Crushing station

A technology of crushing station and crushing device, applied in the field of crushing station, can solve the problems of poor structural stability, inconvenient horizontal and vertical swing of the unloading and discharging device, etc. Well-distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

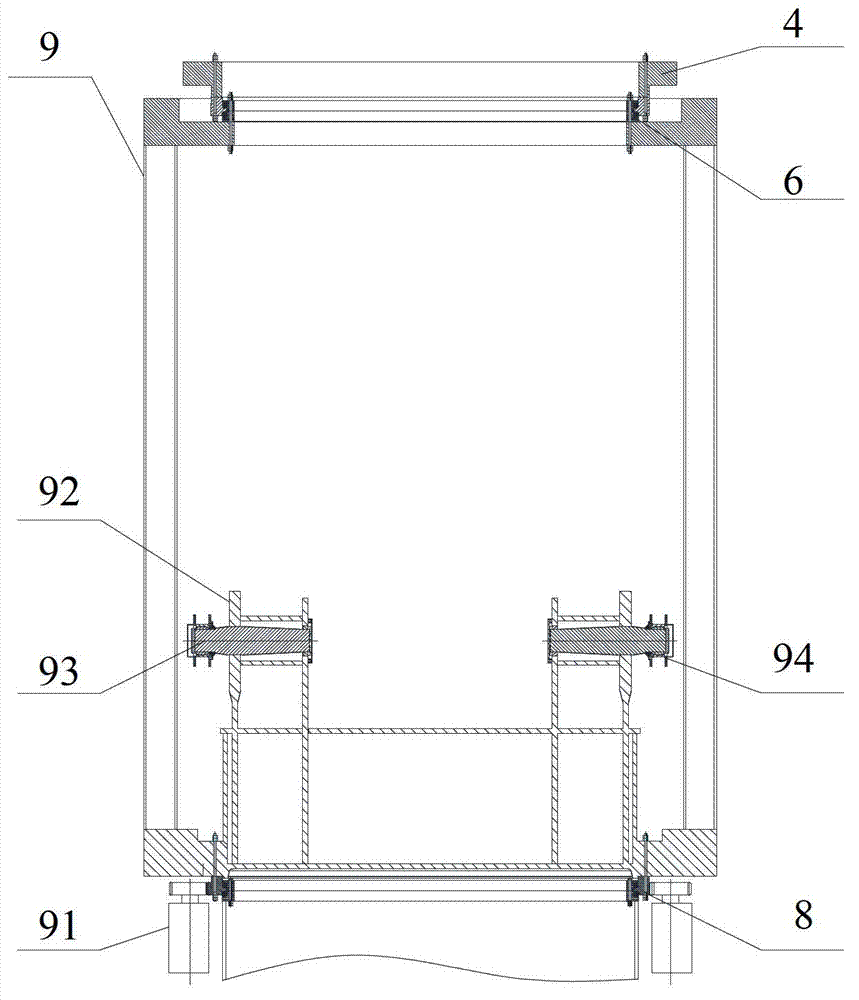

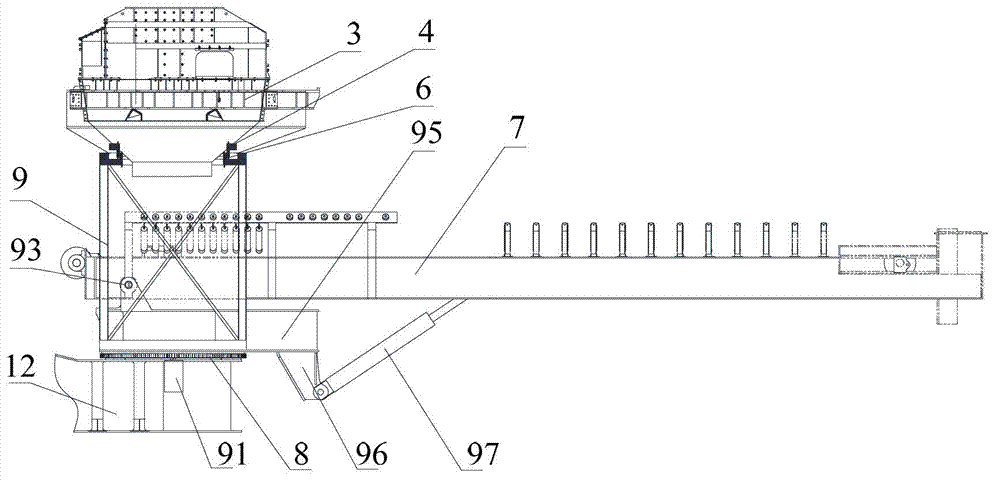

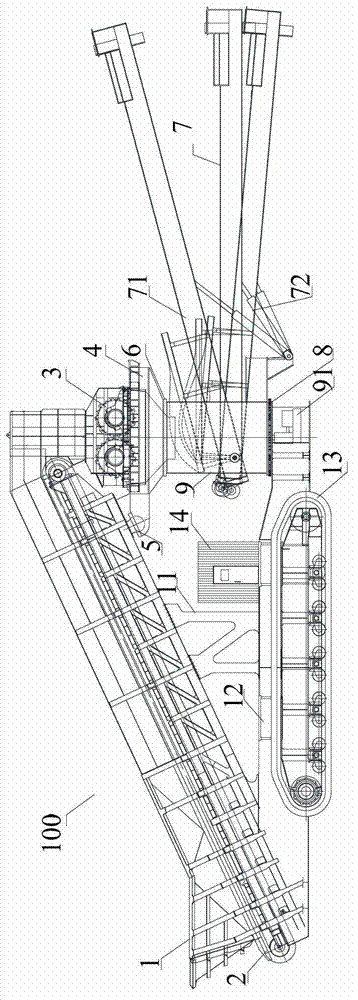

[0063] A crushing station 100 provided in the embodiment of the present invention, such as Figure 1-Figure 3 As shown, it includes: a loading and conveying device, a crushing device 3, an unloading and discharging device 7, a support mechanism and a supporting unit, wherein the charging and conveying device is used to hold materials to be crushed and transport the materials to be crushed; the crushing device 3 is connected to the loading and conveying device for crushing the materials to be crushed; the discharge and discharge device 7 is arranged at the outlet of the crushing device 3, and is used for discharging the crushed materials of the crushing device 3 and Unloading process; there is also a supporting mechanism arranged at the bottom of the crushing device 3, and the discharging and discharging device 7 is installed on the supporting mechanism; wherein, the supporting mechanism can drive the discharging and discharging device 7 to relatively crush The device 3 swings ...

Embodiment 2

