Control circuit and control method of flyback convertor and alternating current-direct current power converting circuit applying control circuit of flyback convertor

A flyback converter and control circuit technology, applied in the field of power supply, can solve the problems of increasing circuit cost and size, unfavorable chip miniaturization, package design, and complicated control scheme, so as to save chip size and improve pin utilization , The effect of saving chip pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Several preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention is not limited to these embodiments. The present invention covers any alternatives, modifications, equivalent methods and schemes made on the spirit and scope of the present invention. In order to provide the public with a thorough understanding of the present invention, specific details are set forth in the following preferred embodiments of the present invention, but those skilled in the art can fully understand the present invention without the description of these details.

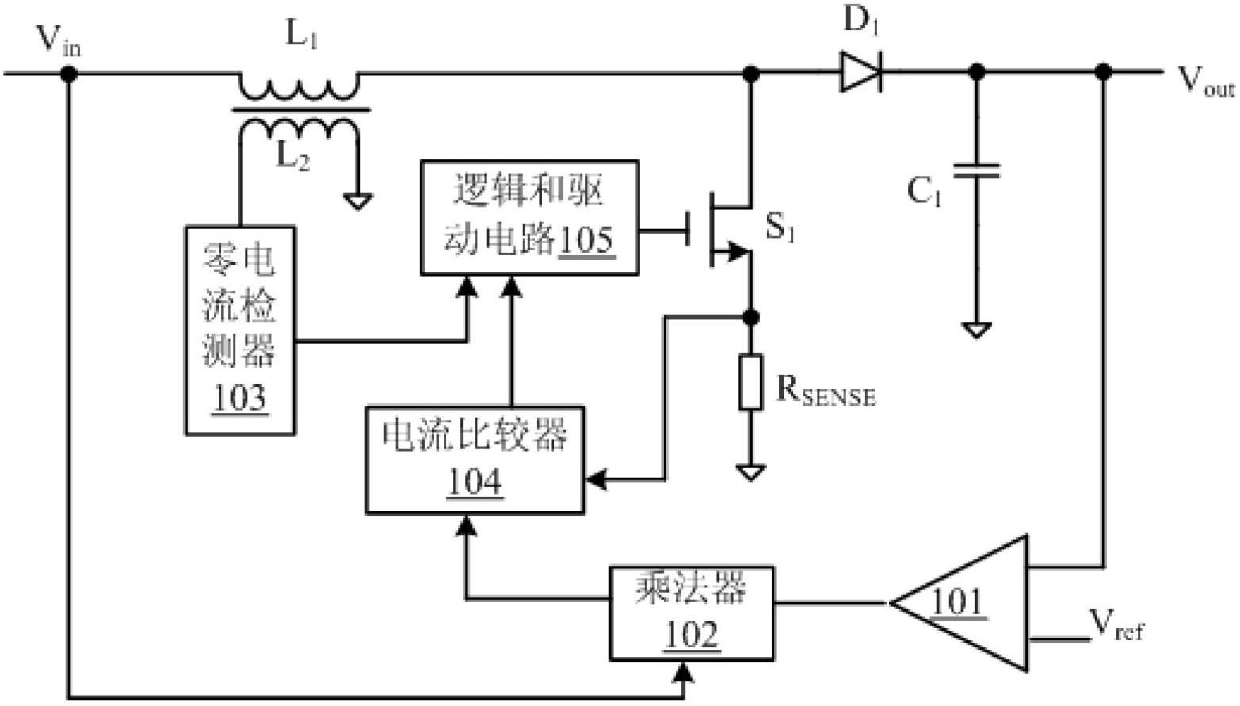

[0048] refer to figure 2 , shows a functional block diagram of a control circuit of a flyback converter according to an embodiment of the present invention. In this embodiment, the control circuit 200 of the flyback converter includes a turn-on signal generation circuit 21 , a turn-off signal generation circuit 22 and a control signal g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com