All-electric driven concrete laser leveler

A laser screed and concrete technology, used in roads, road repair, roads, etc., can solve the problems of heavy hydraulic equipment, inability to apply floor construction, narrow construction scope, etc., to achieve stable rotation speed, simple and lightweight machine structure, anti- The effect of strong overload capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical means, functional features, goals and effects achieved by the present invention easy to understand, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

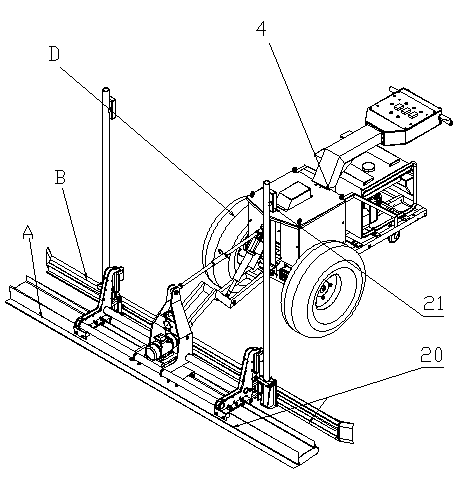

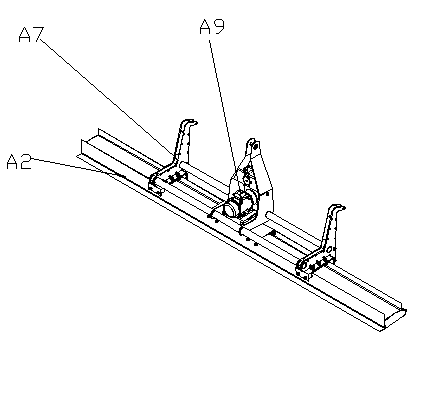

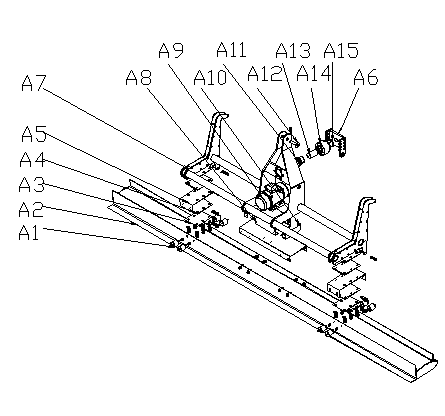

[0042] Figure 1 to Figure 11 Shown is the structural representation of the present invention. Figure 12 to Figure 14 Shown is a schematic diagram of the use state and a schematic diagram of the modules of the present invention.

[0043] The reference signs therein are:

[0044] Vibration plate assembly A: shock absorption block A1, vibration plate A2, bracket welding assembly shock absorption block backing plate A3, bracket welding assembly shock absorption block A4, vibration plate connection U-shaped frame A5, vibration plate boom shaft seat A6, bracket welding Component A7, vibration motor mounting frame A8, vibration motor A9, vibration motor frame reinforcement plate A10, vibration frame boom upper brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com