All-electric micro precise injection moulding machine

An injection molding machine, all-electric technology, applied in the field of micro-precision injection molding machines, can solve problems such as the inability to get rid of the processing and use of small-sized screws, the difficulty in plasticizing materials to meet high precision, and the difficulty in processing small-sized screws. Achieve the effect of saving molding raw materials, solving processing difficulties, and realizing precise control of action positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

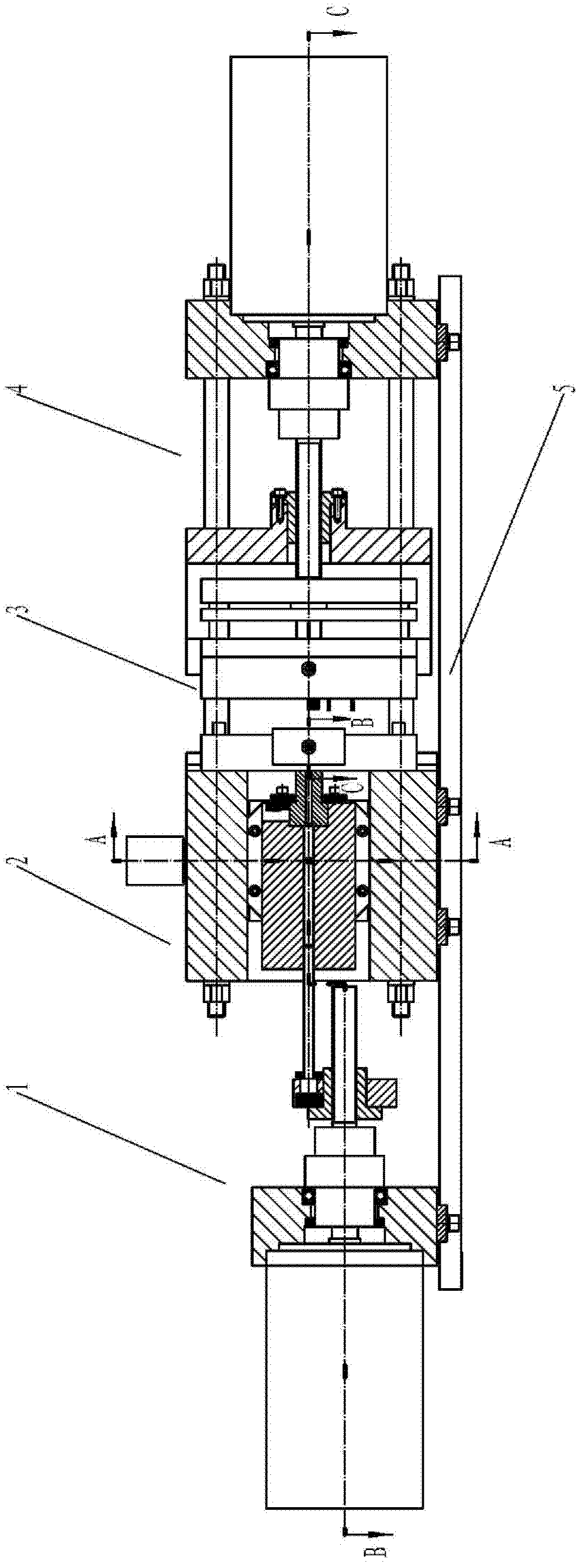

[0022] Such as figure 1 As shown, the present invention is an all-electric miniature precision injection molding machine, which is mainly composed of an injection part 1, a plasticizing part 2, a mold part 3, a mold clamping part 4 and a frame 5, and the injection part 1, the plasticizing part 2 and the closing part The mold section 4 is located on a frame 5 .

