width of the antenna breakImprove the overall appearance and aestheticsCasings/cabinets/drawers detailsMetal casingsEngineeringMetallic materials

The invention discloses a metal shell, a mobile terminal and a manufacturing method. At least one slot area is arranged on the metal shell; each slot area comprises n slots which are sequentially arranged, wherein the width of each slot is smaller than or equal to a set value, so that each slot cannot be seem by naked eyes, and n is an integer which is not smaller than 1. The manufacturing method of the metal shell comprises the following steps of machining a metal material into set shape to obtain a first shell; forming at least one slot area on a set position of the first shell to obtain a second shell, wherein each slot area comprises n slots which are sequentially arranged, the width of each slot is smaller than or equal to the set value, so that each slot cannot be seem by the naked eyes, and n is an integer which is not smaller than 1. The mobile terminal comprises the metal shell. The antenna slot broken width of the metal shell of the mobile terminal is reduced, and the technical effect of enhancing integrated appearance aesthetic perception of a product is realized.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

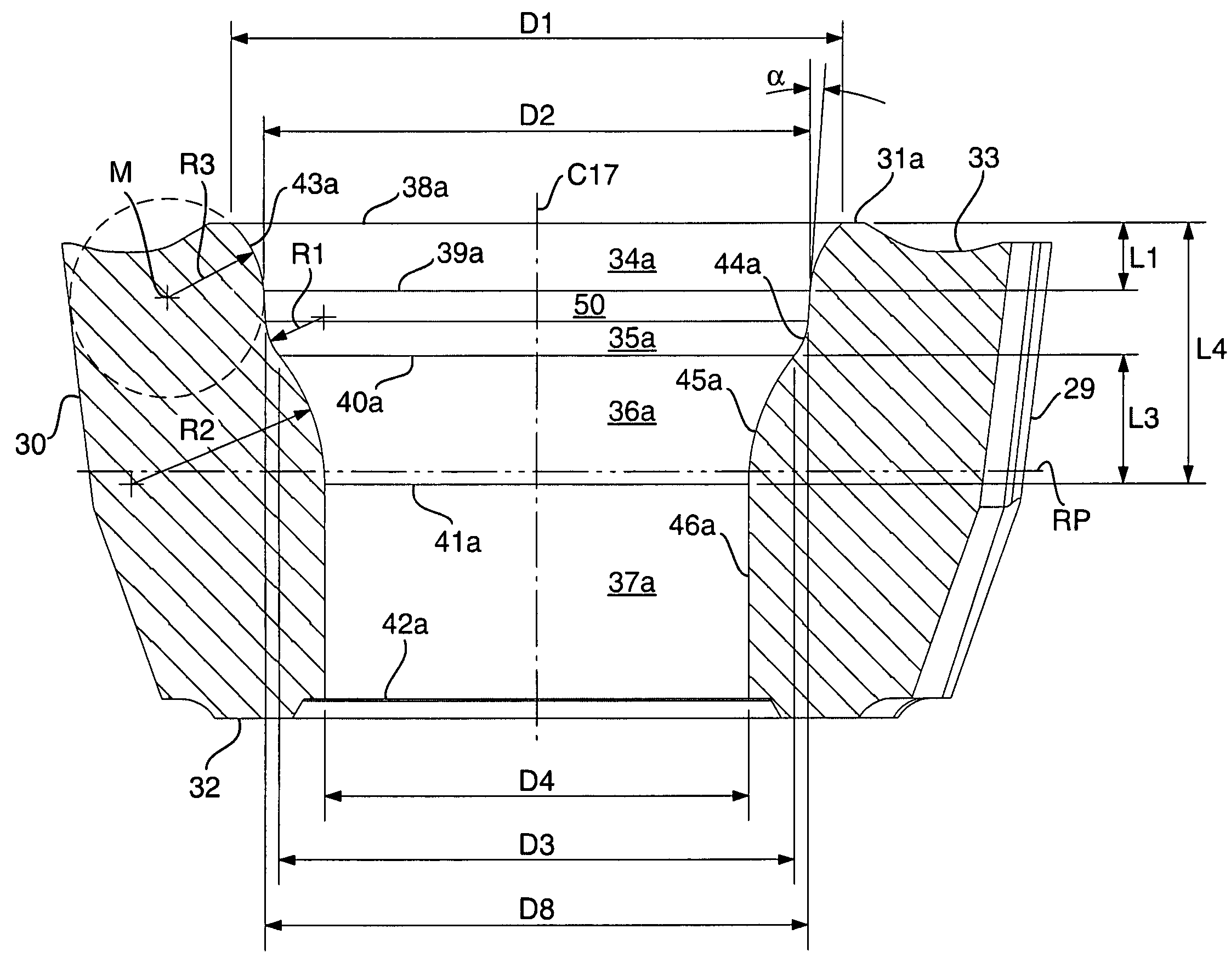

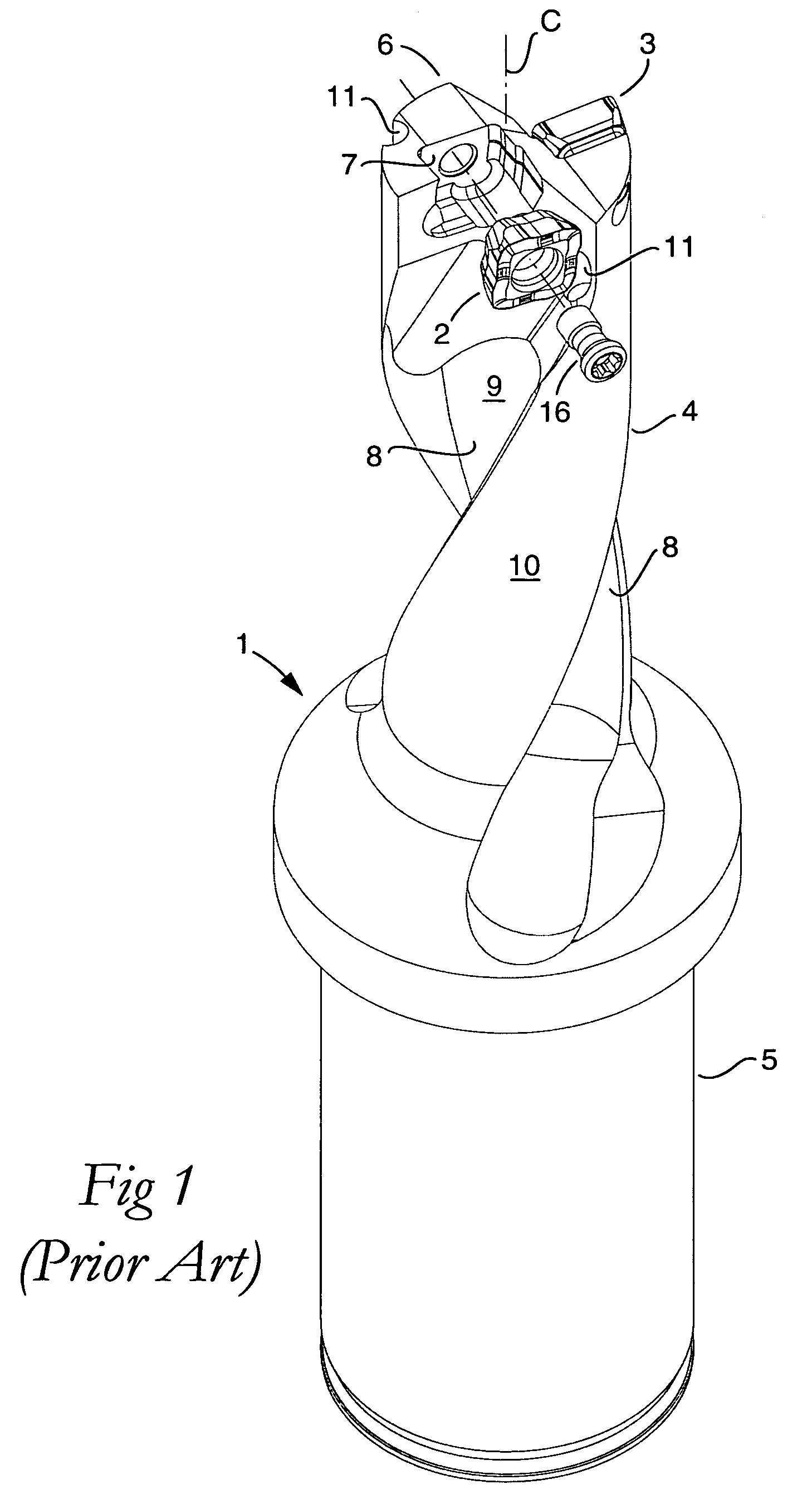

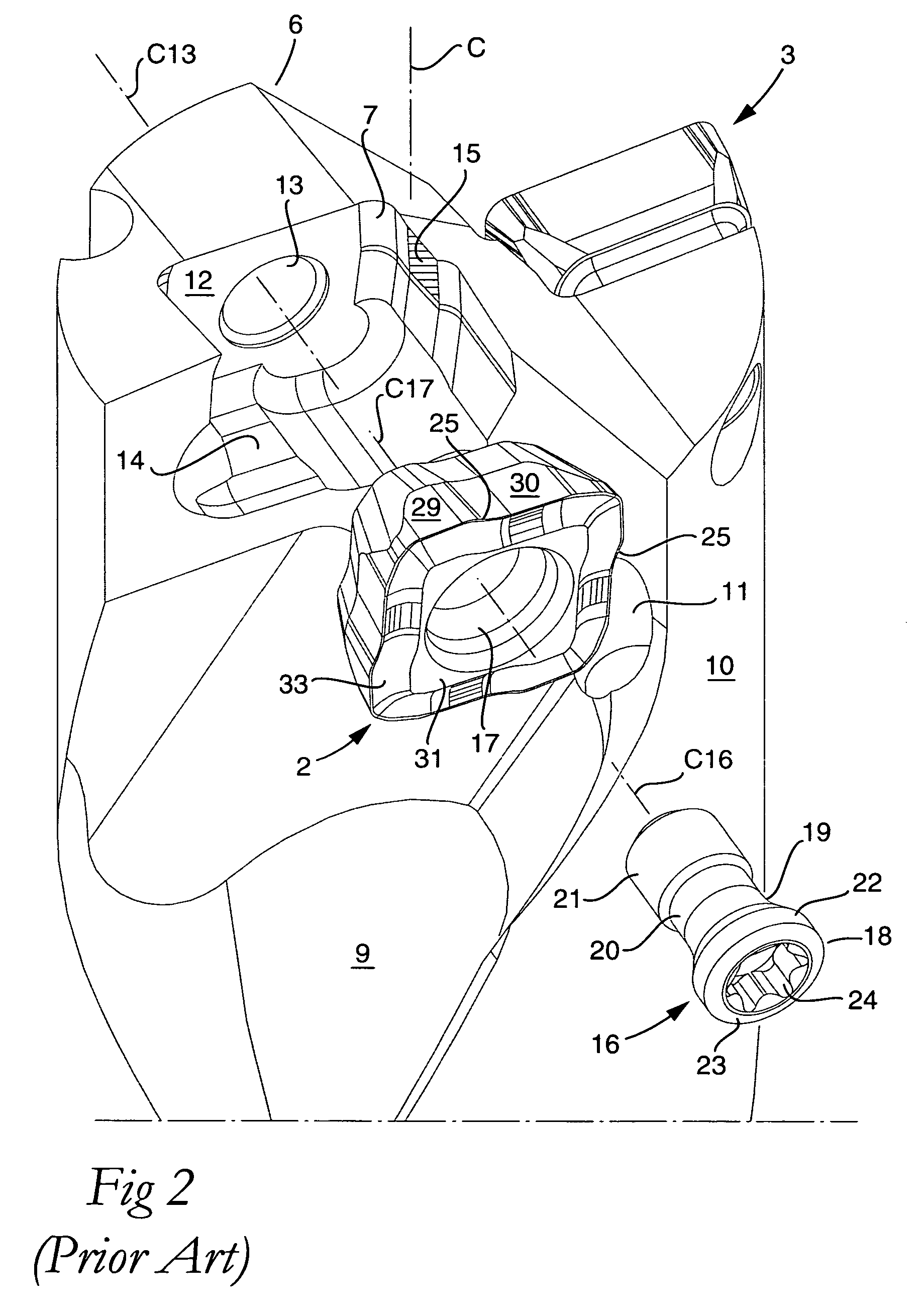

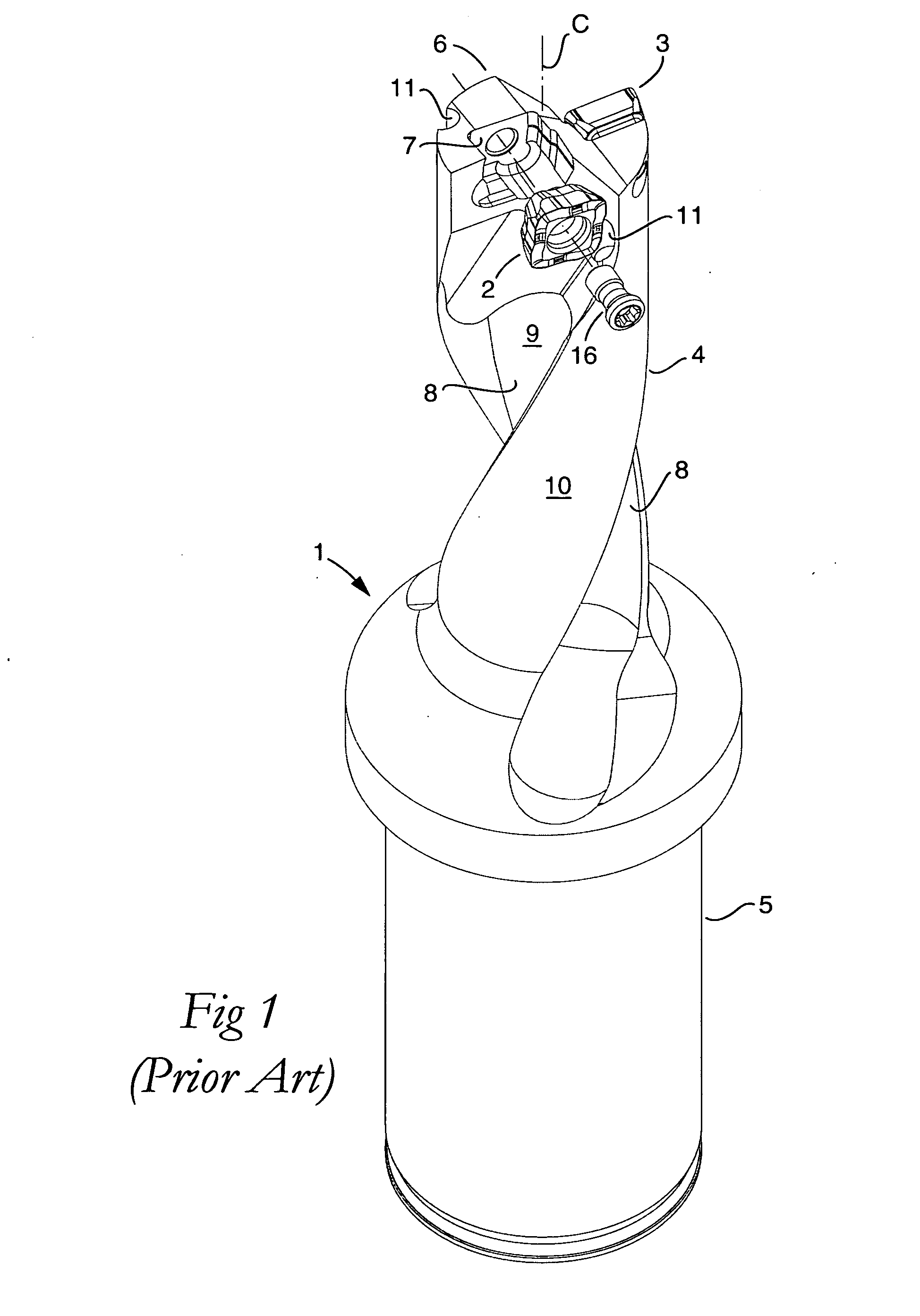

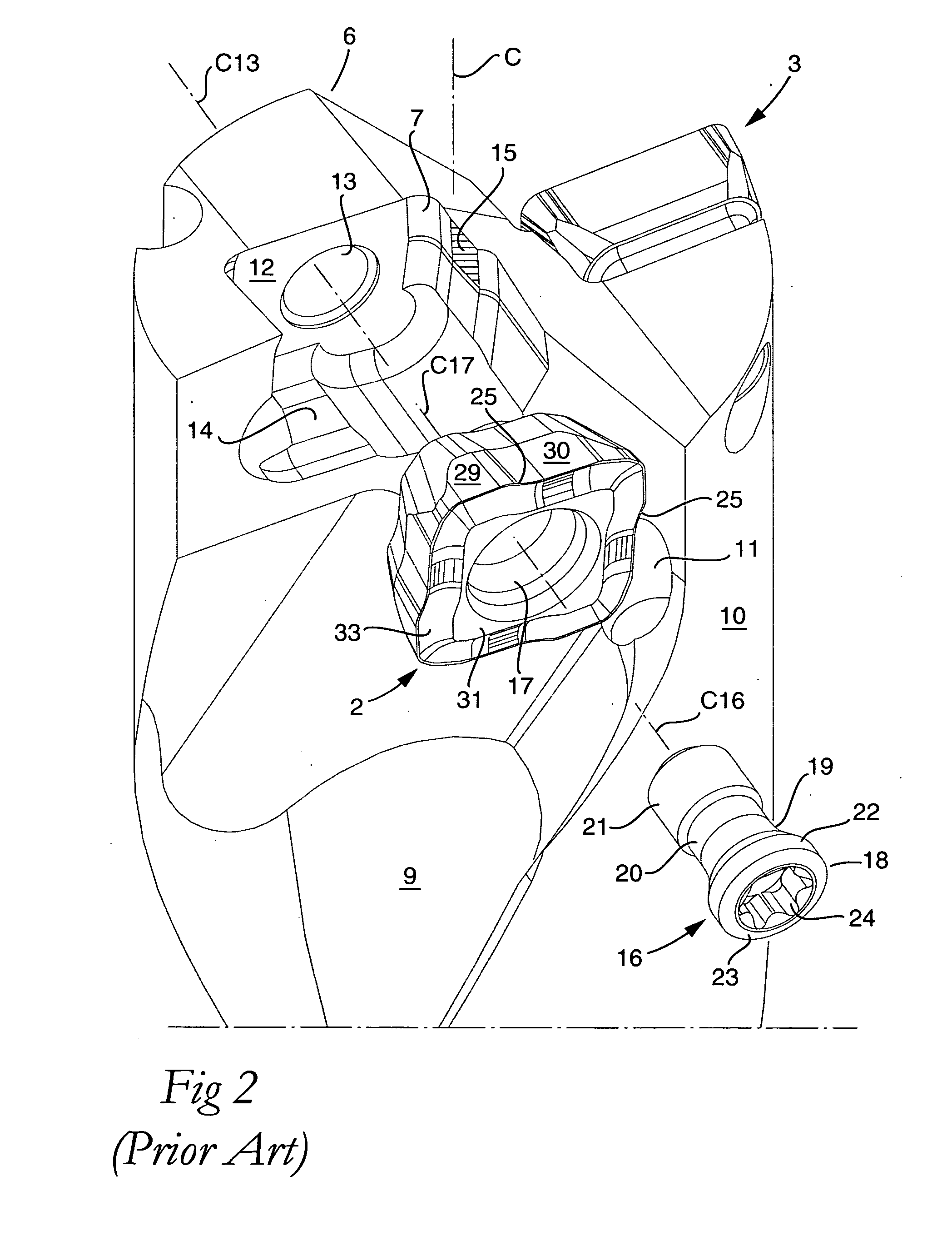

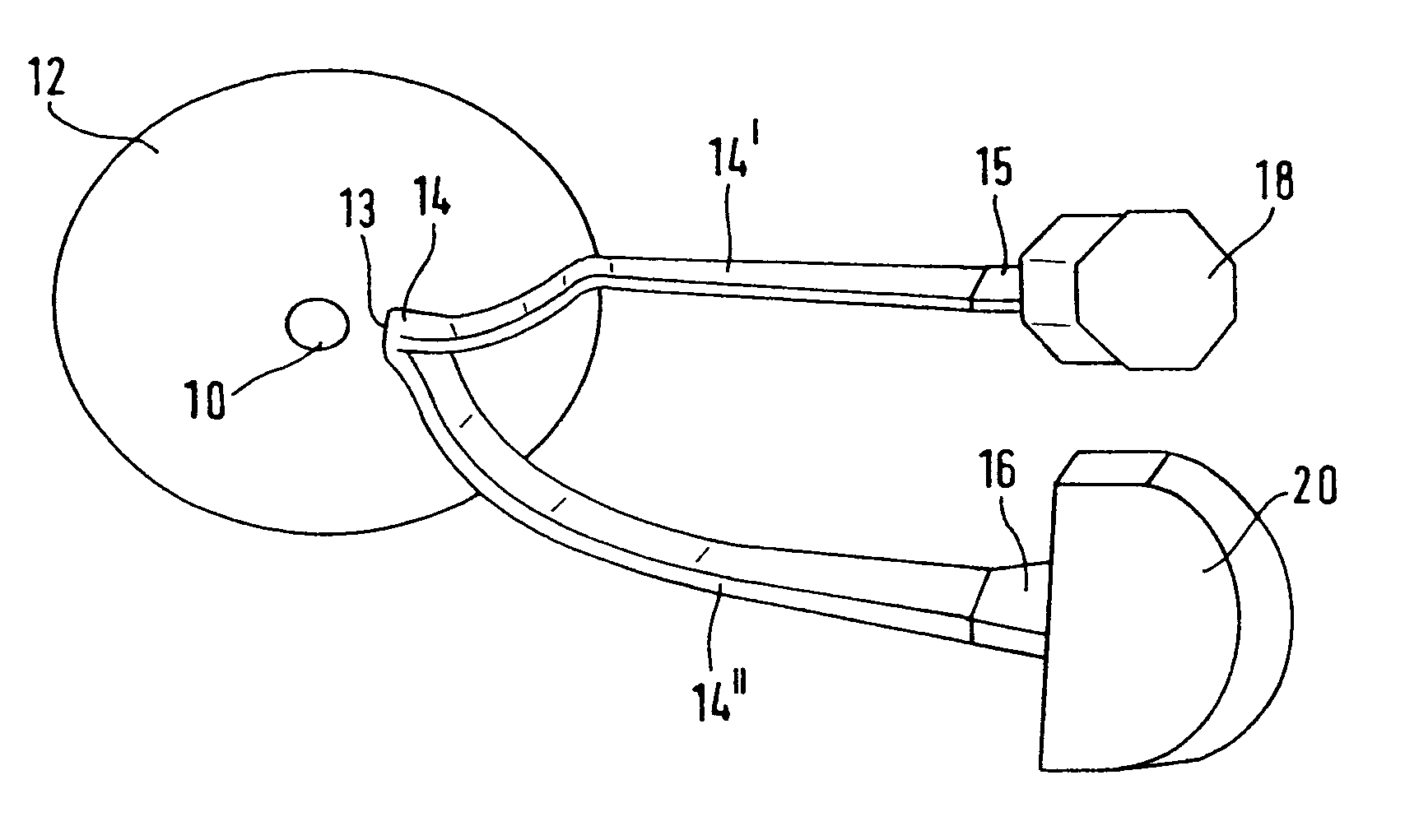

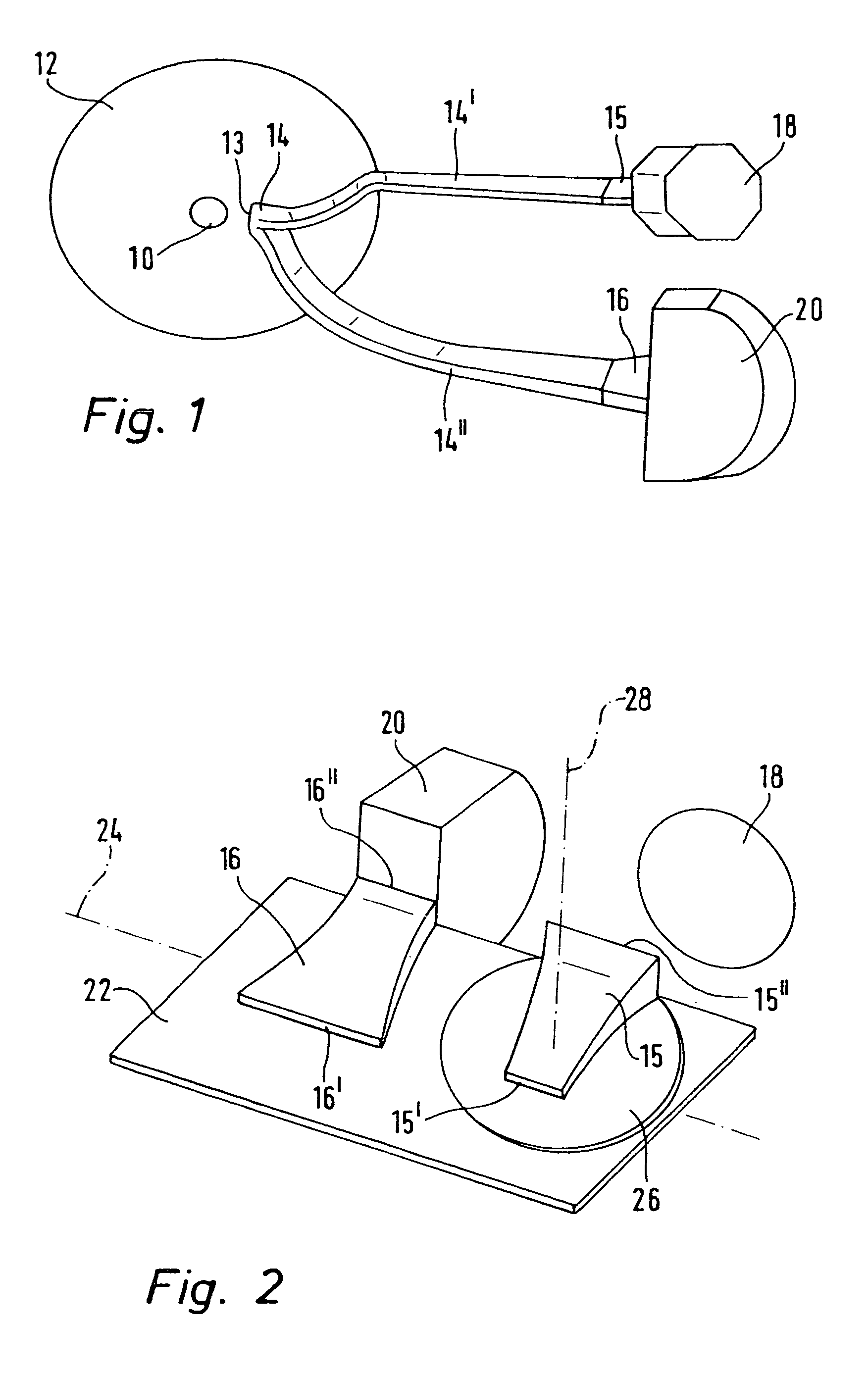

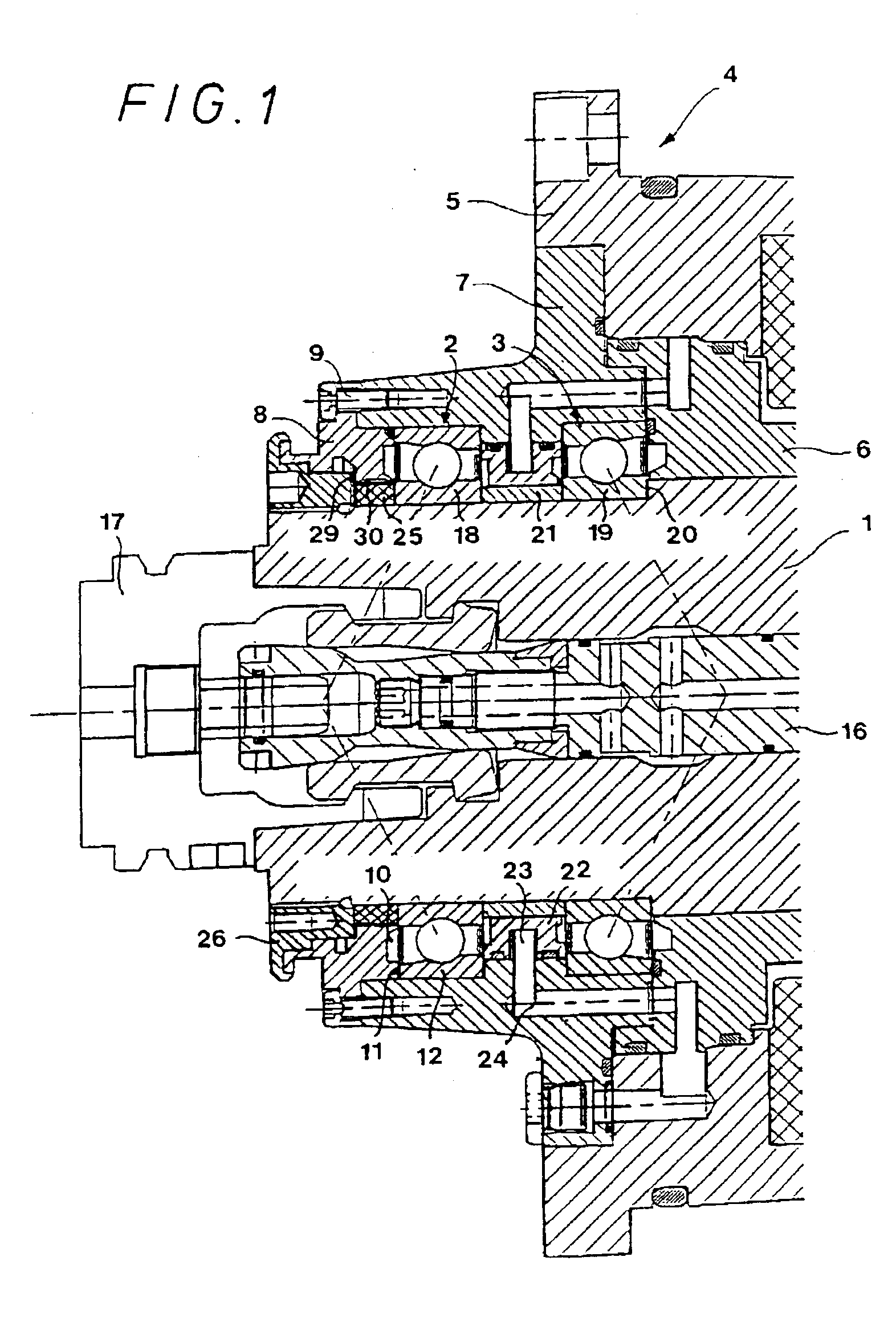

Drill and a drill cutting insert

InactiveUS7677845B2Smoothly pass mouth surfaceRisk minimizationThread cutting toolsWood turning toolsFluteDrill cuttings

A drill for chip removing machining, including a drill body, and a replaceable cutting insert mounted in a pocket formed in a front tip of the drill body. A chip flute extends backwardly from the pocket along the drill body, and the cutting insert is fixed in the pocket by a screw including a head and a shank having a male thread. The cutting insert includes a through hole extending between a topside and an underside. The hole has a basic shape that is rotationally symmetrical in relation to a center axis, and is delimited by a series of surfaces including a mouth surface, converging downward from the topside, and a shoulder surface. The head of the screw is kept pressed against the shoulder surface when the male thread of the screw is tightened in a female thread included in a hole that mouths in a bottom of the pocket. The mouth surface in the hole of the cutting insert has a trumpet-like, cross section-wise convex shape adjacent to the topside of the cutting insert.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

