Device and method for thin wall stainless steel pipe double-cutter symmetric planetary automatic cutting

A technology for automatic cutting of stainless steel pipes, applied in sawing machines, metal sawing equipment, metal processing equipment, etc., can solve the problems of poor feed balance, claws are easily stuck by iron filings, and low cutting efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

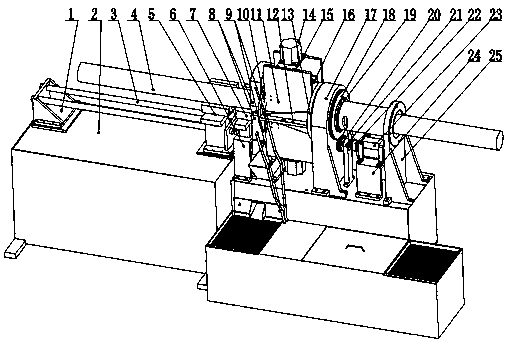

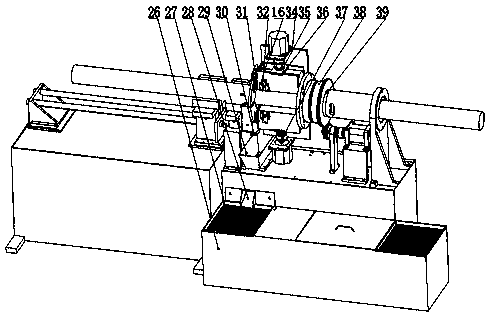

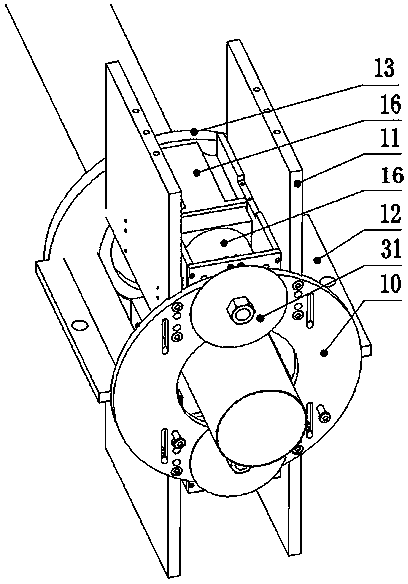

[0033]The technical solution is further described below in conjunction with reference to the accompanying drawings, examples of the embodiments are shown in the accompanying drawings, wherein the same or similar reference numerals represent the same or similar elements or elements with the same or similar functions, but this description only It is used to explain the present invention, but should not be construed as a limitation of the present invention.

[0034] please see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the technical solution adopted by the device of the present invention is: a device for automatic cutting of thin-walled stainless steel tubes with double knives and symmetrical planetary type, comprising: guide post support 1, bed 2, guide post 3, pipe fittings 4, feeding device 5, Fixture bracket 6, fixture 7, water retaining tank 8, cooling water pipe 9, first cutter head 10, two first cutter head support plates 11, two second cutter head sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com