Method for mfg. selective local self-aligned silicide

A production method and technology of silicide, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of reduced process margin, difficulty, and increased manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

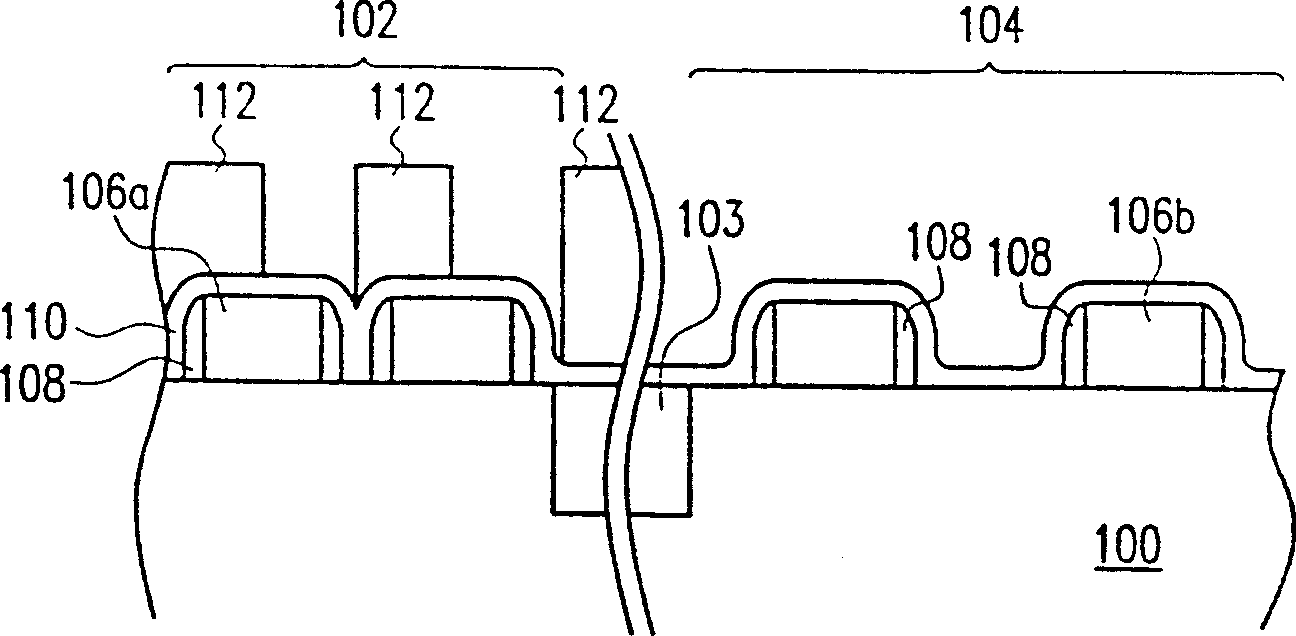

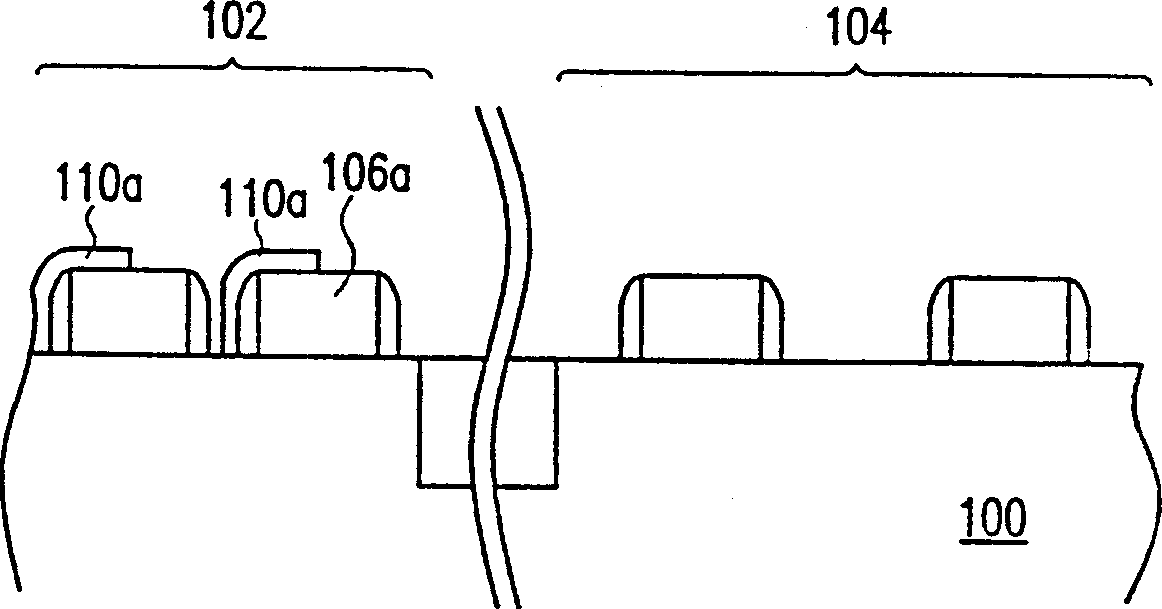

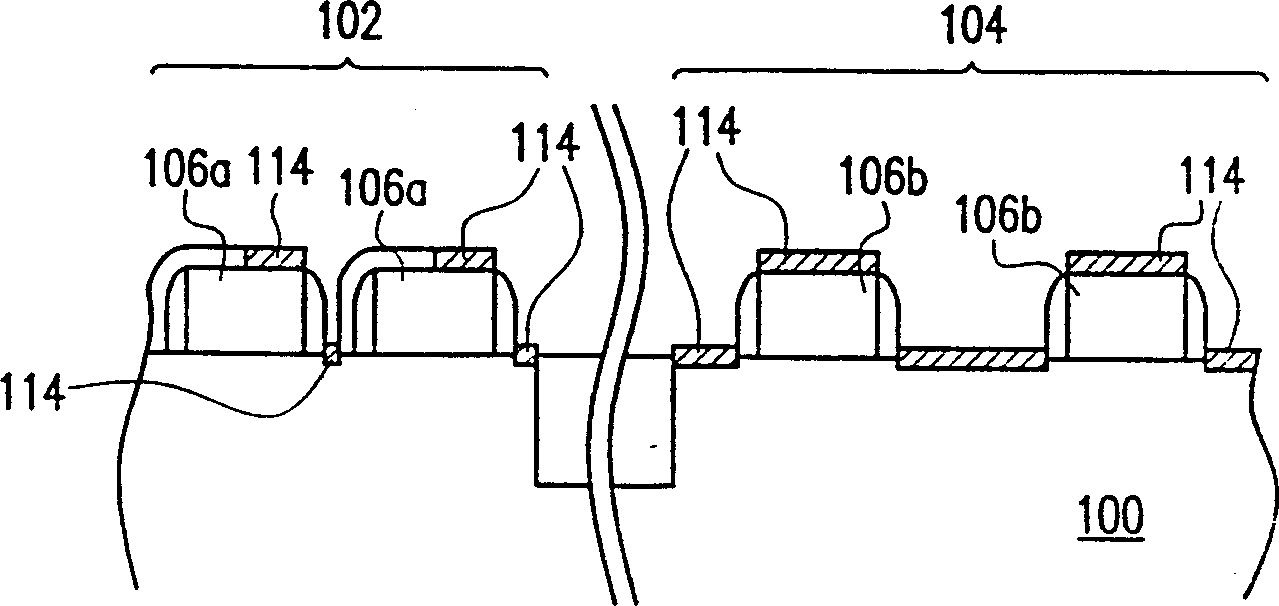

[0029] Figure 2A to Figure 2F It is a cross-sectional view of the manufacturing process of selective local self-aligned silicide according to an embodiment of the present invention.

[0030] Please refer to Figure 2A First, a substrate 200 divided into a memory cell area 202 and a logic circuit area 204 by an isolation area 203 is provided. Then, a plurality of gates 206 a, 260 b are formed on the substrate 200 , and the gap between the gates 206 a of the memory cell region 202 is narrower than that of the gates 206 b of the logic circuit region 204 . In addition, a spacer 208 is formed on the sidewalls of the gates 206a and 206b.

[0031] Next, please refer to Figure 2B , forming a conformal first barrier layer 210 on the substrate 200 , such as a photoresist protection oxide layer (Resist Protect Oxide, PRO) made of silicon oxide, to cover the memory cell area 202 and the logic circuit area 204 . The first barrier layer 210 on the memory cell area 202 can reduce the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com