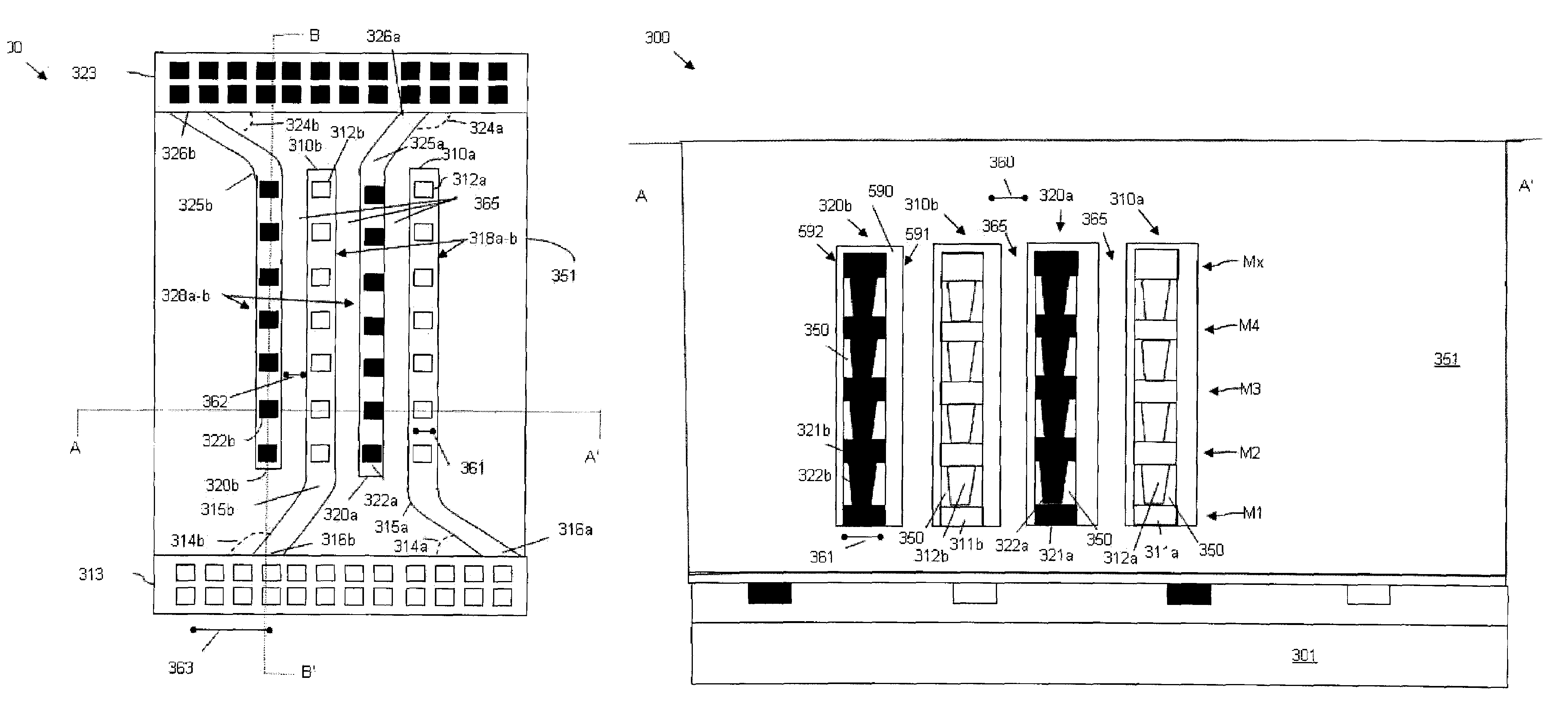

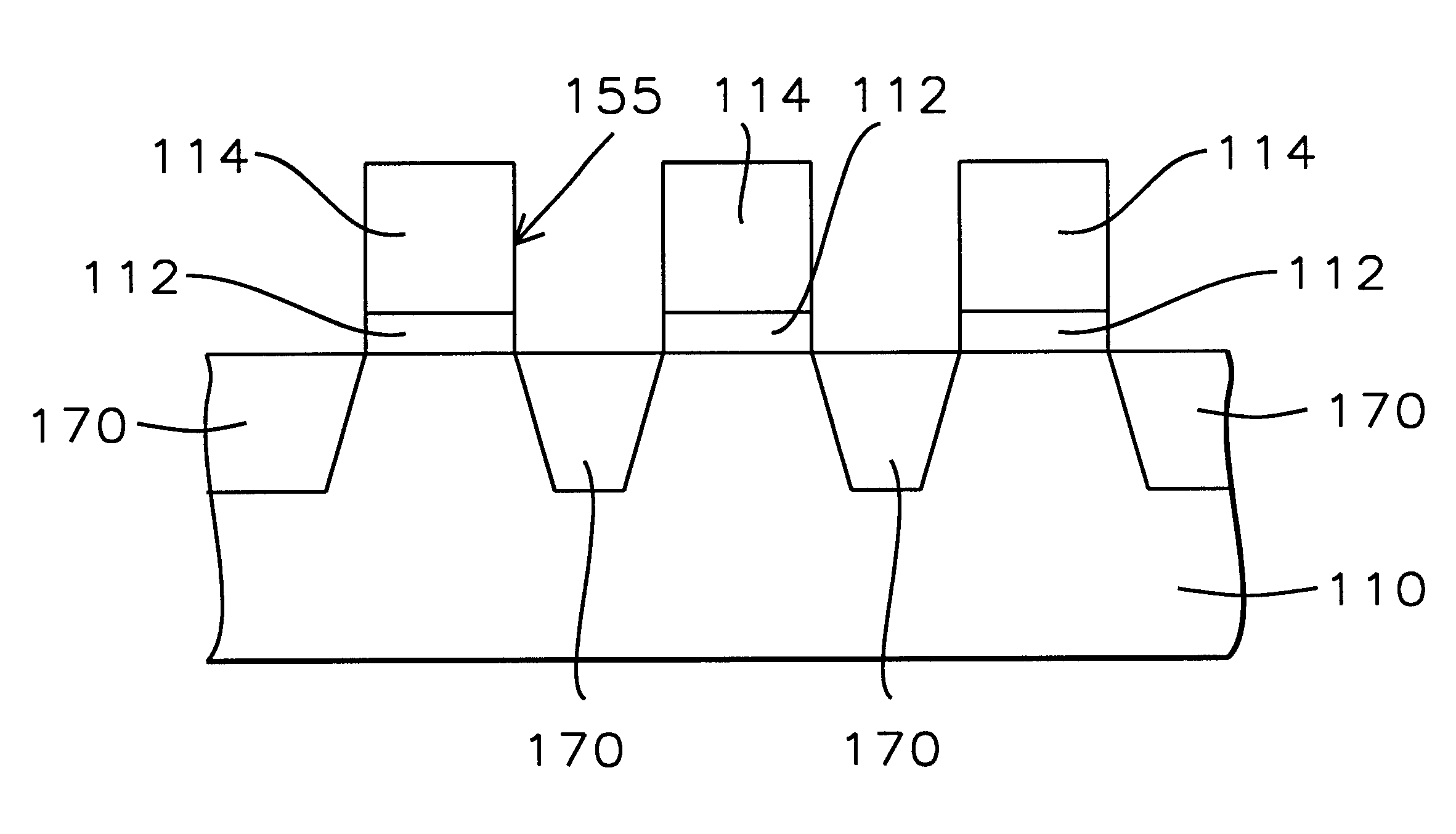

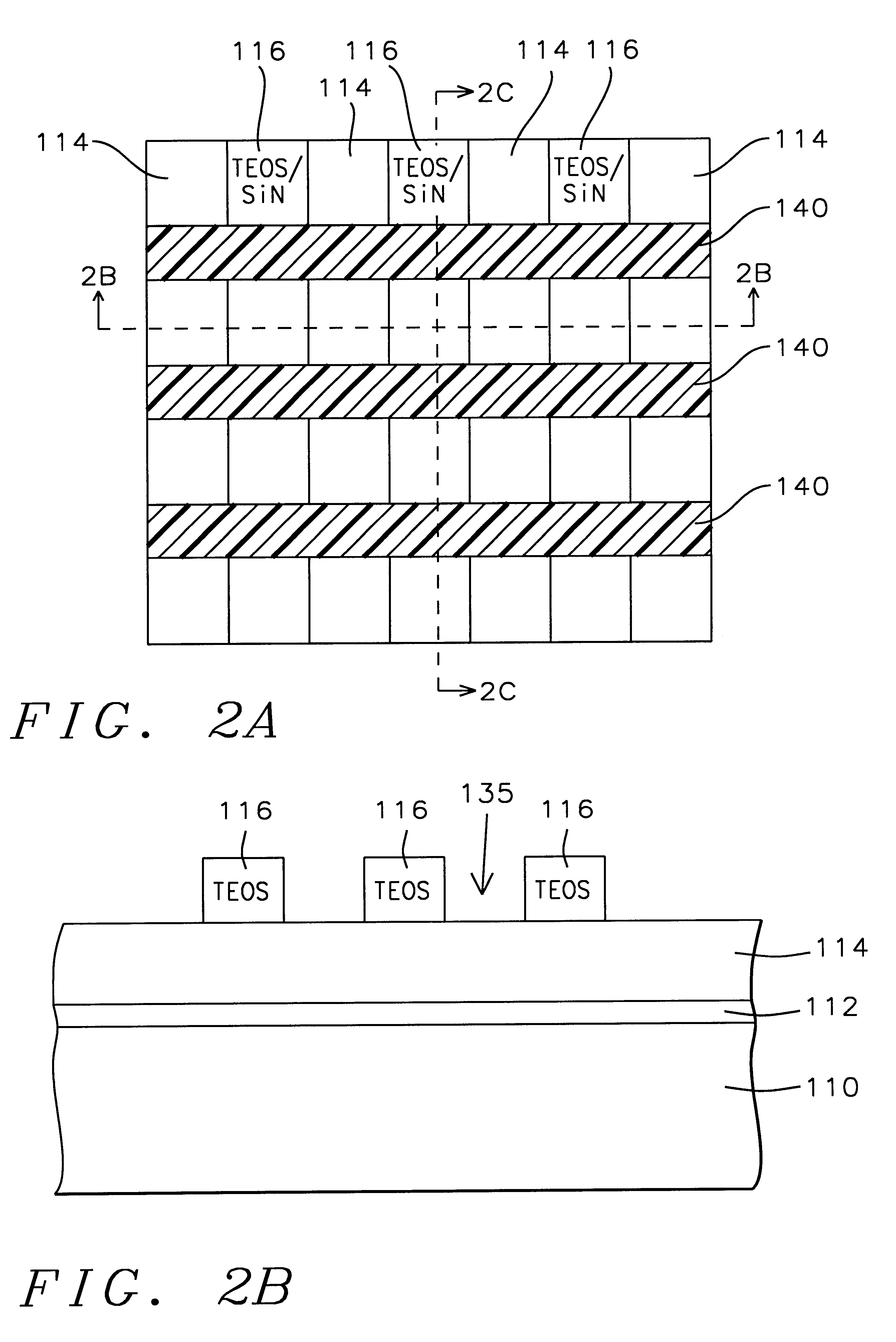

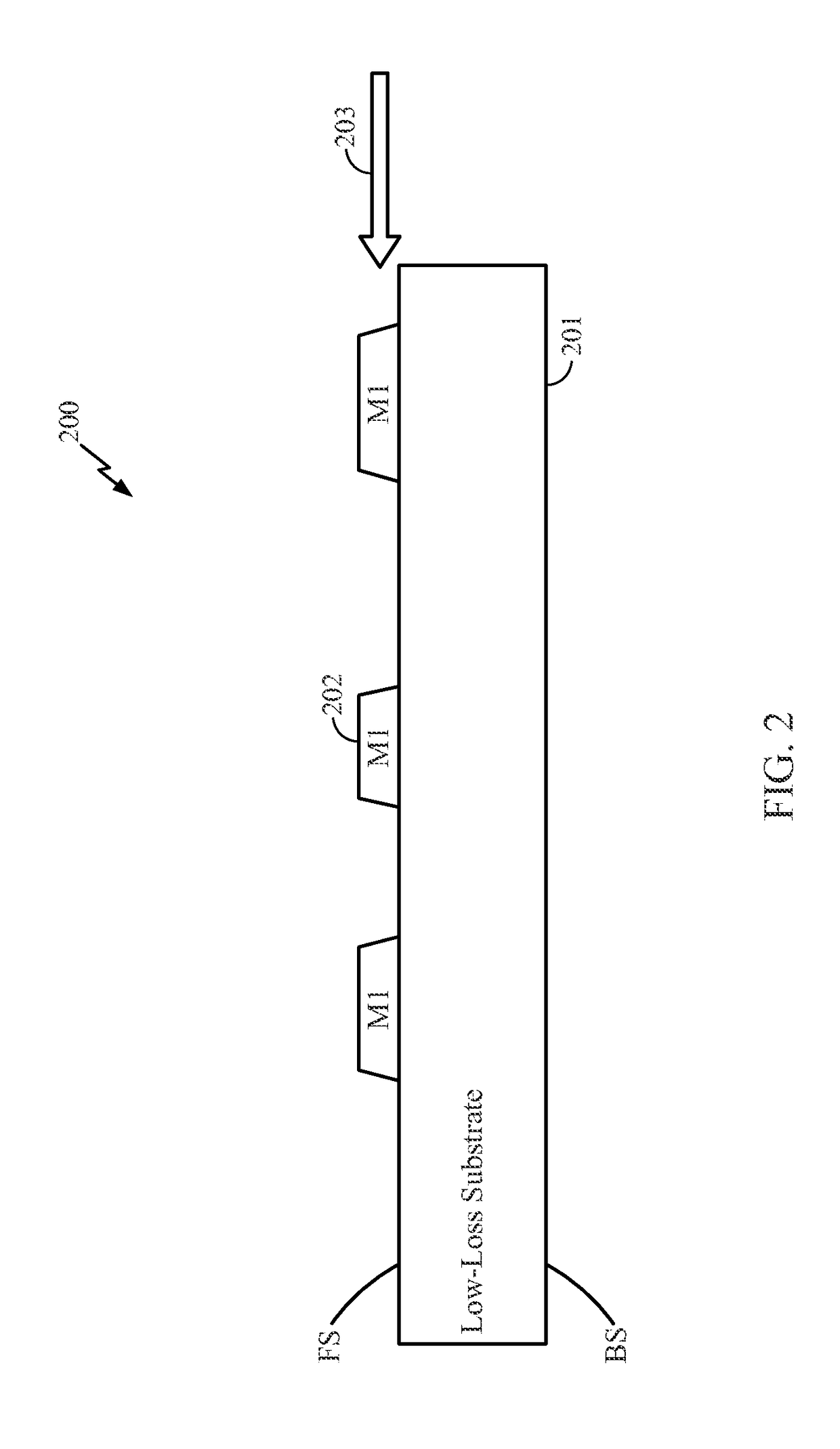

High capacitance density vertical natural capacitors

InactiveUS7466534B2Effective gap distanceIncrease capacitance densityTransistorThin/thick film capacitorDielectricCapacitance

Disclosed are embodiments of a capacitor with inter-digitated vertical plates and a method of forming the capacitor such that the effective gap distance between plates is reduced. This gap width reduction significantly increases the capacitance density of the capacitor. Gap width reduction is accomplished during back end of the line processing by masking connecting points with nodes, by etching the dielectric material from between the vertical plates and by etching a sacrificial material from below the vertical plates. Etching of the dielectric material from between the plates forms air gaps and various techniques can be used to cause the plates to collapse in on these air gaps, once the sacrificial material is removed. Any remaining air gaps can be filled by depositing a second dielectric material (e.g., a high k dielectric), which will further increase the capacitance density and will encapsulate the capacitor in order to make the reduced distance between the vertical plates permanent.

Owner:GLOBALFOUNDRIES INC

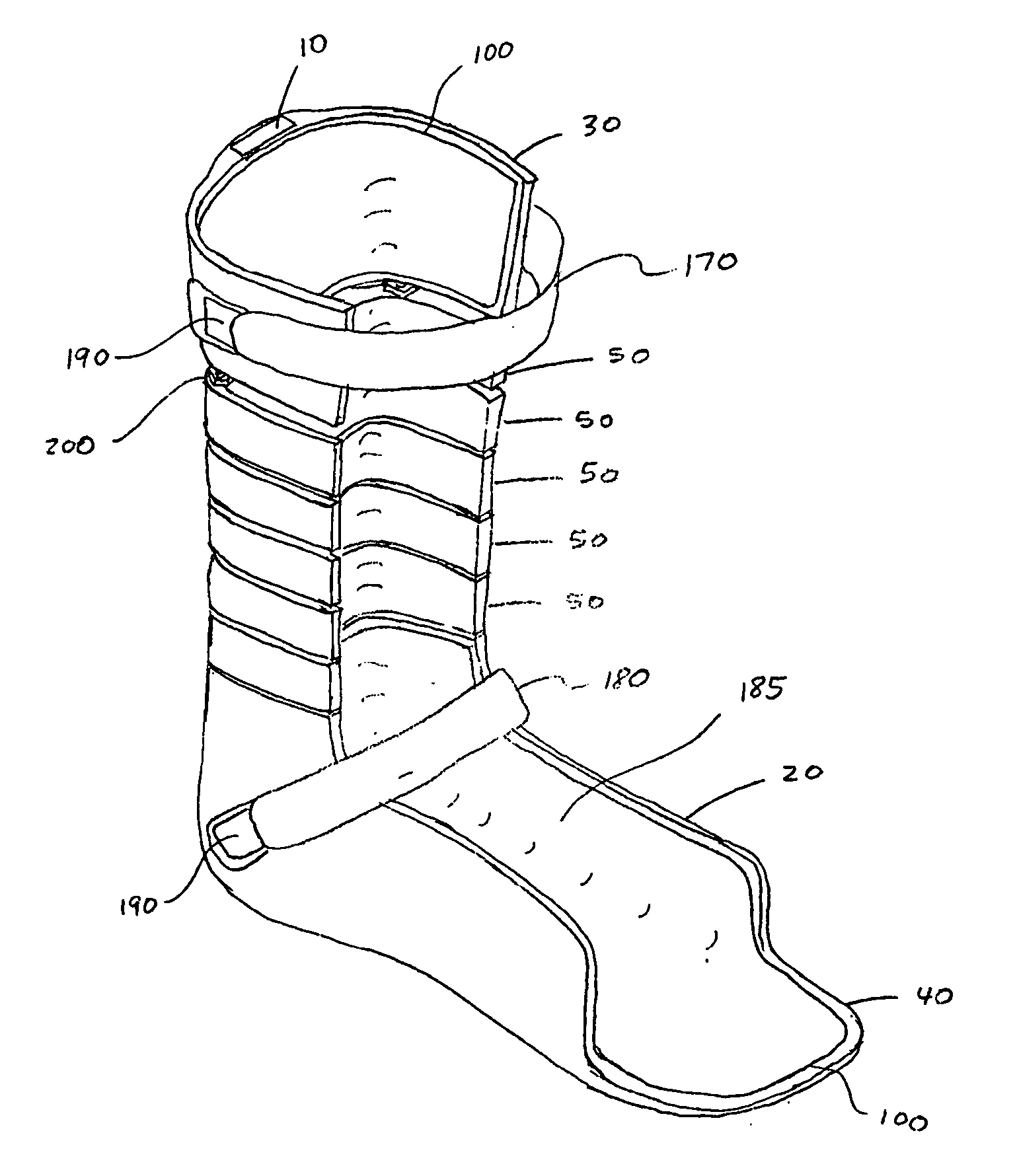

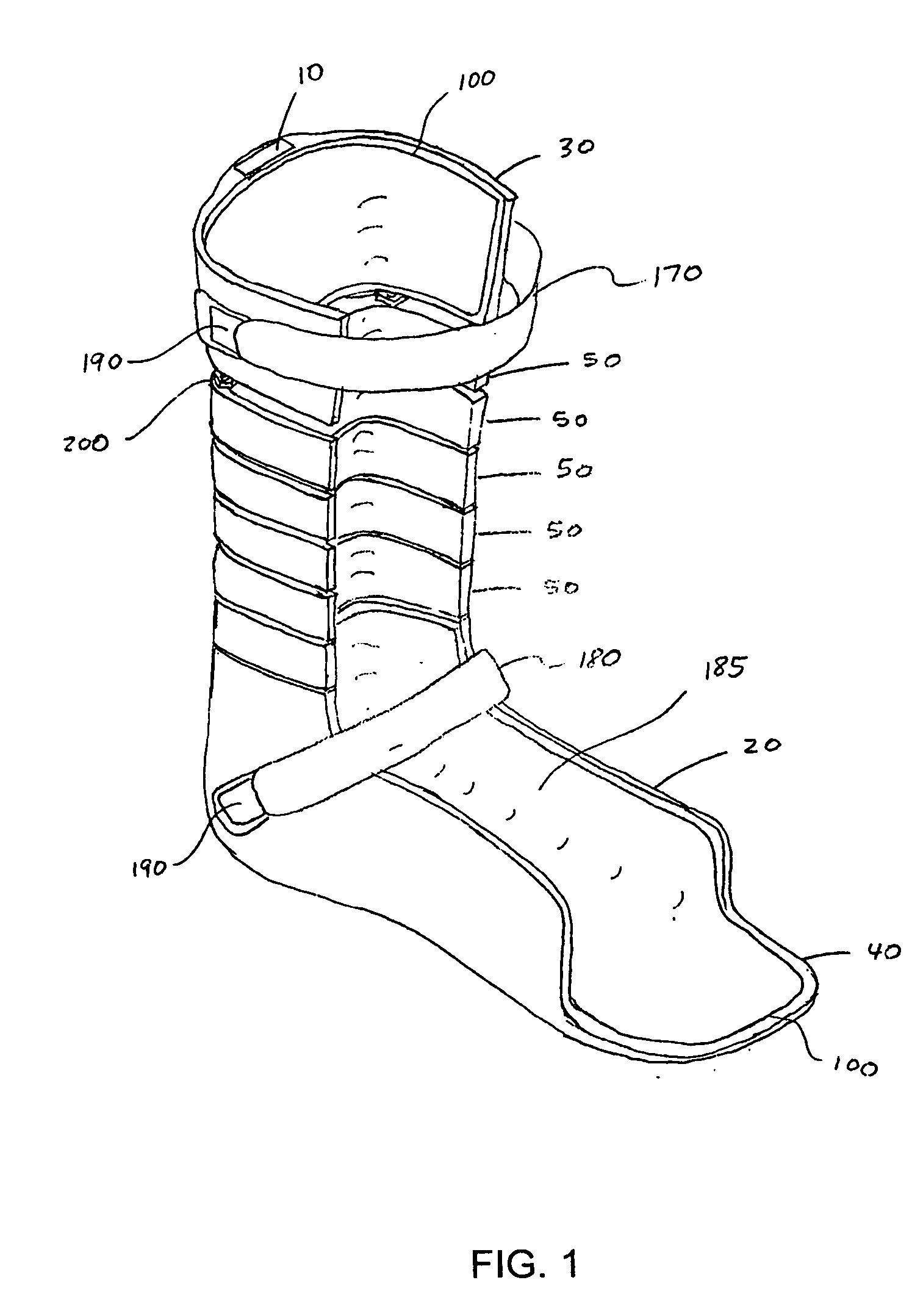

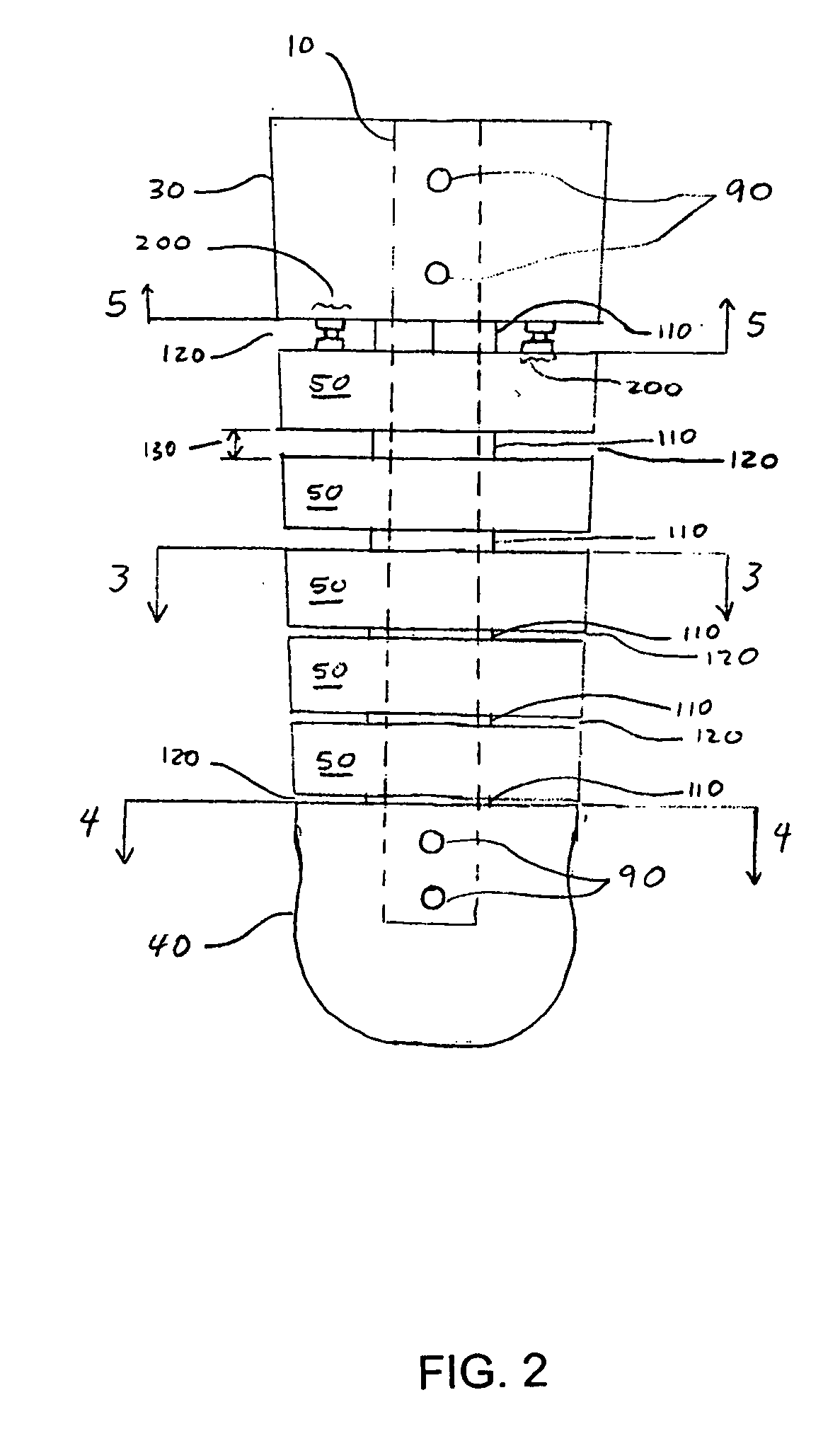

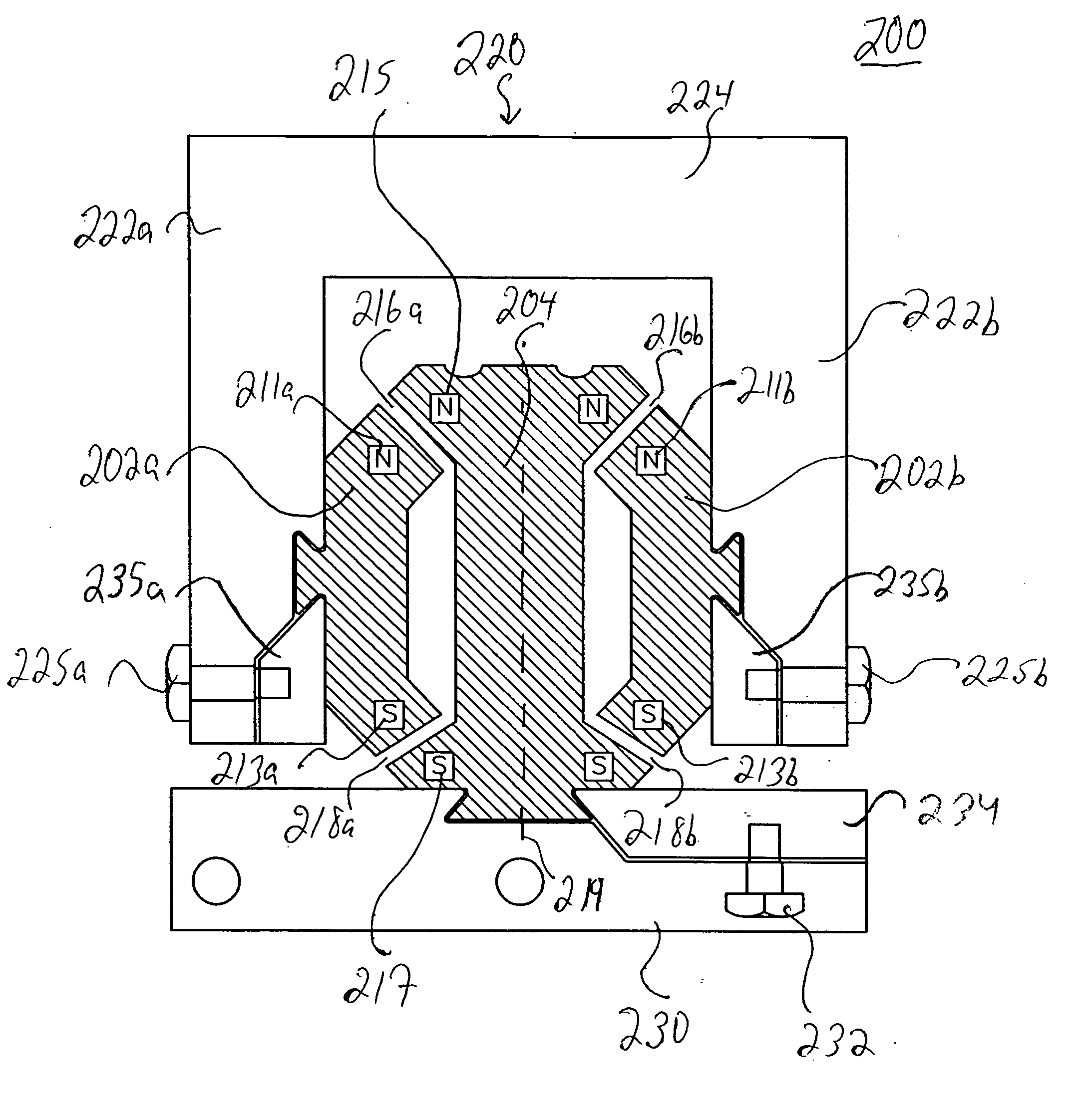

Ankle-foot orthosis

ActiveUS20050273028A1Expanding and narrowing width of gapIncrease stiffnessNon-surgical orthopedic devicesFoot dorsiflexionCattle calf

An ankle-foot orthosis for aiding or enhancing a user's foot and ankle movement, wherein the orthosis comprises at least one strut member, a calf shell, a foot shell, and a plurality of segments. Gaps formed between adjacent segments, an uppermost segment and the calf shell, and a lowermost segment and the foot shell have gap widths, wherein gaps at a higher location have larger gap widths than those at a lower location. Therefore, in dorsiflexion, the gaps close in series from bottom to top, gradually increasing the orthosis stiffness, creating a progressive dorsiflexion stop, and decreasing the magnitude of loads transferred into the user. In plantar flexion, the gaps similarly decrease in series from bottom to top, gradually increasing the orthosis stiffness, creating a progressive plantar flexion stop, and decreasing the magnitude of loads transferred into the user.

