Ultra-low speed big torsional moment special-shape motor dragging and tower type high-efficiency low-consumption intelligent pumping unit

An ultra-low-speed, high-torque technology, which is applied in the field of ultra-low-speed, high-torque special-shaped motor-driven tower-type high-efficiency and low-consumption intelligent pumping units, can solve the problem of large impact loads, stroke lengths that increase in direct proportion to the torque of the gearbox, and beam travel. The machine cannot randomly change the working parameters and other problems, so as to simplify the intermediate links and realize the effect of swabbing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

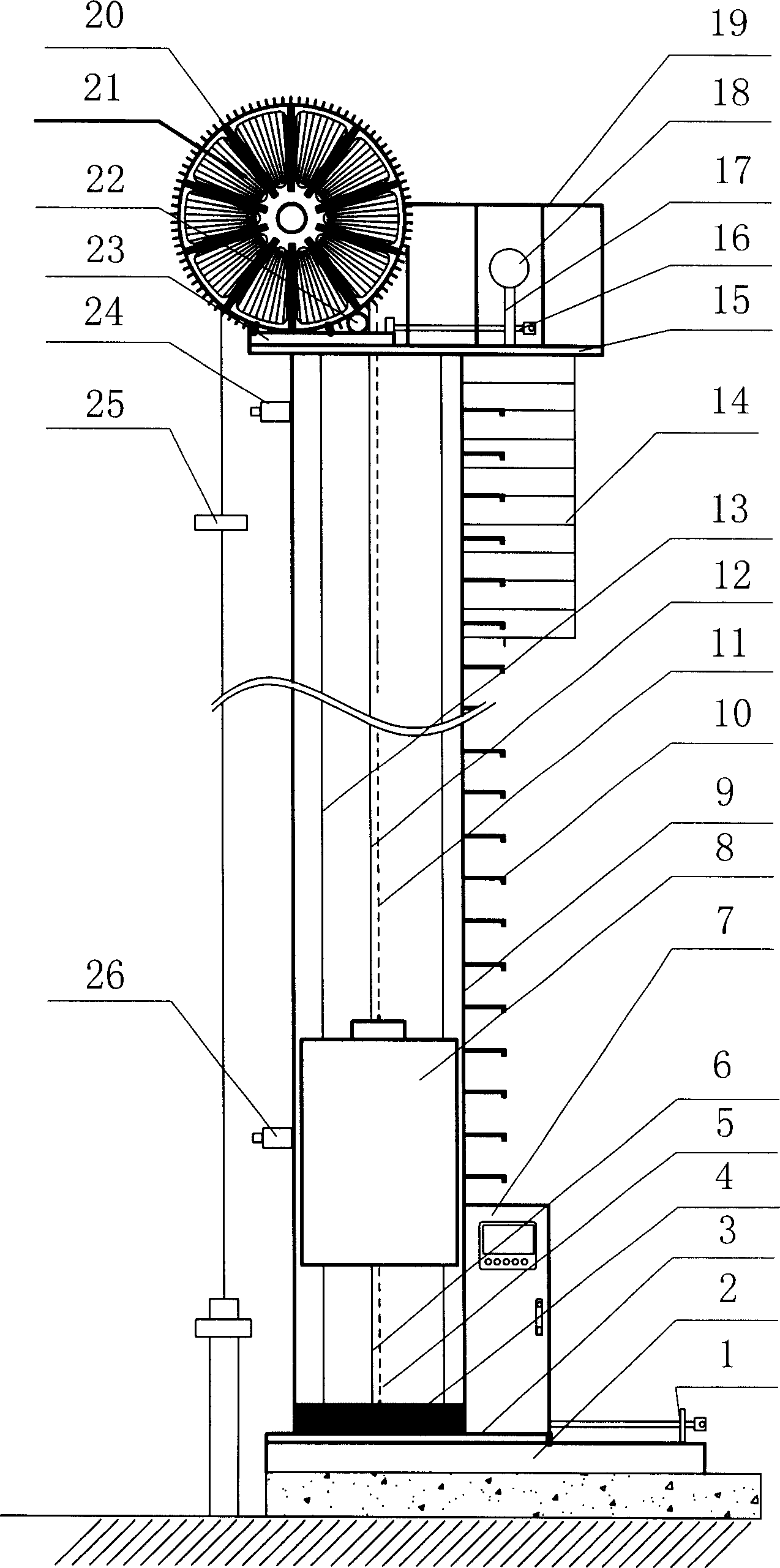

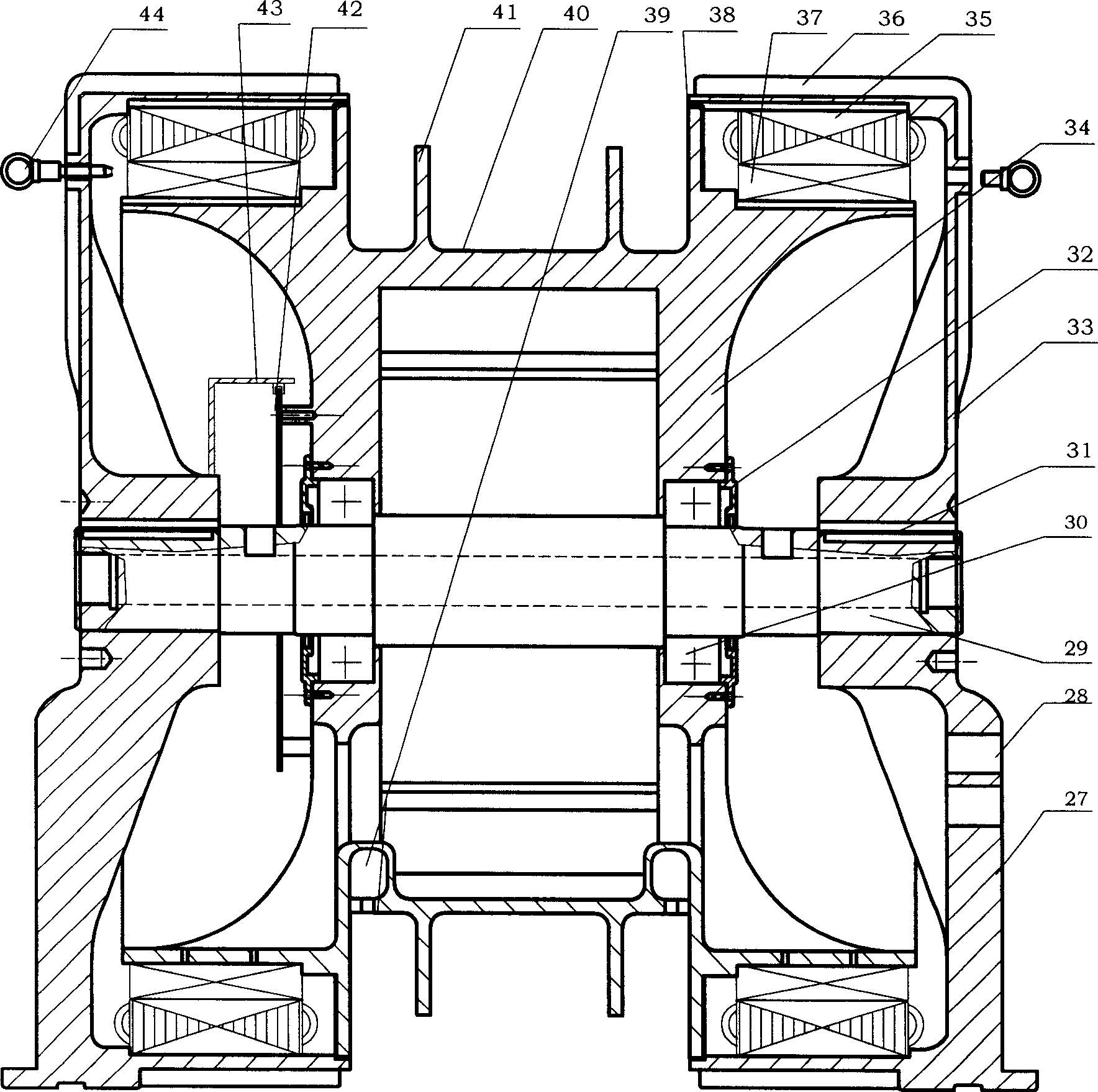

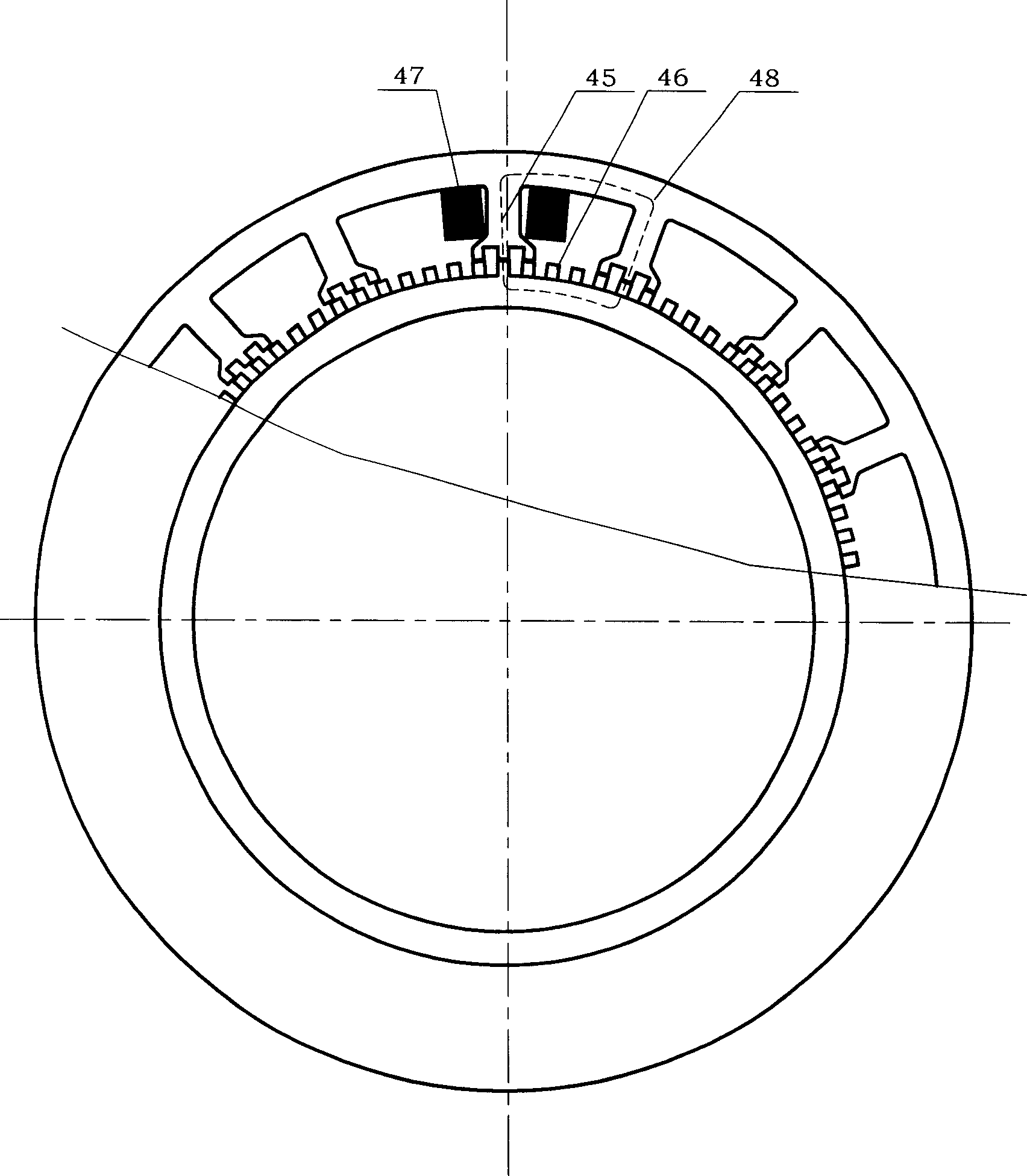

[0104] The tower tube (9) of the super-low-speed, high-torque special-shaped motor dragging tower type high-efficiency and low-consumption intelligent pumping unit of the