Mining linkage all-hydraulic drilling machine

A fully hydraulic, drilling rig technology, used in rotary drilling rigs, drill pipes, drill pipes, etc., can solve the problems of hydraulic systems that cannot be linked, unfavorable for downhole handling, complex structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

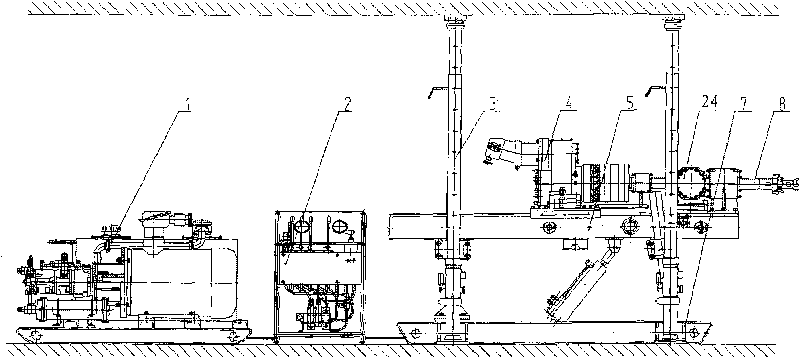

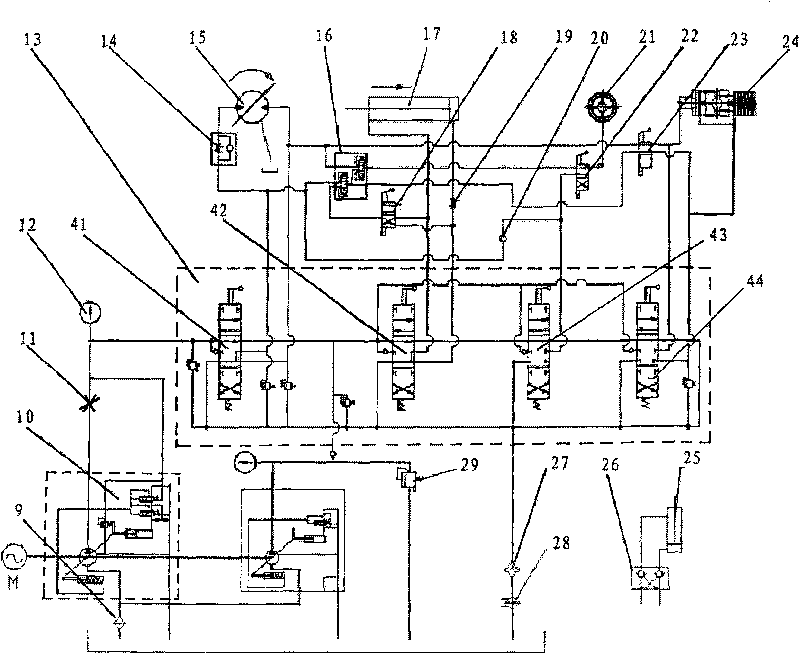

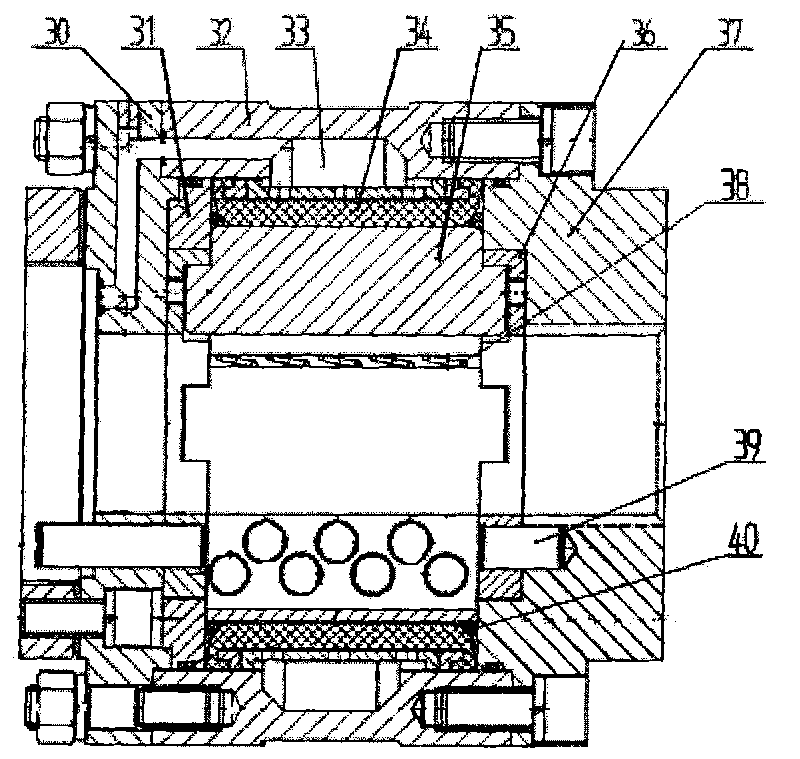

[0027] 1. Pumping station system; 2. Operating table; 3. Column; 4. Power head; 5. Rack; 7. Base; 8. Drilling tool; ;11. Throttle valve; 12. Pressure gauge; 13. Multi-way valve unit; 14. One-way throttle valve; 15. Hydraulic motor; 16. Shuttle valve; 17. Drilling rig propulsion cylinder; Valve; 19. One-way throttle valve; 20. One-way valve; 21. Hydraulic chuck; 22. Chuck linkage / single-action manual reversing valve; 23. Gripper linkage / single-action manual reversing valve; 24. Hydraulic pressure Gripper; 25. Drill angle adjustment cylinder; 26. Two-way hydraulic lock; 27. Fine oil filter; 28. Cooler; 29. Relief valve; 30. Rear end cover; 31. Pressure plate: 32. Shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com