Owner:RONAN REYNOLDS +2

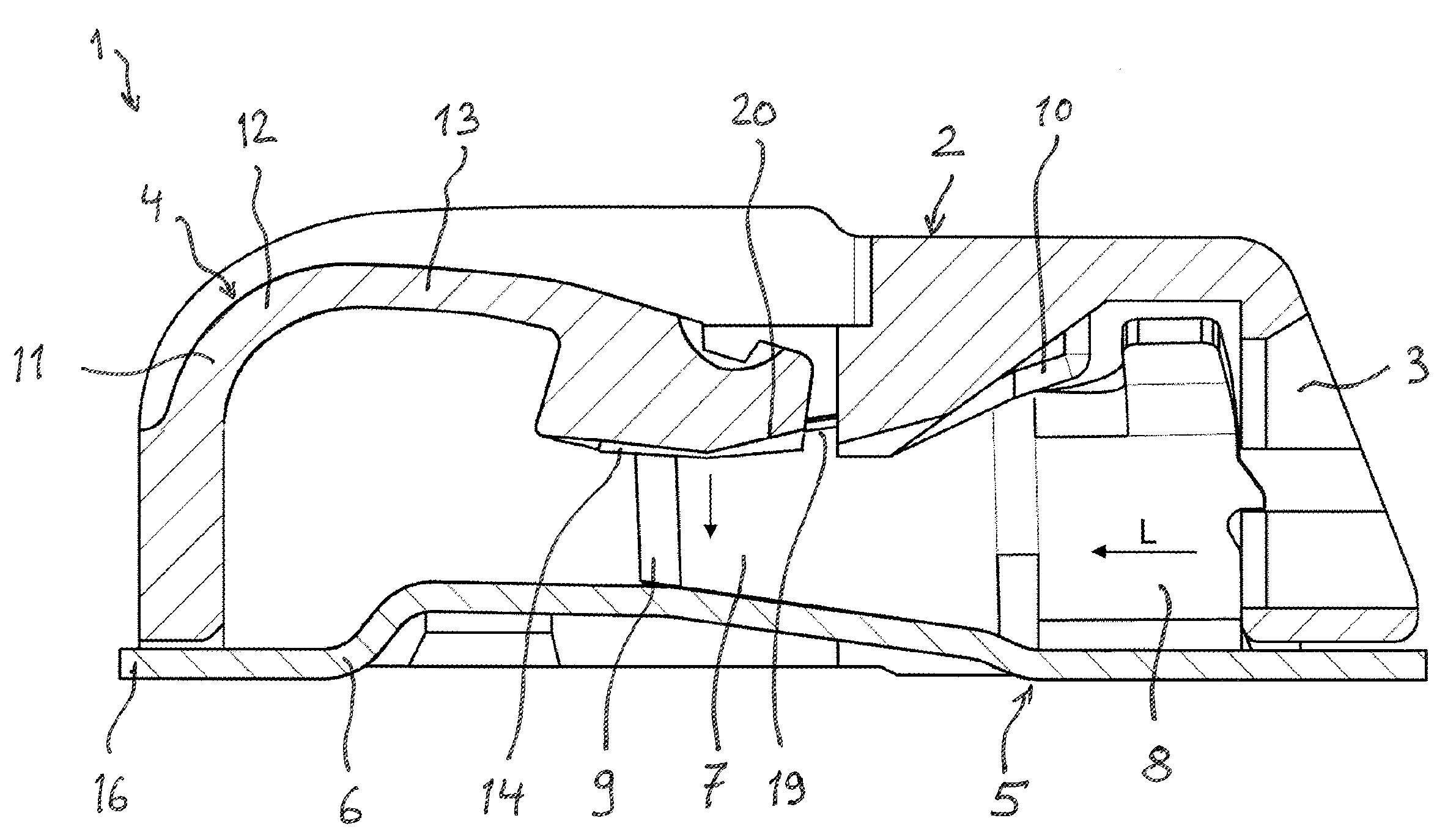

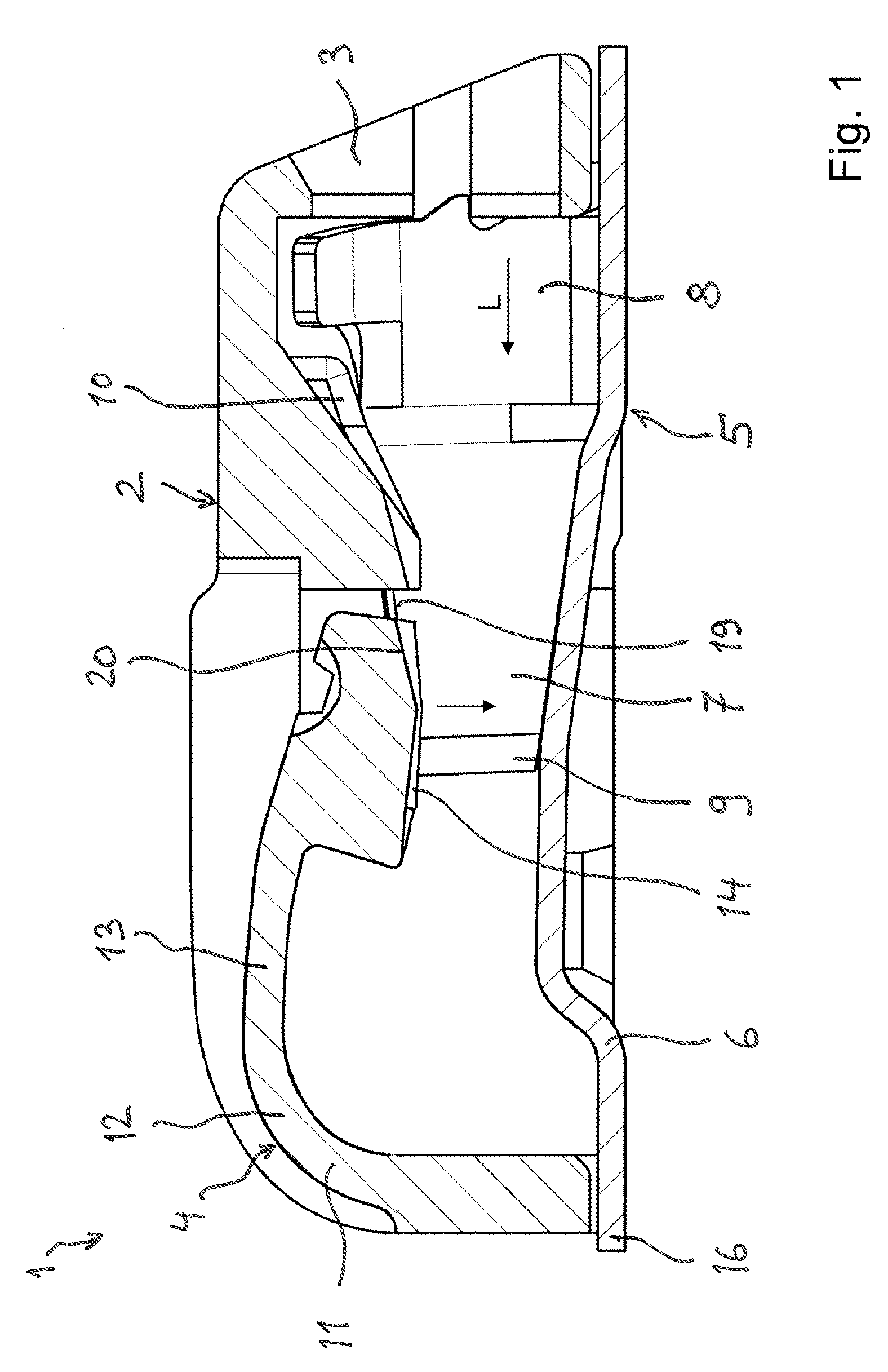

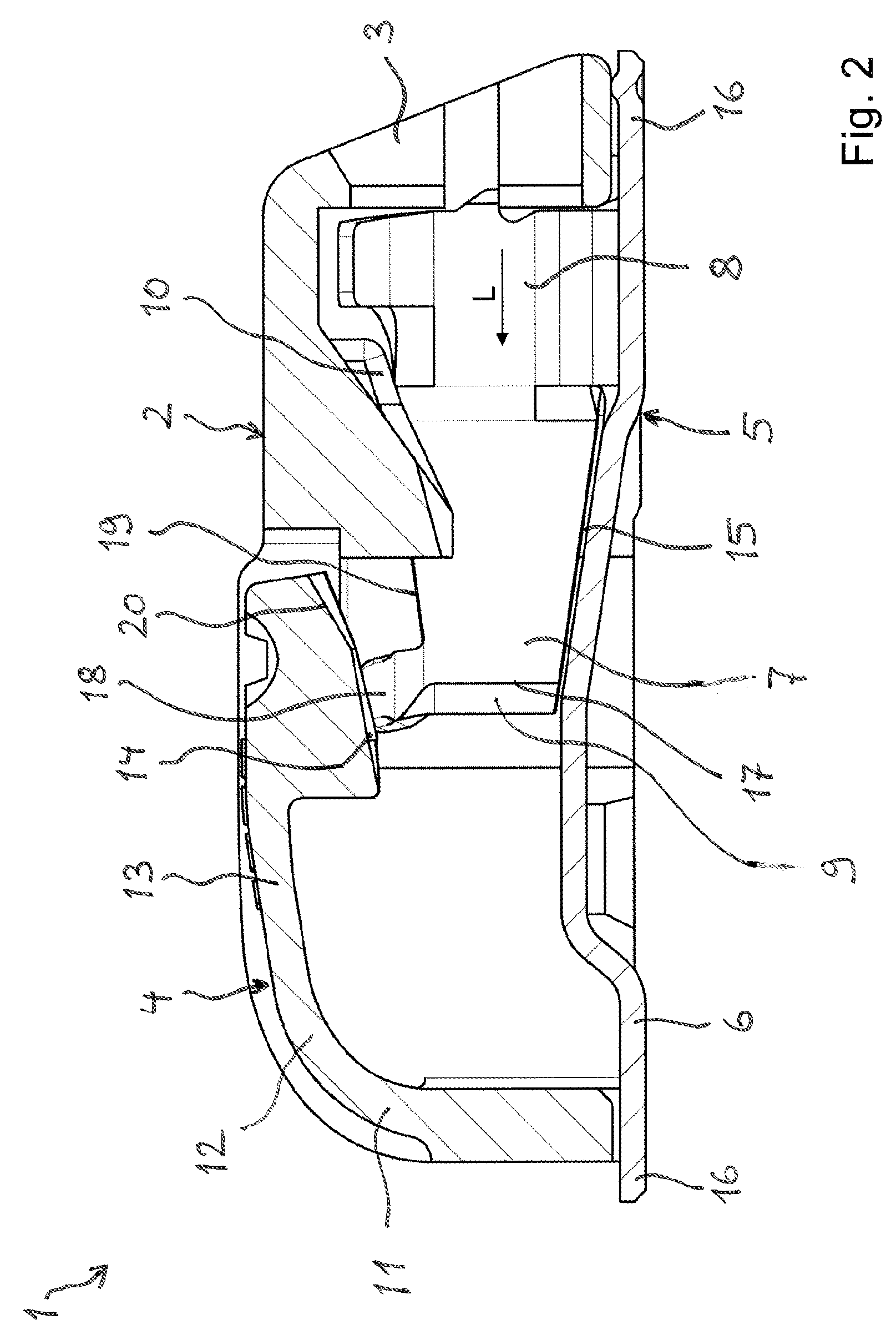

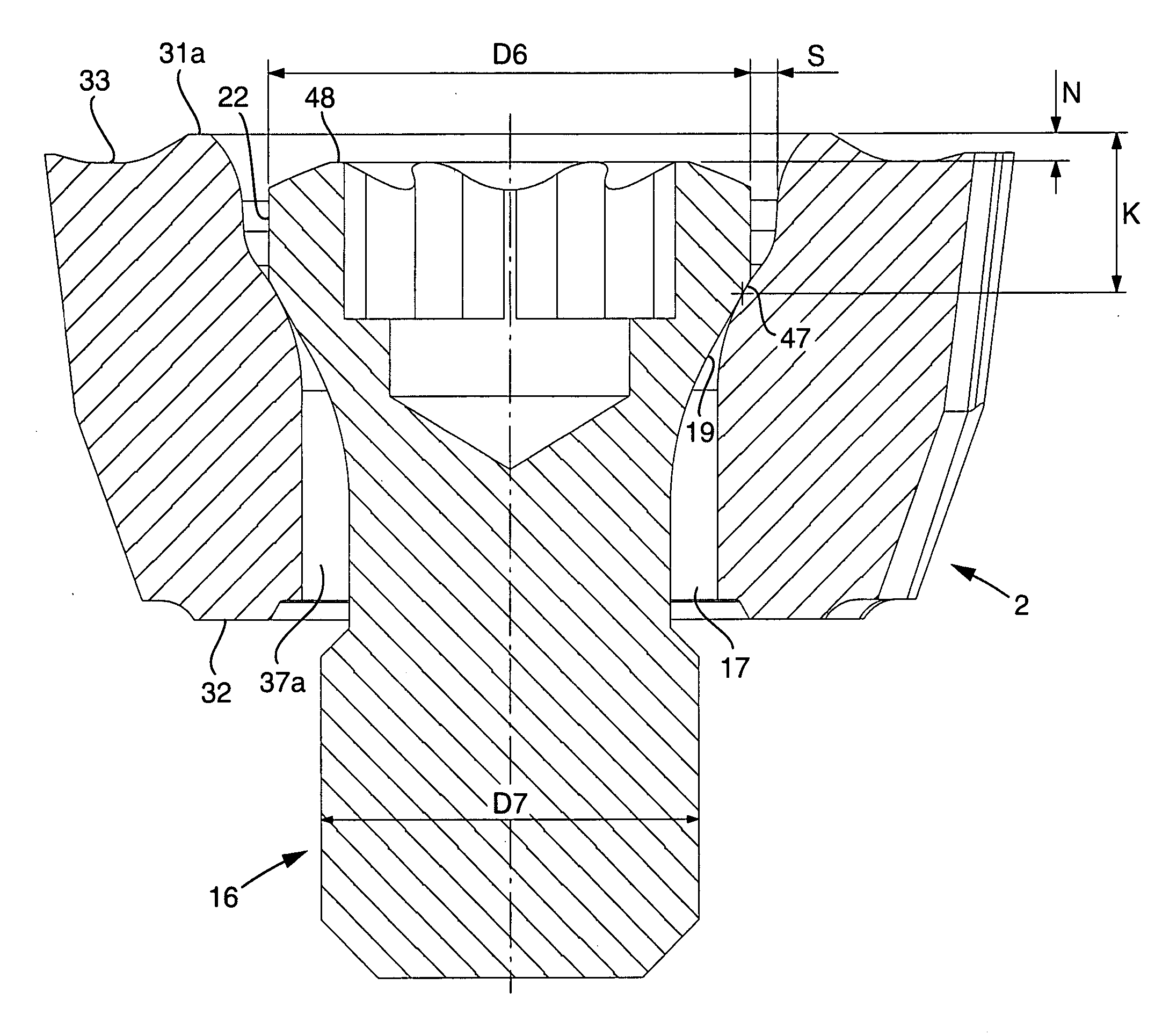

Conductor connection terminal having improved overload protection

ActiveUS9209530B2Reduce the gap widthClearly noticeableElectric discharge tubesCoupling contact membersElectrical conductorSpring force

A conductor connection terminal (1) comprising an insulating housing (2) and comprising at least one spring-force clamping connection (5) in the insulating housing (2) for making the terminal connection of an electrical conductor is described. The spring-force clamping connection (5) has a base plate (6) and at least one spring tongue (7), which is at an angle to the base plate (6), is connected in a root region (8) to the base plate (6) and extends with its tongue end (9), which is movable in spring-elastic fashion, in a conductor plug-in direction (L). The free tongue end (9) is spaced apart from the base plate (6) by a gap (15). The insulating housing (2) has at least one actuating pushbutton (4), which interacts with the tongue end (9) opposite the base plate (6) and has an actuating section (14), which extends in the direction towards the base plate (6), for deflecting the spring tongue (7) transversely to the direction of extent of the spring tongue (7). The actuating pushbutton (4) has at least one resting section (20), which is designed in each case at an associated tongue end (9) to rest on a lateral peripheral edge (19) of the associated tongue end (9) and to shift the tongue end (9) in the direction of the base plate (6) whilst reducing the width of the gap (15) when the actuating pushbutton (4) is shifted in the direction of the base plate (6) so as to open a clamping connection formed by the spring tongue (7) for an electrical conductor of which a terminal connection is intended to be made.

Owner:WAGO VERW GMBH

Drill and drill a cutting insert

InactiveUS20070201962A1Smoothly pass mouth surfaceRisk minimizationThread cutting toolsWood turning toolsFluteEngineering

A drill for chip removing machining, including a drill body, and a replaceable cutting insert mounted in a pocket formed in a front tip of the drill body. A chip flute extends backwardly from the pocket along the drill body, and the cutting insert is fixed in the pocket by a screw including a head and a shank having a male thread. The cutting insert includes a through hole extending between a topside and an underside. The hole has a basic shape that is rotationally symmetrical in relation to a center axis, and is delimited by a series of surfaces including a mouth surface, converging downward from the topside, and a shoulder surface. The head of the screw is kept pressed against the shoulder surface when the male thread of the screw is tightened in a female thread included in a hole that mouths in a bottom of the pocket. The mouth surface in the hole of the cutting insert has a trumpet-like, cross section-wise convex shape adjacent to the topside of the cutting insert.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

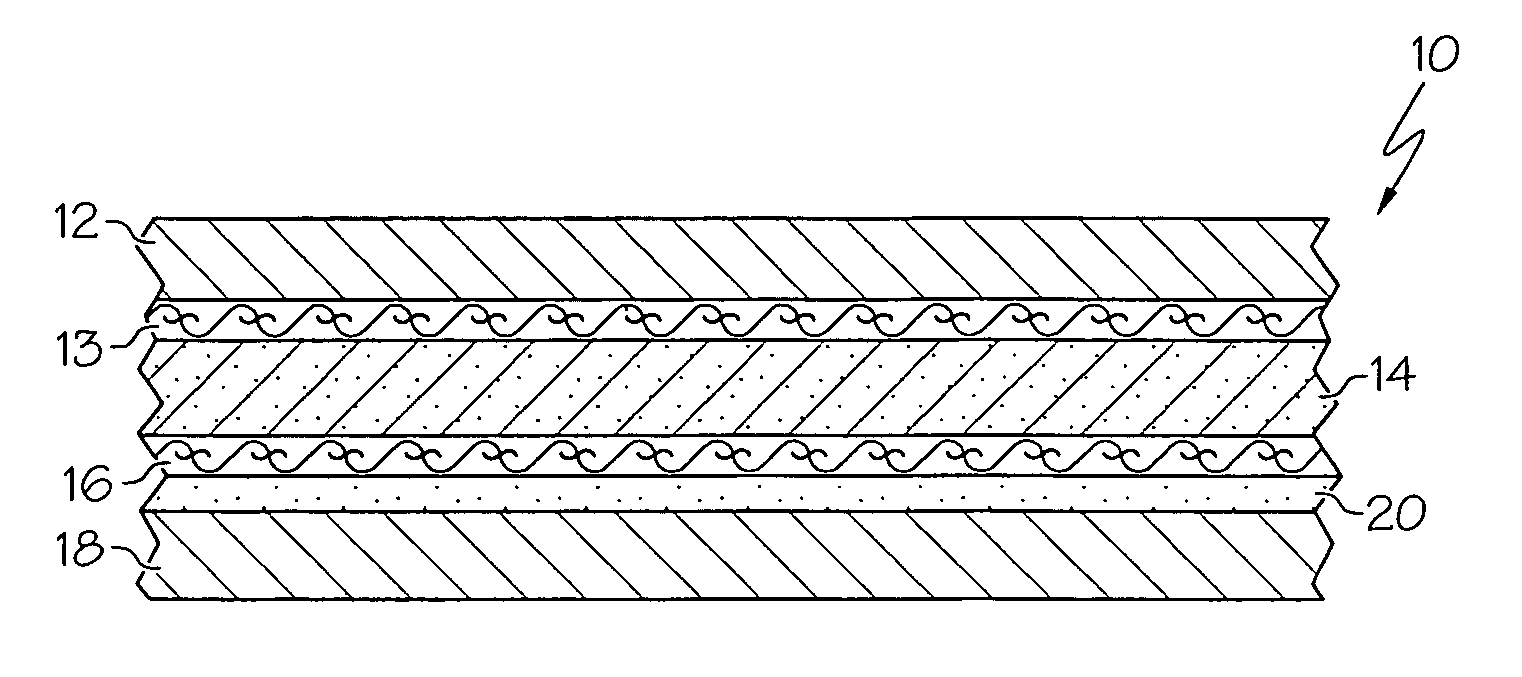

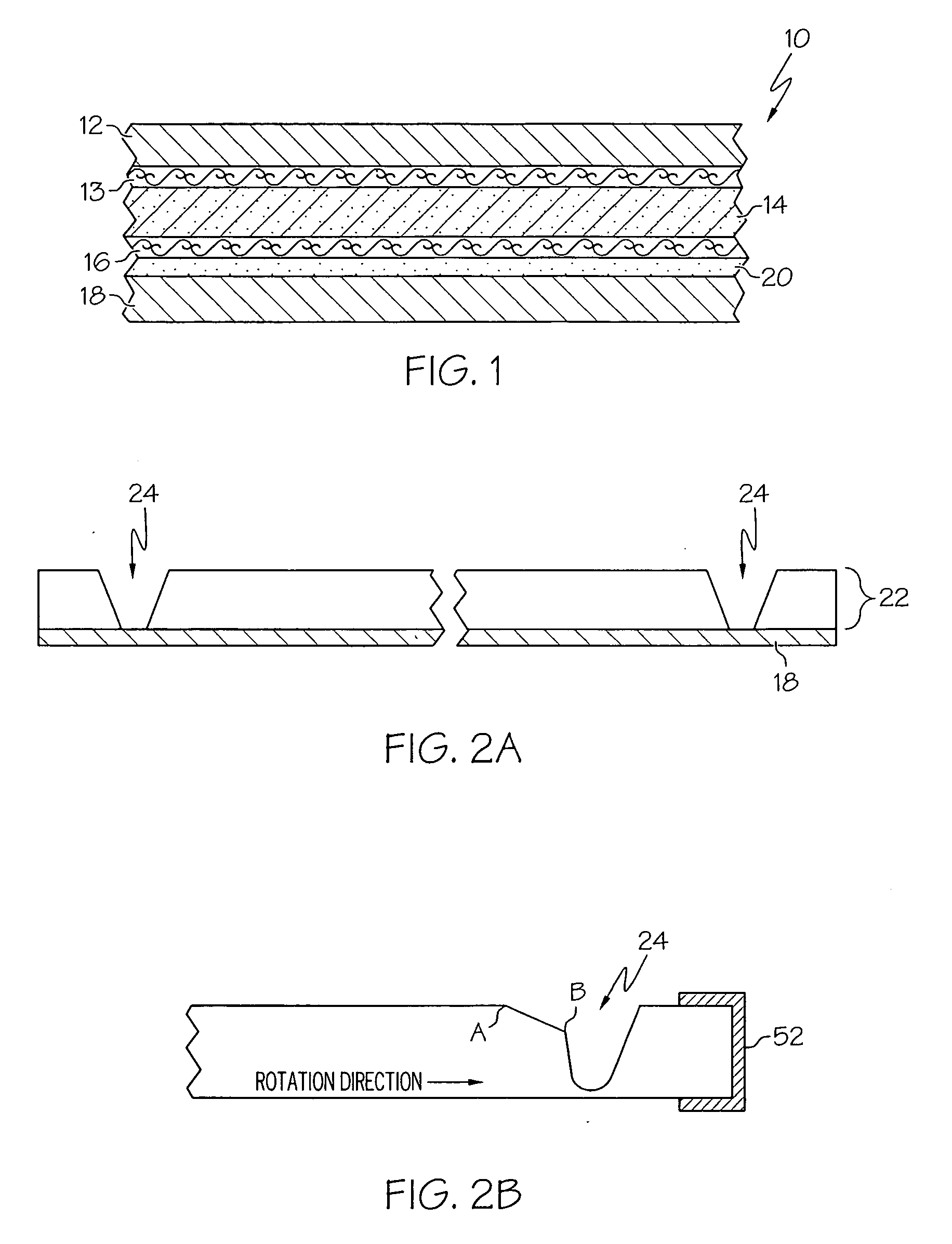

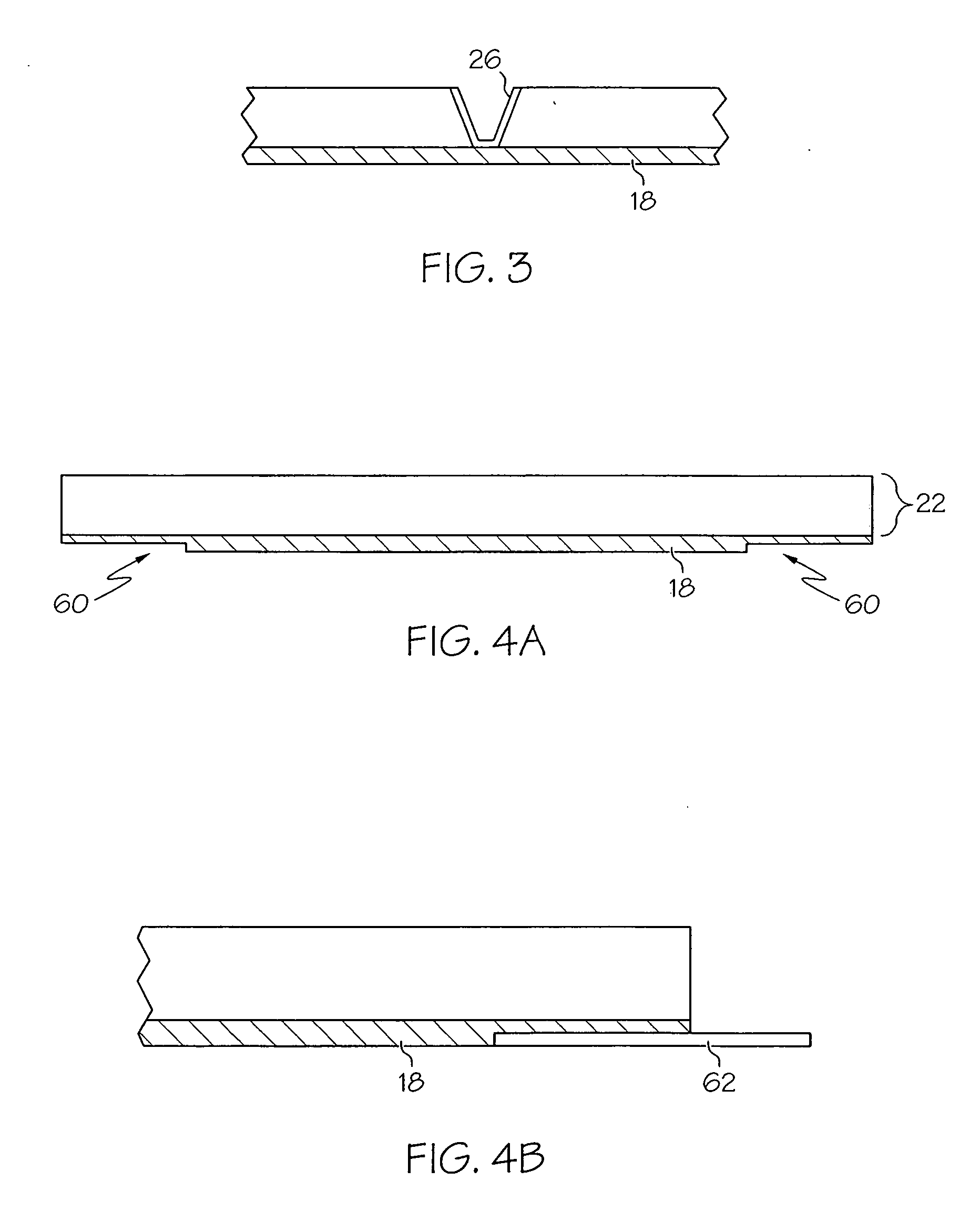

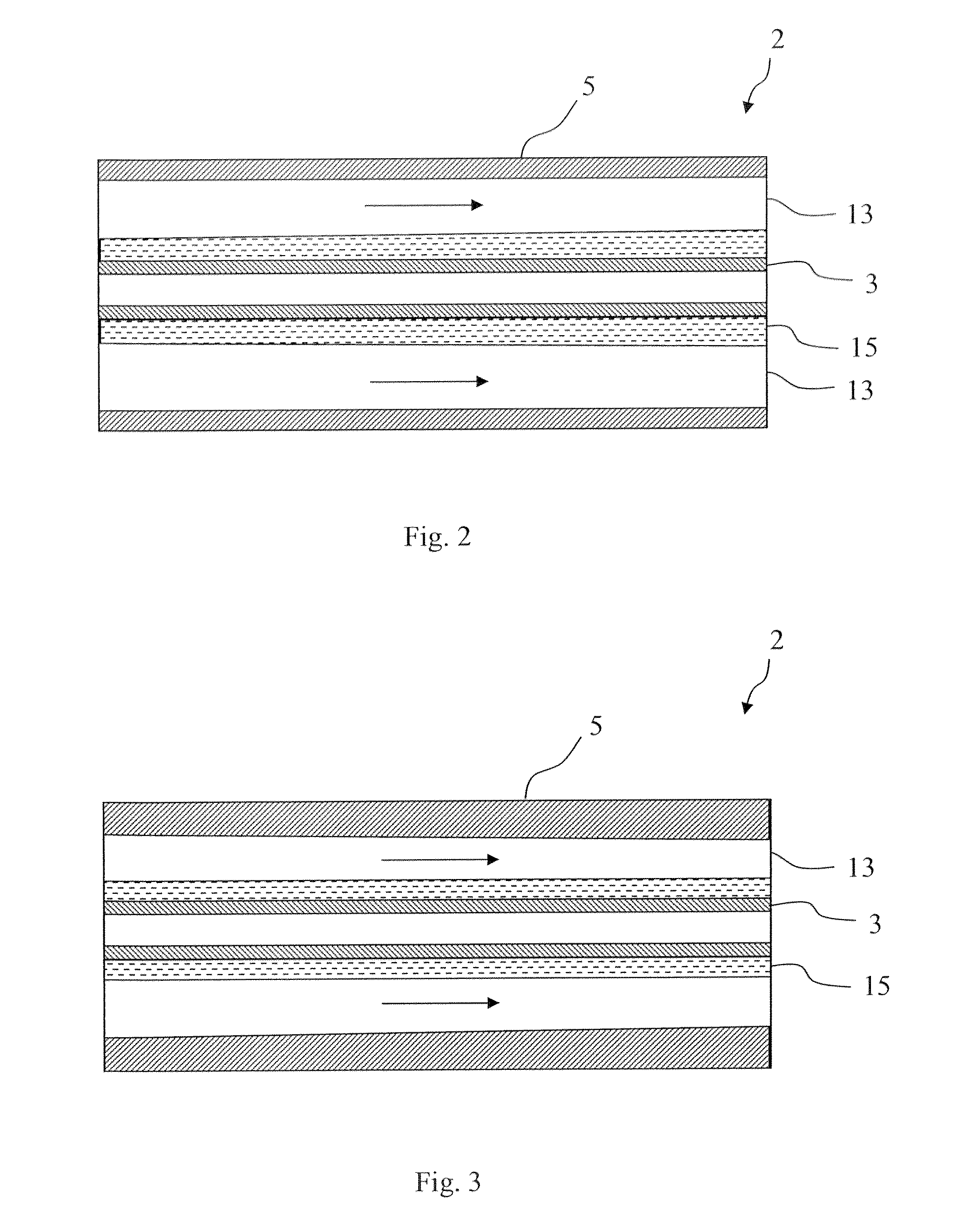

Printing blanket including a non-extensible backing layer and a relief area which may be mounted in a variety of lockup mechanisms

InactiveUS20070101884A1Gauge of the blanket to be reducedReduce the gap widthRotary pressesPrinting blanketsEngineeringPrinting press

A printing blanket is provided which may include a printable surface ply, a compressible ply, one or more reinforcing fabric plies, and a non-extensible backing layer comprising a polymeric material. The printing blanket has first and seconds ends which are adapted to be inserted into the gap of a printing blanket cylinder, where each of the first and second ends may include a relief area formed by removing or molding a portion of the blanket or by removing or molding a portion of the non-extensible backing layer such that the blanket may be mounted in a wide variety of printing presses using a number of different lock-up mechanisms.

