Digital control method for turntable bending machine

A technology of digital control and stretch bending machine, applied in the direction of digital control, electrical program control, etc., can solve problems such as lack of visibility, complicated control process, and incomplete functions, so as to ensure visibility and safety, flexibility and High degree of automation and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

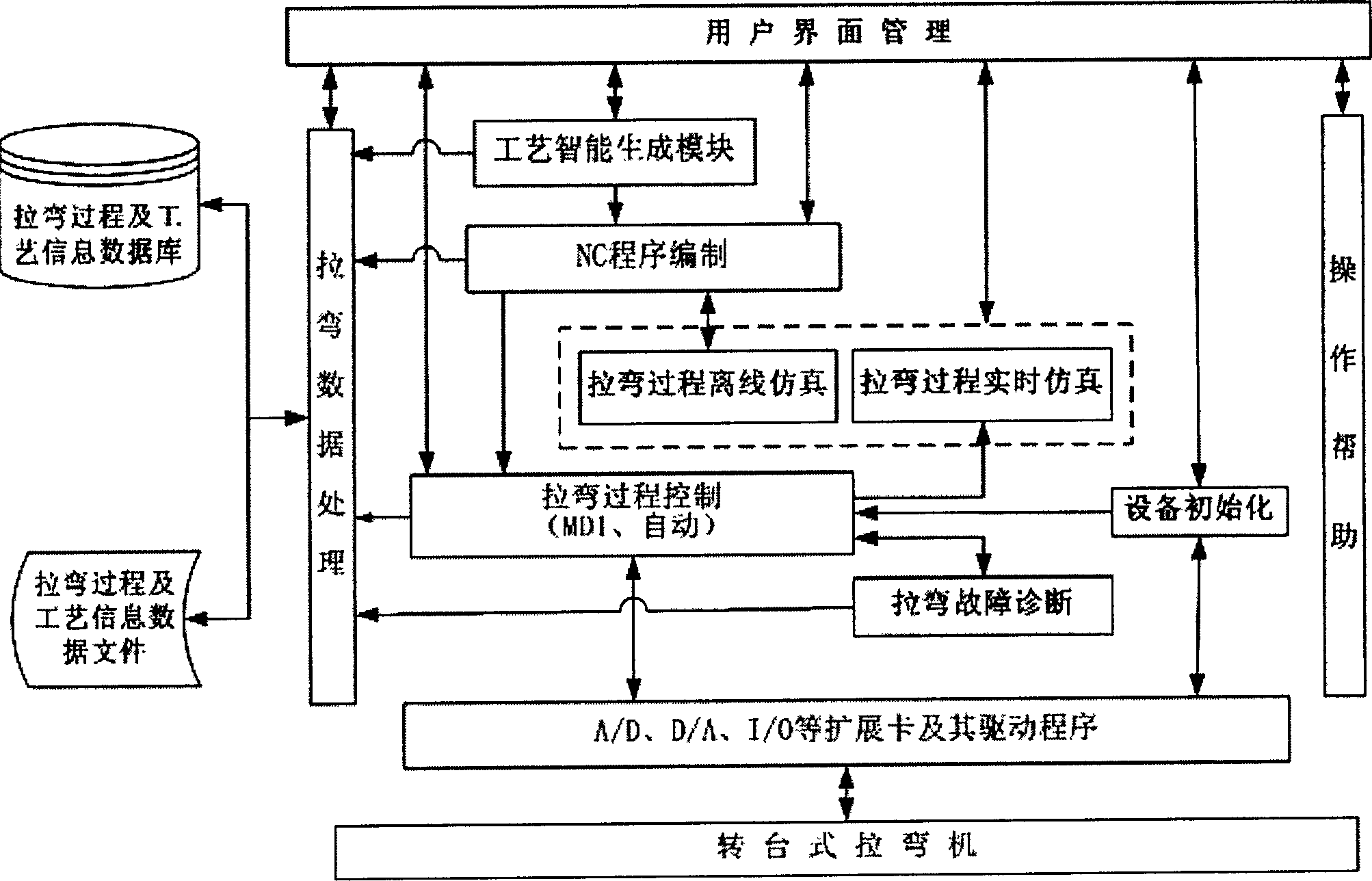

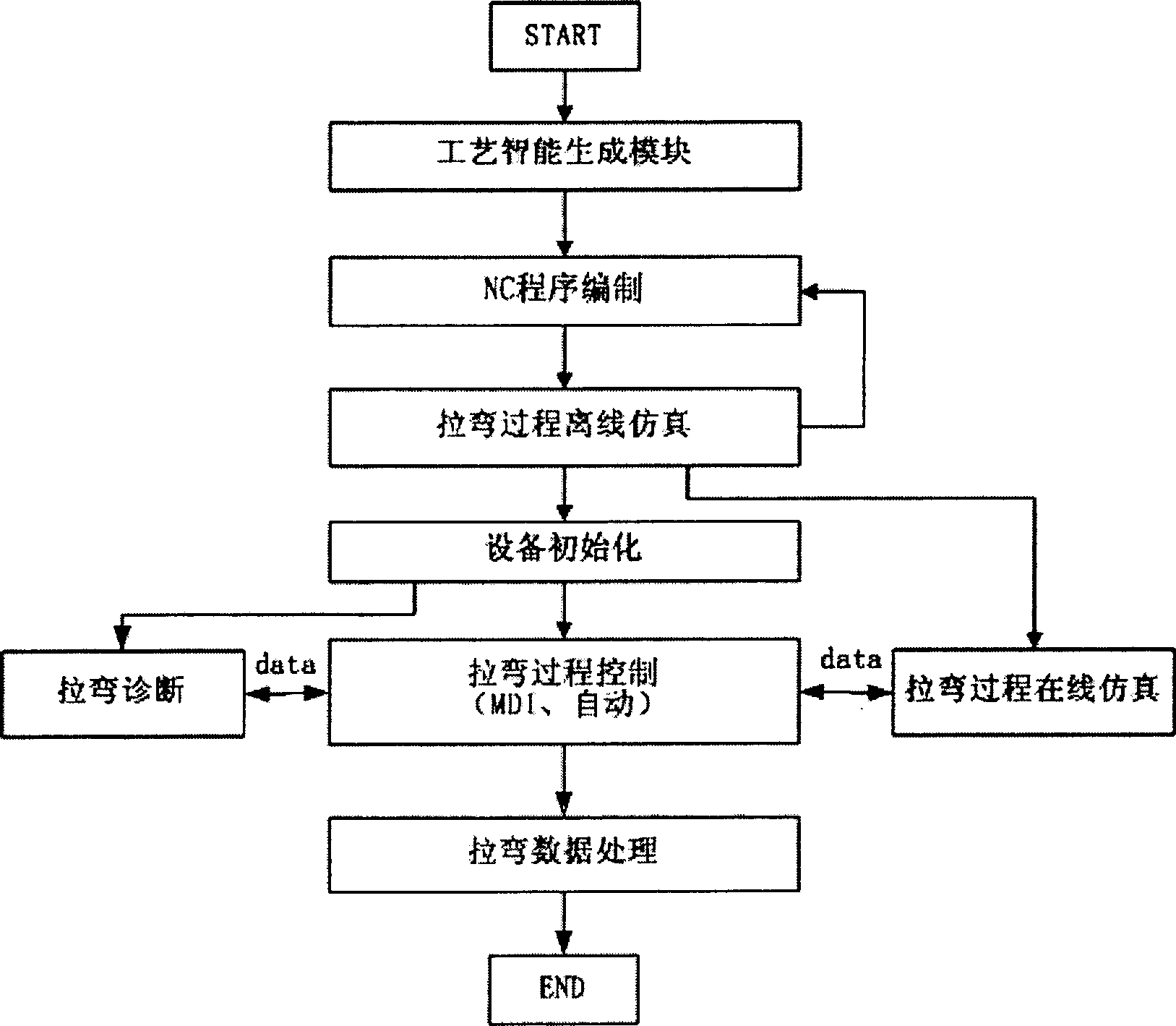

