Metal shell, mobile terminal and manufacturing method

A metal shell and mobile terminal technology, applied in the direction of metal shell, chassis/cabinet/drawer parts, etc., can solve the problems of destroying the integrated beauty of the product and the width of the broken seam, and achieve the improvement of the integrated appearance aesthetics, The effect of reducing the width of the antenna slit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

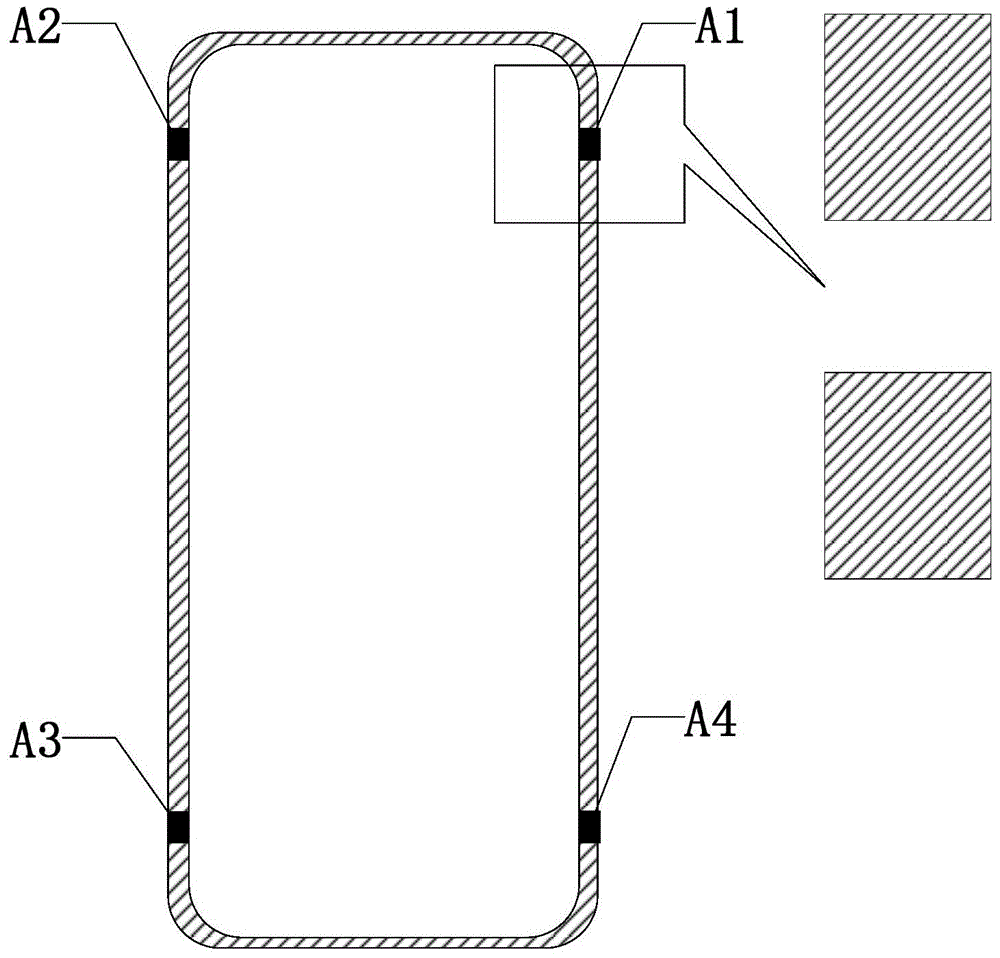

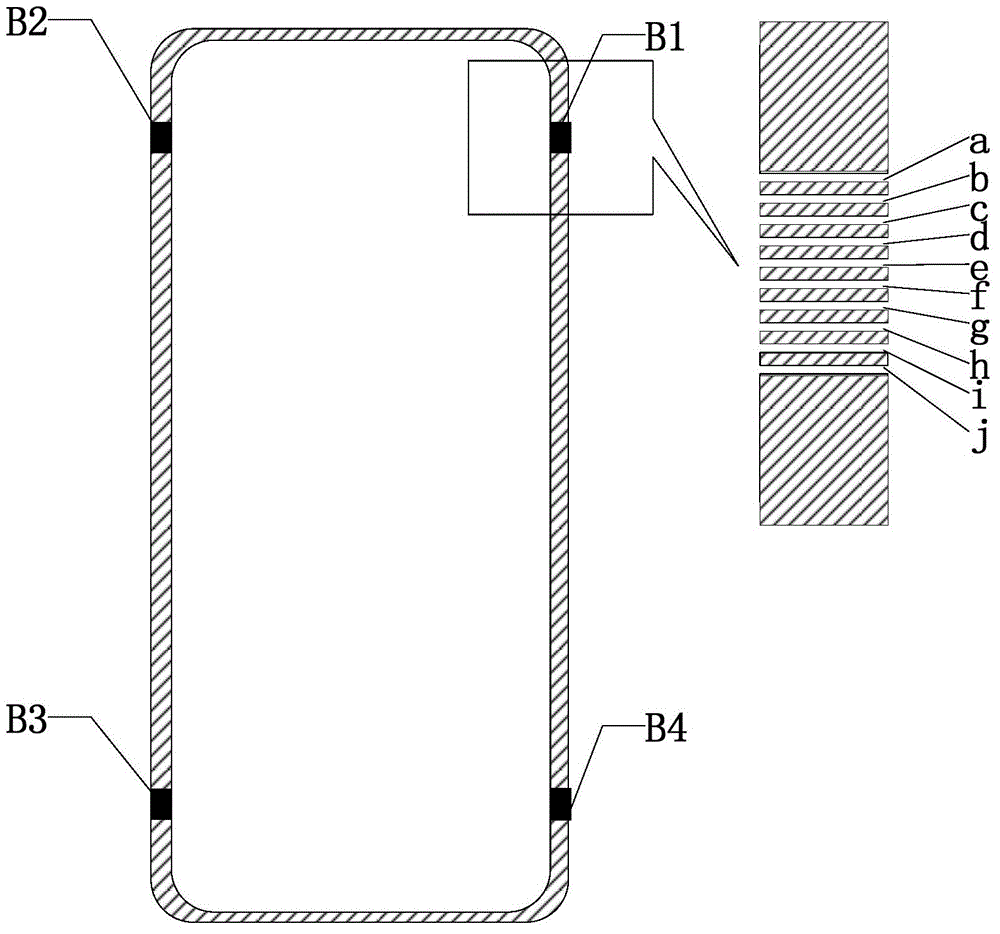

[0038] An embodiment of the present invention provides a metal casing, figure 2 A top view of a metal casing provided for Embodiment 1 of the present invention. Such as figure 2 As shown, four slit areas B1, B2, B3, B4 are set on the metal shell, and each slit area B1, B2, B3, B4 contains n slits, wherein n is an integer not less than 1, and each slit The width is less than or equal to the set value so that each gap is invisible to the naked eye. figure 2 A partial enlarged view of the slit area B1 is also given, and the slit area B1 includes 10 slits in an exemplary manner, a-j in sequence. Wherein the width of the gap a-j is less than or equal to the set value, so that each gap is invisible to the naked eye, the width of the gap a-j can be equal or unequal to each other, the specific setting parameters can be set according to the application scene, this embodiment is here There is no limitation, as long as the width of each slit is less than or equal to the set value, ...