Owner:DAY INT

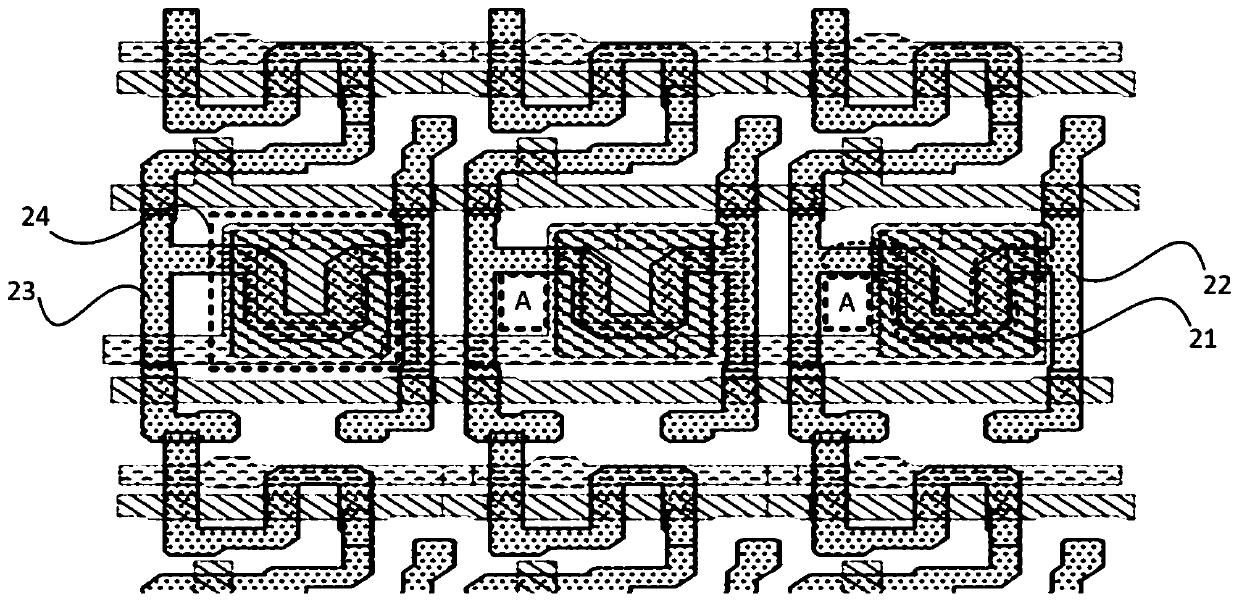

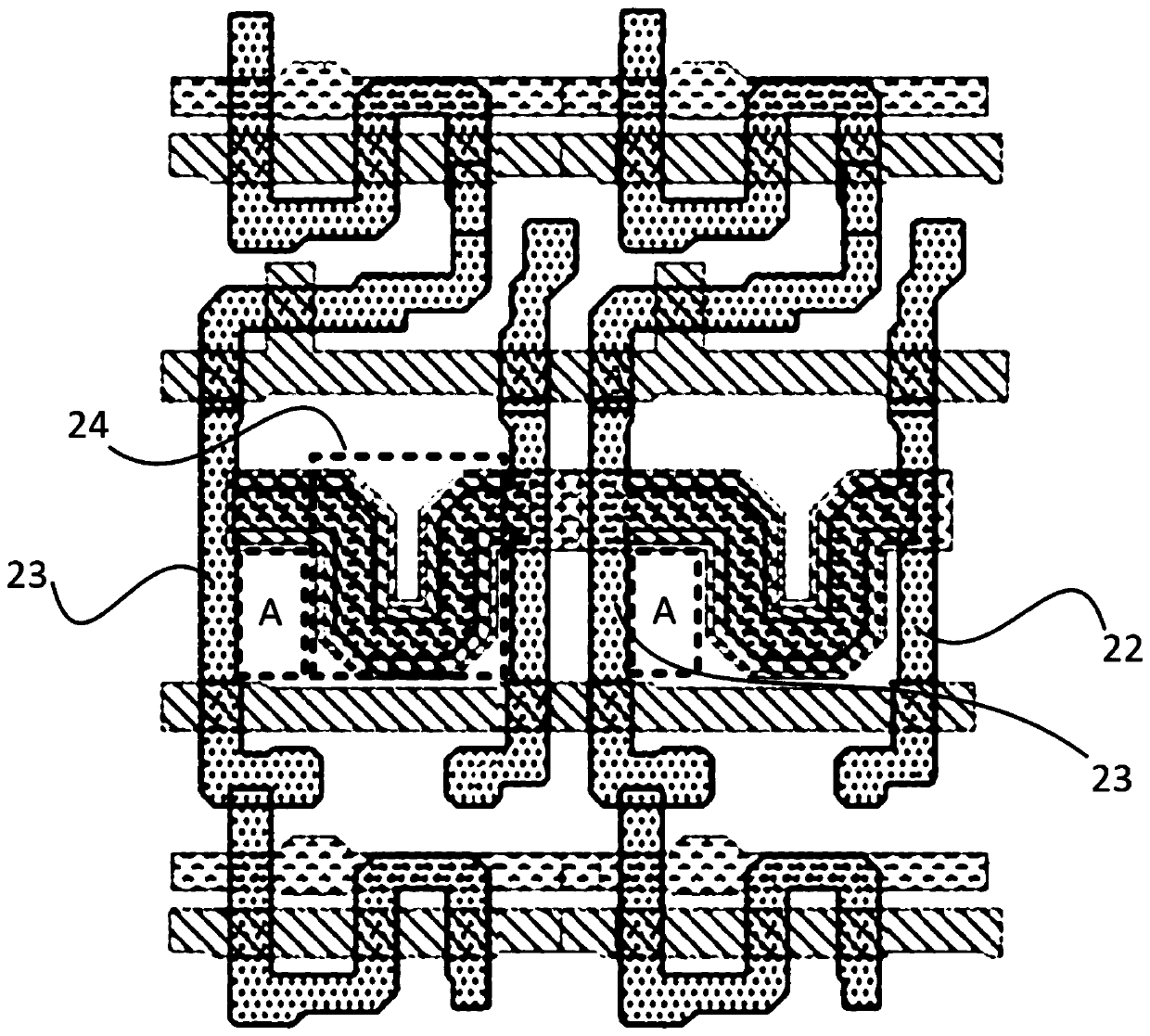

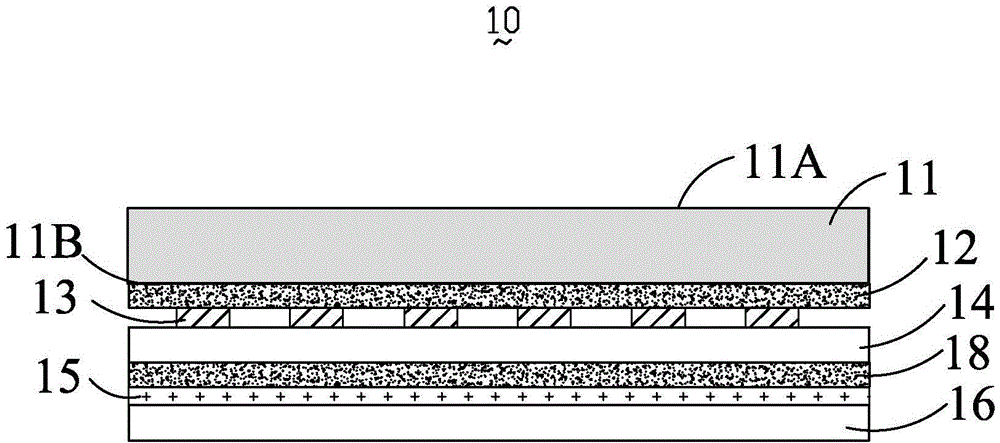

Display panel and display device

ActiveCN110188744AIncrease light transmission areaDiffraction reductionStatic indicating devicesSolid-state devicesCapacitanceImaging quality

The invention provides a display panel and a display device, being characterized in that a fingerprint identification area of the display panel comprises a substrate layer and a pixel circuit; the pixel circuit comprises a DTFT unit, a source electrode wire, a drain electrode wire and a capacitor unit which are arranged on the substrate layer; a source region of the DTFT unit is connected with thesource electrode wire; a drain region of the DTFT unit is connected with the drain electrode wire, and a light transmitting region is arranged between a channel region of the DTFT unit and the drainelectrode wire; the projection of the channel region of the DTFT unit on the substrate layer and the projection of the channel region close to the source electrode wire on the substrate layer reduce the width of a gap between the channel region of the DTFT unit and the source electrode wire and increase the distance between the channel region of the DTFT unit and the drain electrode wire, so thatthe light transmission area of a single light transmission region is increased; and the projection of the capacitor unit on the substrate layer covers the projection of the channel region on the substrate layer, so that diffraction of a gap between the channel region and the source electrode wire is reduced, and the under-screen fingerprint imaging quality is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

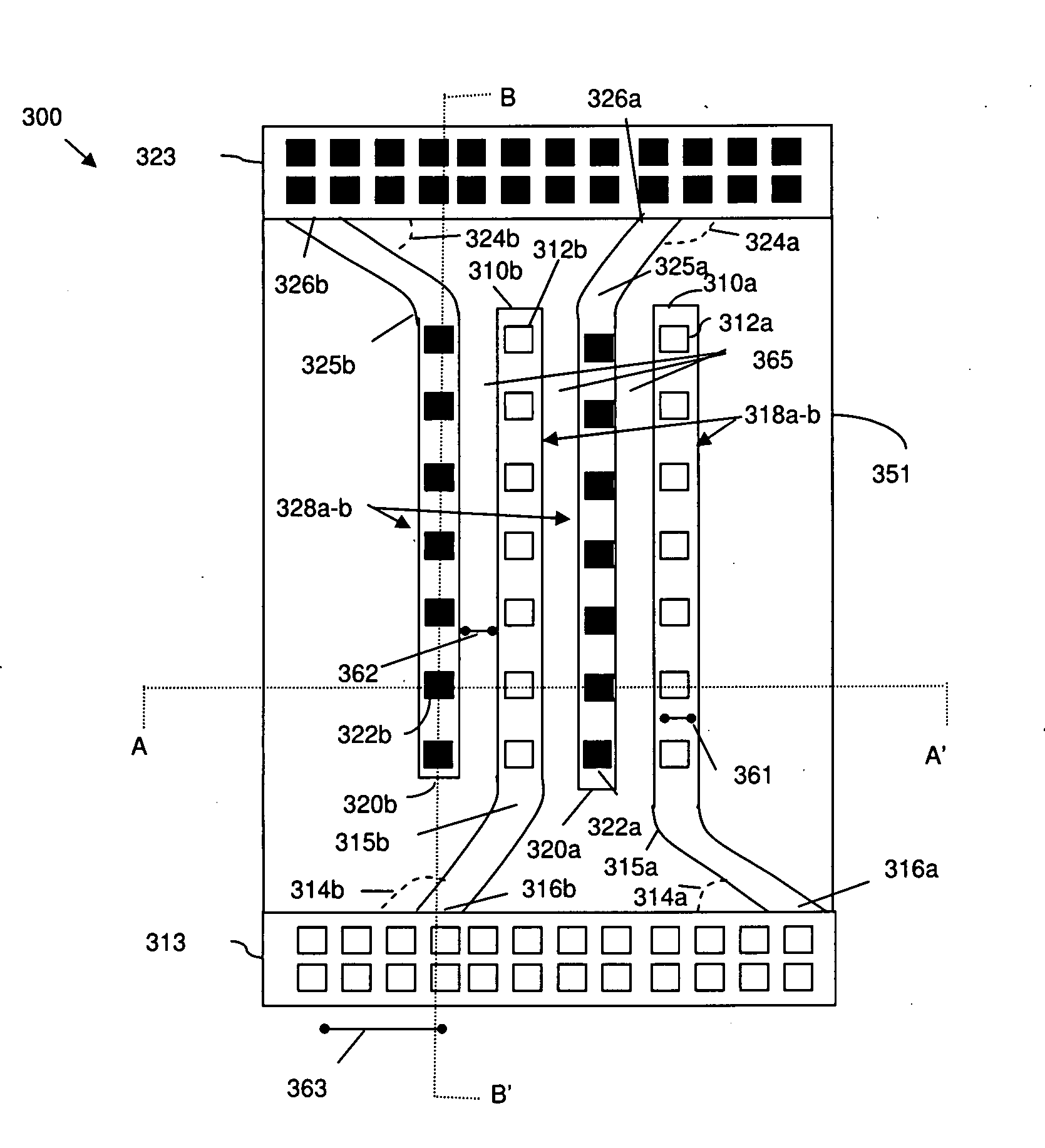

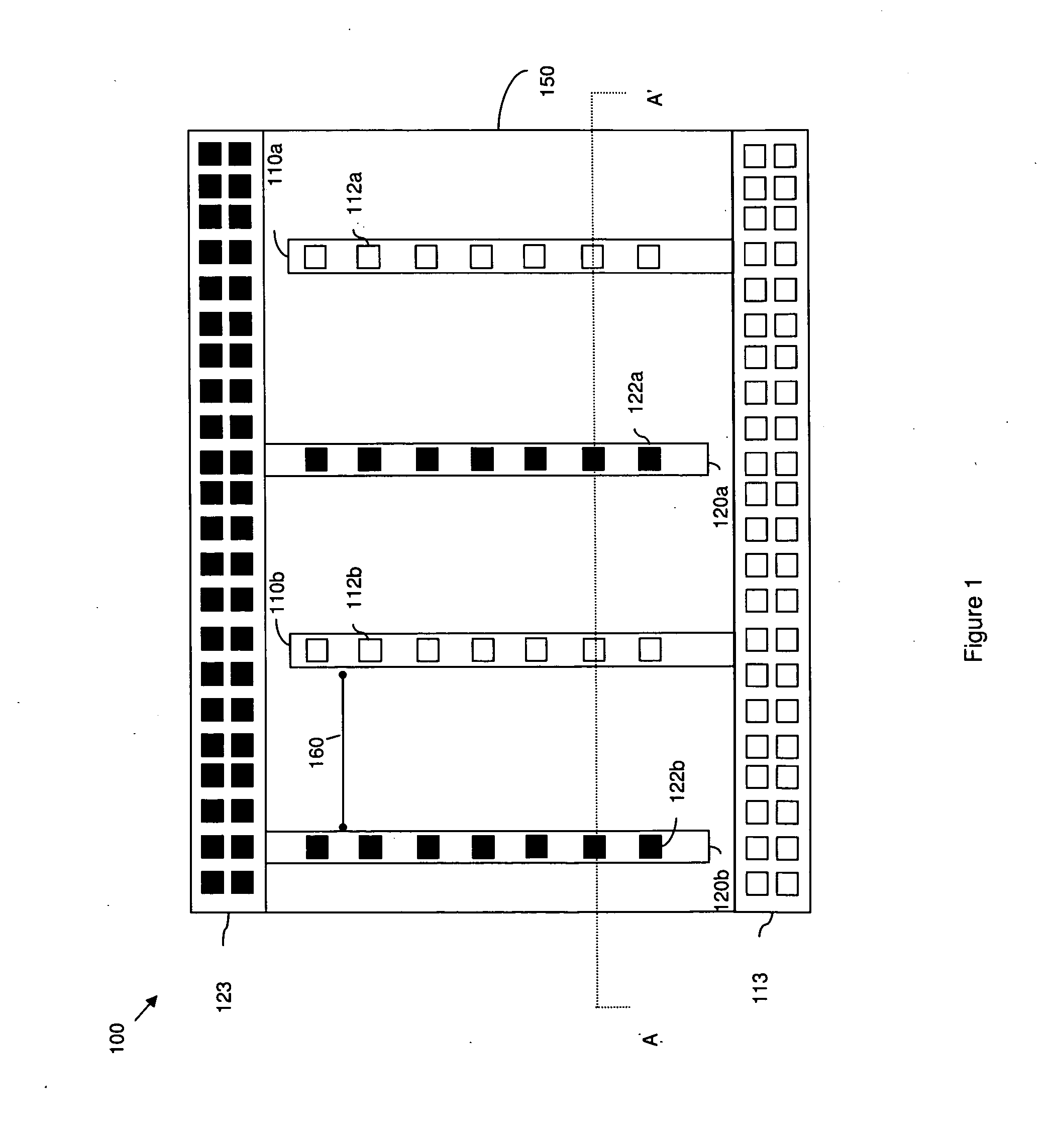

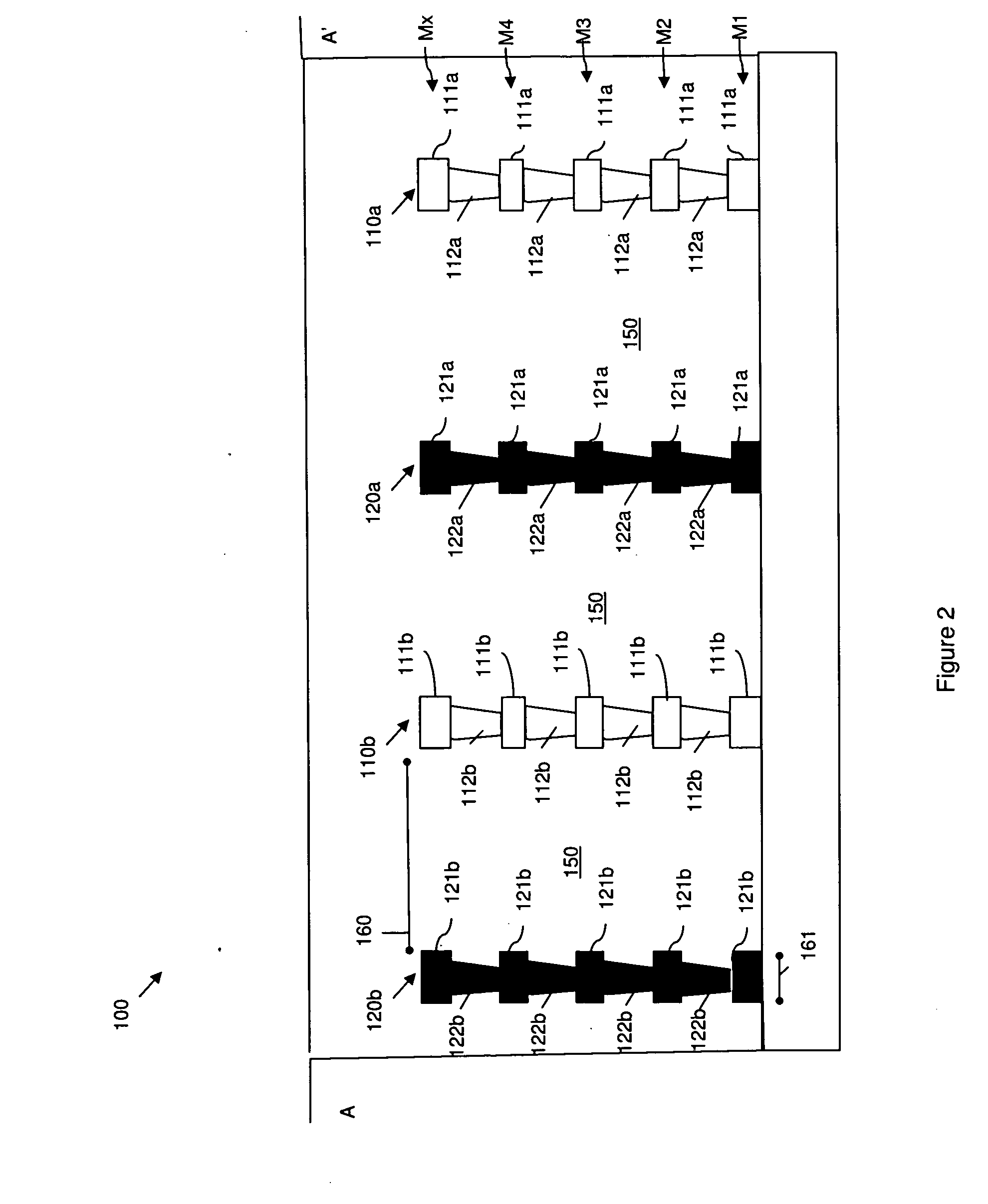

Frequency and/or phase compensated microelectromechanical oscillator

ActiveUS20060022764A1Reduce the gap widthIncreasing available voltage to applyRadiation pyrometryPulse automatic controlFrequency synthesizerFrequency multiplier

There are many inventions described and illustrated herein. In one aspect, the present invention is directed to a compensated microelectromechanical oscillator, having a microelectromechanical resonator that generates an output signal and frequency adjustment circuitry, coupled to the microelectromechanical resonator to receive the output signal of the microelectromechanical resonator and, in response to a set of values, to generate an output signal having second frequency. In one embodiment, the values may be determined using the frequency of the output signal of the microelectromechanical resonator, which depends on the operating temperature of the microelectromechanical resonator and / or manufacturing variations of the microelectromechanical resonator. In one embodiment, the frequency adjustment circuitry may include frequency multiplier circuitry, for example, PLLs, DLLs, digital / frequency synthesizers and / or FLLs, as well as any combinations and permutations thereof. The frequency adjustment circuitry, in addition or in lieu thereof, may include frequency divider circuitry, for example, DLLs, digital / frequency synthesizers (for example, DDS) and / or FLLs, as well as any combinations and permutations thereof.

Owner:ROBERT BOSCH GMBH

Headlights for vehicles

Headlight for motor vehicles, comprising at least one light source and at least one light guide associated with each light source, into which the light emitted by the light source can be coupled via a light coupling surface, wherein each light guide is associated with a light terminator body into which the light from the light guide is passed, wherein the light terminator body has a light output surface and the output light can be imaged through a downstream lens, wherein the at least one light terminator body is fixed on or to a holder and the holder can be pivoted about at least one axis and / or be displaced in at least one plane relative to the at least one lens.

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

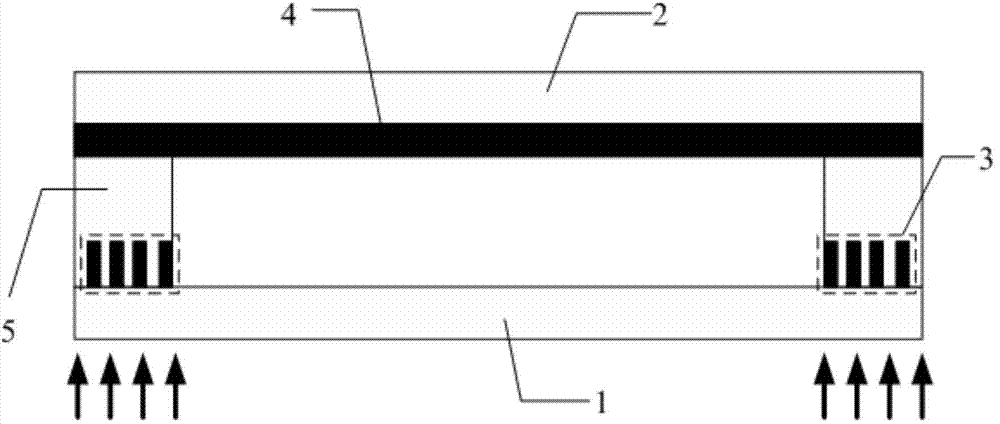

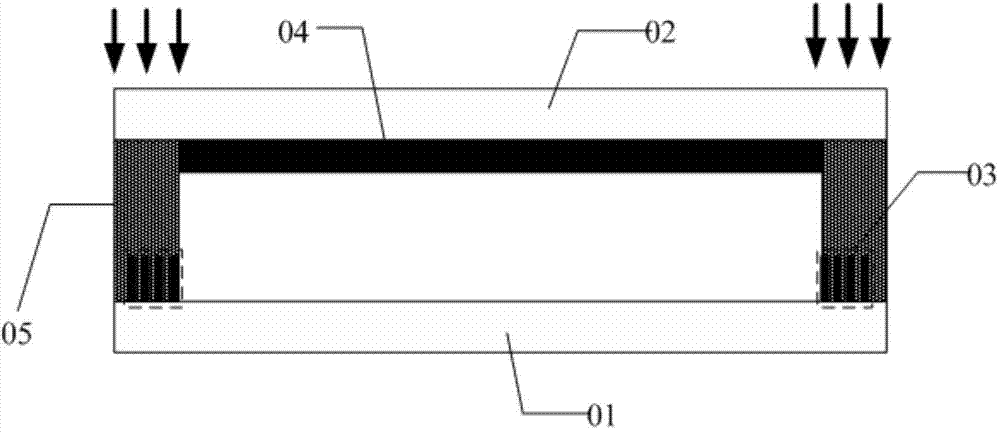

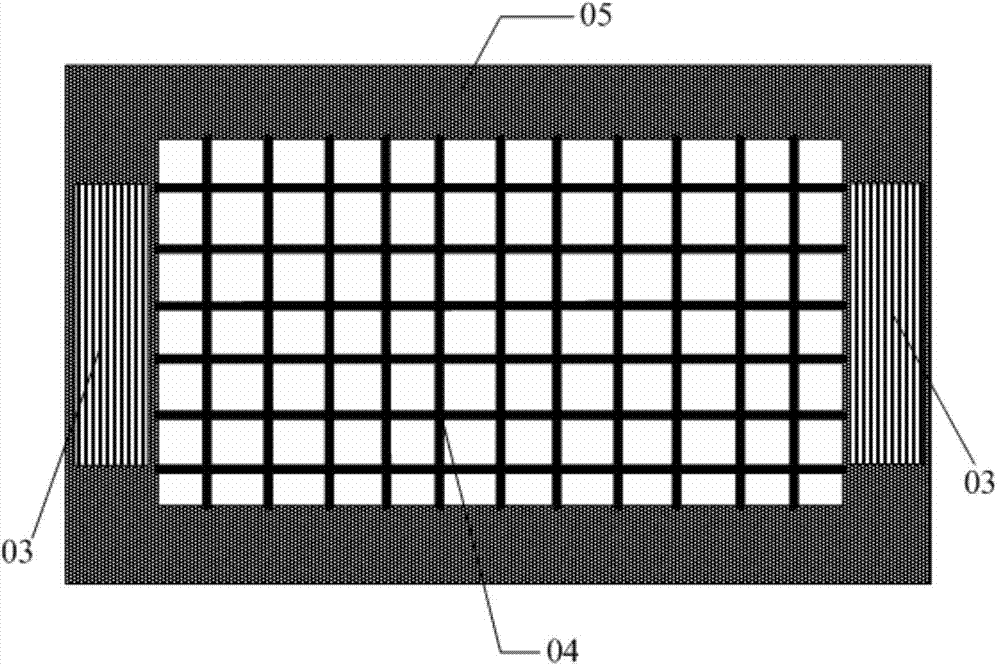

Display panel and manufacturing method thereof and display device

InactiveCN104730739AAvoid light leakageReduce widthNon-macromolecular adhesive additivesCasings with display/control unitsAdhesiveUltraviolet lights

The invention discloses a display panel and a manufacturing method thereof and a display device. Orthographic projection of a drive circuit in a border area and a graph with periphery wires on an array substrate is not overlapped with orthographic projection of a graph of a black matrix in the array substrate, in other words, no black matrixes are arranged in the area where the drive circuit and the graph with the wires are located; therefore, shielding of the black matrixes on ultraviolet light does not needed to be considered, the area where the drive circuit is located and gap width among the periphery wires can be reduced, the width of the border area is reduced, and narrow border design of the display panel is realized; in addition, a border sealing adhesive contains substances formed after discoloration of thermochromism materials with preset concentration during the curing process, so that the border sealing adhesive itself can achieve the effect of preventing the display panel from light leak after the curing treatment although no black matrixes are arranged in the area, where the drive circuit and the graph with the periphery wires are located, of the display panel.