[0094] exist Figure 5 and Image 6 The embodiment of the crushing station 100 shown in can be arranged such that the direction of motion determined thereby is perpendicular to the longitudinal axis of the crusher. Advantages of the mobile crusher: In open-pit mining, the excavator basically digs out rocks, ores or coal along the excavation method parallel to the moving direction of the crusher, so that bulk materials are continuously produced along the parallel line with the moving direction, and crawler walking The mechanism can walk in that direction without scheduling operations.

Embodiment 3

[0096] The embodiment of the crushing station 100 is equipped with a multi-crawler traveling mechanism 13 , and its crawler traveling mechanism 13 is rotatably fixed on the bottom platform of the chassis 12 .

[0097] According to a preferred development, optimal support is achieved when the chassis 12 has three supports for the vehicle frame arranged in a triangle. Here, it can advantageously be provided that one chassis 12 fastened at the feed-side end region of the vehicle frame is provided and that two supports are provided on both sides outside the projection of the crushing device 3 , it is configured in this manner The support triangle thus ensures a correspondingly stable support.

[0098] Considering that the ground of the mining road section may be uneven, according to a preferred improvement plan, a ball joint is used between the chassis 12 and the crawler to be swingably connected to the vehicle frame.

[0099] In particular, the charging conveyor device can be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com