Embodiment 2

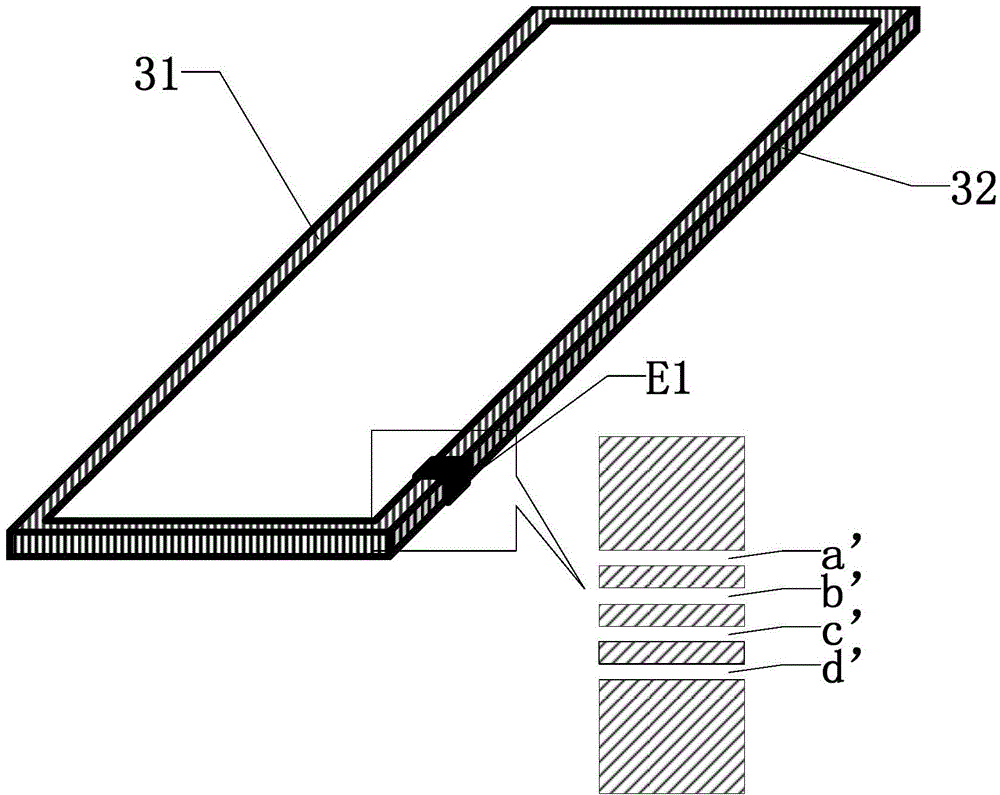

[0044] The metal casing provided by the embodiments of the present invention can be applied to various mobile terminal devices, such as mobile phones, tablet computers and the like. image 3 It is a schematic structural diagram of a metal casing provided by Embodiment 2 of the present invention. Such as image 3 As shown, the metal casing includes a frame 31 , a middle frame 32 and a rear cover (not shown). A gap area E1 is provided on the metal casing, and the gap area E1 is located on the frame 31 and the middle frame 32 . image 3 A partial enlarged view of the slit area E1 is also given, the slit area E1 contains n slits, n is equal to 4, followed by a'-d', E1 contains 4 slits, and the width of each slit is less than or equal to the set value so that each gap is invisible to the naked eye.

[0045] It should be noted that, similar to Embodiment 1, image 3Schematically shows one gap area, and four gaps a'-d' in the gap area, but this is only a specific structure of the...

Embodiment 3

[0051] The embodiment of the present invention also provides a method for manufacturing a metal shell, Figure 6 It is a schematic flowchart of a method for manufacturing a metal shell provided by Embodiment 3 of the present invention. Such as Figure 6 As shown, the method includes:

[0052] Operation 110, processing the metal material into a predetermined shape to obtain a first shell;

[0053] Wherein, the processing technology of the first shell may be stamping the metal material using a numerical control machine tool or a preset stamping die to obtain the first shell. The shape of the first housing can be specifically set according to actual needs. For example, the obtained first casing includes a frame, a middle frame and a back cover, and may also refer to including a middle frame and a back cover, wherein the middle frame and the back cover may be integrally or separately.

[0054] Operation 120, processing at least one gap area on the set position of the first cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com