Electromagnetic lead screw driving type precise-punching presser

An electromagnetic screw and driven technology, applied in the field of fine blanking presses, can solve the problems of short service life, easy damage to permanent magnets, and low control accuracy, achieve low cost, improve production efficiency and processing accuracy, and avoid The effect of spring aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

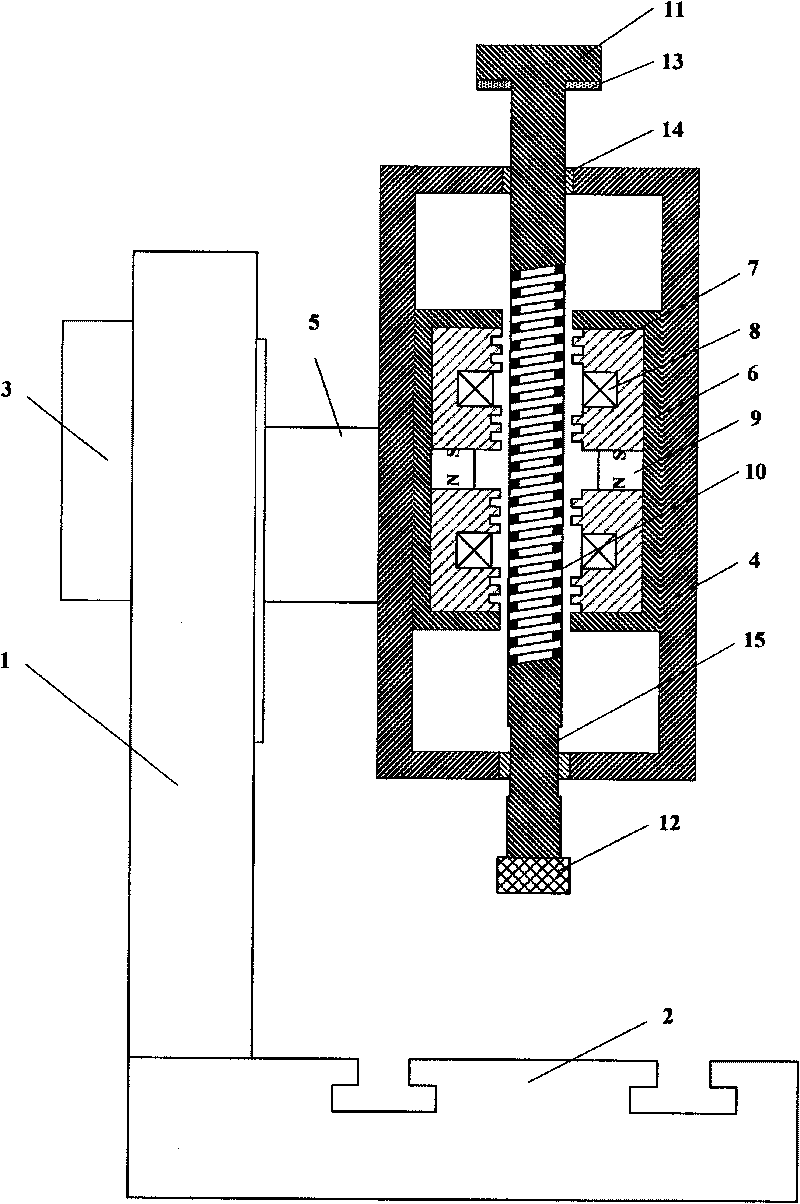

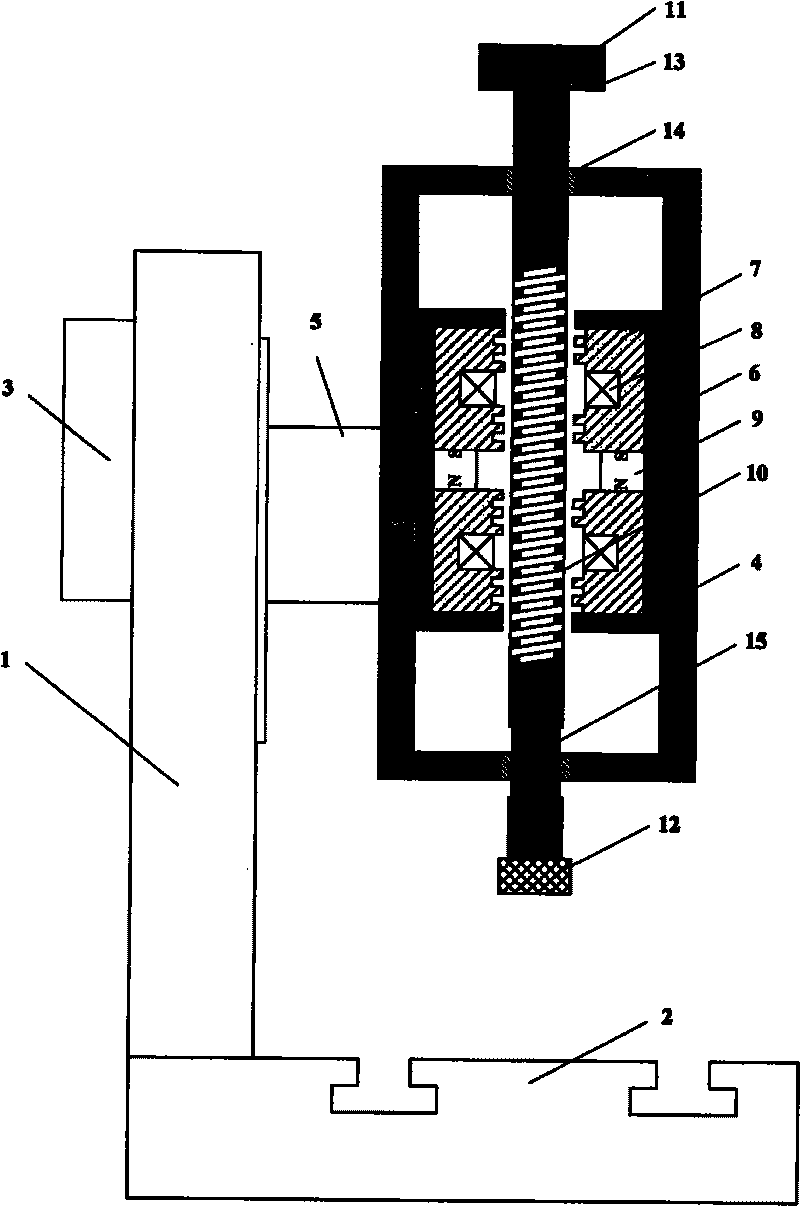

[0026] Such as figure 1 The main structure of the shown fine blanking press consists of a fuselage 1 , a working platform 2 , a controller 3 and a frame 4 . The working platform 2 is provided with a T-shaped slot, which is used to fix the device for clamping the die, the blank holder system, the back pressure system and other components. The frame 4 is connected with the fuselage 1 through the connecting plate 5, and its height can be adjusted according to the requirements of the closed height. The electromagnetic lead screw system is installed on the frame 4. The electromagnetic nut 6 is fixed on the frame 4 by bolts. The electromagnetic nut 6 includes two annular iron cores 7, each annular iron core 7 is divided into upper and lower parts by a coil 8, and the distance between the two parts is n / 2 (n is a positive odd number) double pitch. An annular permanent magnet 9 is sandwiched between the two iron cores 7, and the distance between the two iron cores is n / 4 (n is a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com