Digital electric-hydraulic synchronous control system

A technology of synchronous control and synchronous controller, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., and can solve the problems of difficult synchronous control of hydraulic cylinder volume, large throttling loss and overflow loss, and system Low energy efficiency and other issues, to achieve the effect of improving safety and reliability, response speed, volume control, energy saving, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

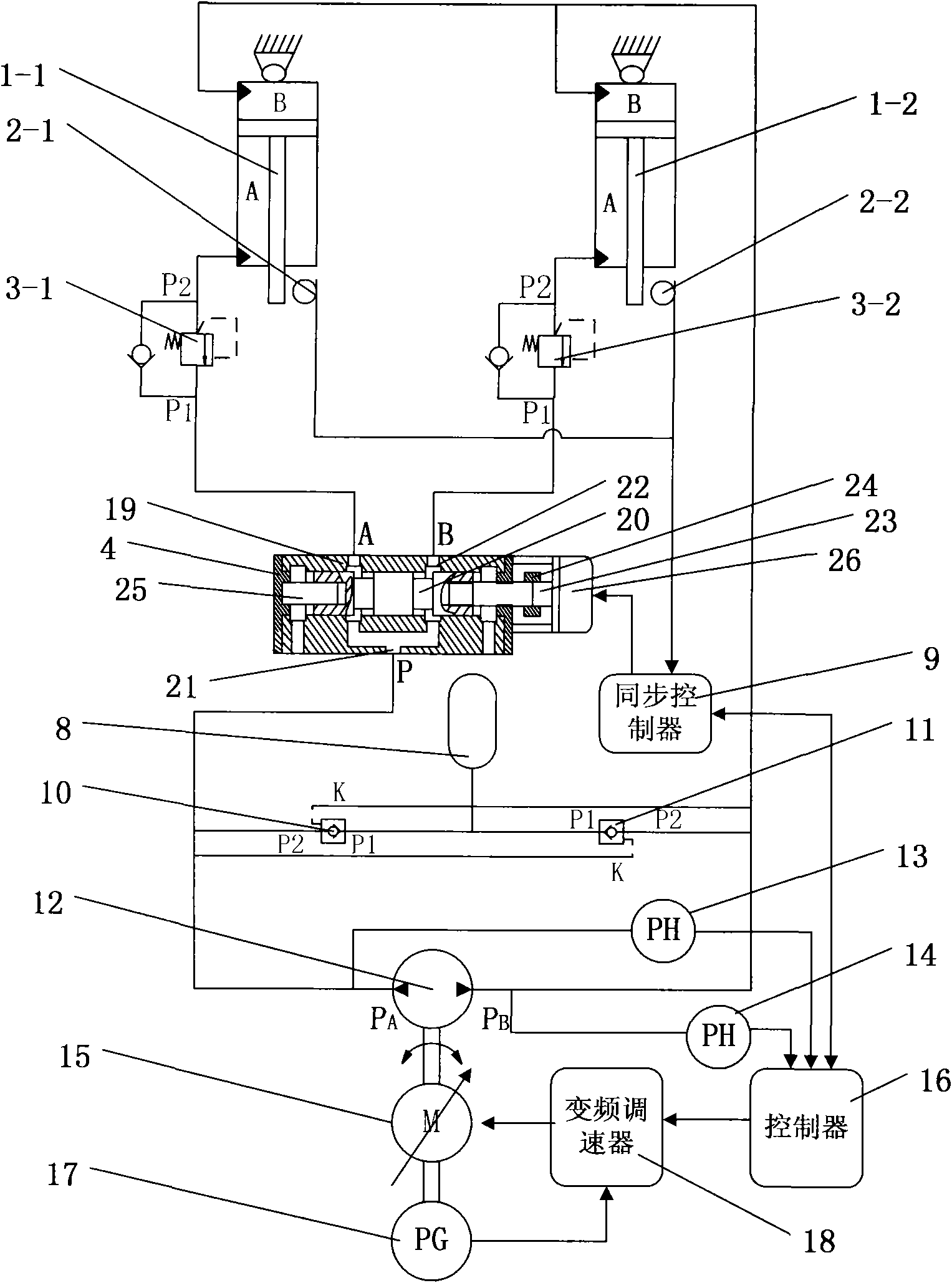

[0056] like figure 1 As shown, the present invention includes a hydraulic actuator, a digital synchronous control mechanism that directly performs synchronous control on the hydraulic actuator, and an electro-hydraulic power source that provides power oil for the hydraulic actuator and the digital synchronous control mechanism, And an electro-hydraulic control system for comprehensively controlling the electro-hydraulic power source and the digital synchronous control mechanism.

[0057] The hydraulic actuators are two or four hydraulic cylinders. In this embodiment, the hydraulic actuators are two and specifically hydraulic cylinder one 1-1 and hydraulic cylinder two 1-2.

[0058] The electro-hydraulic power source includes an oil storage tank, two double-acting hydraulic oil pumps 12 connected to the oil storage tank through hydraulic pipelines, and an electric motor 15 for driving the double-acting hydraulic oil pump 12 . Two hydraulic pipelines between the oil storage tan...

