High-speed dynamic simulation test method for electric mainshaft bearing

A technology of dynamic simulation test and electro-spindle, applied in the direction of mechanical bearing testing, etc., can solve problems such as unreported in relevant literature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

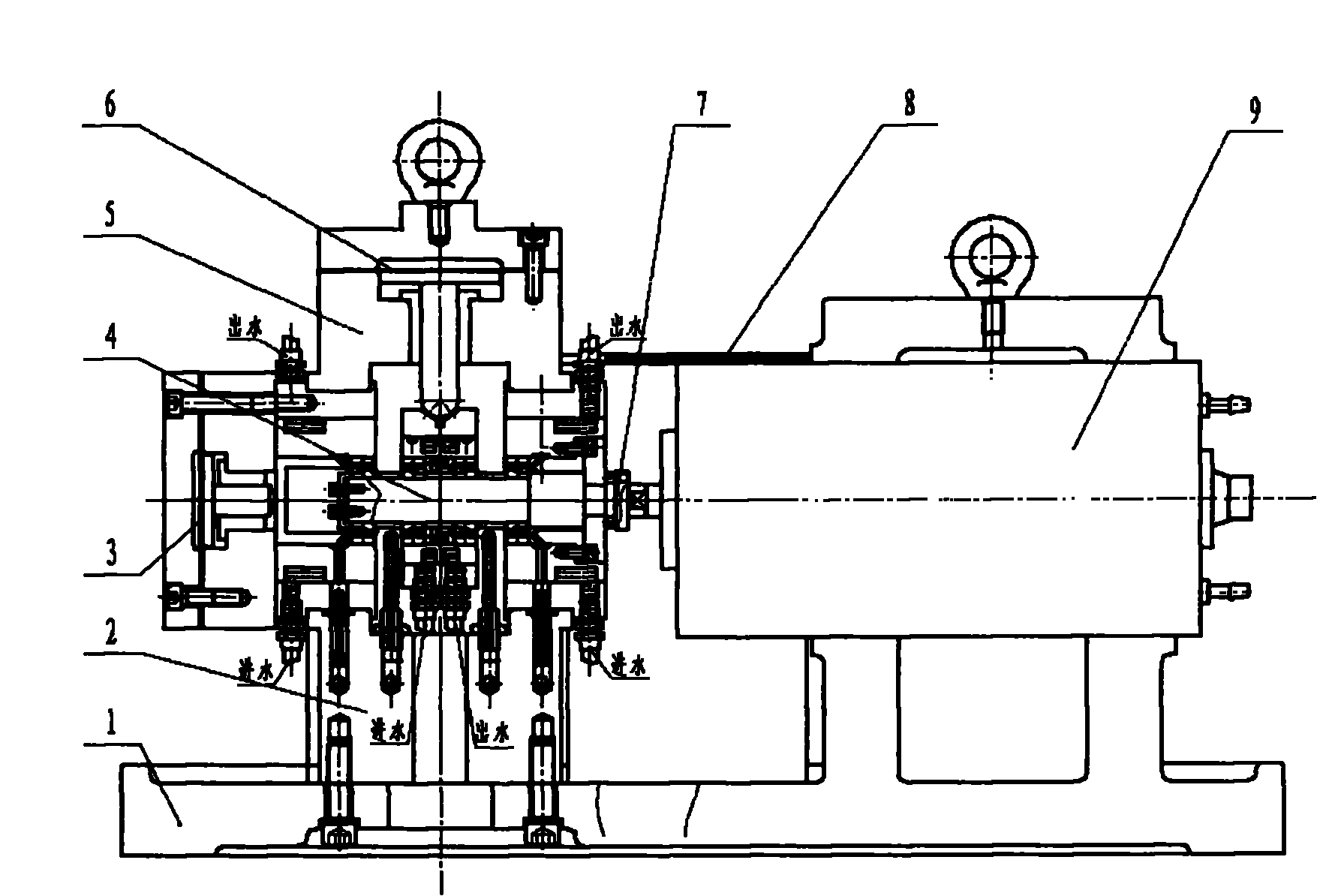

[0057] The high-speed dynamic simulation test method for electric spindle bearings of the present invention includes three contents: test device, assembly and test process.