Owner:BOE TECH GRP CO LTD +1

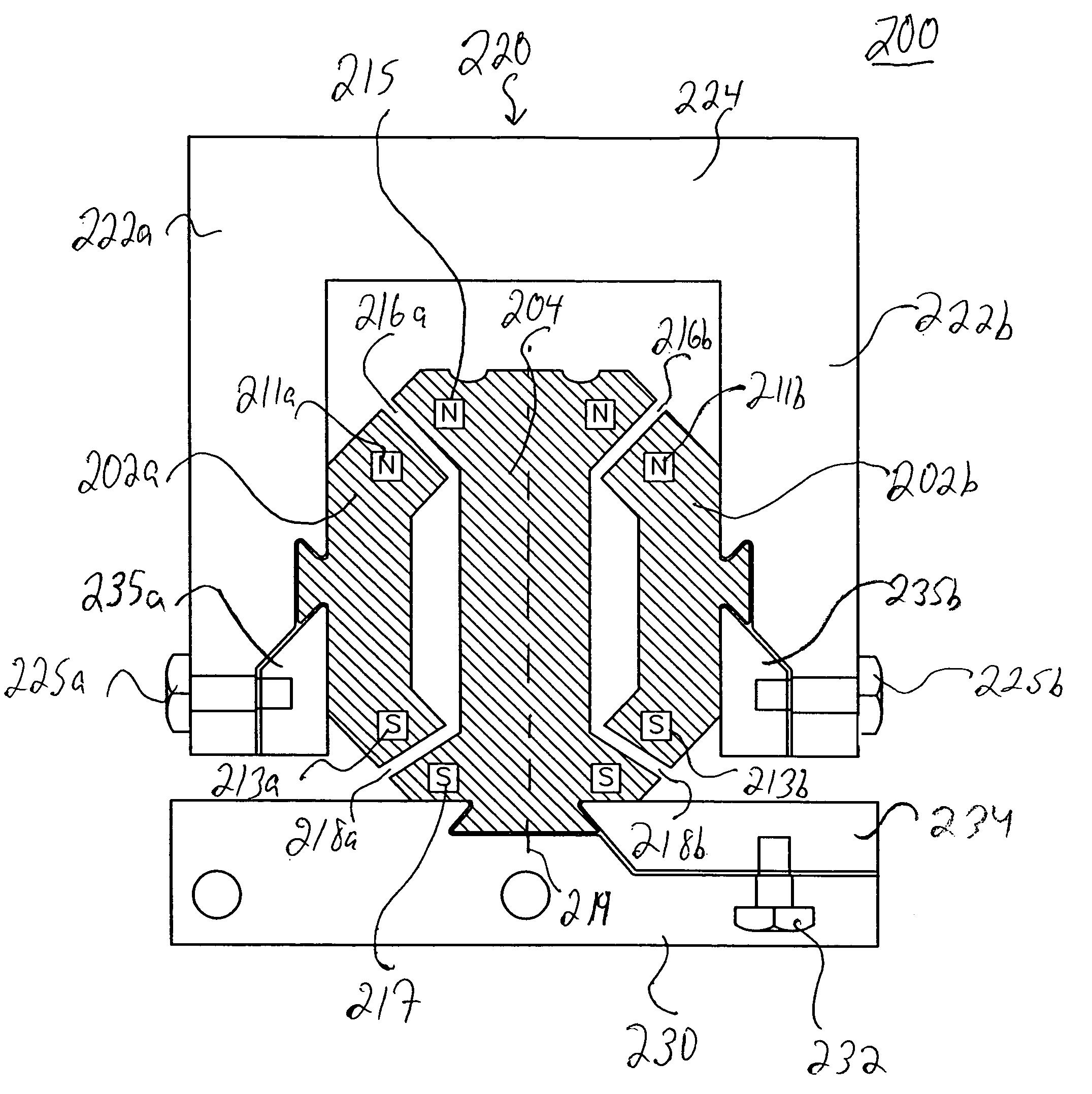

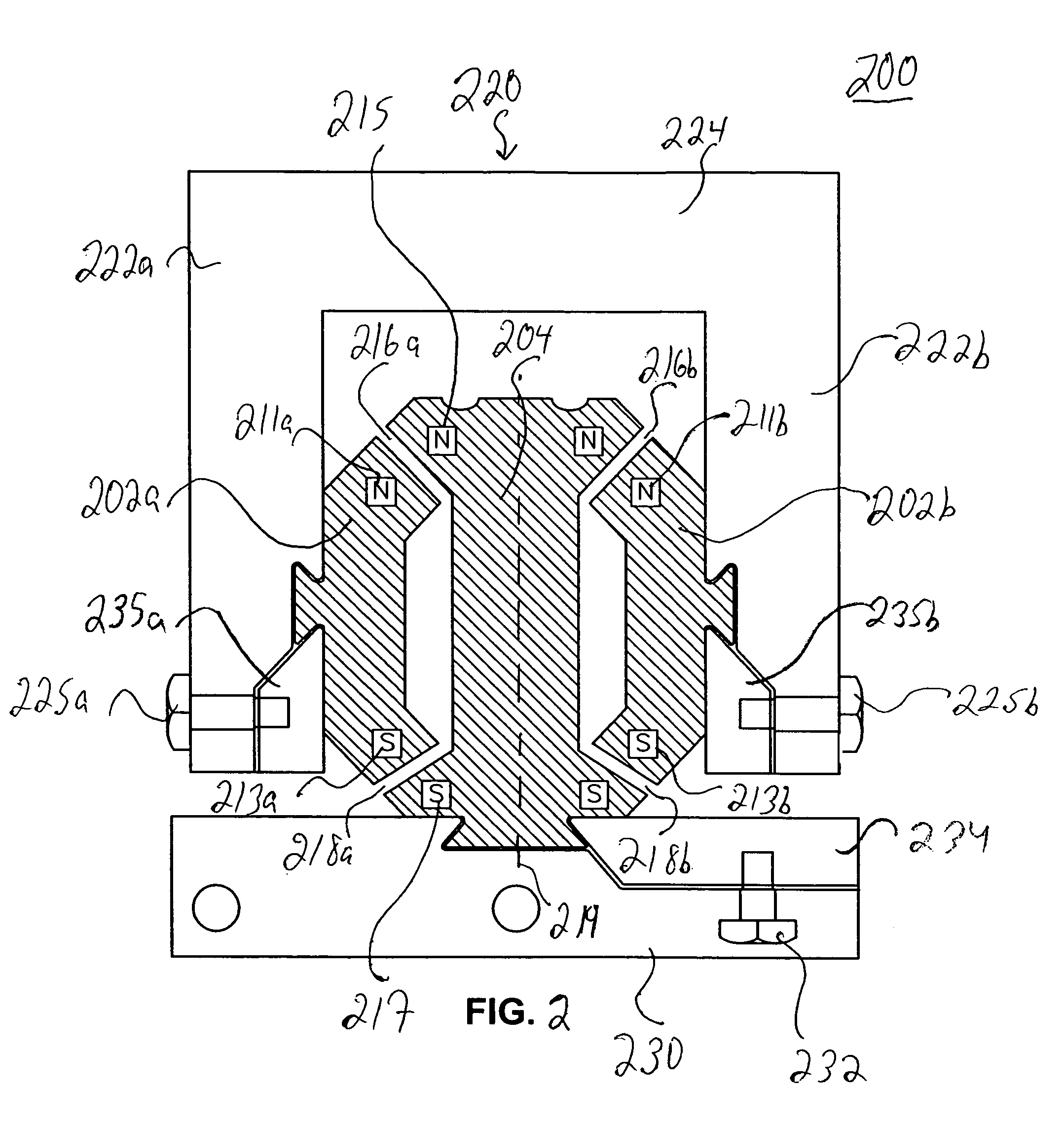

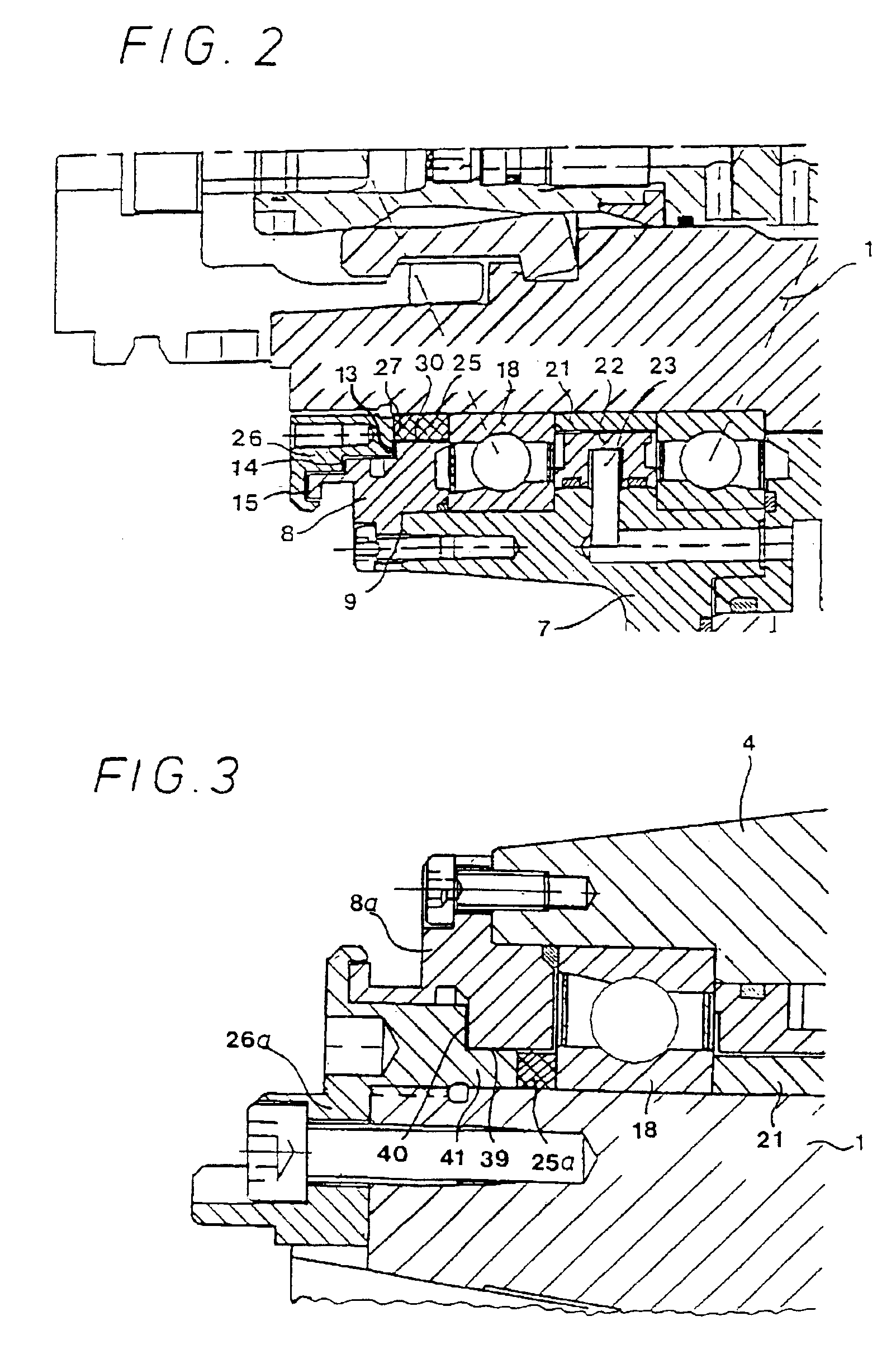

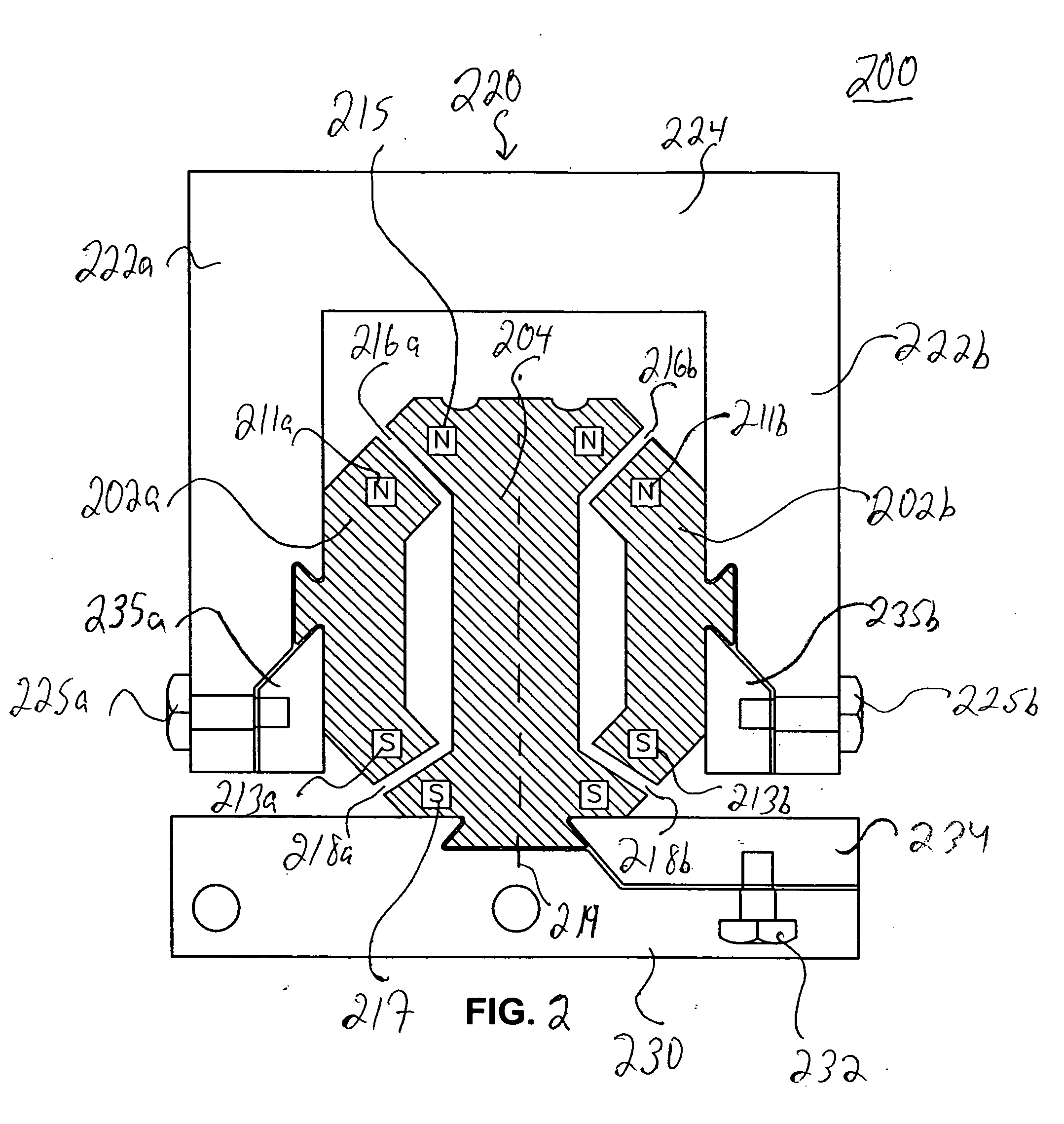

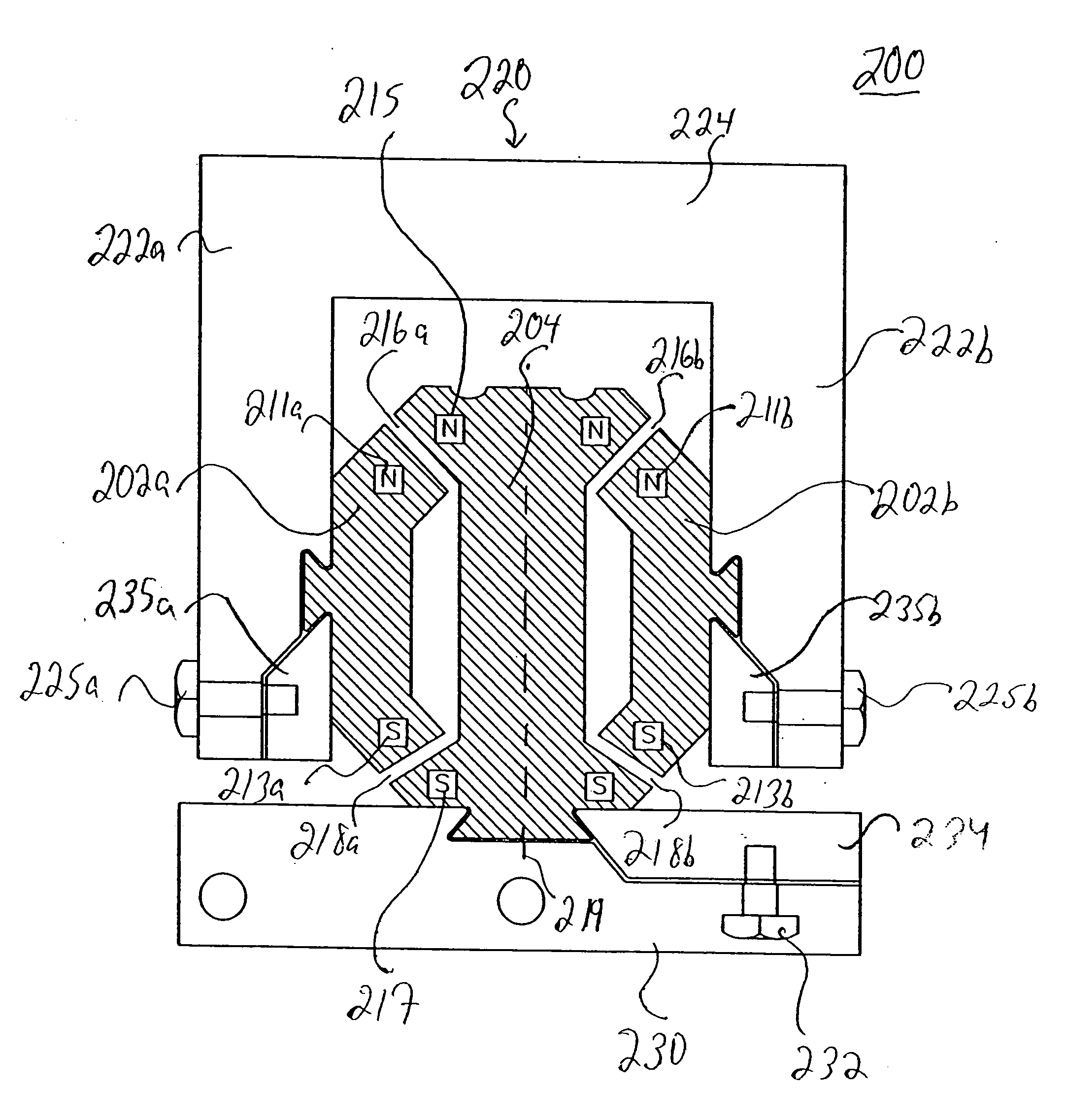

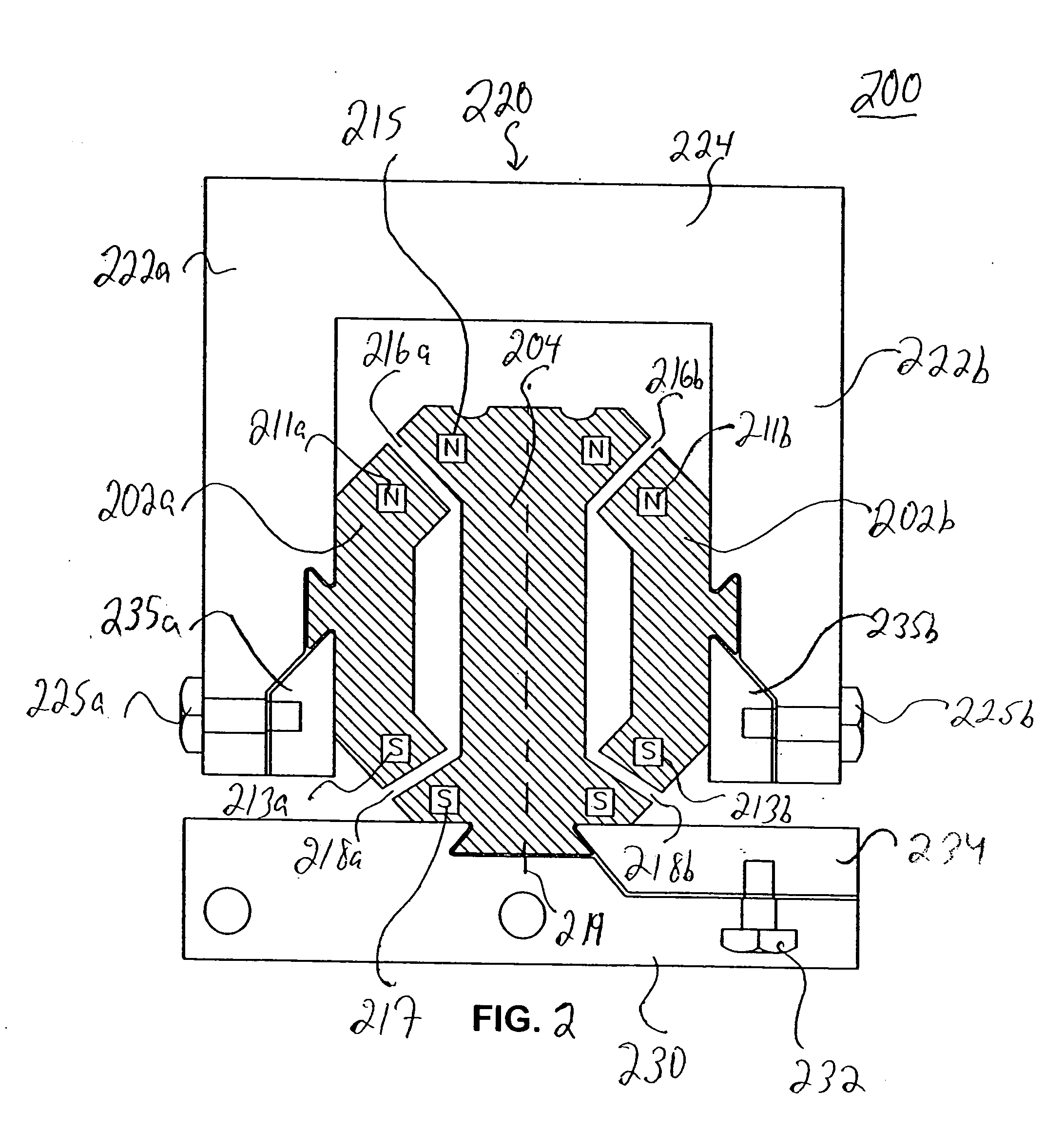

Magnetic bearing assembly using repulsive magnetic forces

InactiveUS7126244B2Reduce the gap widthIncreasing repulsive magnetic forceLinear bearingsMechanical energy handlingMagnetic tension forceMagnetic source

A magnetic bearing assembly utilizes repulsive magnetic forces between components, having magnetic sources, of the bearing at two or more gaps which are angled with respect to an axis of the inner component. Each gap provides force vectors in two directions, while allowing for relative movement of the components in a third direction. The gaps collectively provide a stable equilibrium in the first two directions, meaning that, in response to relative movement of the components in the first or second direction causing a decreased gap width, magnetic repulsive forces at the decreased gap width urge the components away from each other to return to equilibrium. The components of a radial magnetic bearing according to the invention move relative to one another rotationally, and the components of a linear magnetic bearing according to the invention move relative to one another longitudinally.

Owner:ROZLEV CORP

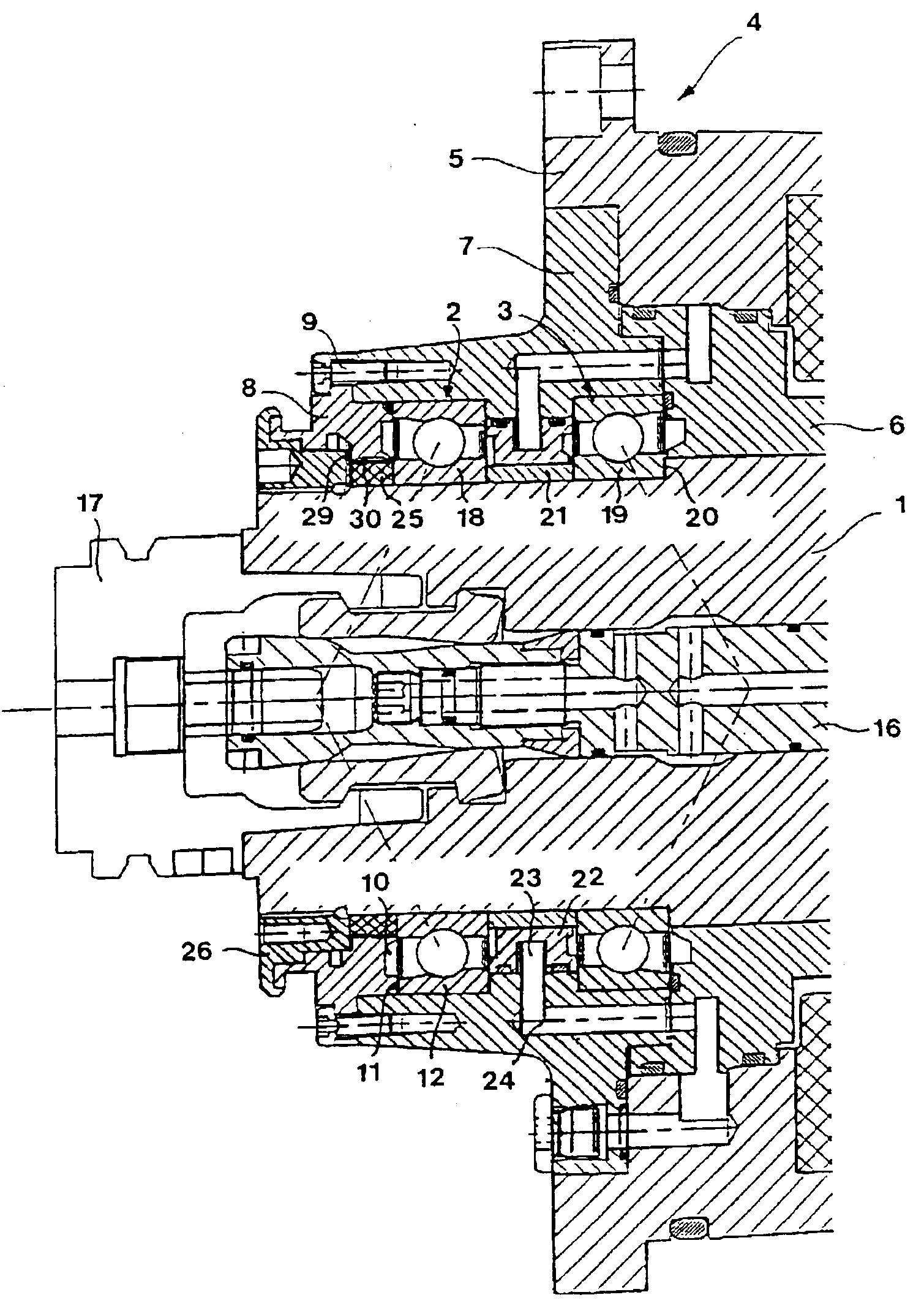

High-speed spindle unit for machine tools

InactiveUS6843623B2Inhibit deteriorationStrong heatingThread cutting machinesBearing assemblyEngineeringMachine tool

A high-speed spindle unit for milling and drilling machines. The spindle unit has a spindle housing on the front end portion of which a terminating ring detachably mounted and a rotationally driven tool spindle which is supported in at least a front roller bearing inside the spindle housing, a ring nut being attached to the front end portion of said spindle. Between the terminating ring and the ring nut a pre-dimensioned ring-shaped gap extending in the radial direction is formed, the gap width of the gap being decreasable to zero with increasing axial load acting on the spindle.

Owner:DECKEL MAHO PFRONTEN GMBH

Magnetic bearing assembly using repulsive magnetic forces

InactiveUS20060145552A1Reduce the gap widthIncreasing repulsive magnetic forceLinear bearingsMechanical energy handlingEngineeringMagnetic tension force

A magnetic bearing assembly utilizes repulsive magnetic forces between components, having magnetic sources, of the bearing at two or more gaps which are angled with respect to an axis of the inner component. Each gap provides force vectors in two directions, while allowing for relative movement of the components in a third direction. The gaps collectively provide a stable equilibrium in the first two directions, meaning that, in response to relative movement of the components in the first or second direction causing a decreased gap width, magnetic repulsive forces at the decreased gap width urge the components away from each other to return to equilibrium. The components of a radial magnetic bearing according to the invention move relative to one another rotationally, and the components of a linear magnetic bearing according to the invention move relative to one another longitudinally.

Owner:ROZLEV CORP

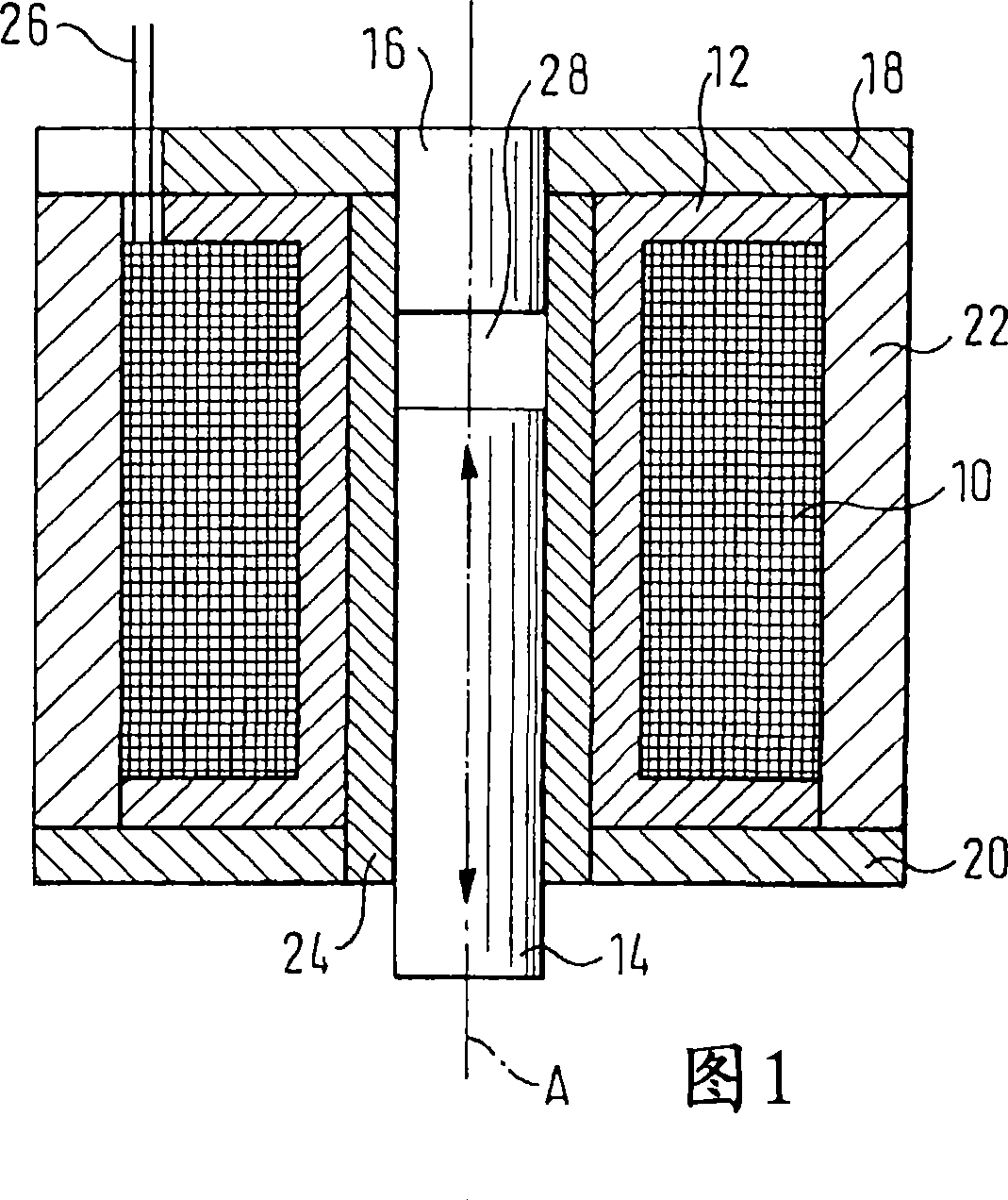

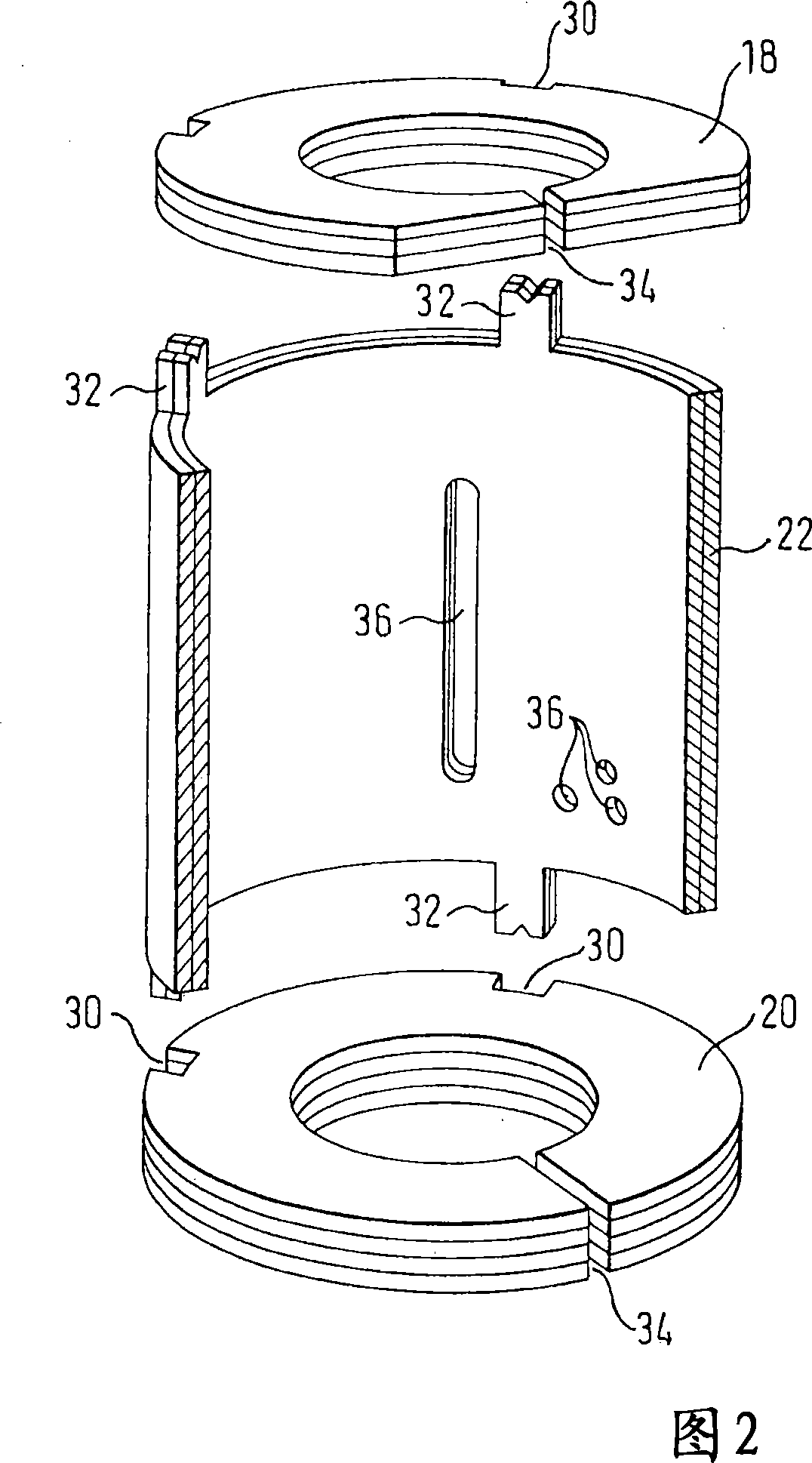

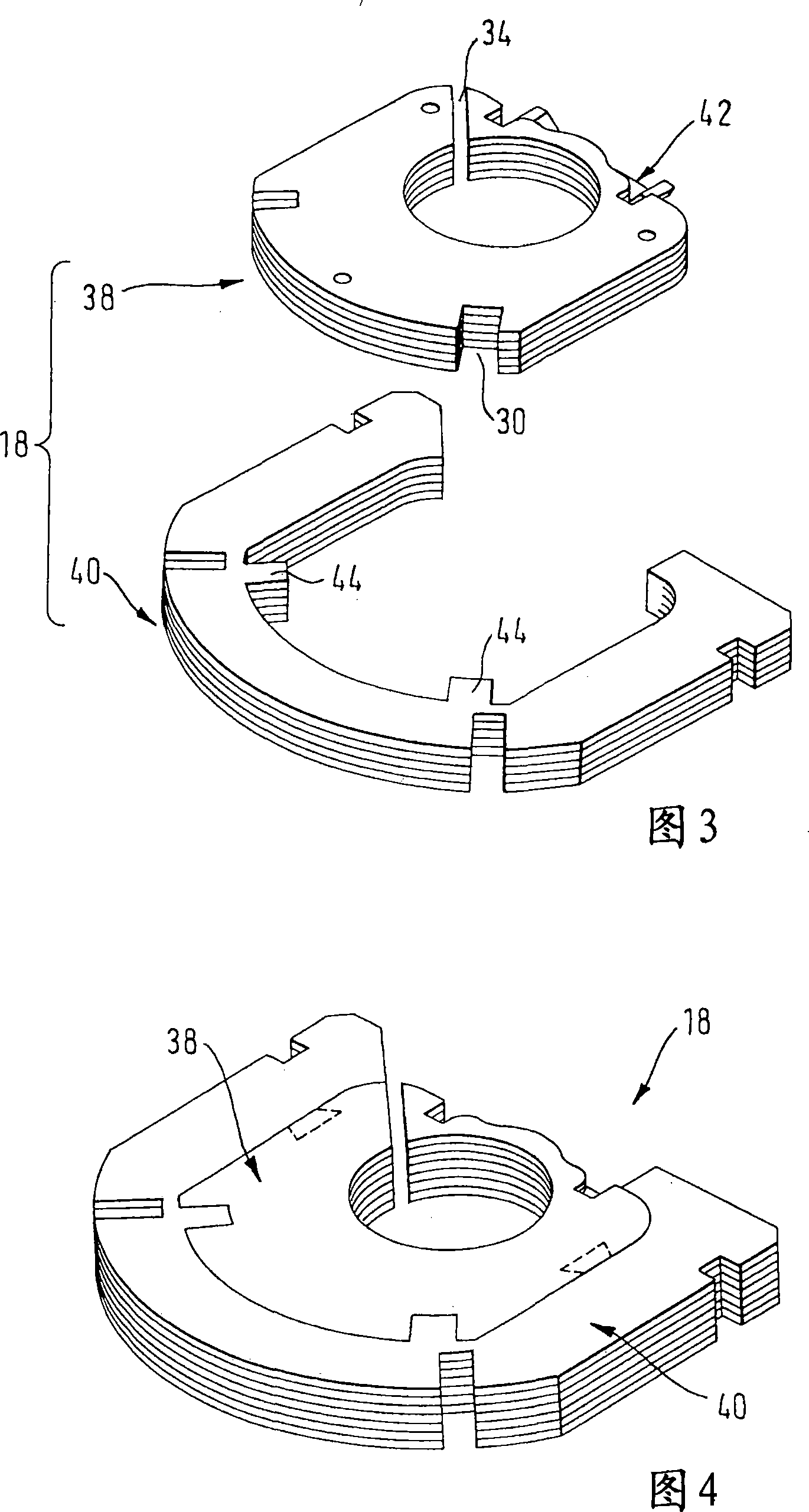

Solenoid unit and method for producing said solenoid unit and a magnet housing for such a solenoid unit

