Mechanical mechanism for converting reciprocating motion power into rotary power

A mechanical mechanism and reciprocating motion technology, applied in the direction of mechanical equipment, transmission devices, belts/chains/gears, etc., can solve the problems of non-adjustable ratio of torque and speed, low mechanical efficiency, vibration of mechanical equipment, etc., to achieve convenience and stepless Speed regulation or stepped speed regulation, low production cost and high mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

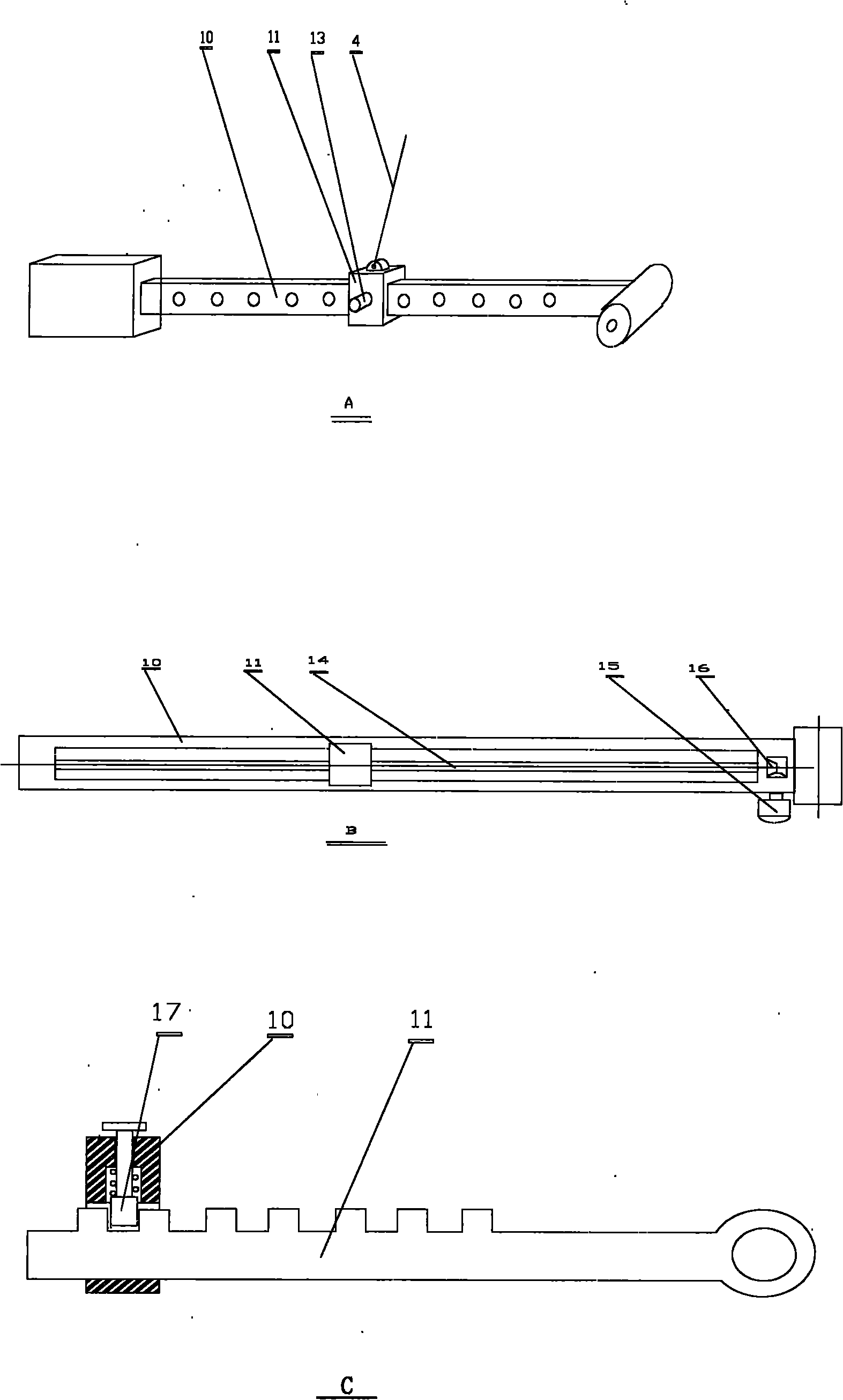

[0026] The principle of the present invention and its implementation will be further described below in conjunction with the accompanying drawings.