present invention is welded with 1200, wall thickness 20mm threaded pipe; the moving machine guide rail (2), the tower tube top platform ( 15) Welding with I-beam; special-shaped motor (20) adopts ultra-low-speed, high-torque special-shaped inner rotor short magnetic circuit switch reluctance speed regulating motor, special-shaped inner rotor and special-shaped outer stator are cast steel at one time, and the outer stator has a maximum outer diameter∮ 1600, the maximum outer diameter of the inner rotor is ∮1380, the main shaft uses a hollow shaft, the outer stator core adopts a large tooth and three small tooth structure, and the stator and rotor tooth poles adopt "WM golden combination", that is, four-phase winding 3×32 / 180, The rated speed of the motor is 0-20 rpm, the rated torque is greater than 20kNm, an...

Embodiment approach 2

[0113] The tower tube (9) of the ultra-low-speed, high-torque special-shaped motor dragging tower type high-efficiency and low-consumption intelligent pumping unit of the present invention is welded with 1000, wall thickness 20mm threaded pipe; the moving machine guide rail (2), the tower tube top platform ( 15) Welding with I-shaped steel; the special-shaped motor (20) adopts a super-low-speed, high-torque special-shaped outer rotor short magnetic circuit switch reluctance speed-regulating motor, and the special-shaped outer rotor and special-shaped inner stator are casted with cast steel at one time. The maximum diameter of the outer rotor is ∮1412 , the maximum outer diameter of the inner stator is ∮1210, the main shaft uses a hollow shaft, the outer rotor core adopts tooth poles with equal pitch, the stator and rotor tooth poles adopt "WM golden combination", that is, the three-phase winding 3×18 / 120, the rated speed of the motor 0-50 rpm, rated torque greater than 16kNm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Motor power | aaaaa | aaaaa |

| Motor power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com