Display panel and manufacturing method thereof and display device

A technology for a display panel and a manufacturing method, which is applied to the housings with display/control units, electrical equipment housings/cabinets/drawers, instruments, etc., which can solve the problems of unfavorable display panels such as narrow borders and widened spaces, and achieve width reduction. Small size, reduced gap width, and the effect of preventing light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the display panel provided by the embodiments of the present invention, its manufacturing method and the display device will be described in detail below with reference to the accompanying drawings.

[0032] The shapes and sizes of the regions in the drawings do not reflect the true proportions of the display panel, but are only intended to schematically illustrate the content of the present invention.

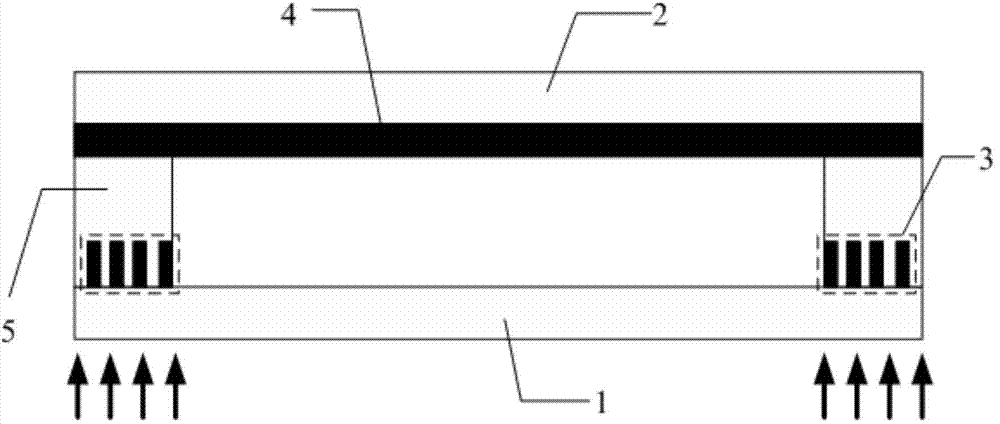

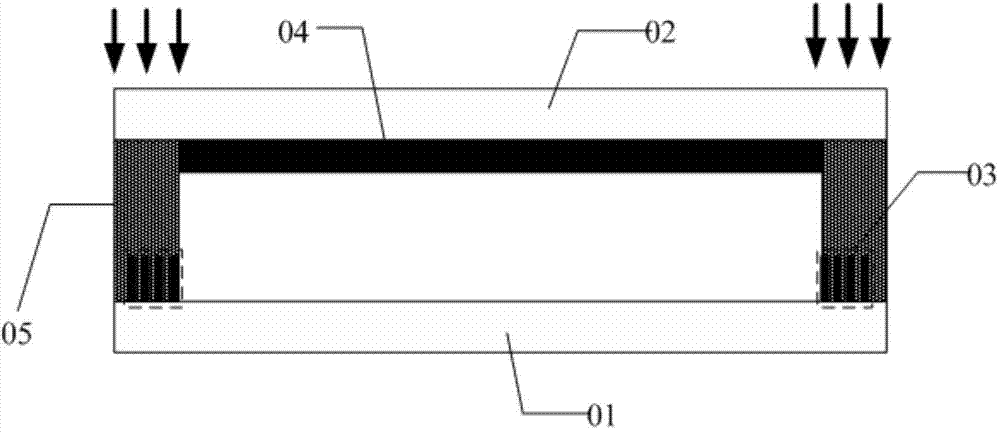

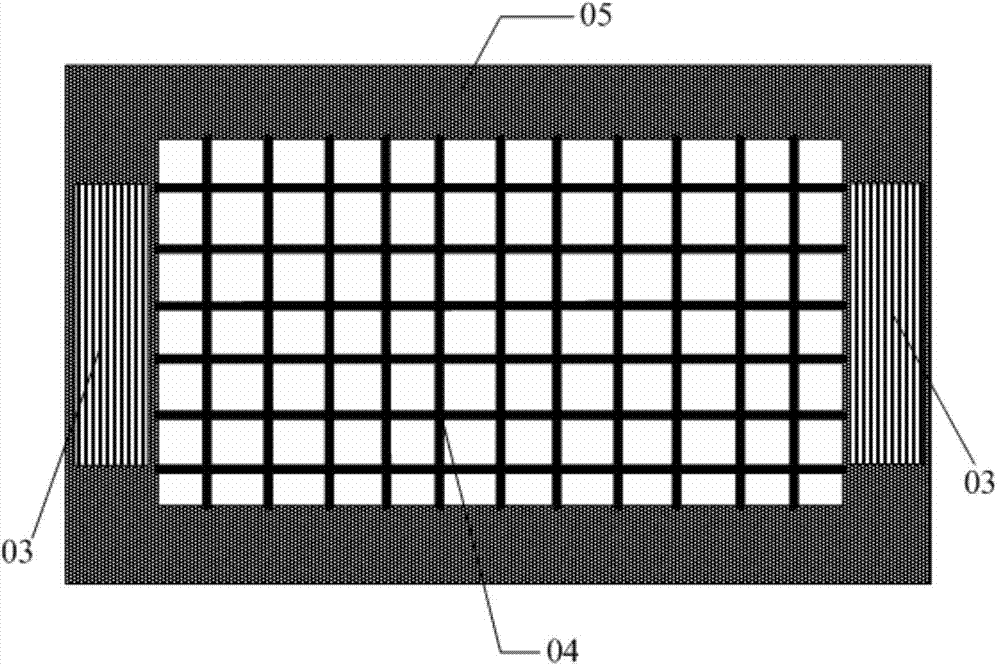

[0033] An embodiment of the present invention also provides a display panel, such as figure 2 As shown, the display panel includes an array substrate 01 and an opposite substrate 02 arranged oppositely; wherein,

[0034] The pattern of the drive circuit 03 and peripheral wiring (not shown in the figure) is provided in the frame area of the side of the array substrate 01 facing the opposite substrate 02, and the side of the array substrate 01 facing the opposite substrate 02 and / or the opposite substrate 02 faces One side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com