Roller grinding device capable of stabilizing material layer and improving grinding effect of fine particles

A fine particle and grinding technology, applied in cement production, grain processing, etc., can solve problems such as grinding roller vibration, inability to completely and effectively intercept particle groups, and reduced energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing:

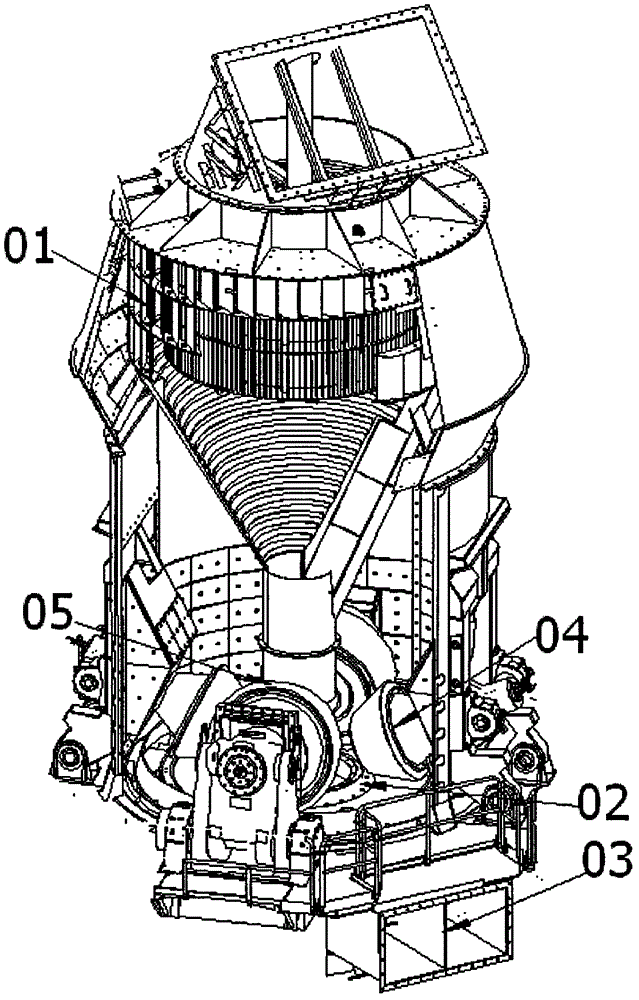

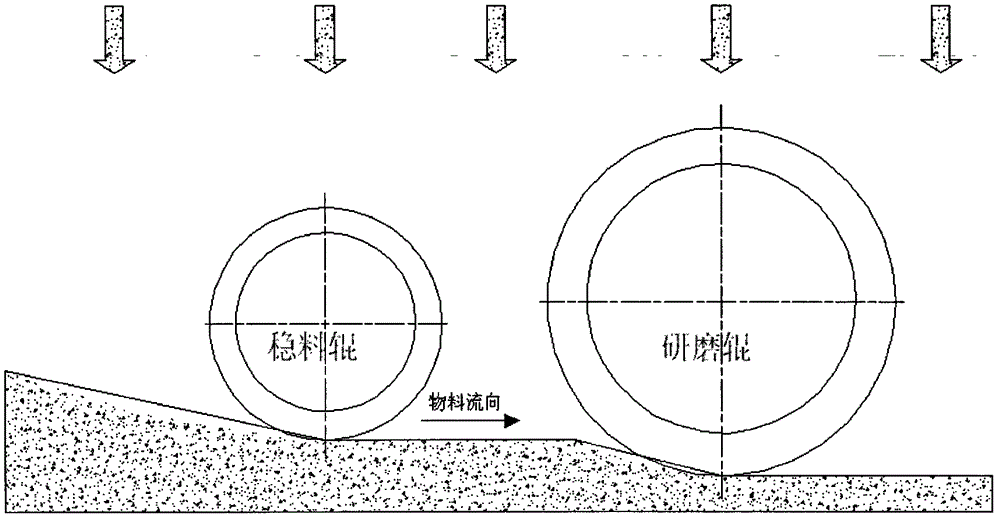

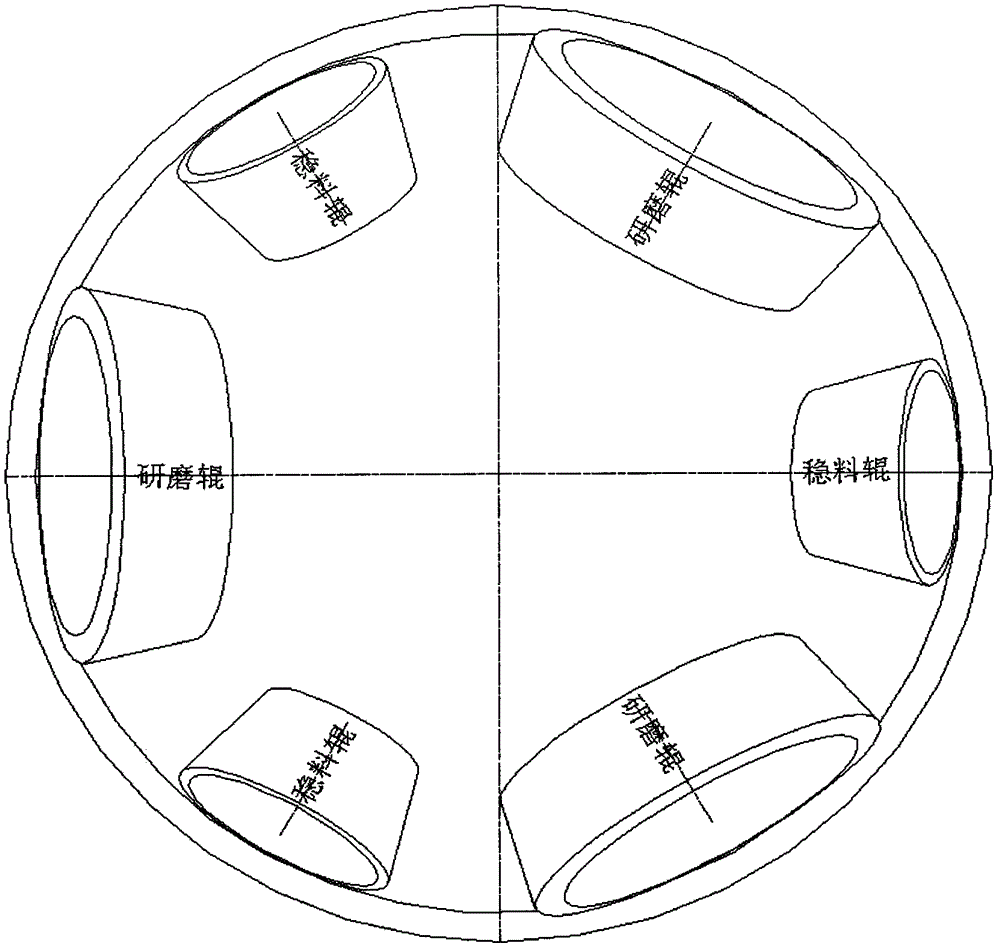

[0012] Depend on figure 1 As shown, the condition of the stable fine particle layer of the present invention and its vertical roller mill relate to the grinding of granular materials such as slag and similar substances produced by iron and steel smelting and clinker produced by cement rotary kiln. By using this device, The granular material to be ground is conveyed to the upper discharge pipe of the vertical roller mill and then enters the horizontal grinding table 02. The hot air passing through the air chamber 03 dries the material and brings the finer material after grinding into the sorting device 01 for sorting. Finished product, the material is pre-compacted by the stabilizing roller 04 first, so that the gas in it is discharged, and the material forms a firm wedge shape, so that the grinding roller 05 can intercept them smoothly, roll and grind them, and after passing through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com