Speed changer

A technology of transmission and claw clutch, applied in the direction of gear transmission, transmission control, belt/chain/gear, etc., can solve the problems of unstable performance, high maintenance cost, low mechanical efficiency, etc., to achieve easy operation and continuous production. Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

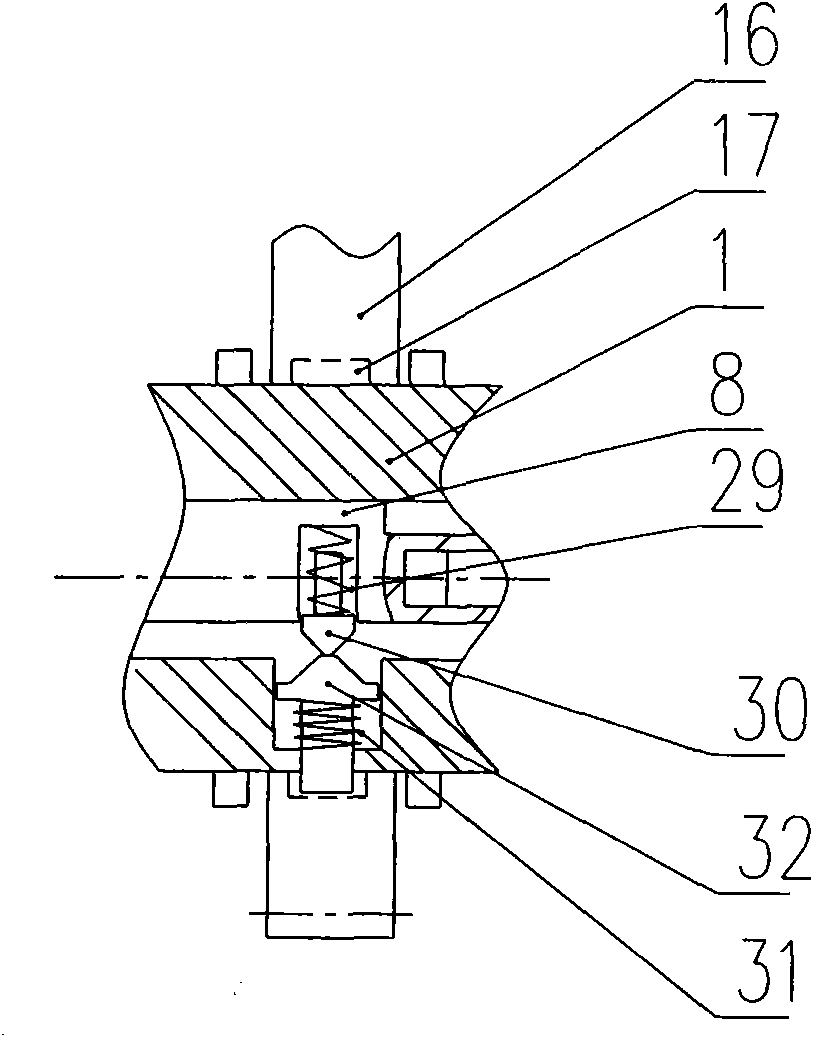

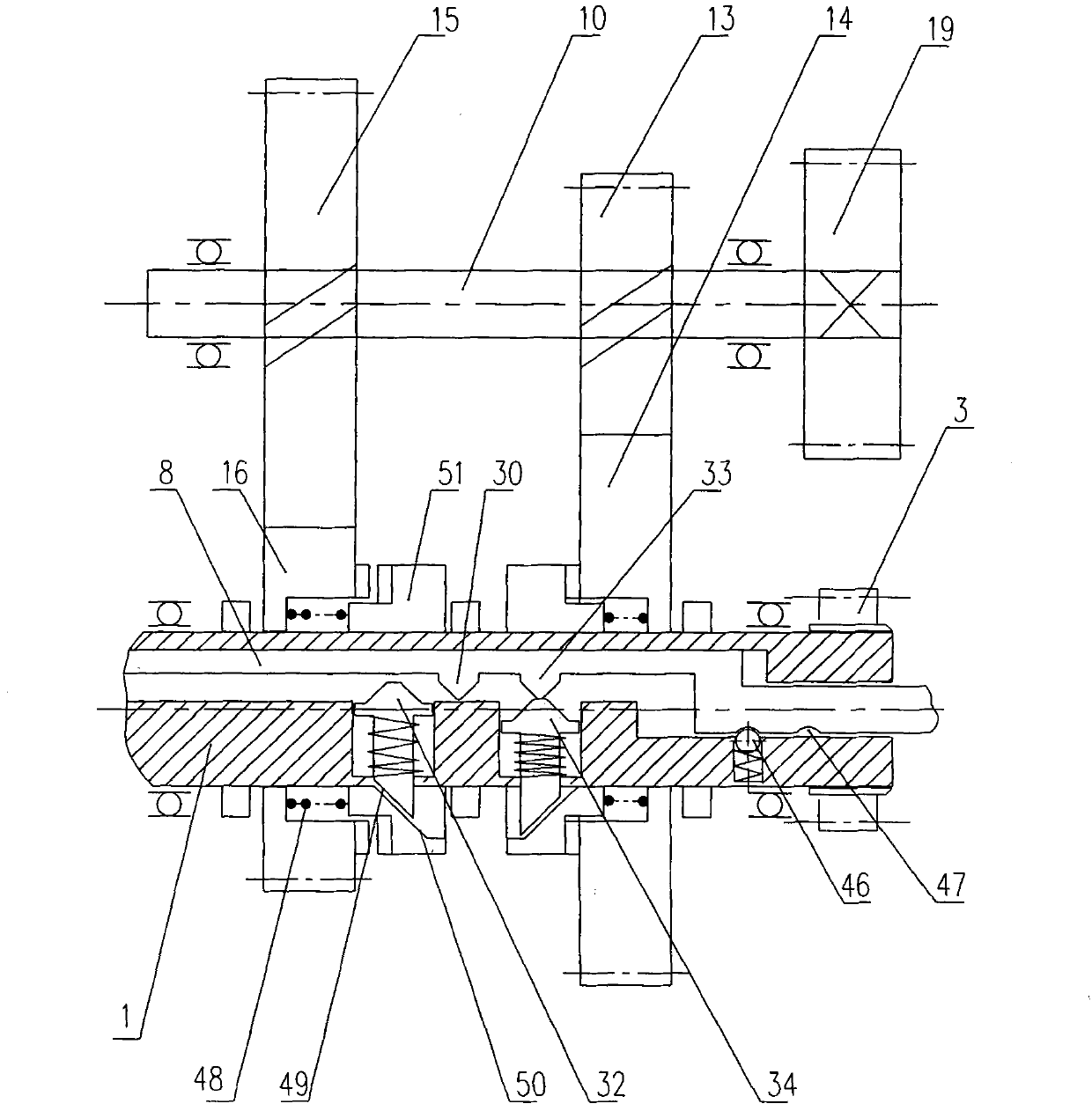

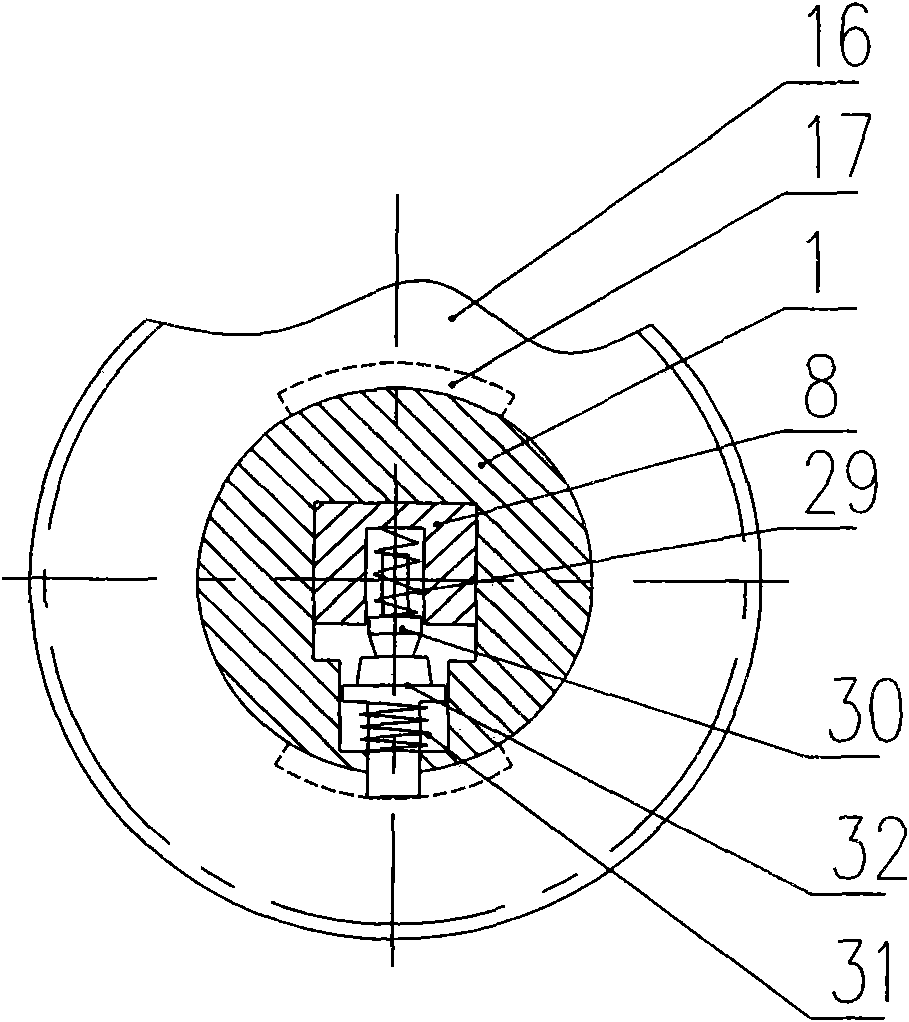

[0034] Such as figure 1 , figure 2 and image 3 As shown, the power input gear 3 is fixed to the outer casing 43, and one end of the outer casing is processed with an inner circular sliding tooth 45 and a thrust inner ring 44. The sliding tooth 45 is installed on the outer ring groove 2 at one end of the gear shaft 1, and the gear shaft 1 The thrust outer ring 6 is fixed on the top, and the outer sleeve can rotate forward and reverse relative to the gear shaft. The sliding sleeve 42 and the outer sleeve 43 are matched by a helical rack, and the sliding sleeve 42 and the gear shaft 1 are matched by a straight rack or a helical rack. The sleeve 42 is installed between the thrust inner ring 44 of the overcoat and the thrust outer ring 6 of the gear shaft, and the sliding sleeve can reciprocate and axially move between the thrust inner ring of the overcoat and the thrust outer ring of the gear shaft. A compressed spring 7 is installed between an axial end face of the sliding sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com