A vacuum interrupter aging device based on multi-power synthesis

A technology of vacuum interrupter and multi-power supply, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problem of difficult to effectively control the degree of burn-in, burn-in trend and consistency, and the aging depth of the contact surface and the durability of burn-in Insufficient, single discharge energy, large randomness of discharge frequency and other problems, to achieve the effect of improving aging uniformity, low insulation requirements and cost overhead, and low breakdown difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

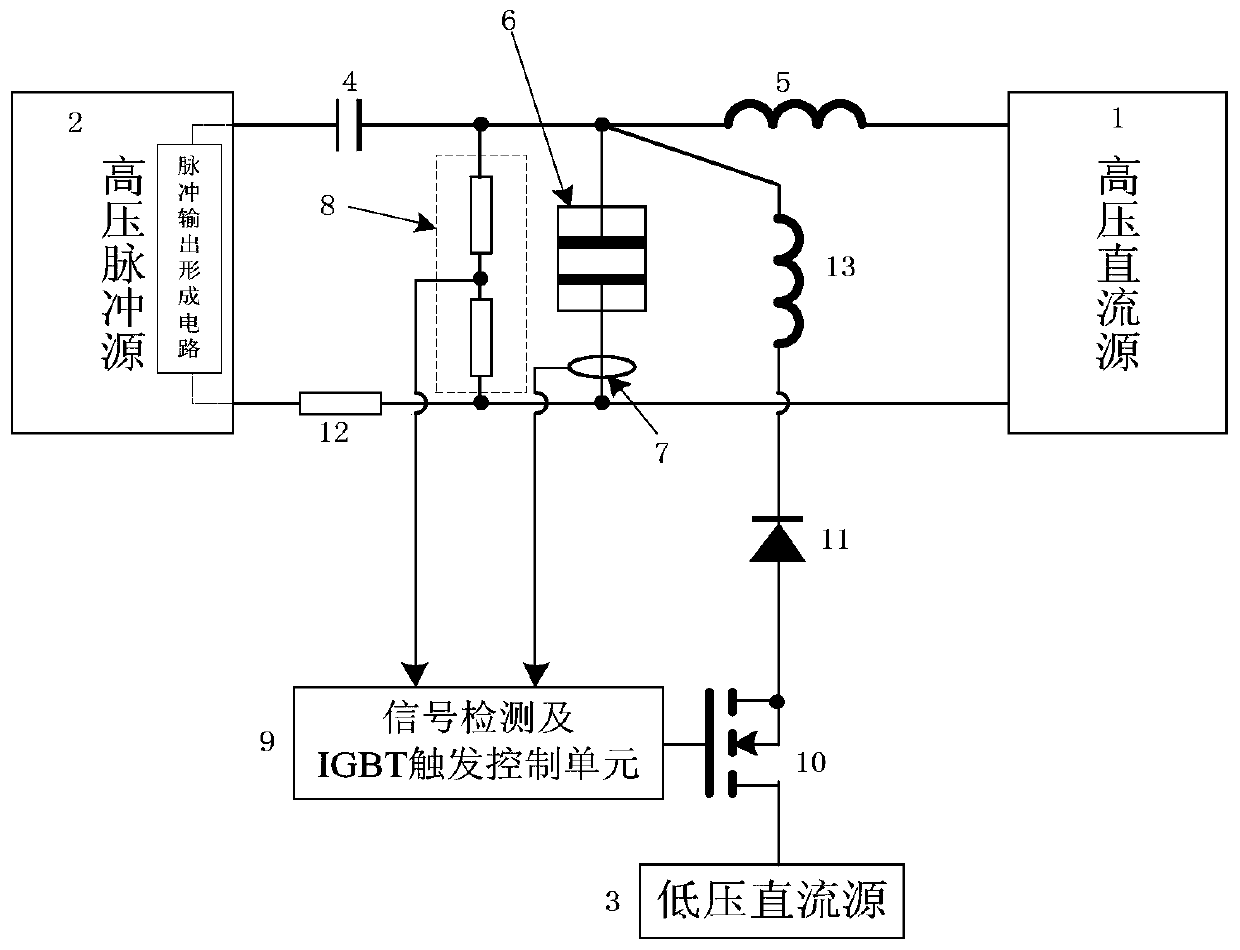

[0024] refer to figure 1 , the vacuum interrupter aging device based on multi-power synthesis according to the present invention includes a low-voltage DC source 3, an IGBT chip 10, a high-voltage pulse source 2, a high-voltage DC source 1, a signal detection and IGBT trigger control unit 9, for detecting The current detection unit 7 for the current on the vacuum interrupter 6 and the voltage detection unit 8 for detecting the voltage on the vacuum interrupter 6; the voltage output terminal of the low-voltage DC source 3 is connected to the collector of the IGBT chip 10, and the high-voltage pulse source The ground terminal of 2 and the ground terminal of high-voltage DC source 1 are connected to one end of vacuum interrupter 6, and the other end of vacuum interrupter 6 is connected to the high-voltage end of high-voltage DC source 1, the high-voltage end of high-volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com