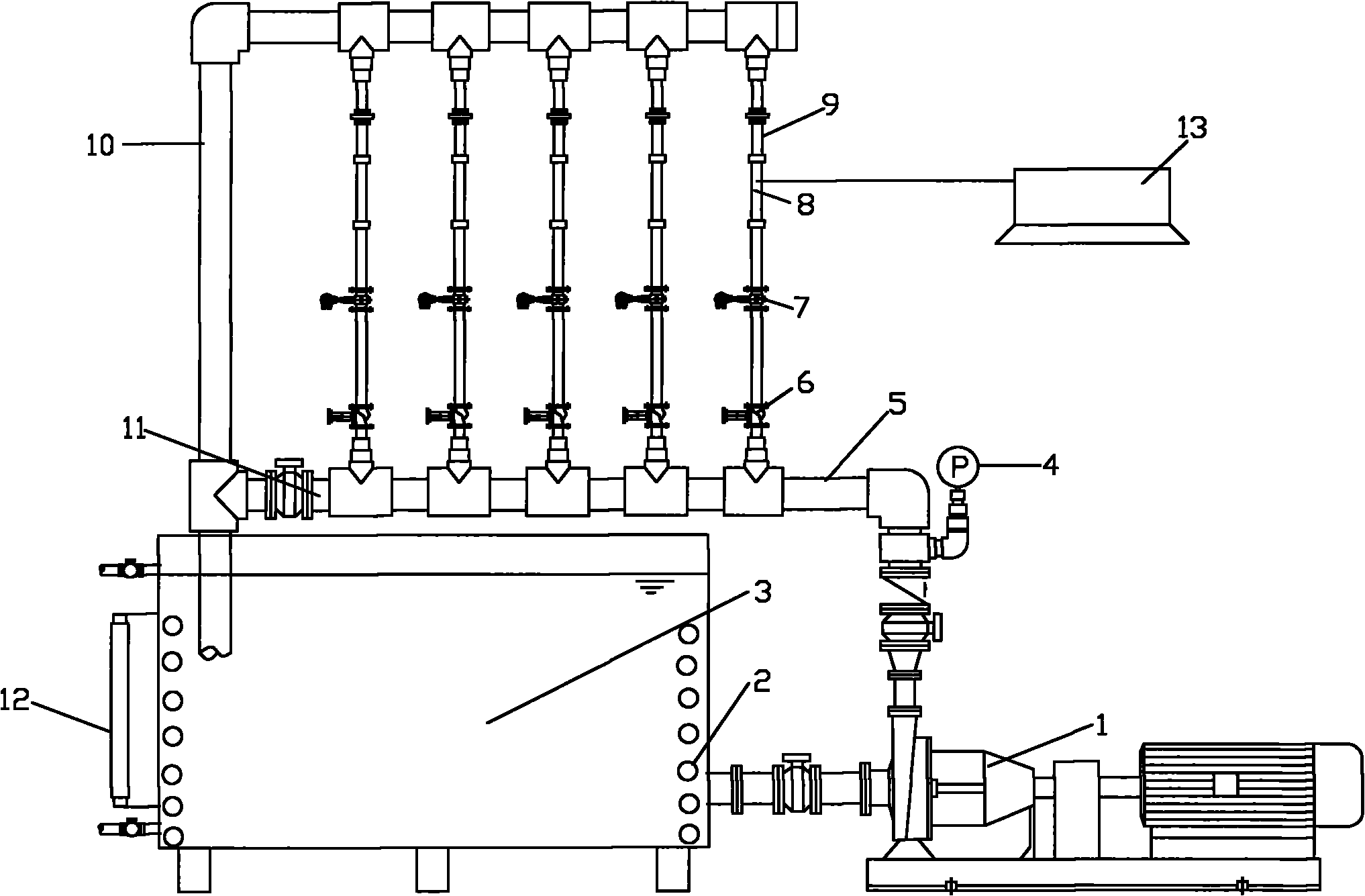

Erosion corrosion test device of seawater piping system metal member

A metal component, scouring corrosion technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem that the scour corrosion performance of pipes has not been officially reported, and achieves reduction of test costs, convenience of test research, and increase of The effect of a large medium flow rate range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

