Tea powder grinding machine

A technology of grinder and tea powder, applied in the direction of solid separation, cocoa, chemical instruments and methods, etc., can solve the problems of pulverization, no tea leaves, etc., and achieve the effect of improving efficiency, facilitating grinding, and ensuring the effect of crushed materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

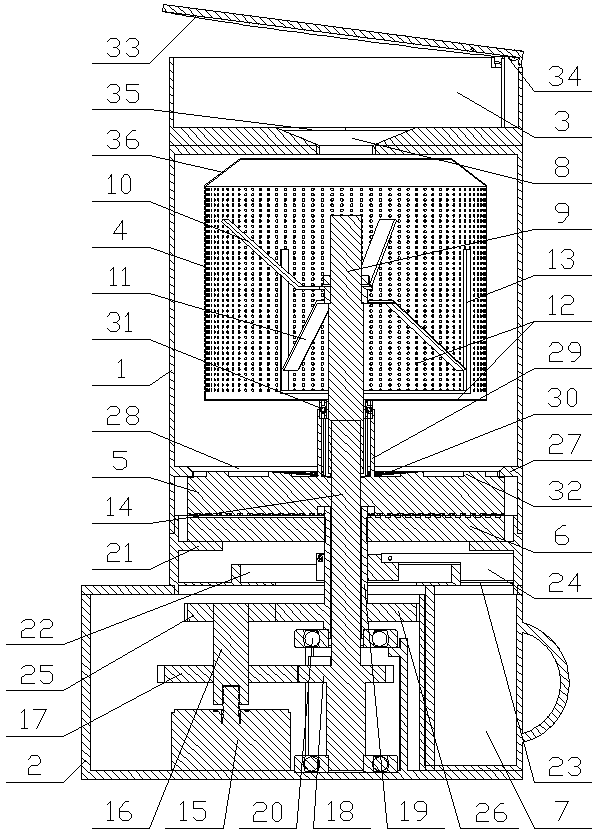

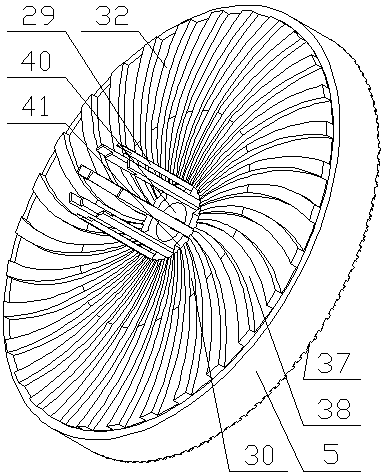

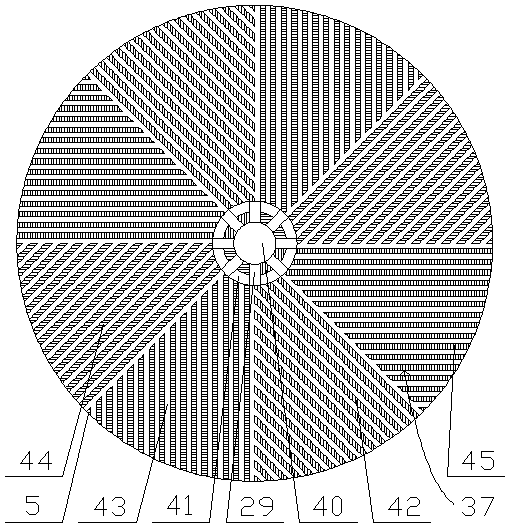

[0056] combine Figure 1~Figure 4 It can be seen that the present invention includes a casing 1, the bottom of the casing 1 is communicated with a base 2, the top of the casing 1 is connected with a feed trough 3, and the casing 1 is provided with mutual Connected crushing device and grinding device, the crushing device and grinding device are coaxially arranged, and are respectively connected to the drive motor 15 in the base 2 through the transmission shaft A14; the bottom of the feed tank 3 is provided with a feed port 8. The feed port 8 is located directly above the crushing device, and one side wall of the base 2 is provided with a filling slot for placing the filling container 7, and the base 2 is located at the position of the filling slot The top surface of the top surface is provided with the discharge opening 23 that communicates with casing 1.

[0057] The crushing device includes a filter screen cylinder 4, the top of which is open, and the bottom of the filter sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com