Greenhouse gas conversion device and method utilizing magnetic field to strengthen blade gliding arc

A greenhouse gas conversion device technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of limited greenhouse gas processing capacity, poor arc speed, damaged reactor, etc., to avoid thermal damage to the reactor , the effect of reducing the speed difference and reducing the heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

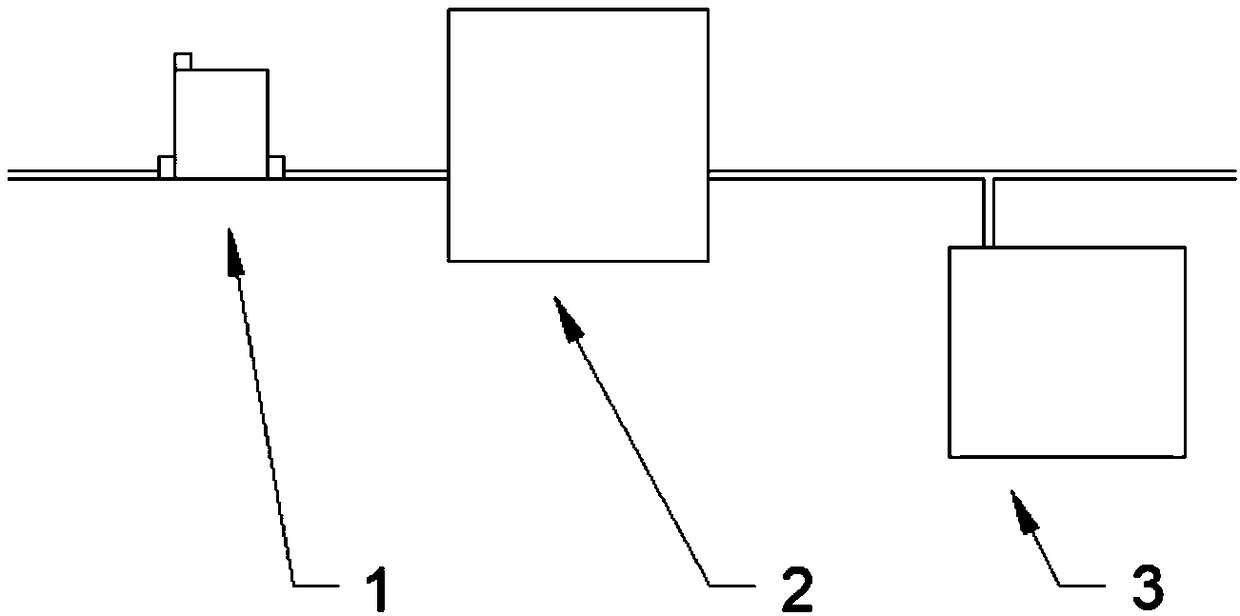

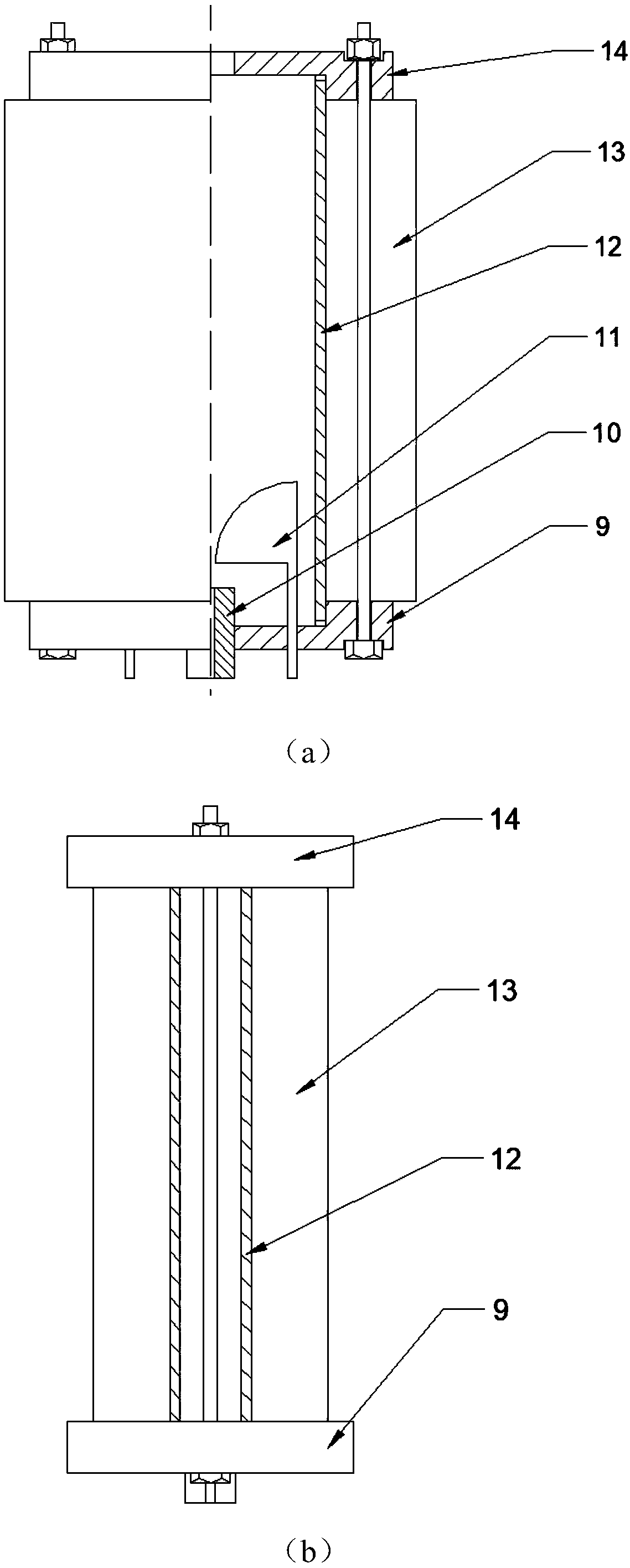

[0027] like Figure 1-3 As shown, the present invention provides a greenhouse gas conversion device that utilizes a magnetic field to strengthen the blade sliding arc, including a blade sliding arc stabilization system and a reactor;