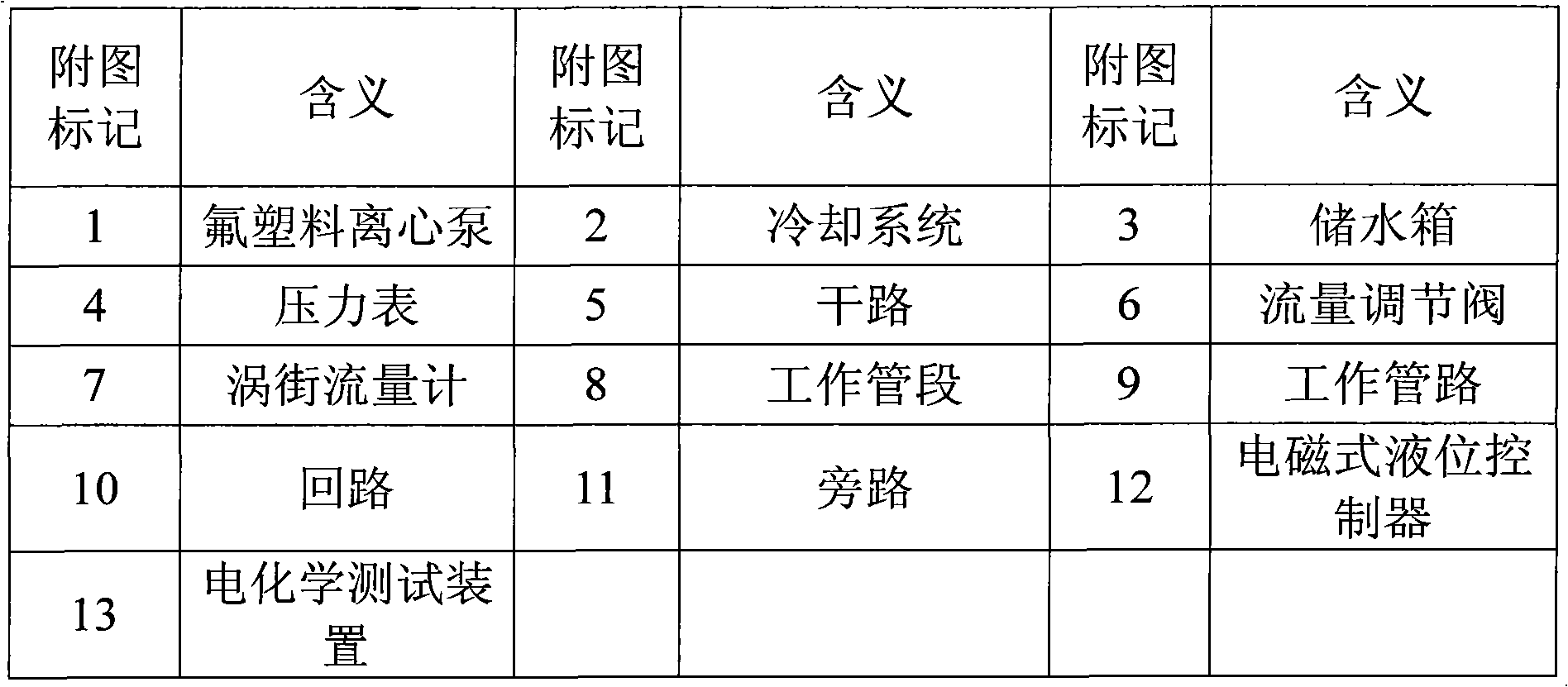

Method used

Image

Examples

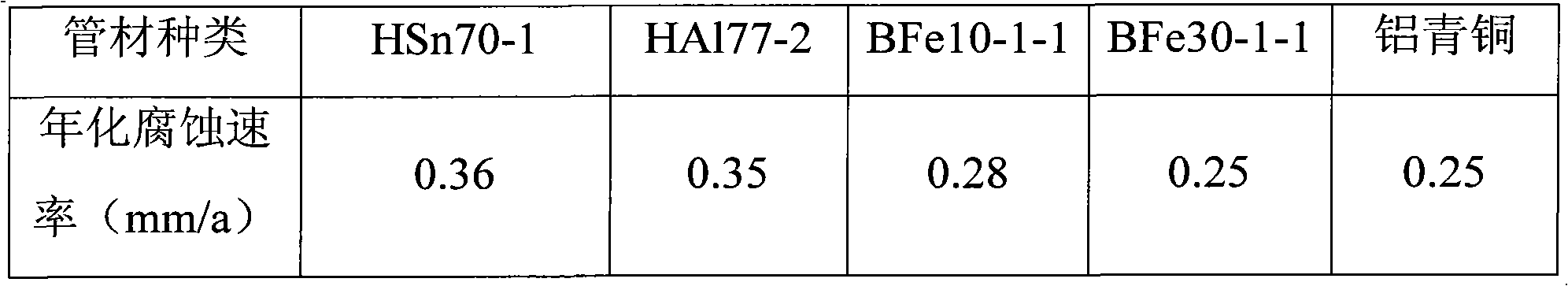

Embodiment 1

[0032] Select a pipe sample of appropriate specifications, measure its original size, quality, etc., find out the various physical parameters used in the calculation, and then install the sample on the device to start the test. During the test, pay attention to observe and record the temperature of the medium, the flow rate, the total amount of the medium in the water storage tank, the change of the surface state of the sample, etc. Due to the existence of evaporation, it is necessary to replenish the medium in the water storage tank in time. After the test period is over, remove the sample according to the "Preparation, Cleaning and Evaluation of Corrosion Samples" standard, clean, weigh and calculate, and use various tissue performance analysis instruments for analysis, and finally obtain the erosion corrosion resistance data of the material. This example Only a schematic illustration is given for the results of the annualized corrosion rate. The specific parameters of the t...

Embodiment 2

[0047] Select a pipe sample of appropriate specifications, measure its original size, quality, etc., find out the various physical parameters used in the calculation, and then install the sample on the device to start the test. During the test, pay attention to observe and record the temperature of the medium, the flow rate, the total amount of the medium in the water storage tank, the change of the surface state of the sample, etc. Due to the existence of evaporation, it is necessary to replenish the medium in the water storage tank in time. After the test period is over, remove the sample according to the "Preparation, Cleaning and Evaluation of Corrosion Samples" standard, clean, weigh and calculate, and use various tissue performance analysis instruments for analysis, and finally obtain the erosion corrosion resistance data of the material. This example Only a schematic explanation is given for the results of the annualized corrosion quick record. The specific parameters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com