Integrated controller for optimizing pulse dust removal

A technology of pulse dust removal and controller, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of high cost of software and hardware, huge system, difficult to popularize, etc., achieve strong functions, improve system efficiency, The effect of reducing equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

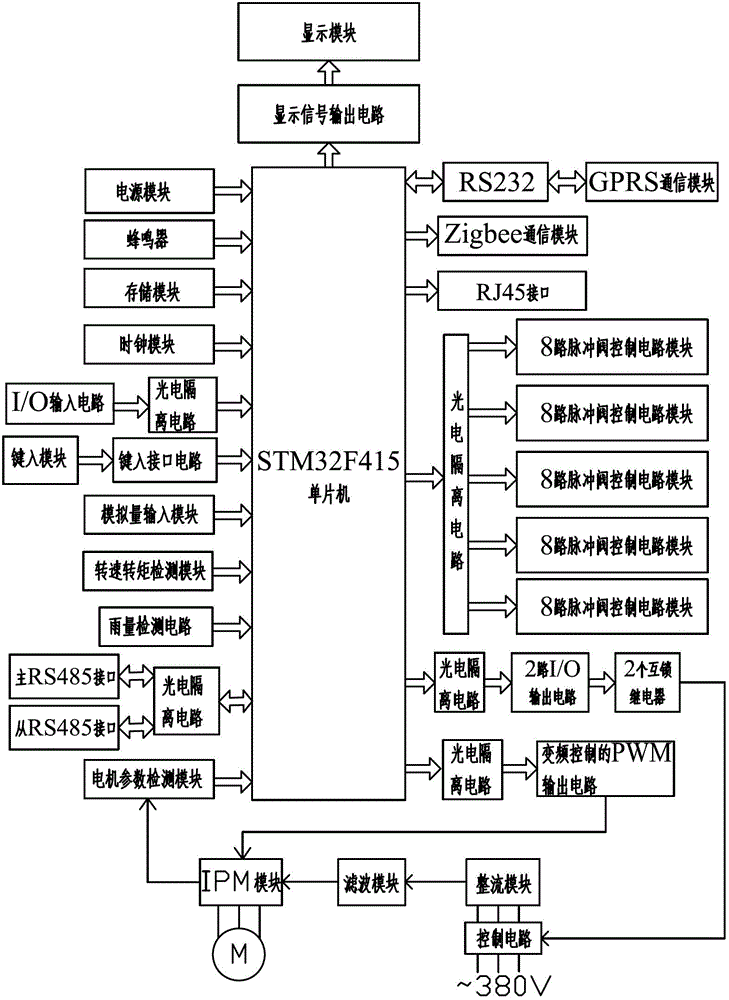

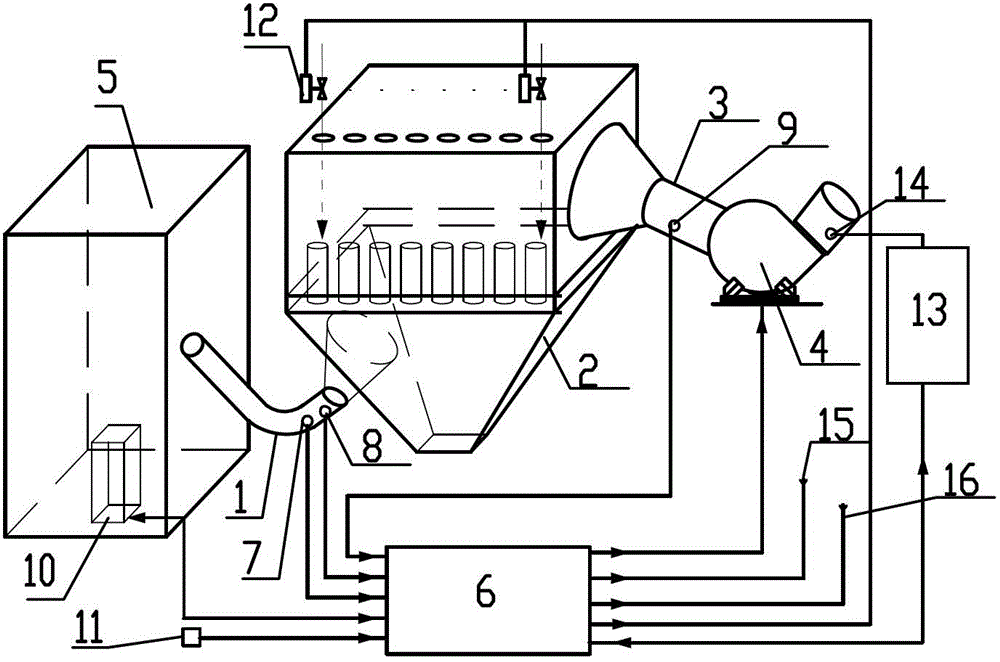

[0025] Such as figure 1 As shown, a kind of integrated controller applied to pulse dust removal optimization treatment of the present invention includes a housing, a central processing unit, a power supply module, a storage module, a clock module, and an analog input module arranged on the circuit board in the housing , switch input module, rainfall detection circuit, motor parameter detection module, speed torque detection module, control signal output module, I / O output circuit, PWM output circuit, rectifier module, filter module, IPM module, display signal output circuit, Communication interface circuit, GPRS communication module and Zigbee communication module, and the display module and input module arranged on the housing, the power supply module, storage module, clock module, analog input module, switch input module, rain detection circuit, The motor parameter detection module, speed torque detection module, control signal output module, I / O output circuit, PWM output c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com