Embodiment 2

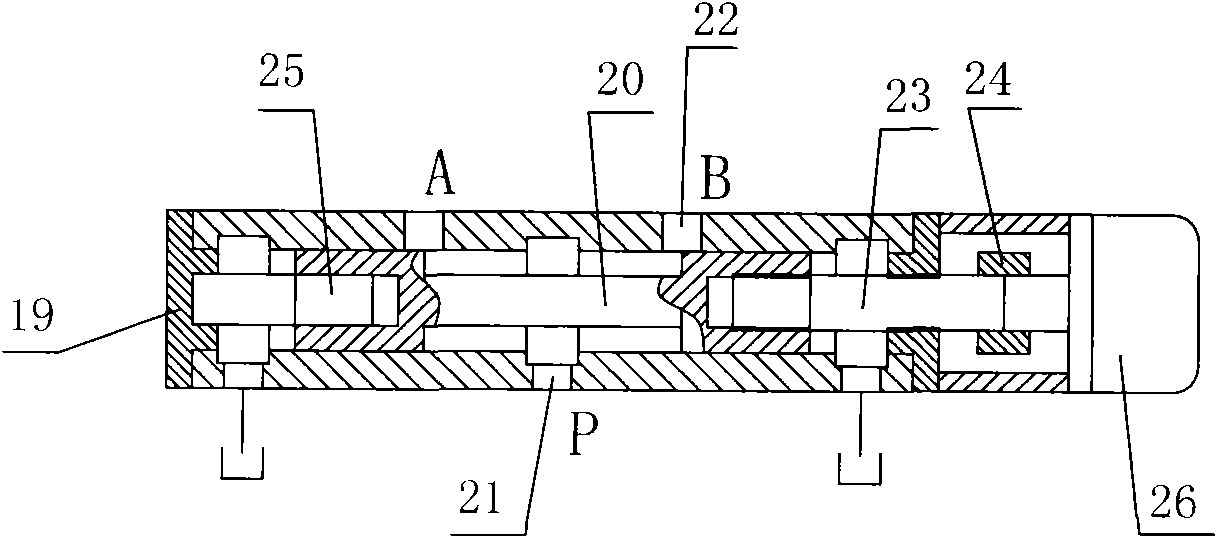

[0074] The difference between this embodiment and Embodiment 1 is that: the spool 20 of the digital synchronous valve, that is, the spool valve, is a single boss structure, and a boss capable of laterally blocking the valve cavity is arranged in the middle, and passes through the valve core. The left and right outer ends of the boss respectively adjust the openings of the two diverter ports 22, and the boss is set facing the oil inlet 21, and the oil inlet 21 and the two diverter ports 22 form two about The boss is a symmetrical confluence-distribution oil passage. In this embodiment, the structures, control methods and functions of other parts are the same as those in Embodiment 1.

Embodiment 3

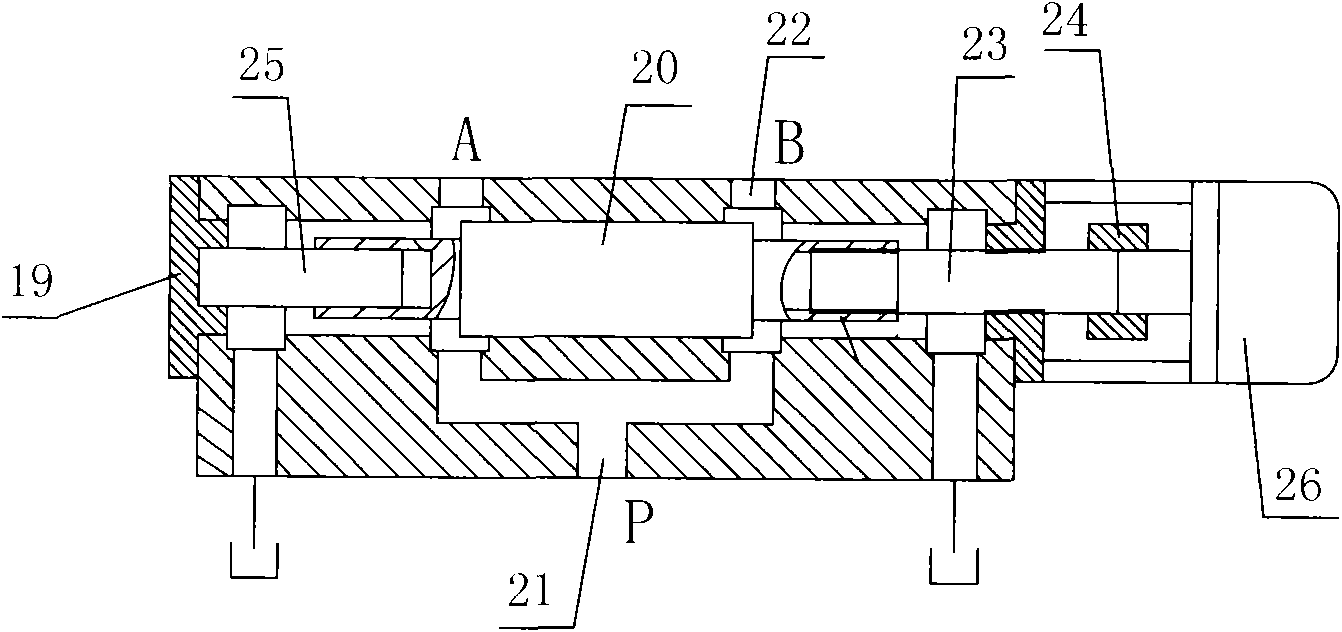

[0076]The difference between this embodiment and Embodiment 1 is that: the spool 20 of the digital synchronous valve, that is, the spool valve, has a three-boss structure, on which three bosses capable of laterally blocking the valve cavity are arranged and three From left to right, the bosses are left boss, middle boss and right boss. The middle boss is set facing the oil inlet 21 and the openings of the two diverter ports 22 are adjusted through the inner ends of the left boss and the right boss respectively. The oil inlet 21 and the two diverter ports 22 are respectively Between the left boss and the middle boss, and between the middle boss and the right boss, two left and right symmetrical converging and diverging oil passages are formed. In this embodiment, the structures, control methods and functions of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com