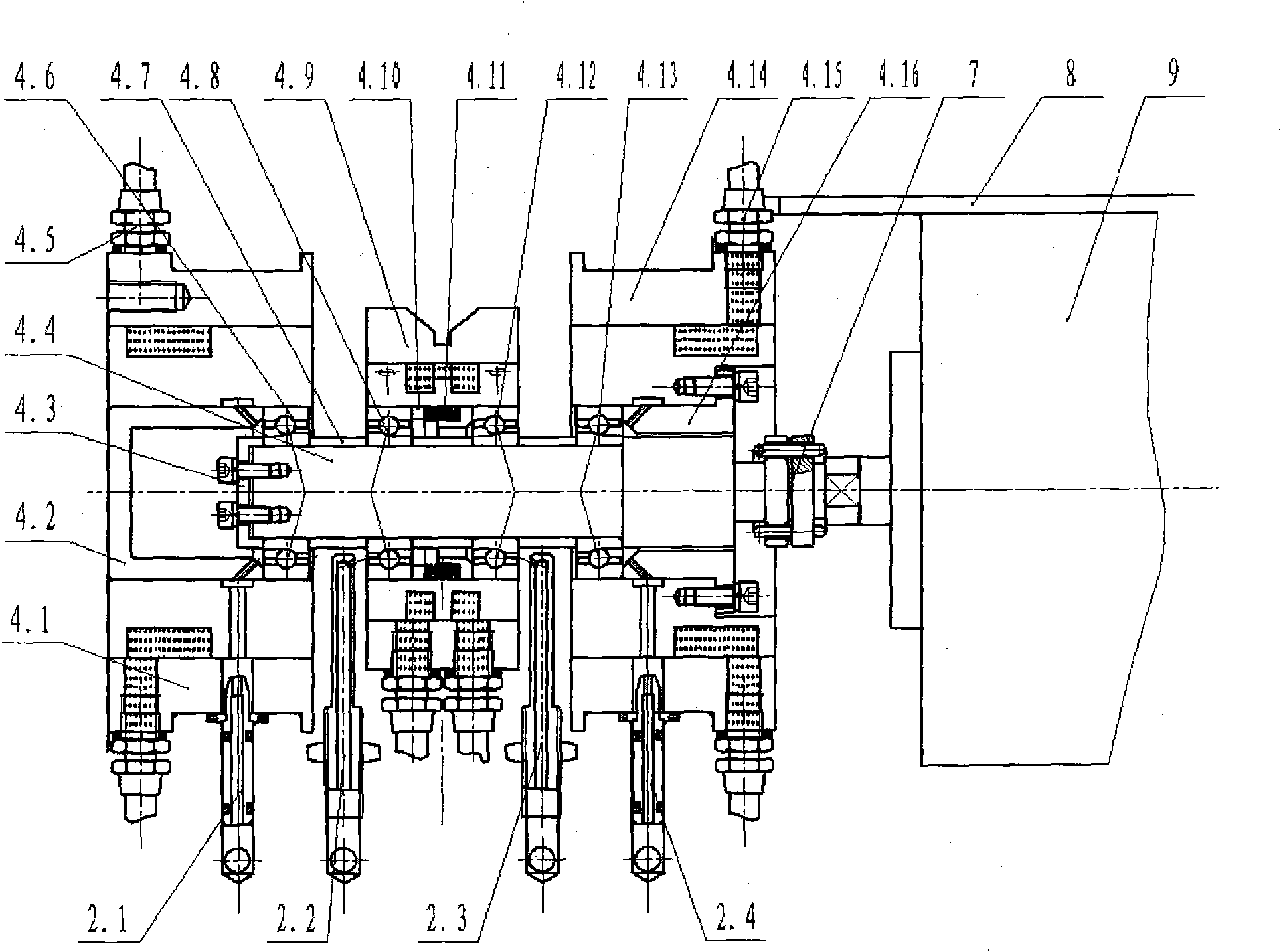

[0058] combine image 3 , the "bearing" referred to in the title of this application specifically refers to the first test bearing 4.6 and the second test bearing 4.13 installed in pairs in the present invention. Unless otherwise specified, the first test bearing 4.6 and the second test bearing 4.13 are referred to as Test bearings, the test bearings belong to the same type of B7 series high-speed precision angular contact ball bearings with slopes in the inner ring, or the test bearings belong to the same type of general-purpose 7 series high-speed precision angular contact ball bearings with slopes in the outer ring. In addition, the first companion bearing 4.8 and the second companion bearing 4.12 used in conjunction with the high-speed dynamic simulation test method also belong to the same product mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com