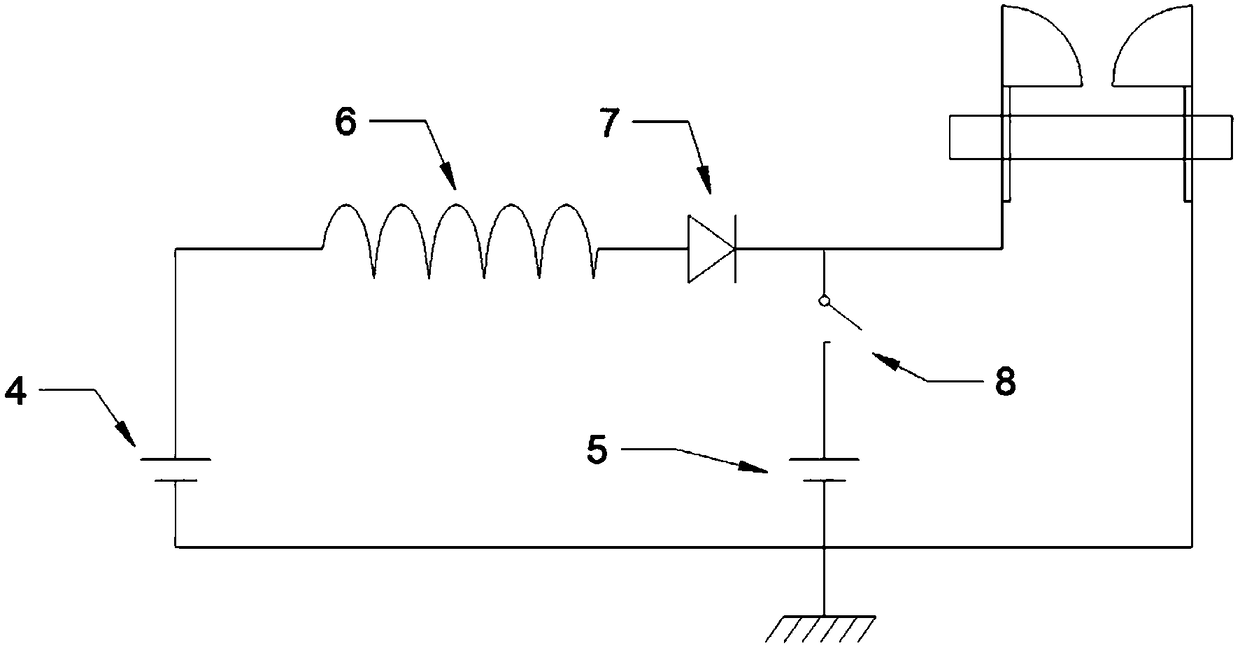

[0028] The blade sliding arc stabilization system includes a first DC power supply 4, a second DC power supply 5, an inductance coil 6, a diode 7, and an electromagnetic relay switch 8; the first DC power supply 4, the inductance coil 6, and the diode 7 are connected in series, and the electromagnetic relay The switch 8 is connected in series with the second DC power supply 5, and the two series branches are connected in parallel to the two electrodes 11 of the reactor; the positive and negative poles of the two DC power supplies are in the same direction and the negative pole is grounded; the voltage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com