ActiveCN101189689ASimplify processing stepsImprove stabilityCores/yokesElectromagnets with armaturesSolenoid valveTransformer

An electromagnetic unit for a solenoid valve, has a magnetic coil and a ferromagnetic circuit surrounding the magnetic coil (10), which has a fixed magnet housing and a movable magnetic armature (14). The magnet housing is comprised of a cover (18), a wall (22) and a floor (20) in the form of multilayered transformer laminations. -

Owner:BURKERT WERKE

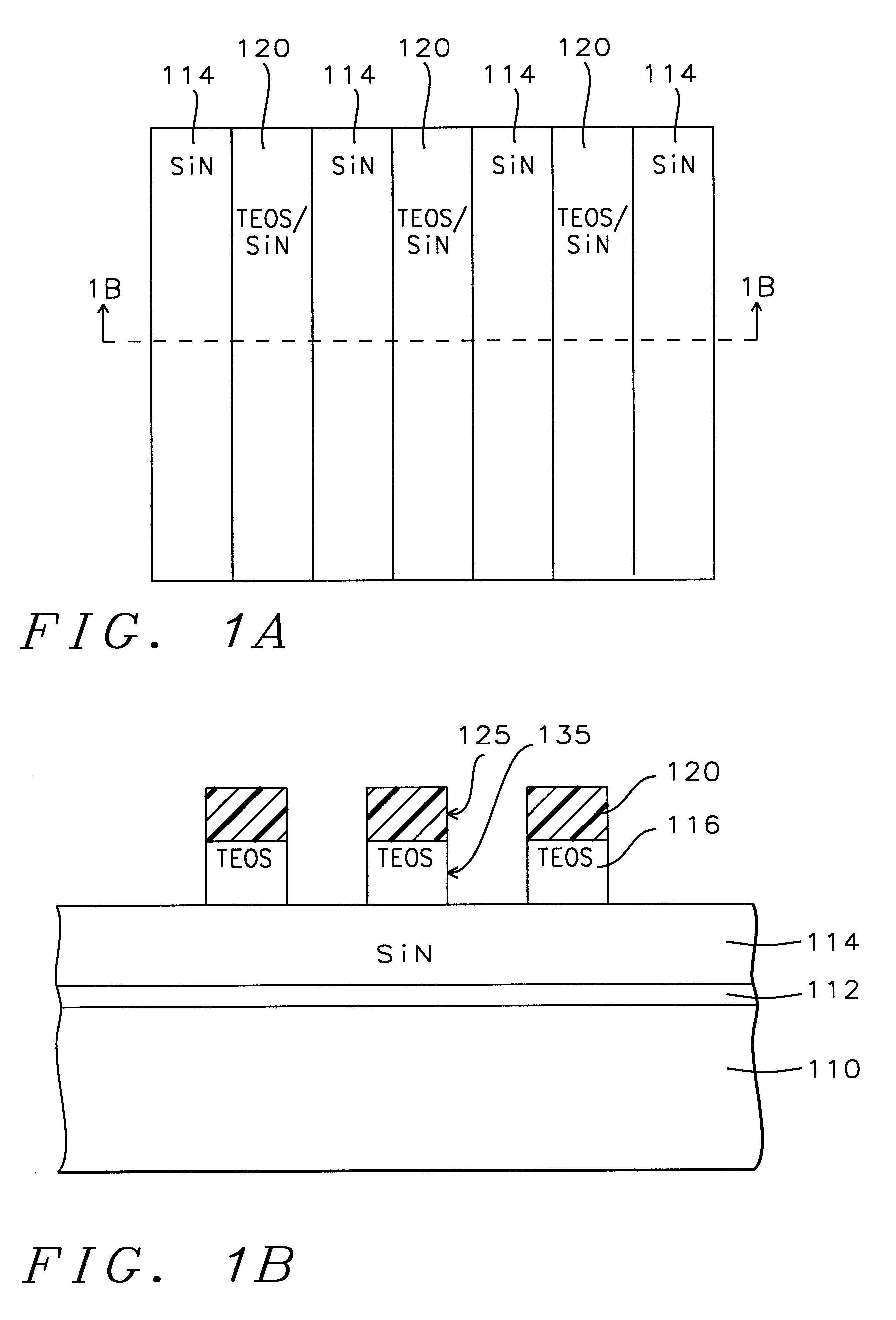

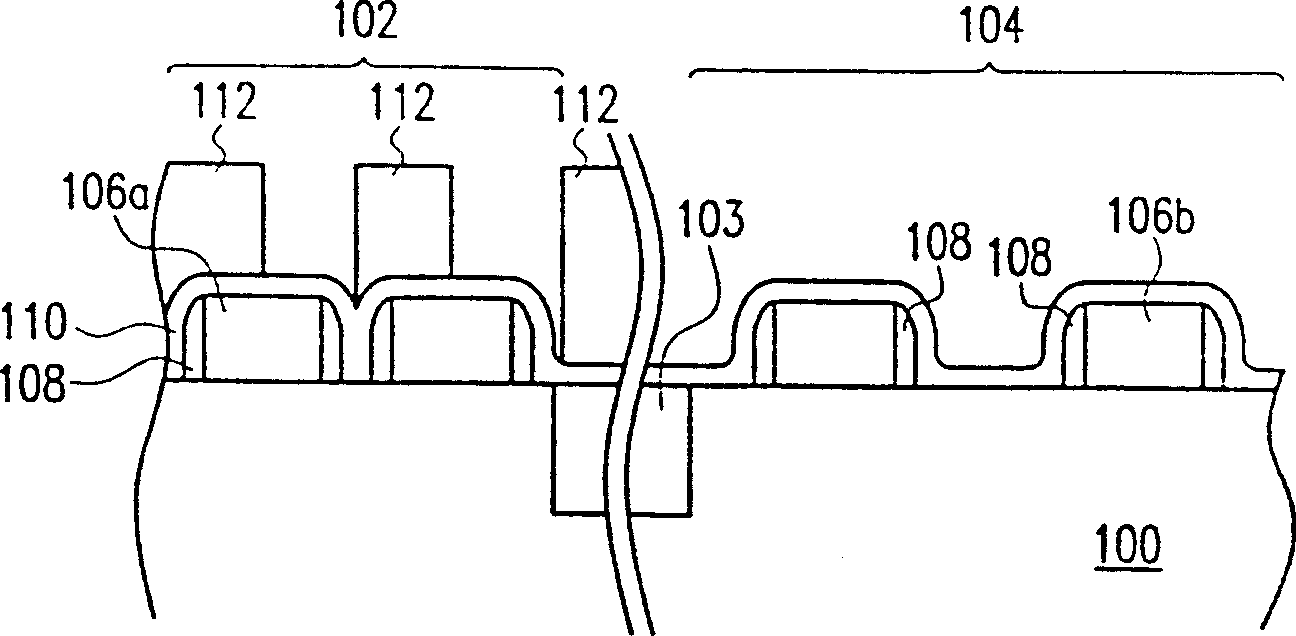

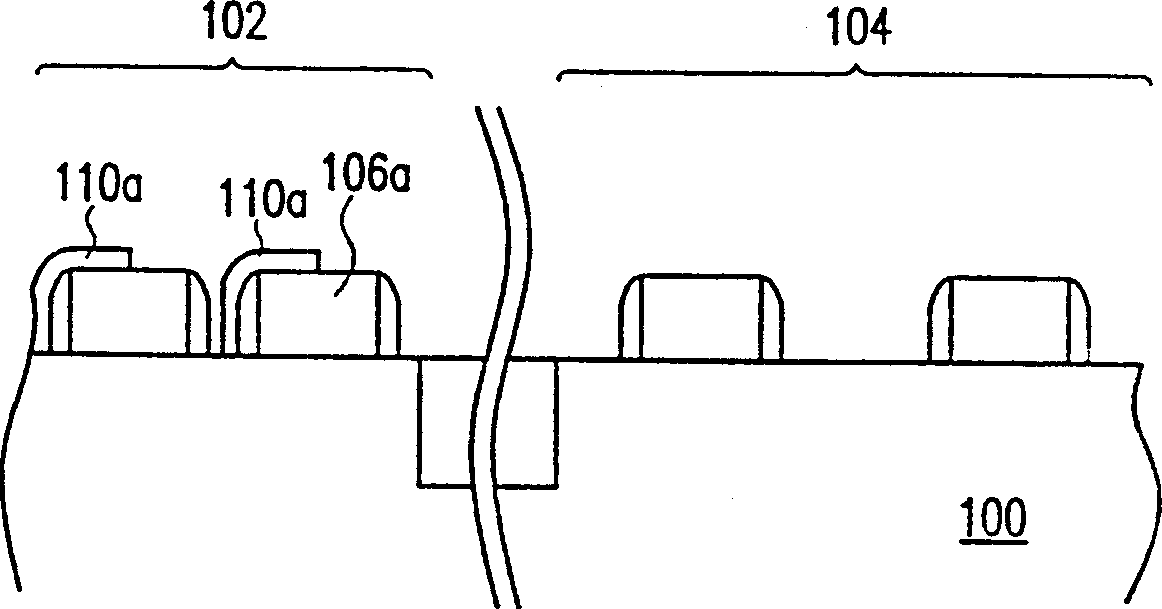

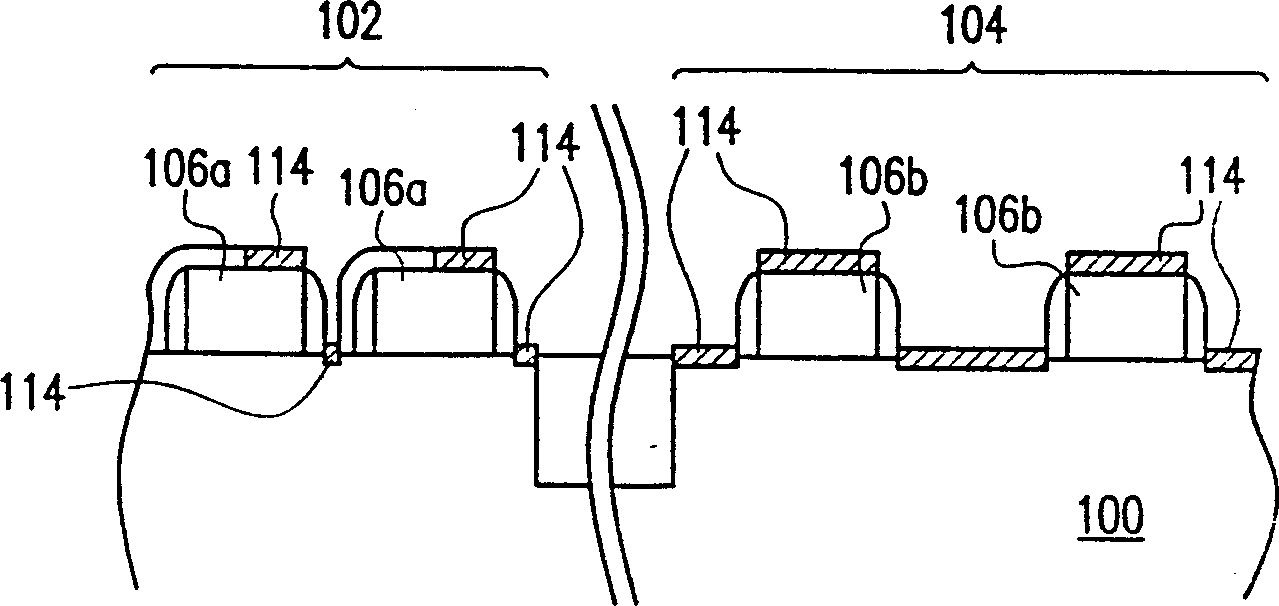

Method for forming a square oxide structure or a square floating gate structure without rounding effect

InactiveUS6245685B1Reduce the gap widthEliminate the effects ofSolid-state devicesSemiconductor/solid-state device manufacturingLOCOSOxide

A method for forming a square oxide structure or a square floating gate without a rounding effect at its corners. A first dielectric layer is formed on a pad layer for a square oxide structure or a polysilicon layer overlying a gate oxide layer for a floating gate, and a second dielectric layer is formed on the first dielectric layer. The second dielectric layer is patterned to form parallel openings in a first direction using a first photosensitive mask. A second photosensitive mask, having a plurality of parallel openings in a second direction perpendicular to the first direction is formed over the second dielectric layer and the first dielectric layer. The first dielectric layer is etched through square openings where the openings in the second photosensitive mask and the openings in the second dielectric layer intersect, thereby forming square openings in the first dielectric layer. The second photosensitive mask and the second dielectric layer are removed. The square oxide structure is completed by etching a trench in the semiconductor structure and forming an STI or LOCOS. The square floating gate is completed by growing polysilicon oxide structures in the square openings in the first dielectric layer and removing the first dielectric layer to form a pattern of openings therebetween, and etching the polysilicon layer through the pattern of openings between the polysilicon oxide structures forming square floating gate polysilicon regions under the polysilicon oxide hard masks.

Owner:TAIWAN SEMICON MFG CO LTD

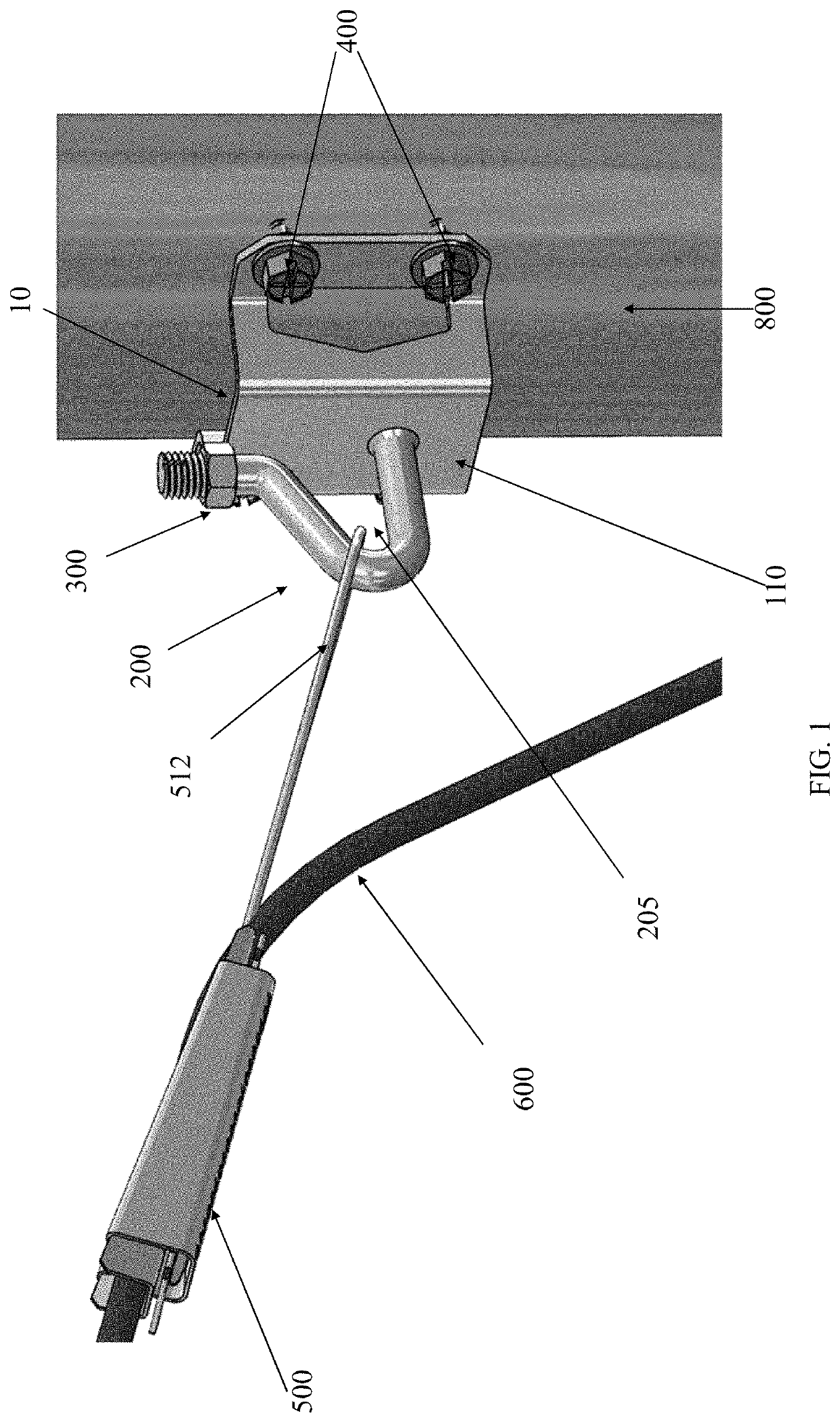

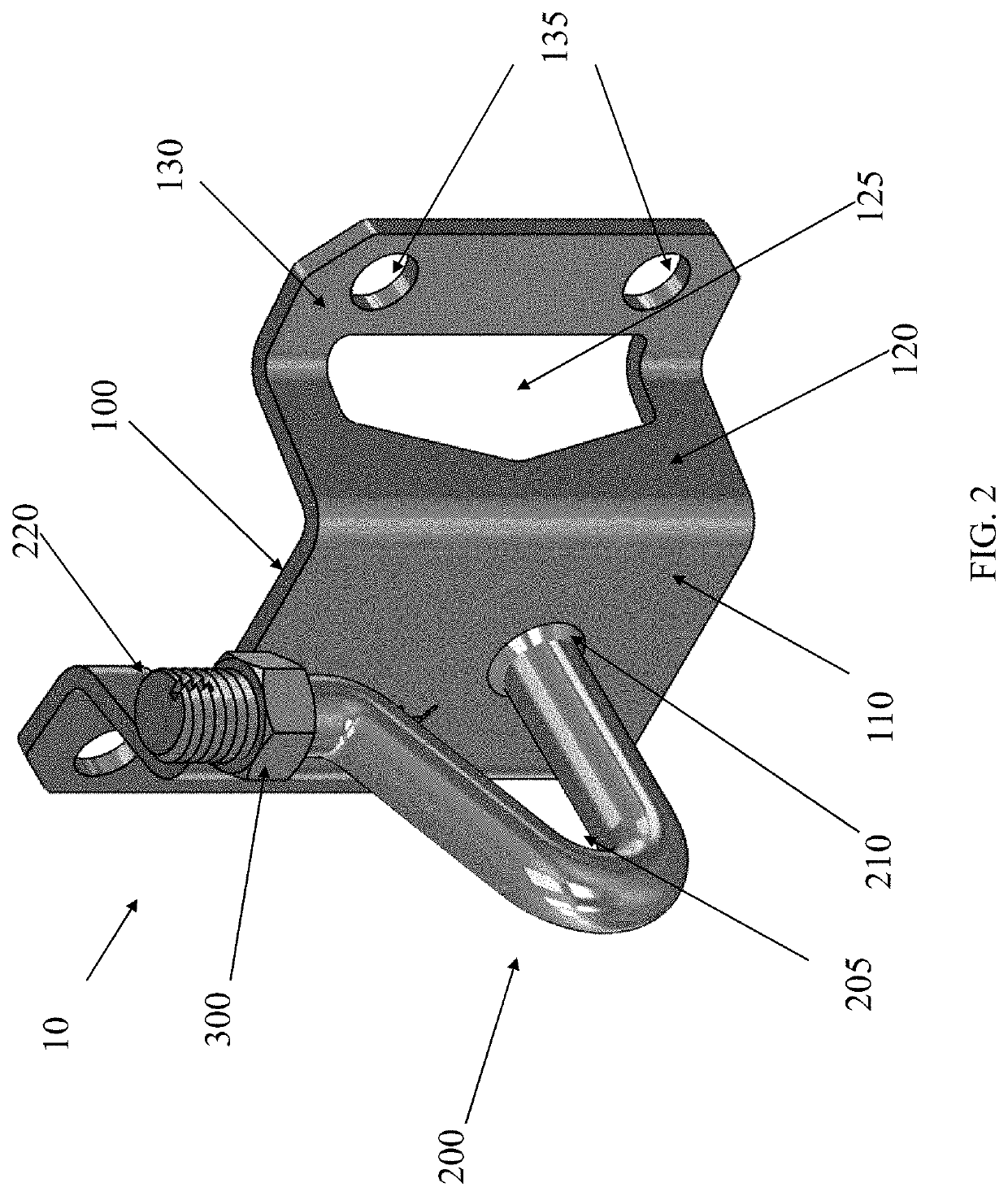

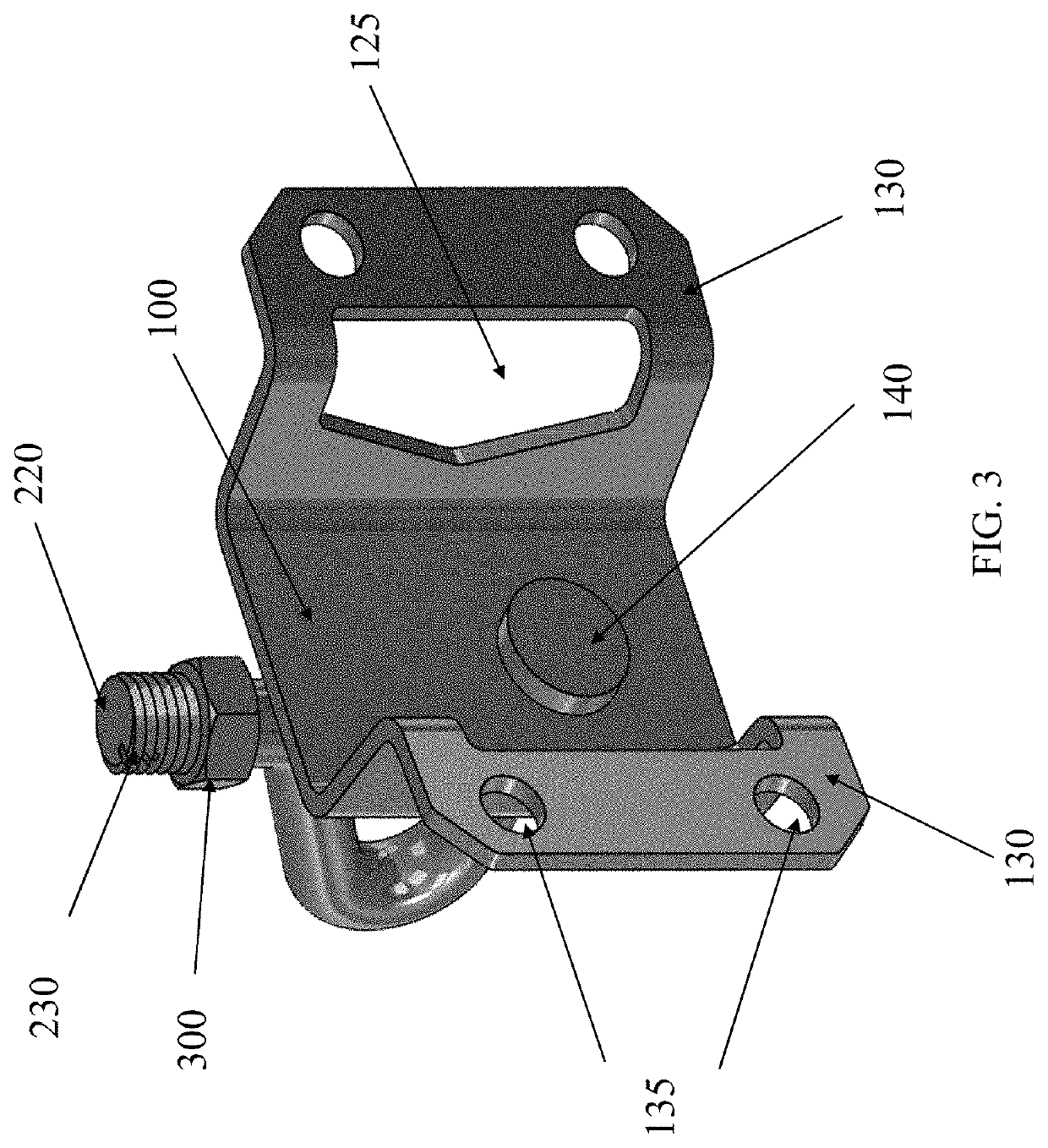

Bracket device and method

ActiveUS20200003274A1Reduce the gap widthOverhead installationMachine supportsWire rodStructural engineering

A bracket device to secure a tail wire of a drop wire clamp to a structure including a base having a surface. The bracket device further includes a retention hook having a first end, a second end, and retention region defined between the first end and second end. The first end of the retention hook is coupled to the base surface, and the second end of the retention hook is disposed at a predetermined distance from the base surface to define a gap therebetween having a width. The bracket device further includes a locking nut that is cooperatively coupled to the second end of the retention hook and adapted to move between an unlocked position to permit a wire to enter the retention region and a locked position in which a wire is retained by the retention hook in the retention region by a reduction of the gap width.

Owner:ALLIED BOLTS

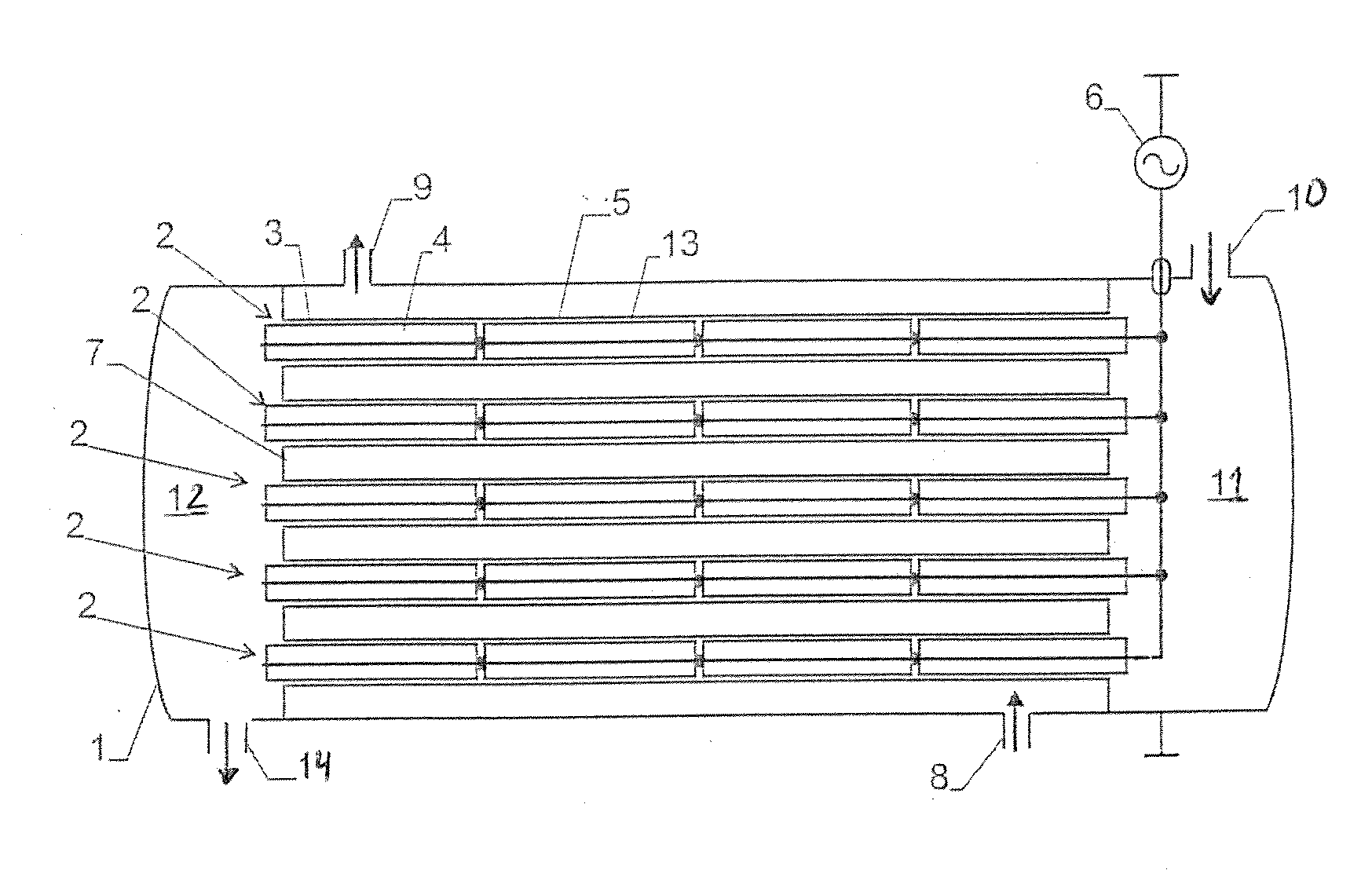

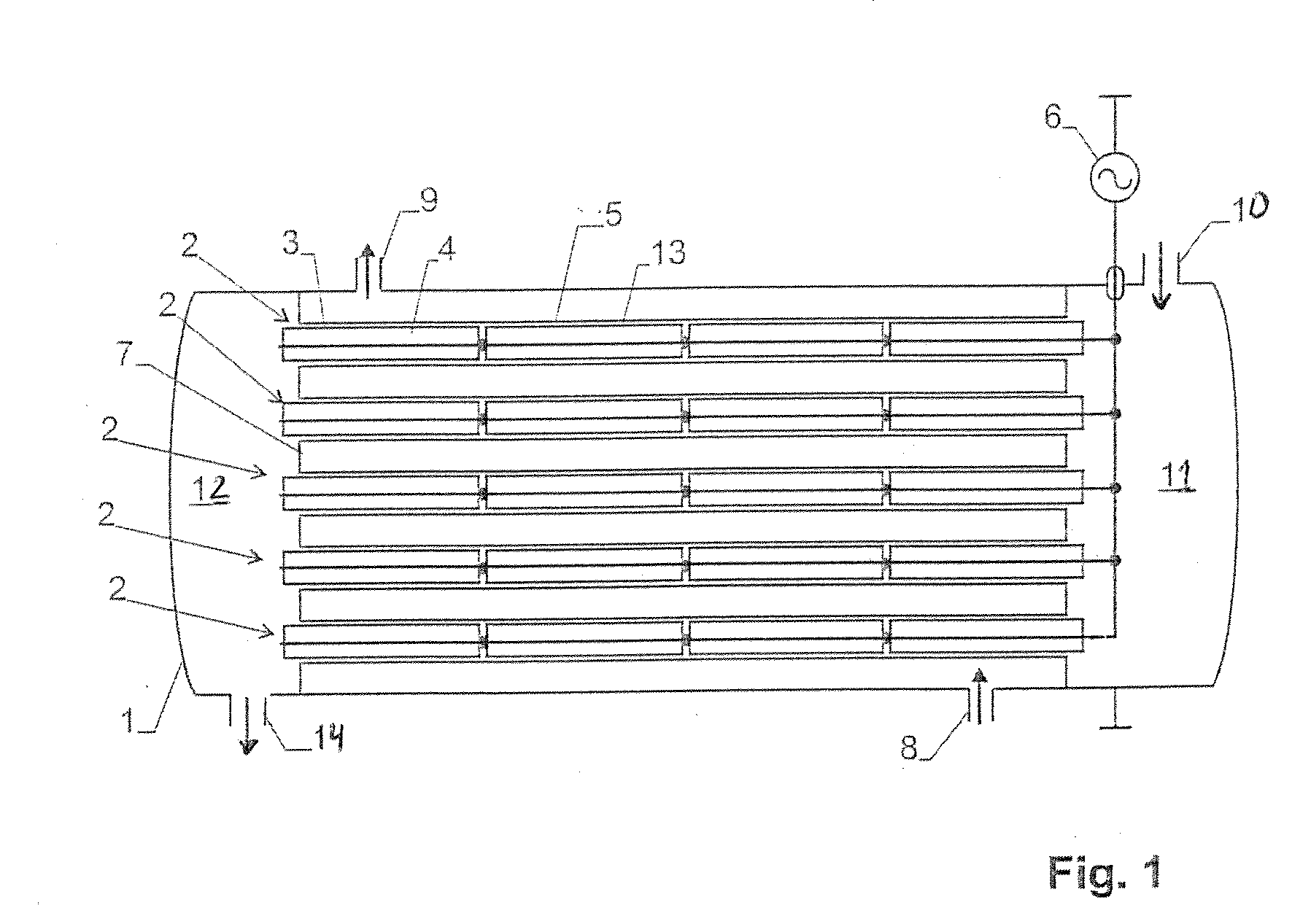

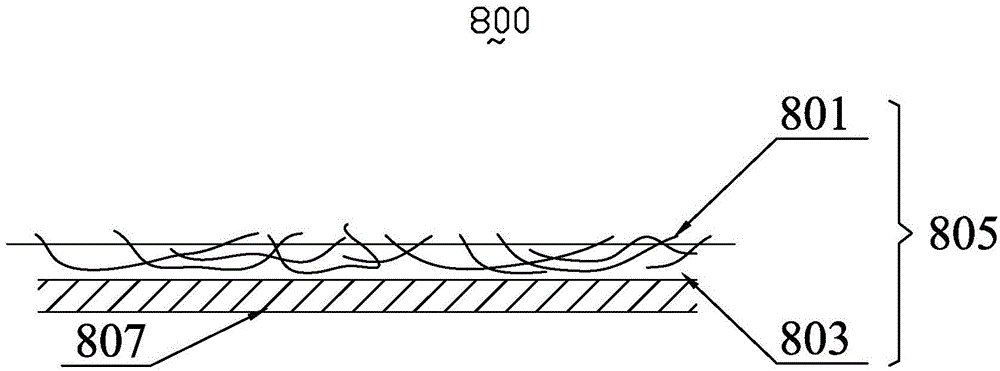

Ozone Generator

ActiveUS20080193343A1Effect of degradation can be reducedLimited capacityElectrical discharge ozone preparationEnergy based chemical/physical/physico-chemical processesOzone generatorLayer thickness

The invention relates to an ozone generator, comprising two electrodes and a dielectric layer arranged between the above such that between the dialectic layer and one of the electrodes an ozonizing gap is formed, through which an oxygen-containing gas can be run. In the direction of the flow of the gas, a dielectric capacity (CD) of the dielectric layer of the gas becomes smaller and / or layer thickness of the dielectric layer becomes greater, such that a gap width of the ozonizing gap is greater on the inlet side than the outlet side.

