Touch panel and manufacturing method therefor

The technology of a touch panel and its manufacturing method is applied in the directions of instruments, electrical digital data processing, and the input/output process of data processing, etc., which can solve problems such as low local touch sensitivity, poor anti-damage performance, and complicated manufacturing process, and achieve improved Touch sensitivity, good flexibility, low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

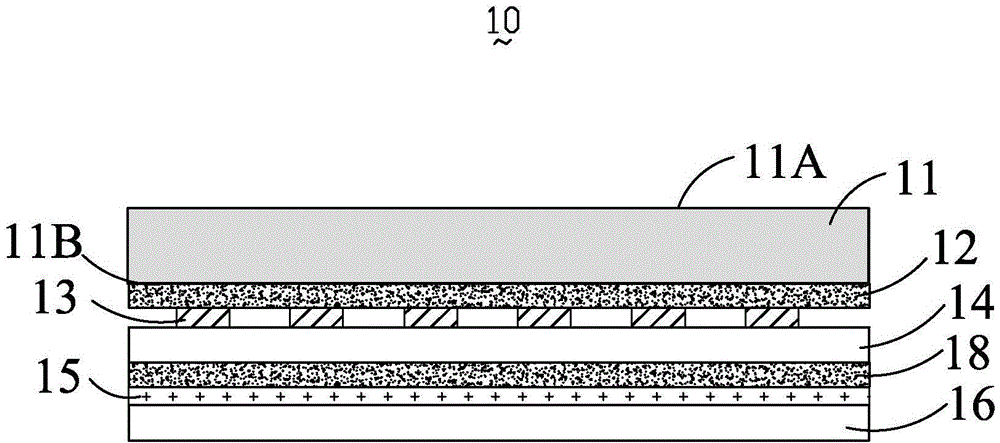

[0088] Modified Embodiment 1: From the superposition effect of the first nano-silver wire electrode string 131 and the second nano-silver wire electrode string 151, the first side wall 131a of the first nano-silver wire electrode string 131 located on the outermost side and the first nano-silver wire electrode string 131 The distance length of the boundary of the two nanometer silver wire electrode strings 151 is T, T=W=H, that is, viewed from the Y direction, the first nanometer silver wire electrode strings 131 are arranged at equal intervals on the entire touch panel 10, and when this parameter is satisfied In the case of , the touch sensitivity of the touch panel 10 can be further improved.

[0089] Modified Embodiment 2: The width W of the non-conductive region 133 is equal to the distance H between the two first nano-silver wire electrode strings 131, and the non-conductive region 133 is arranged in the middle of the first nano-silver wire electrode string 131, that is, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com