High-temperature high-speed test method for sealed bearing and test device

A test method and technology of sealed bearings, applied in the direction of mechanical bearing testing, etc., to achieve ideal results, save auxiliary test bearings, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

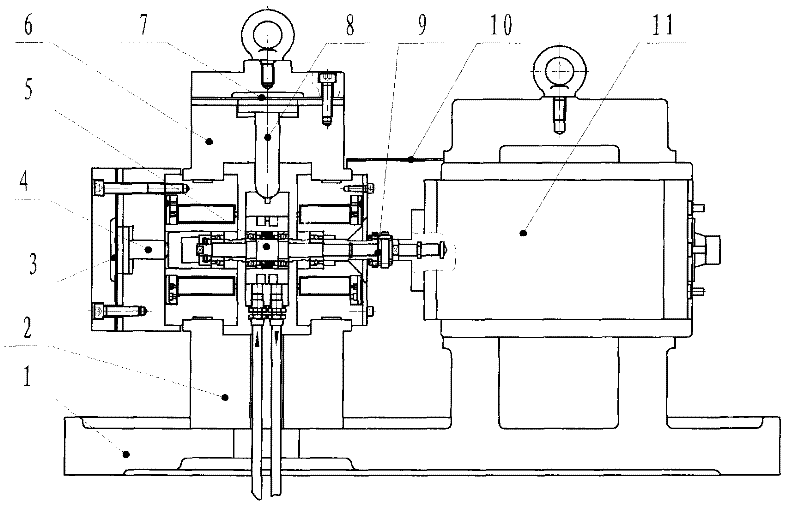

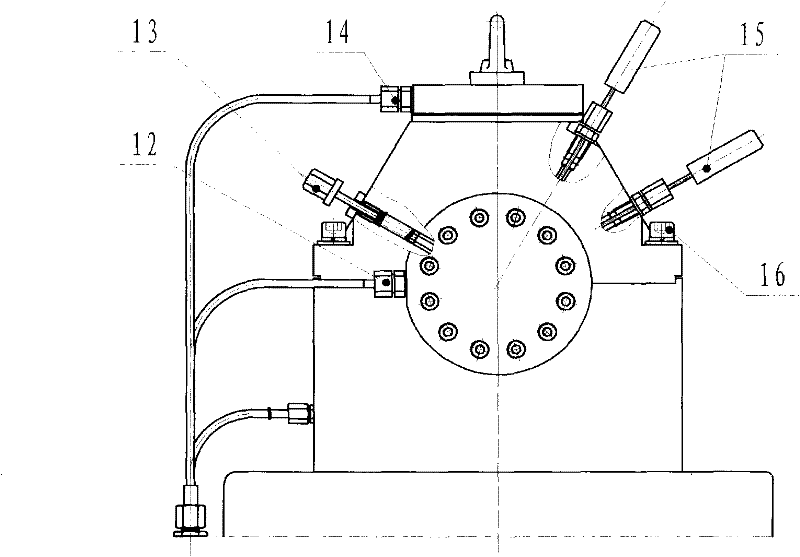

[0025] combine figure 1 and 2 The test device for realizing the high-temperature and high-speed test method for sealed bearings consists of a frame 1, a main body base 2, an axial loading cylinder 3, an axial loading piston 4, a test head assembly 5, a main body gland 6, and a radial loading cylinder 7 , a radial loading piston 8, a coupling 9, a protective cover 10, an electric spindle 11, an axial loading oil pipe 12, a vibration sensor 13, a radial loading oil pipe 14 and a temperature sensor 15, and the electric spindle 11 is fixed on the right end of the frame 1 .

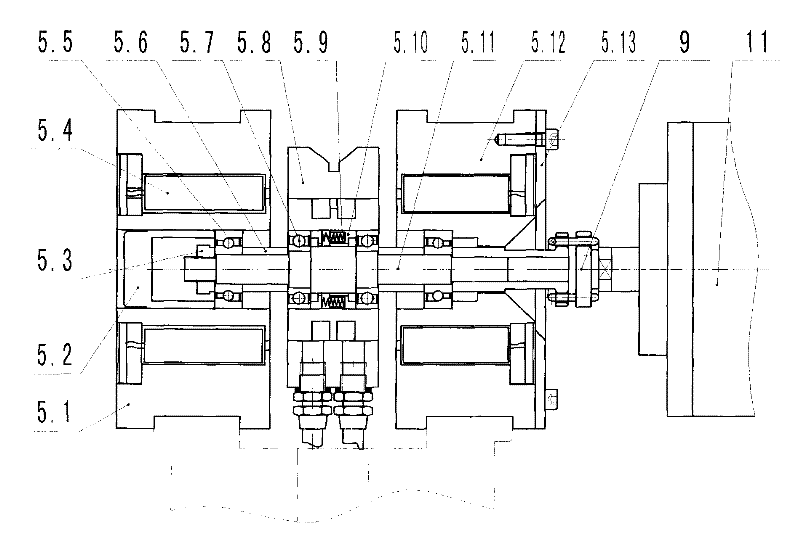

[0026] The test head assembly 5 is the core component of the test device, including a left bush 5.1, an axial load sleeve 5.2, a nut 5.3, a cylindrical heater 5.4, a test bearing 5.5, a spacer 5.6, an accompanying test bearing 5.7, a radial load Cover 5.8, spring 5.9, pressure ring 5.10, test spindle 5.11, right bushing 5.12, flange end cover 5.13.

[0027] The electric spindle is connected with the test s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com