Owner:DEGREMONT SOC DITE

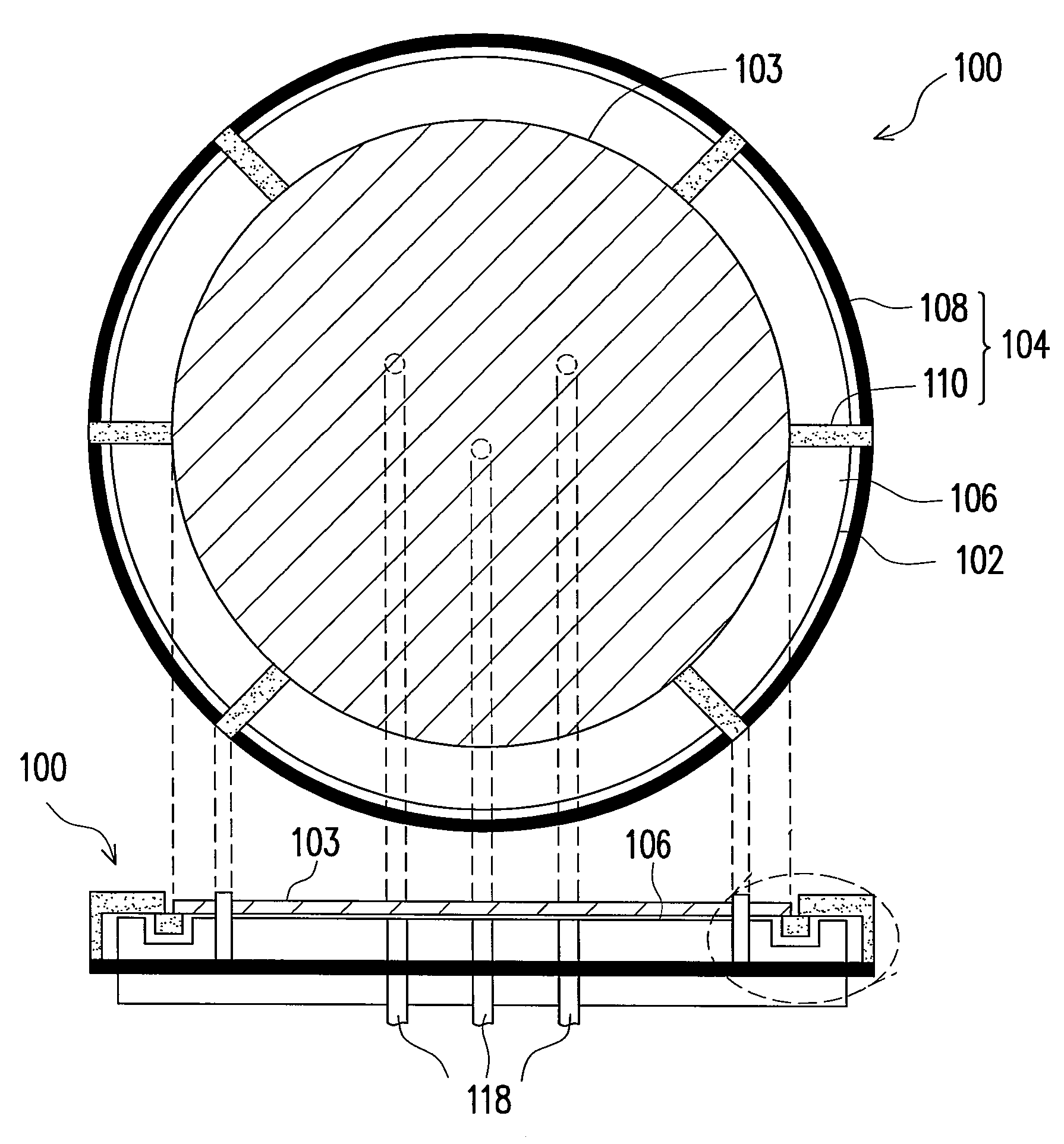

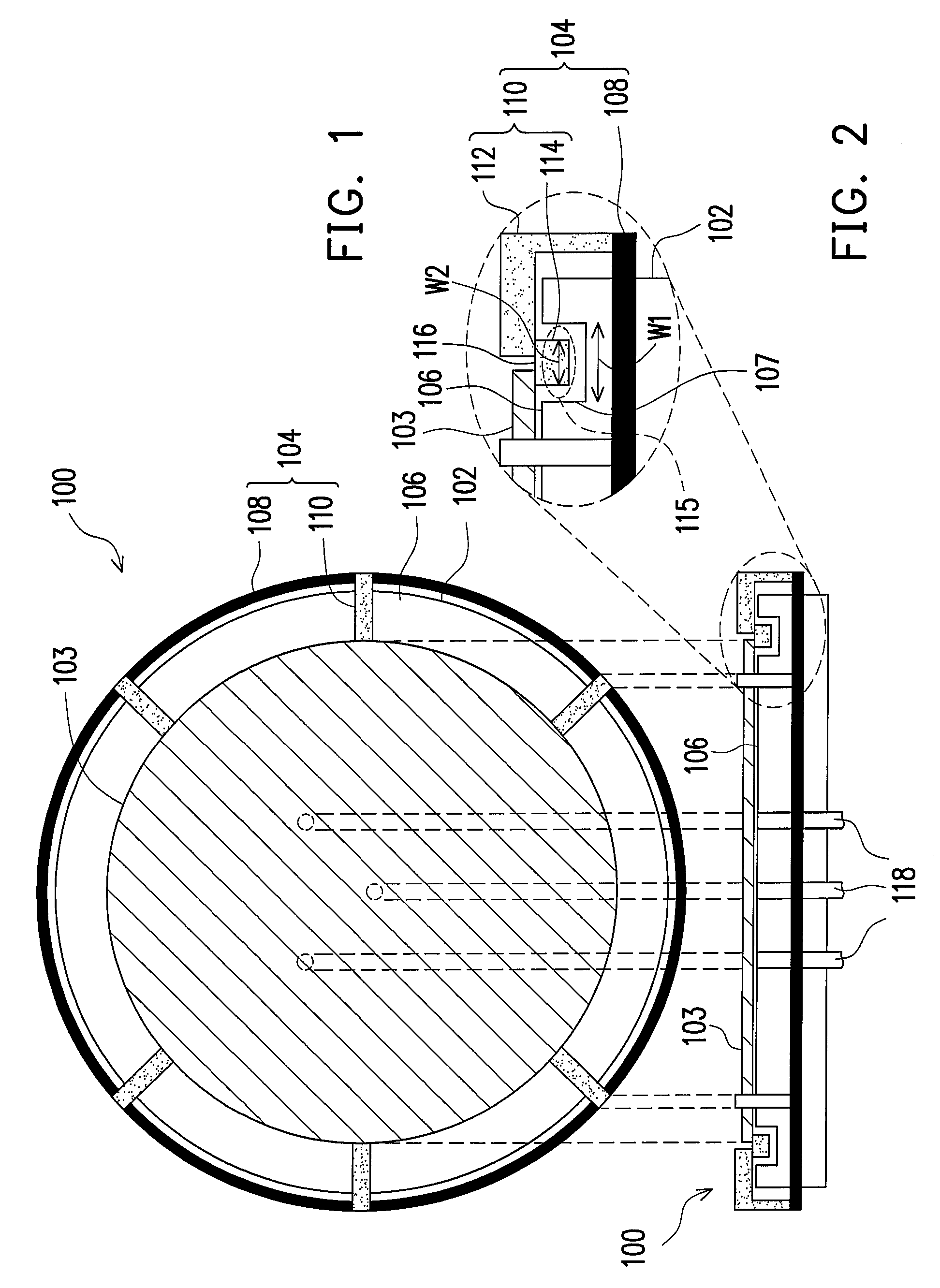

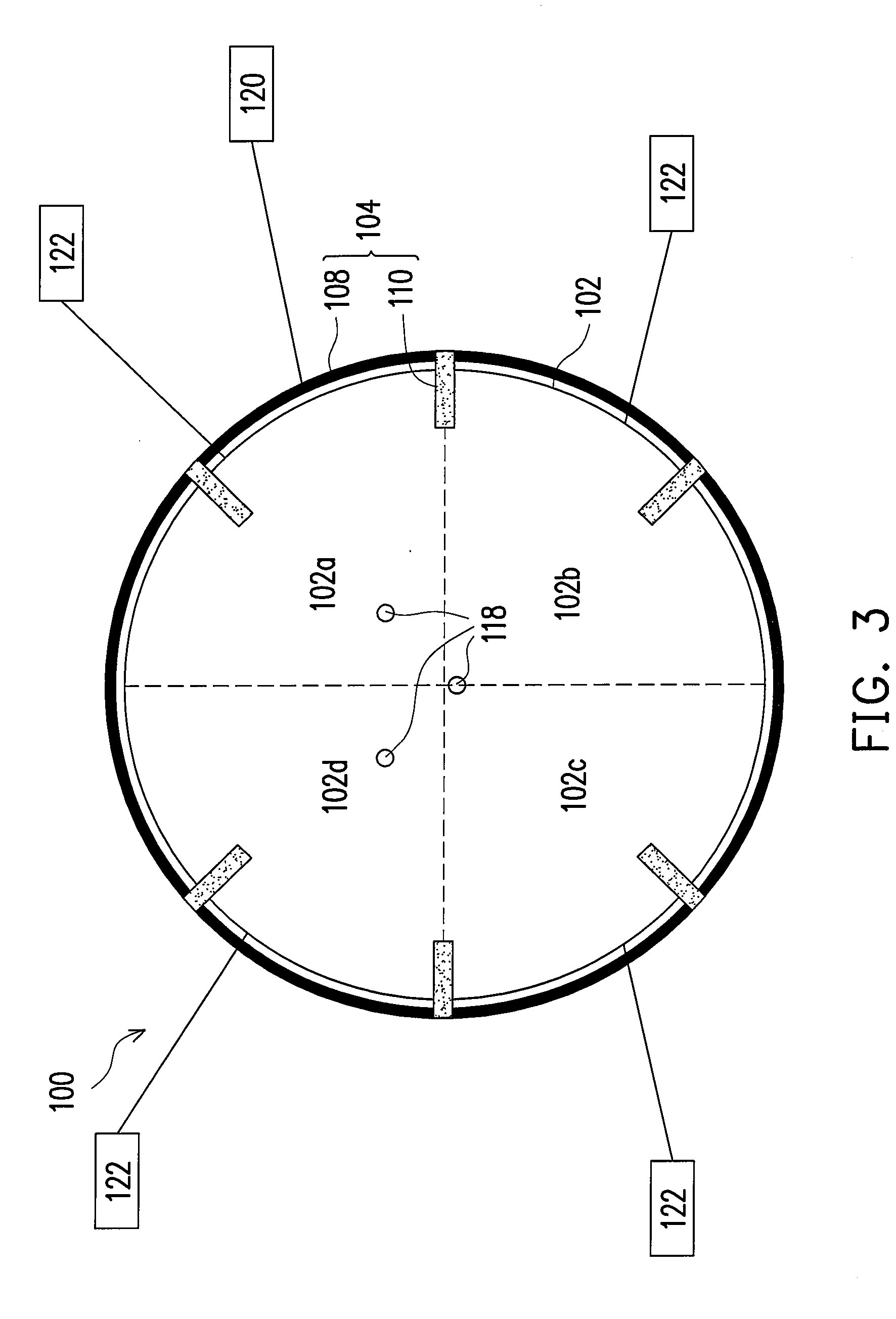

Baking apparatus, baking mehod and method of reducing gap width

ActiveUS20090286407A1Uniform temperature distributionImprove performancePhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringGap width

A baking apparatus including a hot plate and a substrate rotation member is provided. The hot plate has a heating surface. The substrate rotation member includes a rotation ring and a plurality of support arms. The rotation ring is configured to surround the hot plate. The support arms are disposed over the heating surface of the hot plate. Each of the support arms includes a connection part and a support part, wherein the connection part is configured to connect the rotation ring and the support part, and a supporting surface of the support part for supporting the substrate is higher than the heating surface of the hot plate.

Owner:MACRONIX INT CO LTD

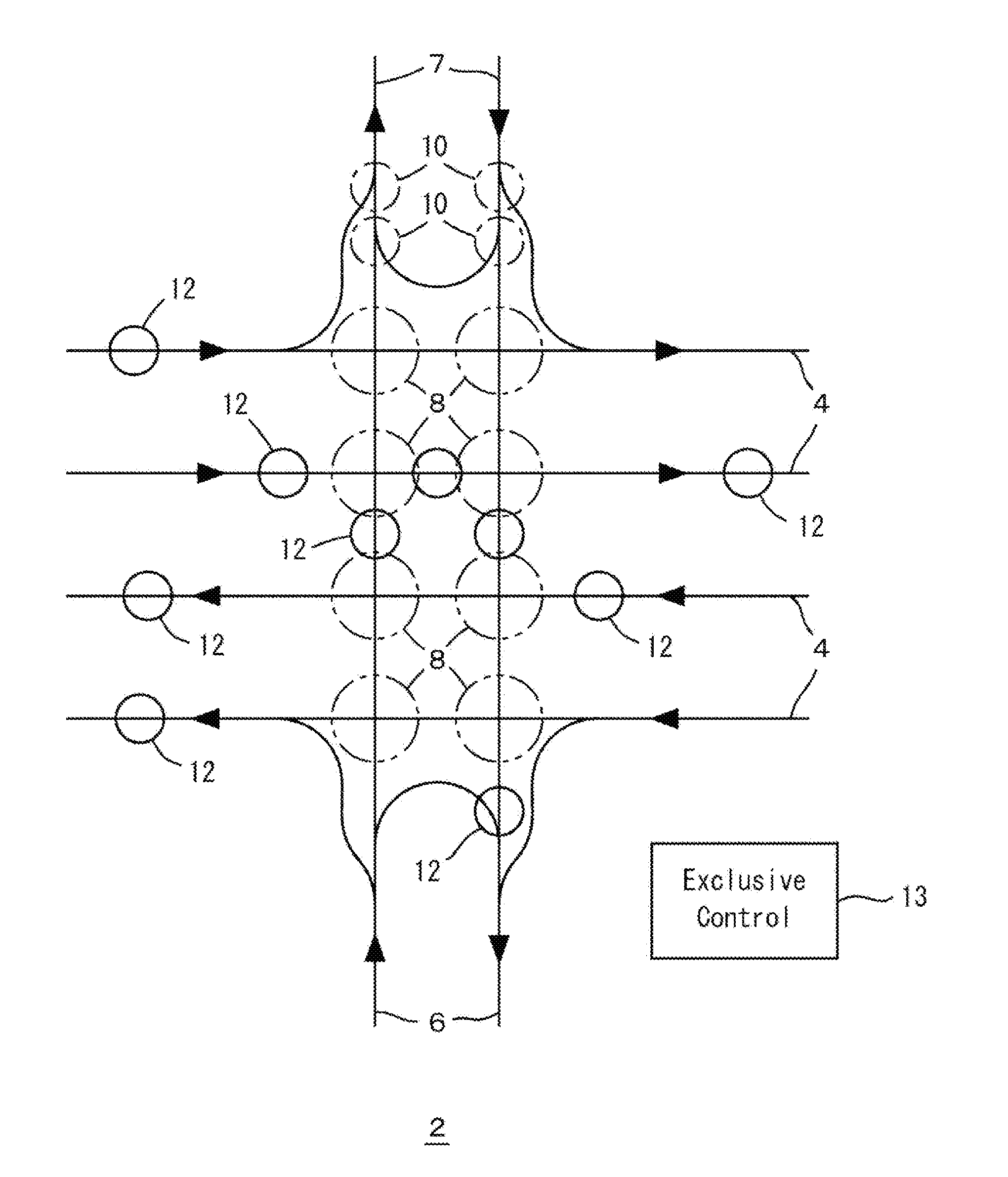

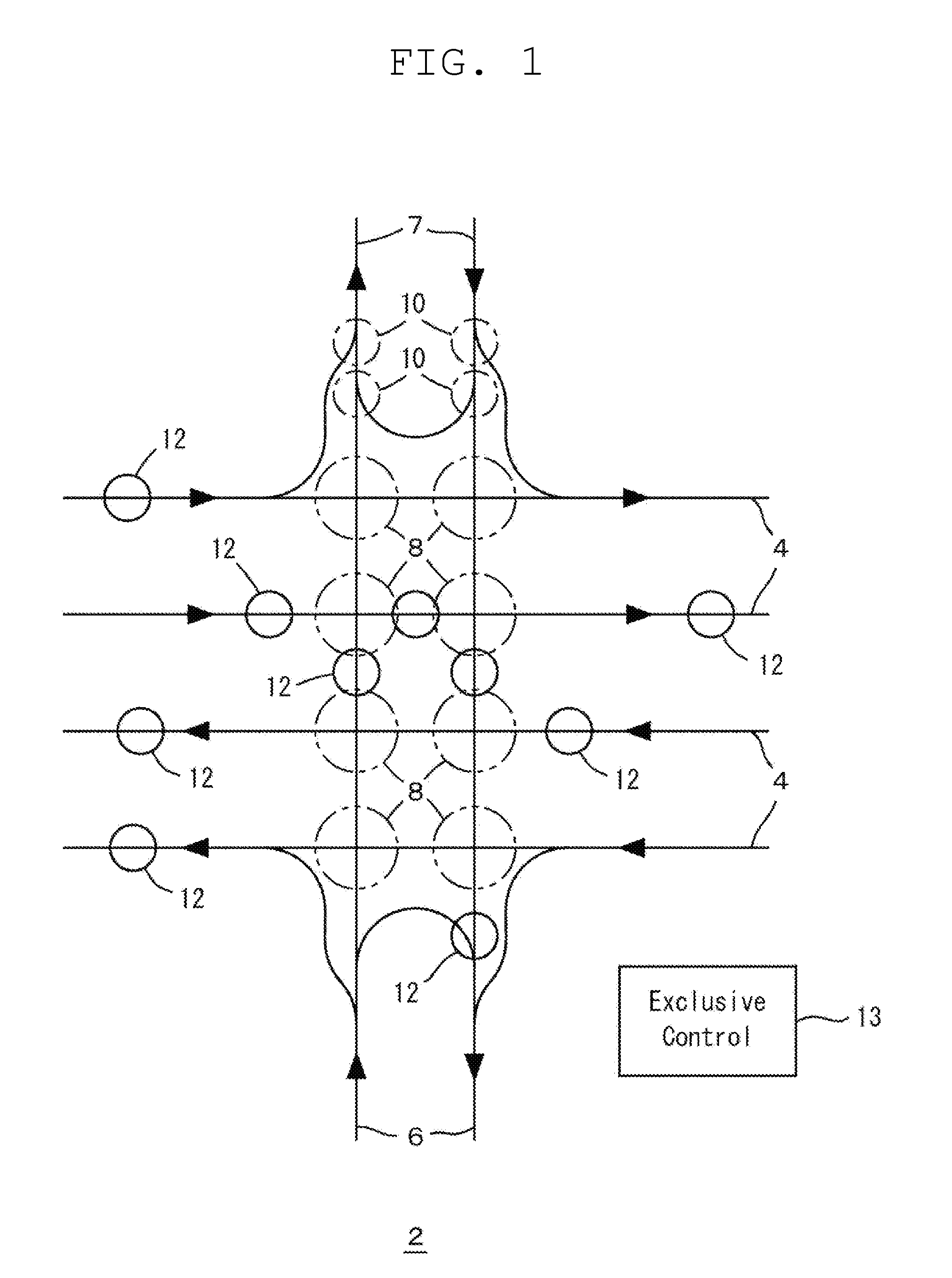

Travelling vehicle system and travelling method for travelling vehicle

ActiveUS20160288808A1Smooth travelImprove driving stabilityElevated railway with suspended vehicleTurntables/traversersEngineeringAxial distance

Owner:MURATA MASCH LTD

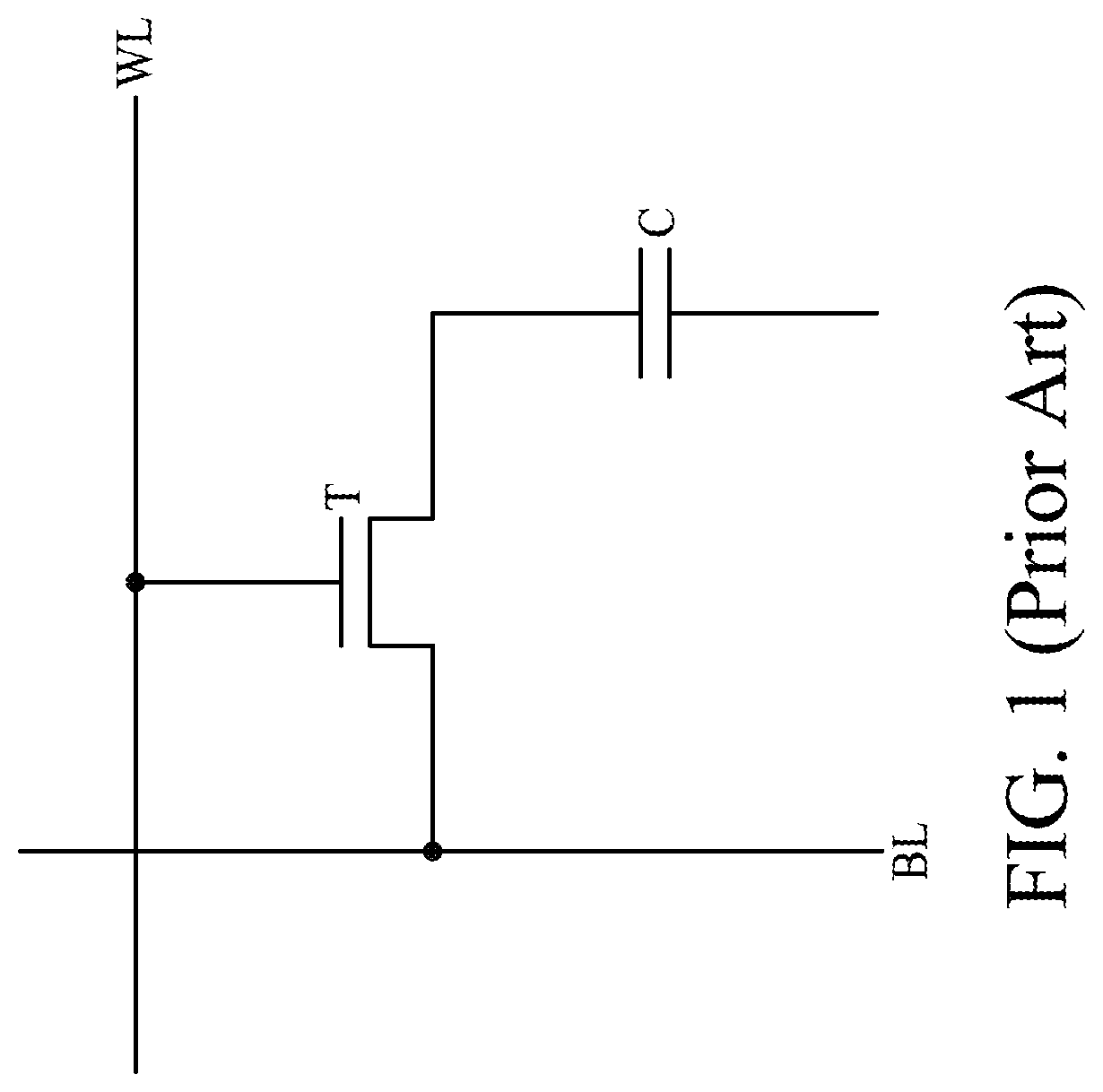

Method for mfg. selective local self-aligned silicide

InactiveCN1435875AIncrease Gap Key WidthReduce the gap widthSemiconductor/solid-state device manufacturingPolycrystalline siliconEngineering

A process for preparing the selectively local self-alignment silicide includes covering a common barrier layer on the memory unit region with more narrow gaps, generating another barrier layer on substrate to cover the memory unit region and logic circuit region, and back etchnig to expose the polysilicon gate and silicon substrate, where said self-alignment silicide is formed, and selectively generating the local self-alignment silicide.