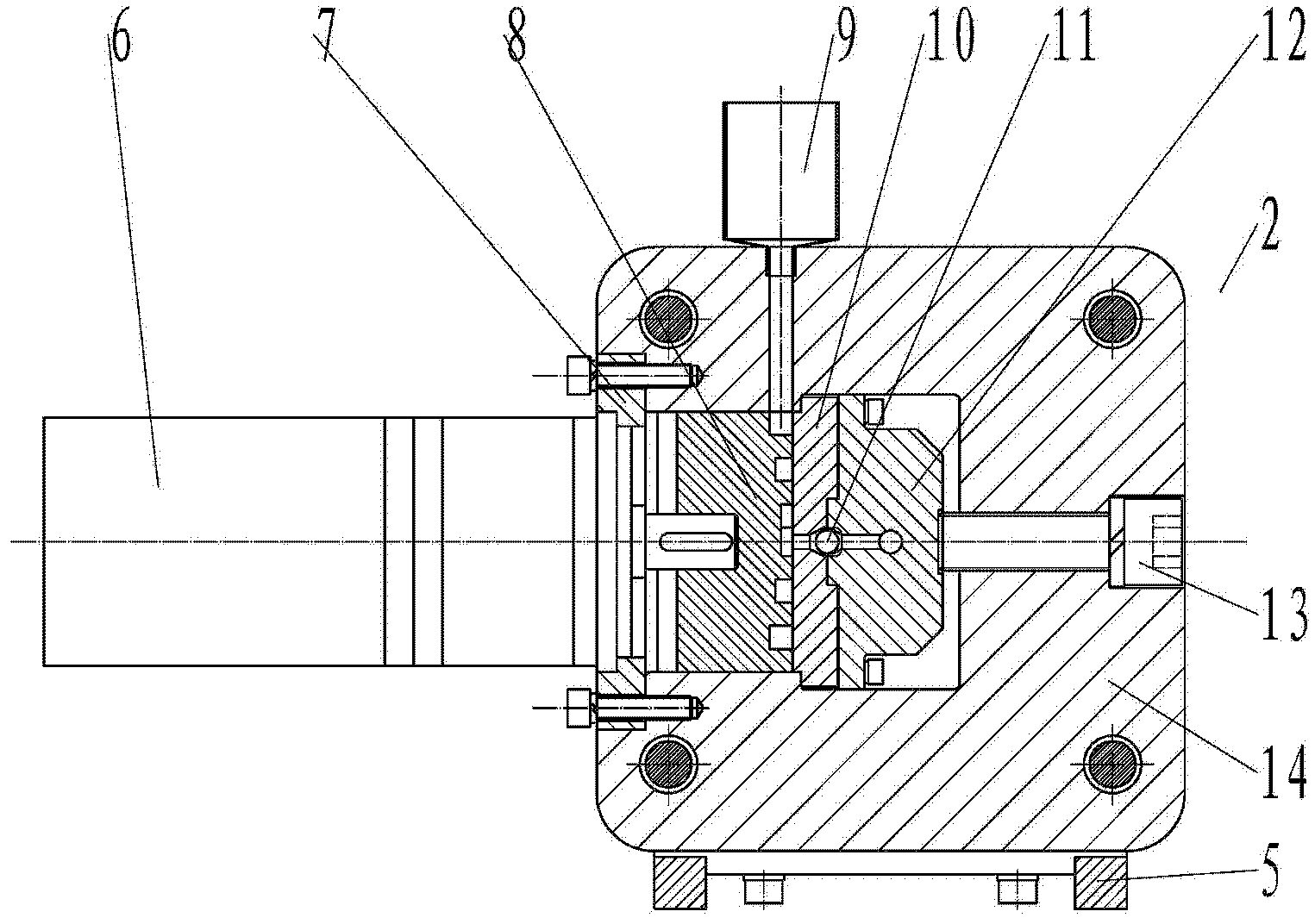

[0023] figure 2 Shown is a cross-sectional view of the plasticizing part 2 ( figure 1 The left side view of the cross-section of the hopper axis), the plasticizing part 2 consists of a machine base 14, a plasticizing servo motor 6, a plasticizing motor mounting plate 7, an end screw plate 8, a hopper 9, a heating plate 10, screws 13, and a machine barrel 12 and check ball 11 etc. are formed. The plasticizing servo motor 6 is installed on the plasticizing motor mounting plate 7 by screws, and then the mounting plate 7 is fixed on the base 14 with screws; the plasticizing motor 6, the end screw disk 8, the heating pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com