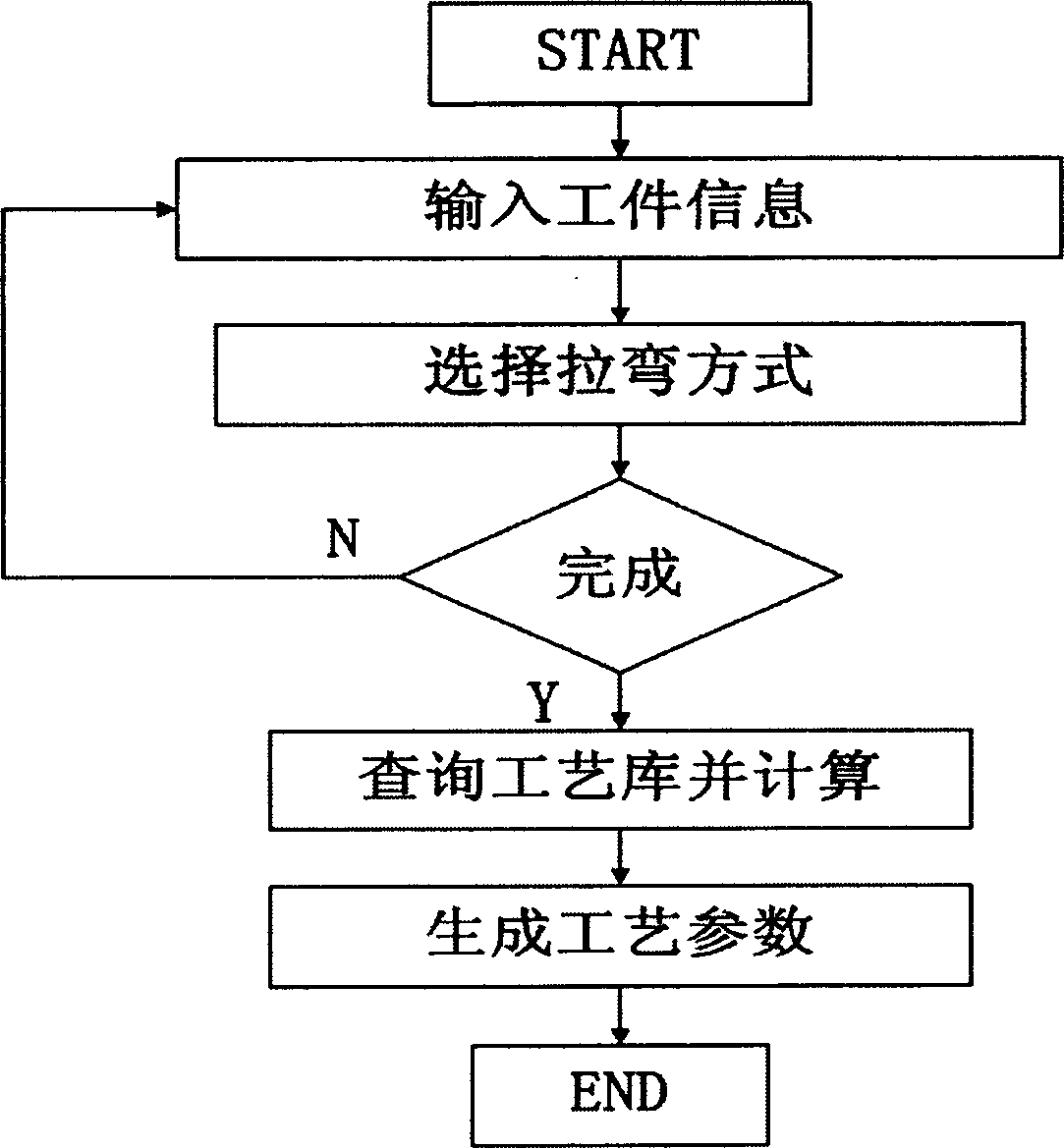

[0023] Refer to figure 1 , The present invention adopts a layered system structure, layering can realize isolation of each layer, and communication between layers is carried out through a standard interface. The first layer is the management. It is the management part of the system, which mainly realizes the interaction function between the user and the software, the setting and management of the menu and the interface; the second layer is the control layer. It is the control part of the system, which mainly realizes the stretching and bending process control. It consists of eight modules: equipment parameter calibration, process intelligence generation, NC programming, stretching and bending simulation, stretching and bending process control, stretching and bending diagnosis, stretching and bending data processing, and operation assistance. Composition; the third layer is the driver layer, which mainly realizes the communication function with the underlying hardware board. It co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com