Owner:MACRONIX INT CO LTD

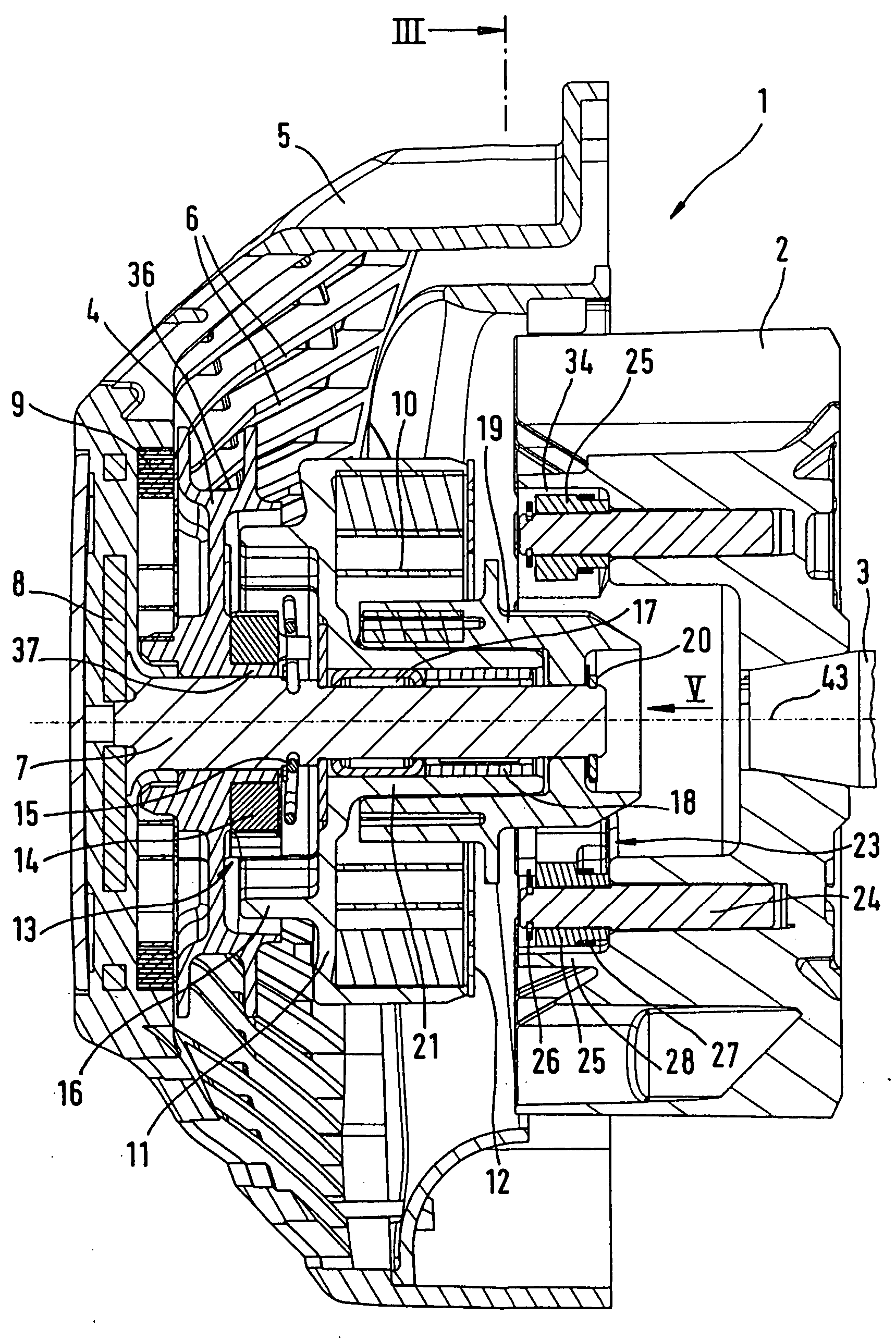

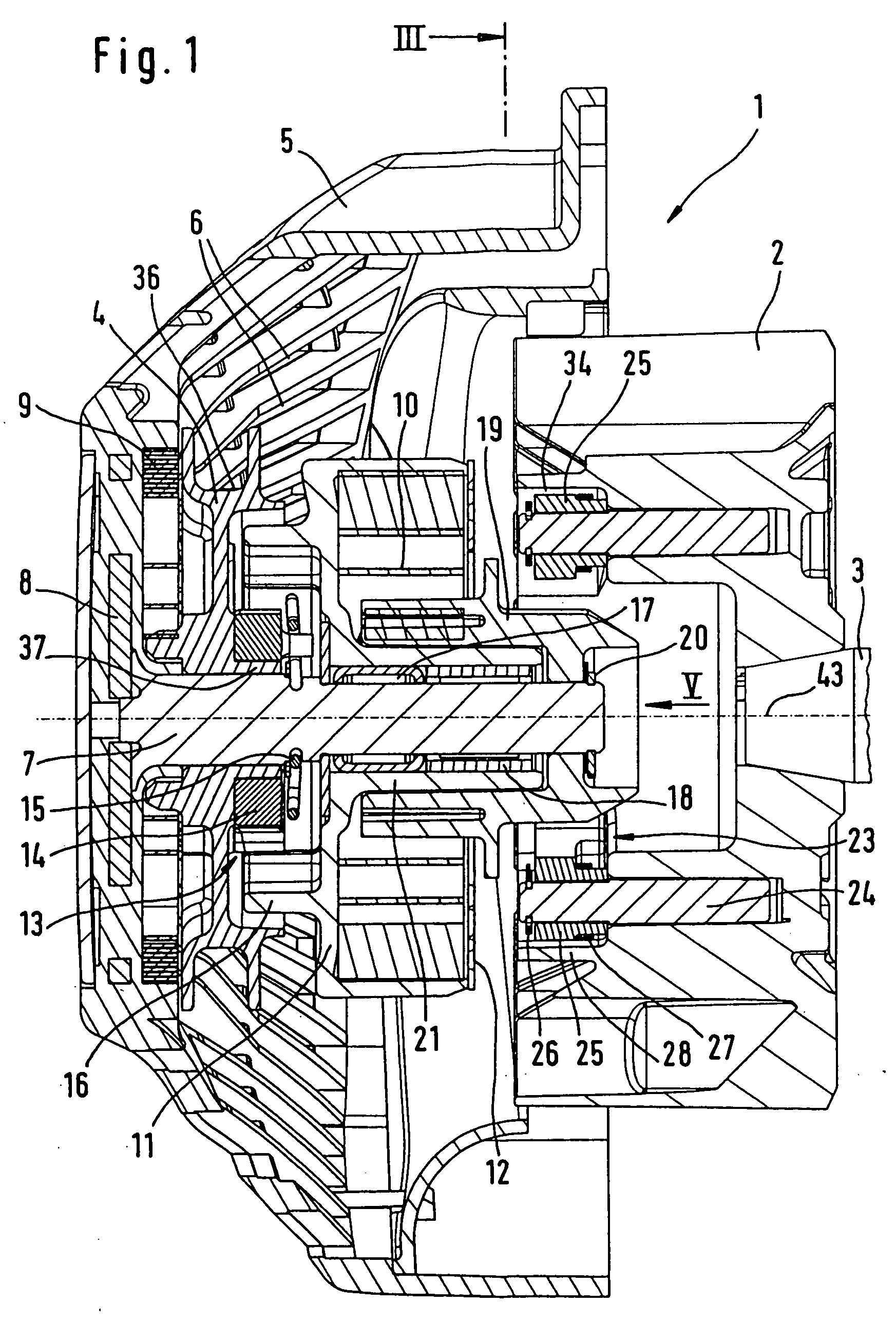

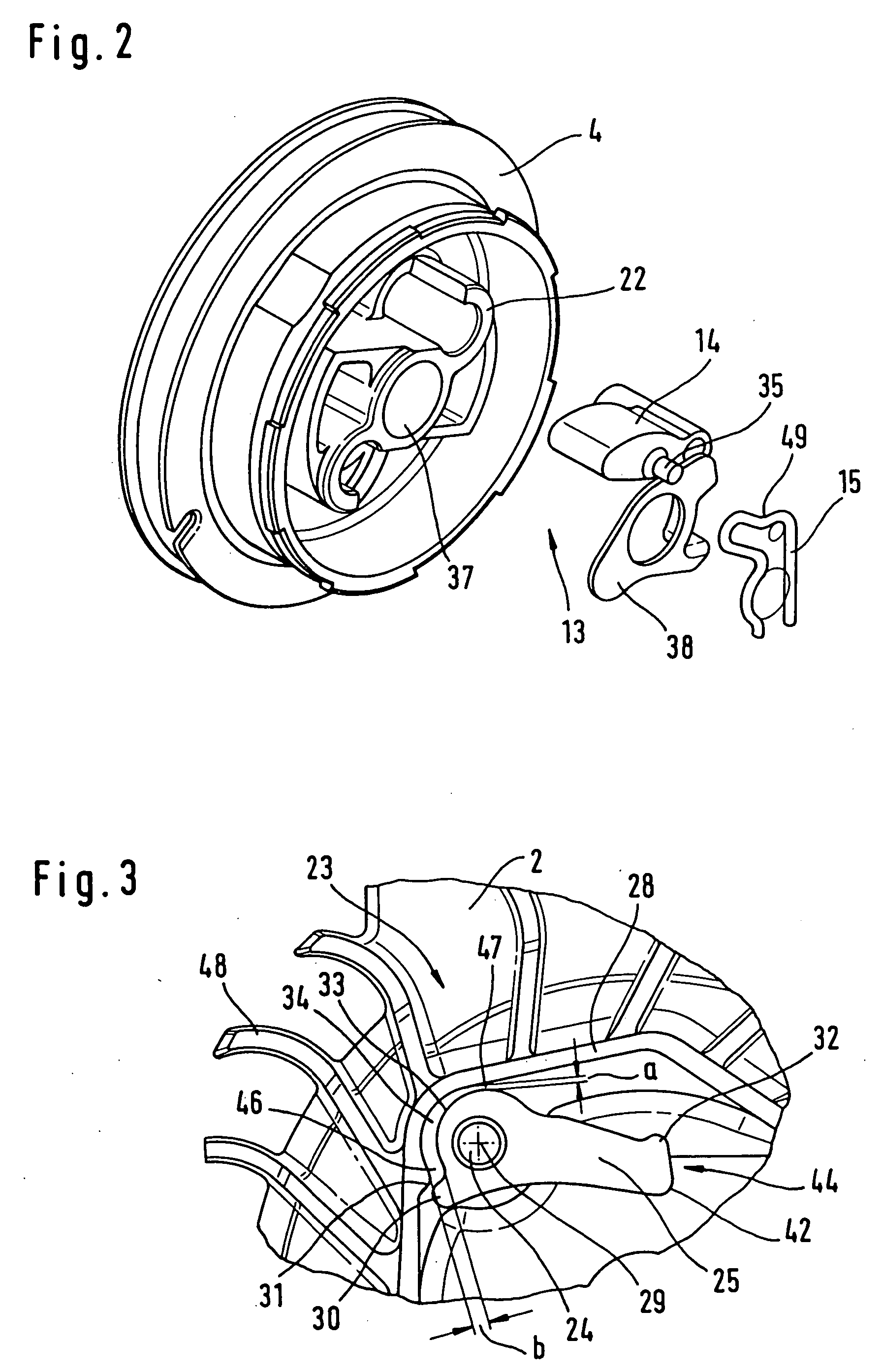

Starter device for an internal combustion engine

InactiveUS20050051124A1Good removal of dirtImprove protectionPower operated startersMuscle operated startersRotational axisEngineering

A starter device for an internal combustion engine includes a starter drum which can be coupled to the crankshaft (3) of the engine via at least one catch (13, 23). The catch (23) has at least one pivotally journalled pawl (25) which coacts with an entrainer (19) in a first position (44) and connects the starter drum to the crankshaft (3). In a second position (45) of the pawl (25), the crankshaft (3) and the starter drum are decoupled from each other. A wall (28) is arranged radially outside of the rotational axis (29) of the pawl (25). A gap (34) is formed between the pawl (25) and the wall (28). In order to prevent that the movability of the pawl (25) is negatively affected by dirt collected between the pawl (25) and the wall (28), the width of the gap (34) changes with the pivoting of the pawl (25).

Owner:ANDREAS STIHL AG & CO KG

High capacitance density vertical natural capacitors

InactiveUS20080305606A1Effective gap distanceIncrease capacitance densityTransistorThin/thick film capacitorDielectricCapacitance

Owner:GLOBALFOUNDRIES INC

High capacitance density vertical natural capacitors

InactiveUS20080304203A1Effective gap distanceIncrease capacitance densityTransistorThin/thick film capacitorDielectricCapacitance

Owner:GLOBALFOUNDRIES INC

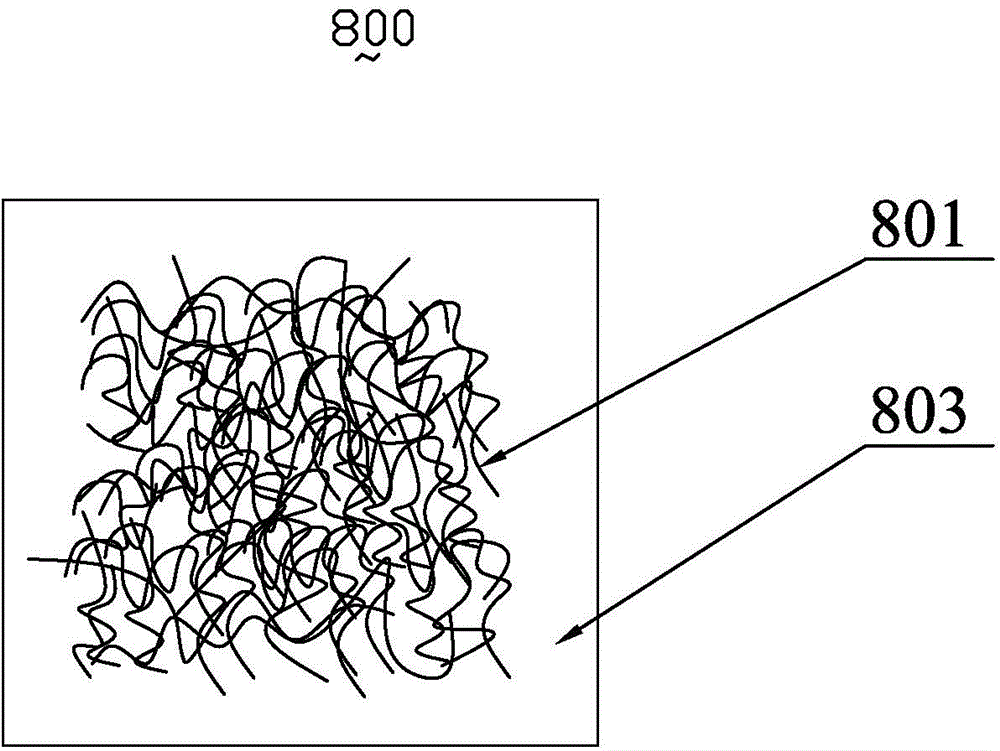

Touch panel and manufacturing method therefor

ActiveCN105487728ALower resistanceImprove flexibilityInput/output processes for data processingTouch panelNanotechnology

The invention provides a touch panel. The touch panel comprises a plurality of first silver nanowire electrode strings arranged at intervals in a first direction and a plurality of second silver nanowire electrode strings arranged at intervals in a second direction, wherein the first silver nanowire electrode strings are insulated from the second silver nanowire electrode strings; each first silver nanowire electrode string comprises a plurality of branches; at least one non conductive region is defined among the branches; and the branches are regularly distributed on the touch panel. The touch panel provided by the invention has the advantages of high touch sensitivity, excellent optical performance and the like. The invention furthermore provides a manufacturing method for the touch panel. The method has the advantages of low cost, simple manufacturing process and the like.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

Magnetic bearing assembly using repulsive magnetic forces

InactiveUS20070024139A1Reduce the gap widthIncreasing repulsive magnetic forceLinear bearingsMechanical energy handlingMagnetic tension forceMagnetic source

A magnetic bearing assembly utilizes repulsive magnetic forces between components, having magnetic sources, of the bearing at two or more gaps which are angled with respect to an axis of the inner component. Each gap provides force vectors in two directions, while allowing for relative movement of the components in a third direction. The gaps collectively provide a stable equilibrium in the first two directions, meaning that, in response to relative movement of the components in the first or second direction causing a decreased gap width, magnetic repulsive forces at the decreased gap width urge the components away from each other to return to equilibrium. The components of a radial magnetic bearing according to the invention move relative to one another rotationally, and the components of a linear magnetic bearing according to the invention move relative to one another longitudinally.

Owner:ROZMUS JOHN J

Vertical-coupling transformer with an air-gap structure

InactiveUS10002700B2Improve isolationReduced insertion lossPrinted circuit assemblingSemiconductor/solid-state device detailsInductorEngineering

Owner:QUALCOMM INC

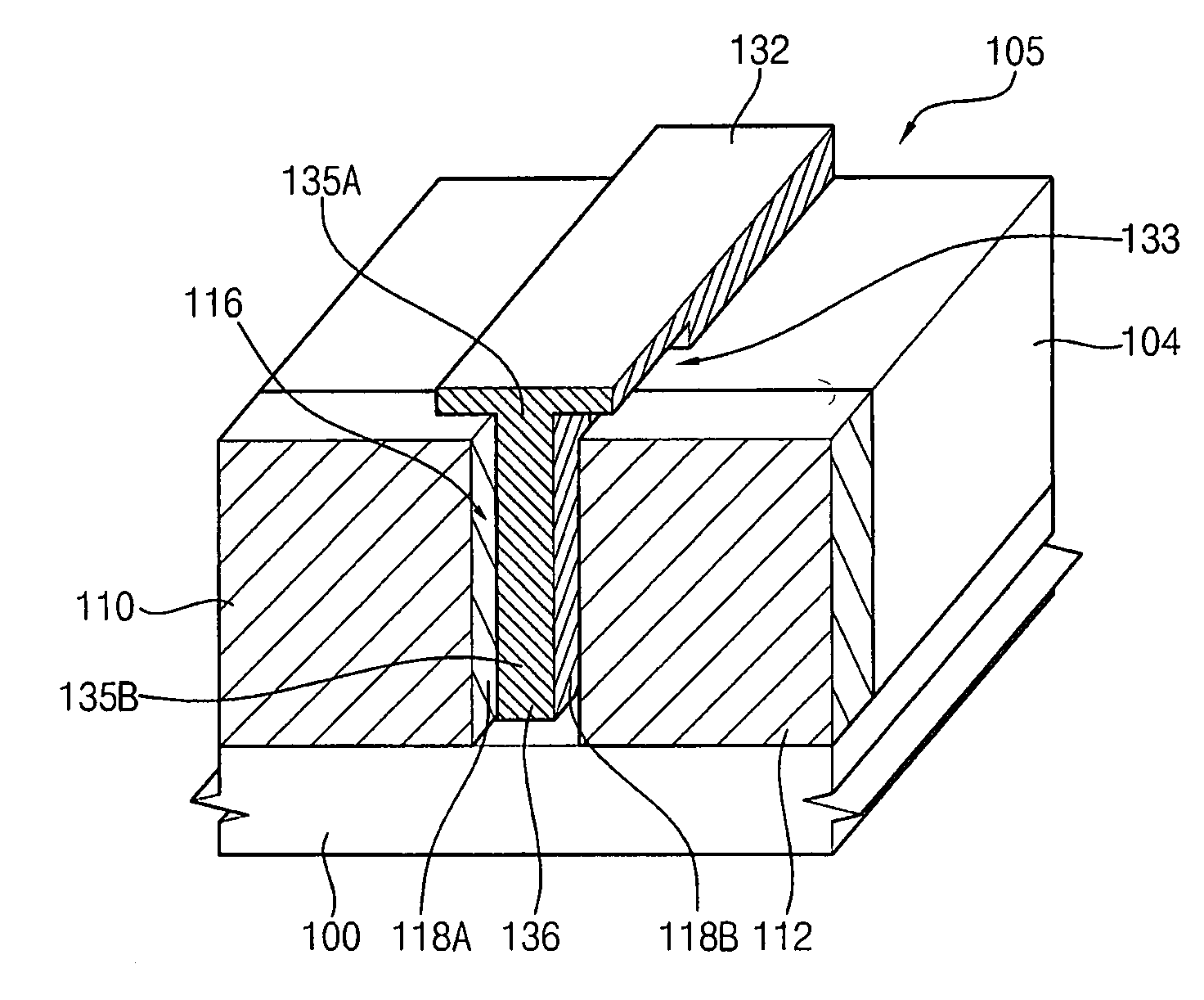

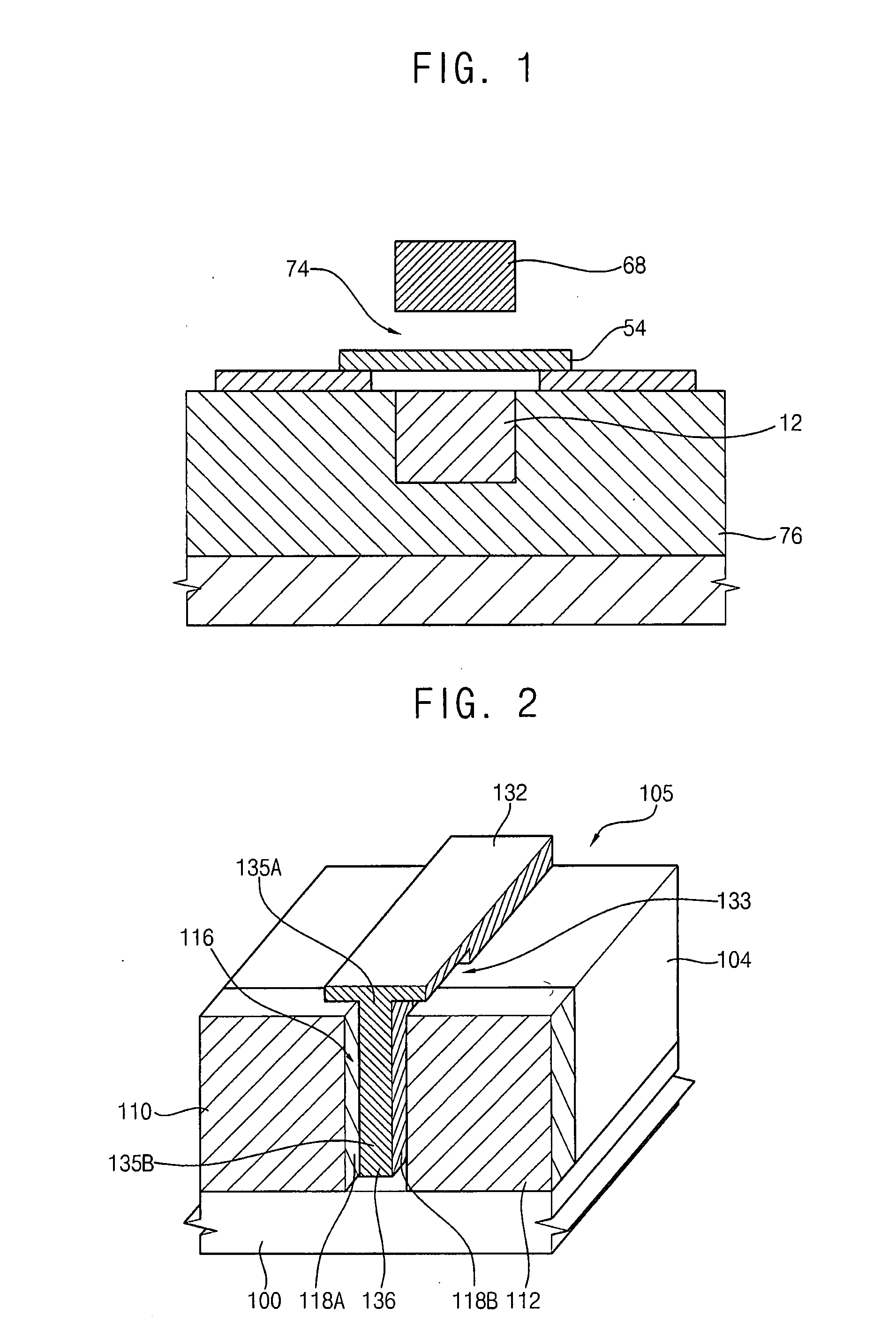

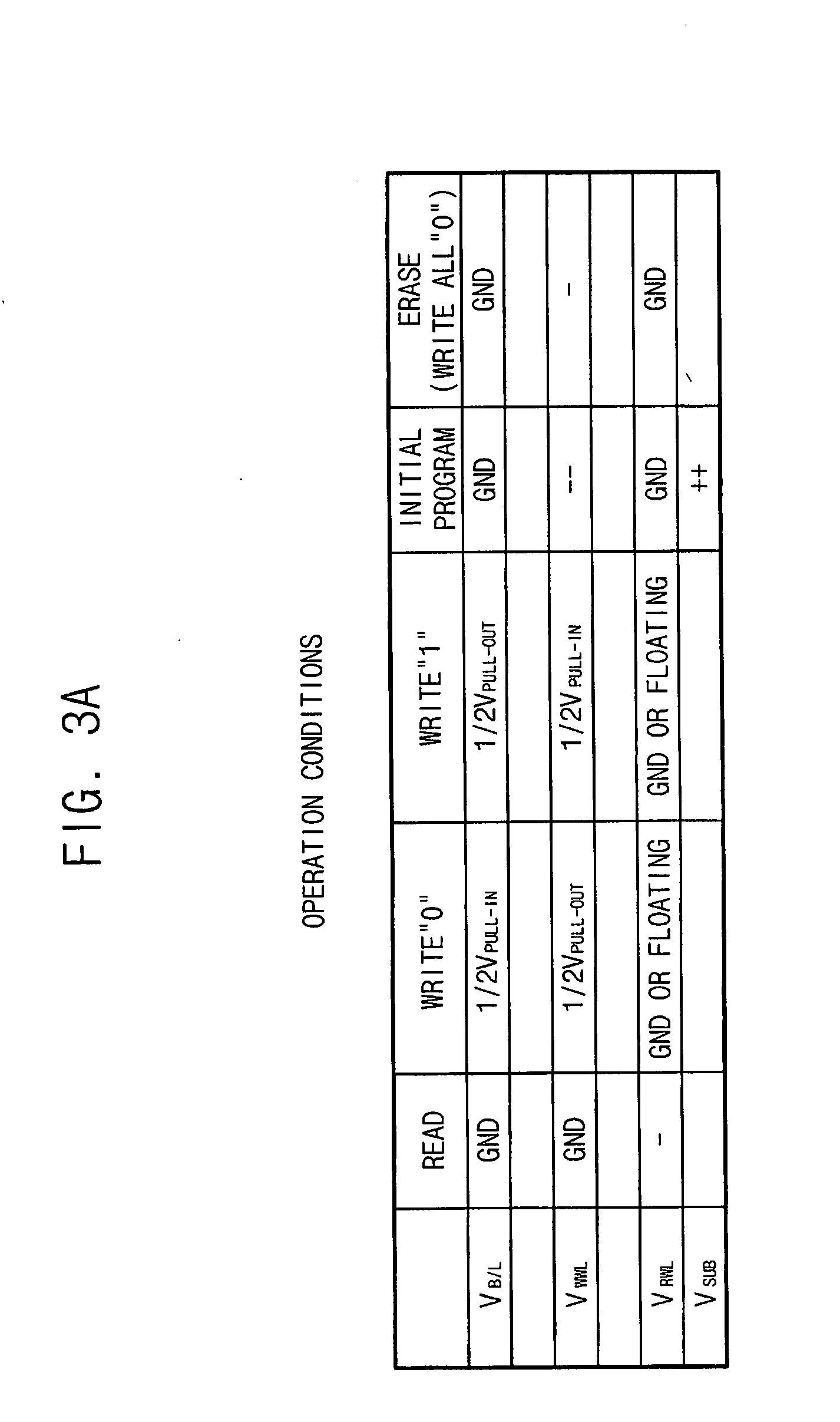

Vertical electromechanical memory devices and methods of manufacturing the same

InactiveUS20080035928A1Run at high speedImprove data retentionTransistorElectrostatic/electro-adhesion relaysRest positionEngineering

In a memory device and a method of forming a memory device, the device comprises a substrate, a first electrode extending in a vertical direction relative to the substrate, and a second electrode extending in a vertical direction relative to the substrate, the second electrode being spaced apart from the first electrode by a vertical gap. A third electrode is provided that extends in a vertical direction in the electrode gap, the third electrode being spaced apart from the first electrode by a first gap and the third electrode being spaced apart from the second electrode by a second gap, the third electrode being elastically deformable such that the third electrode deflects to be electrically coupled with the first electrode through the first gap in a first bent position and to be electrically coupled with the second electrode through the second gap in a second bent position, and to be isolated from the first electrode and the second electrode in a rest position.

Owner:SAMSUNG ELECTRONICS CO LTD

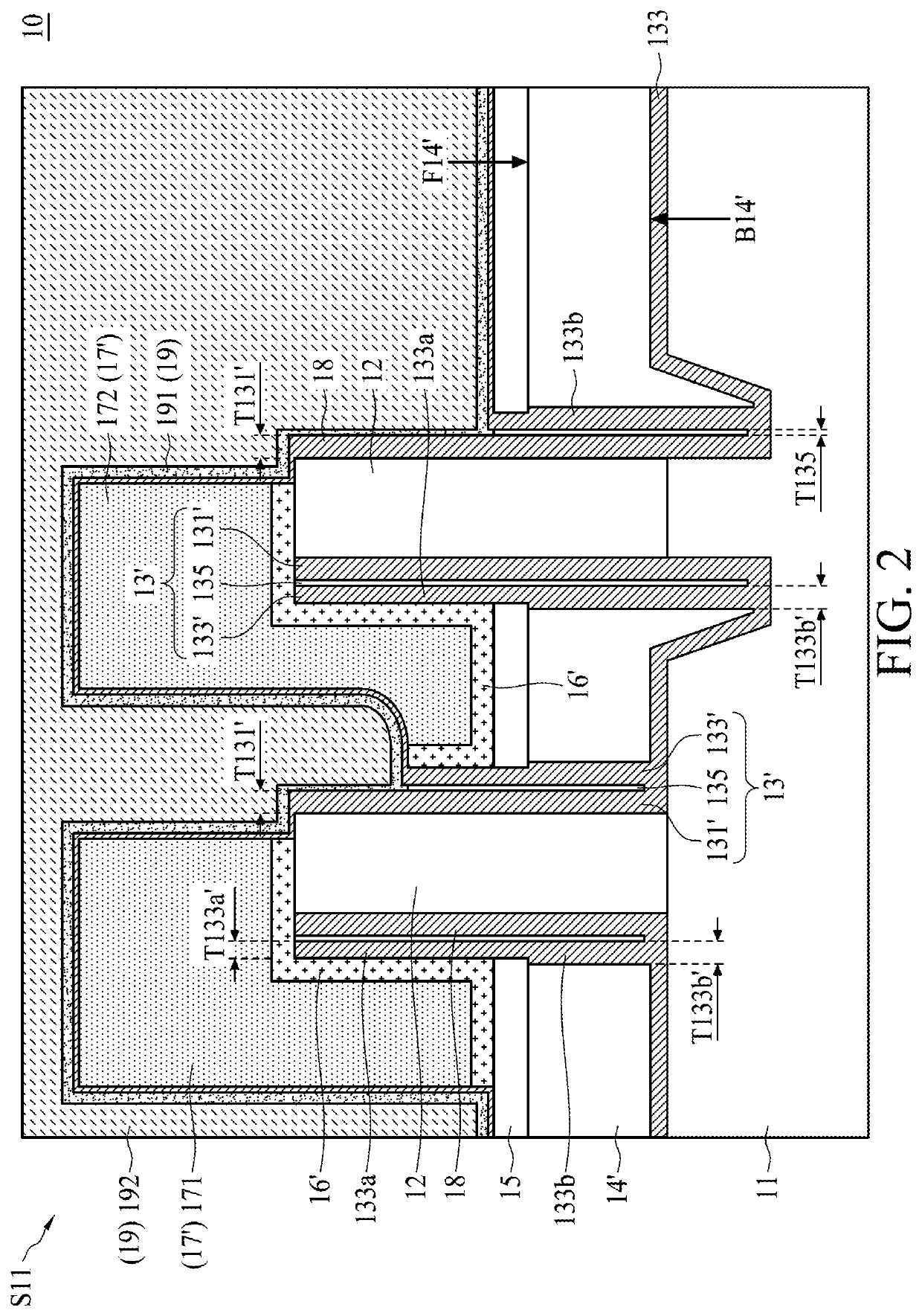

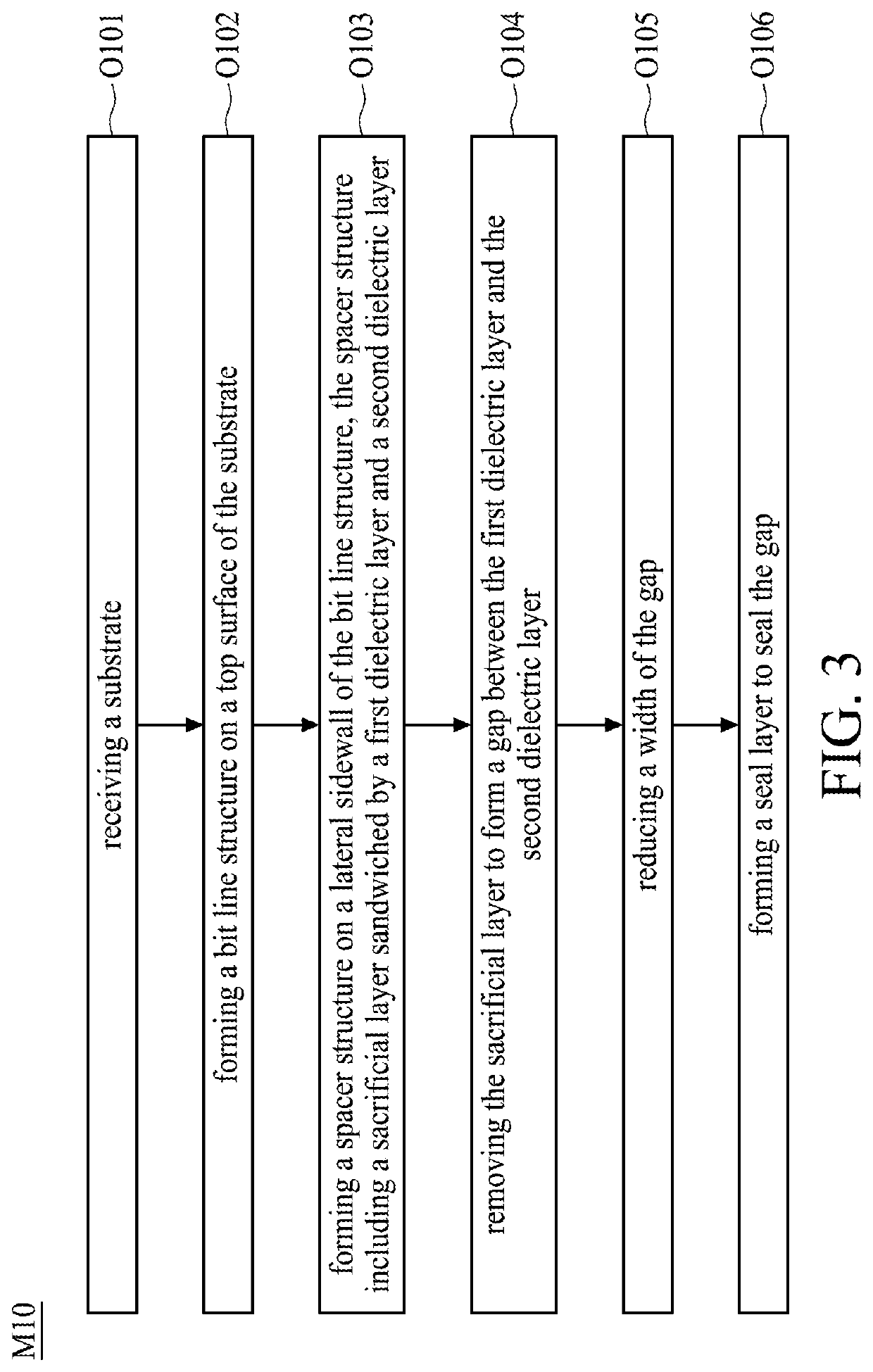

Semiconductor structure and manufacturing method of the same

ActiveUS11133318B2Reduce the gap widthReduce widthTransistorSemiconductor/solid-state device detailsBit lineSemiconductor structure

The present disclosure provides a semiconductor structure. The semiconductor structure includes: a polysilicon layer, having a first surface and a second surface opposite to the first surface; a substrate, disposed on the second surface of the polysilicon layer; a bit line structure, disposed on the substrate, penetrating through the polysilicon layer and protruding from the first surface of the polysilicon layer; and a spacer structure, disposed on lateral sidewalls of the bit line structure, including an air gap sandwiched by a first dielectric layer and a second dielectric layer, wherein a first portion of the second dielectric layer is in the polysilicon layer, a second portion of the second dielectric layer is outside the polysilicon layer, and a thickness of the second portion of the second dielectric layer is less than a thickness of the first portion of the second dielectric layer.

Owner:NAN YA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com