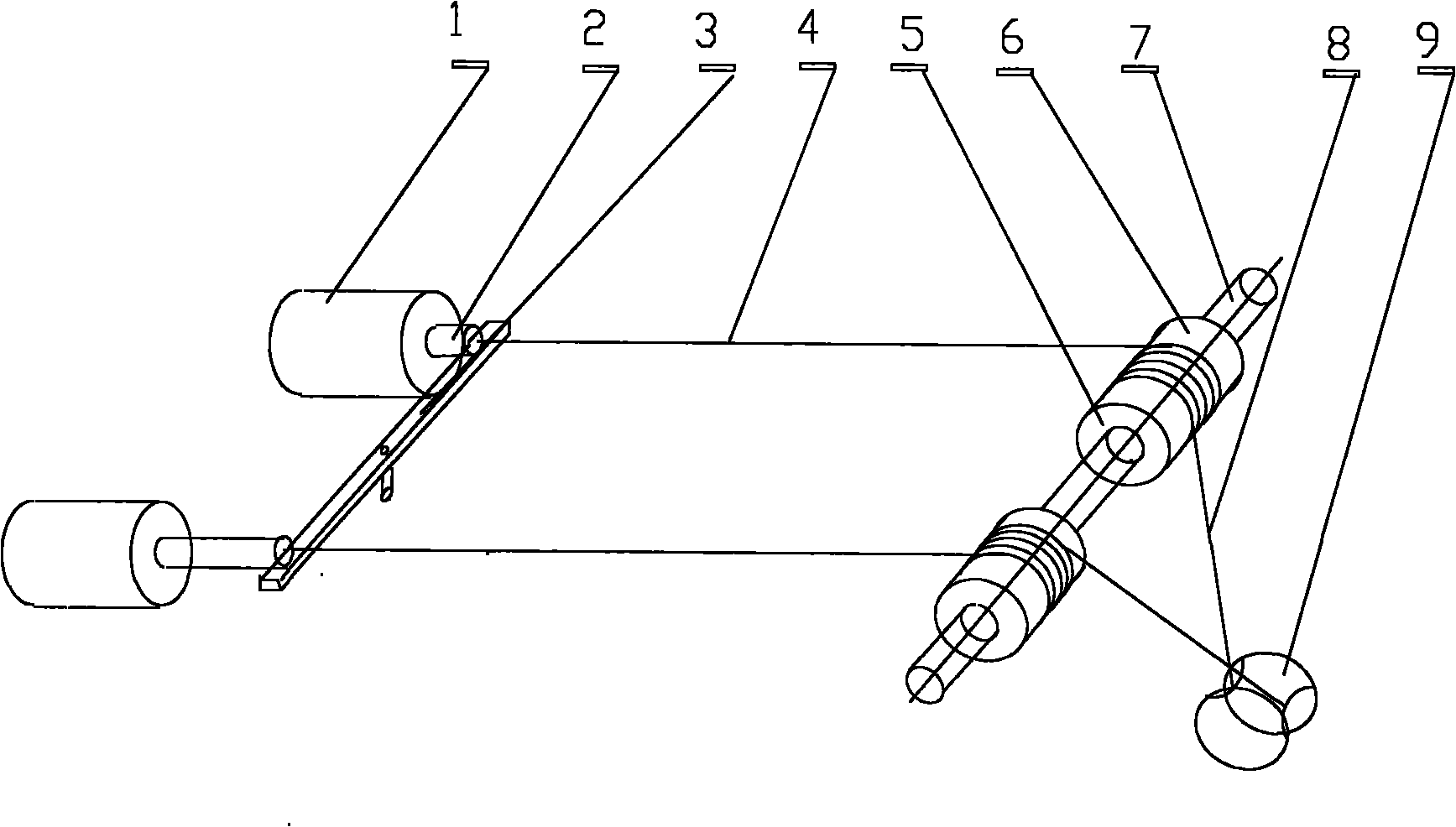

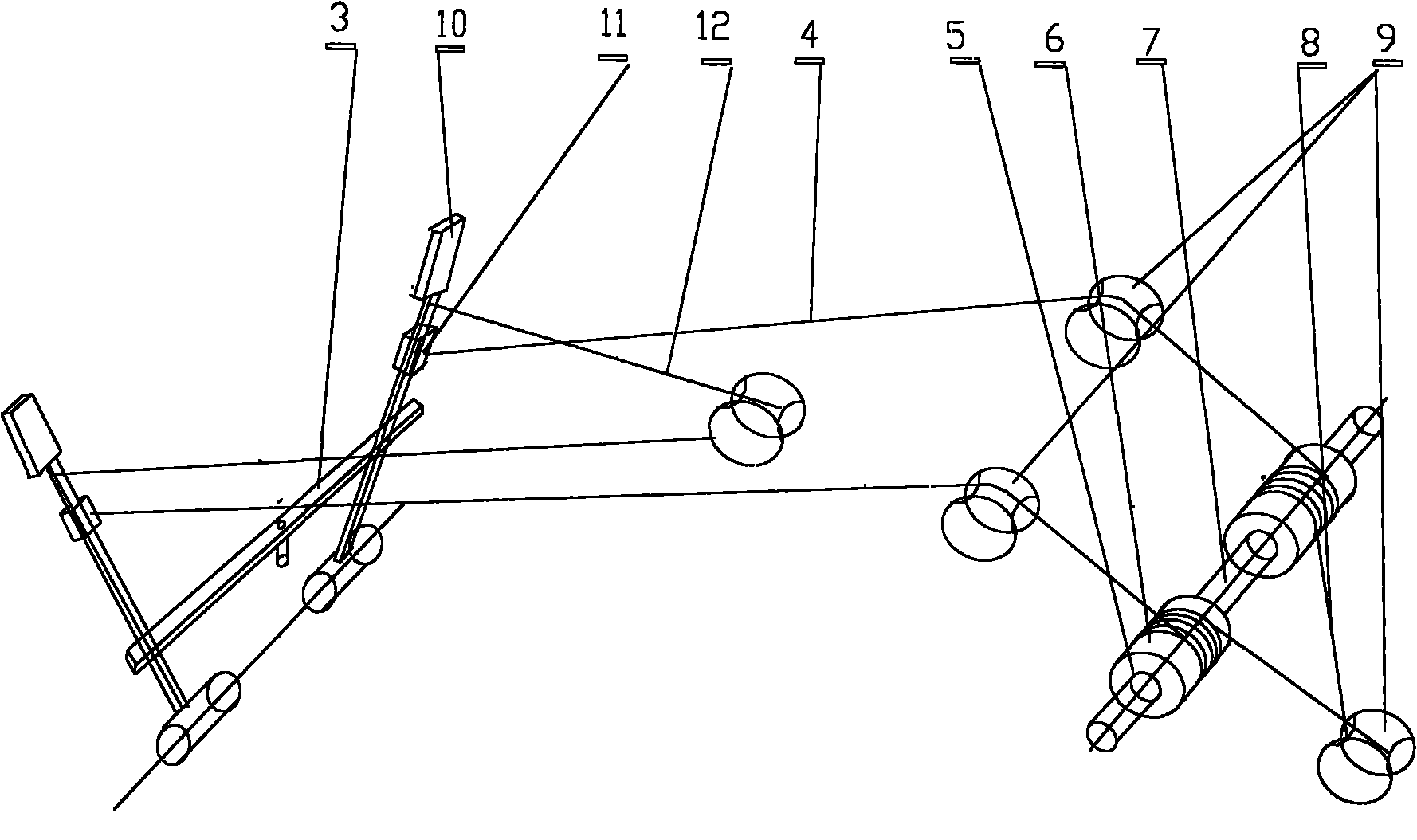

[0027] attached figure 1 Among them, the power source of the reciprocating motion is the cylinder (1) and the piston (2), which can be driven by compressed air or pressure steam. The two pistons (2) pull the two rope drums (6) to rotate through the rope (4) in turn, and the rope drum ( 6) Drive the power output shaft (7) to rotate through the overrunning clutch (5). This cylinder (1) can be a cylinder powered by compressed air or steam, or it can also be the cylinder of an internal combustion engine. The return stroke of piston (2) does not output power, and at this moment the revolution of rope drum (6) is to be formed by the mechanism pulling of revolving stay cable (8), pulley (9).

[0028] Utilize the revolving rope drum (6) to pass through the rope (4) again, and also can pull the return stroke of the piston (2) that does ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com