Moveable platform

A technology for moving worktables and working platforms, which is applied to measuring devices, instruments, and mechanical devices, etc., can solve the problems of impossible exchange and movement of worktables, achieve simple and effective control methods, save equipment investment, and short time intervals Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

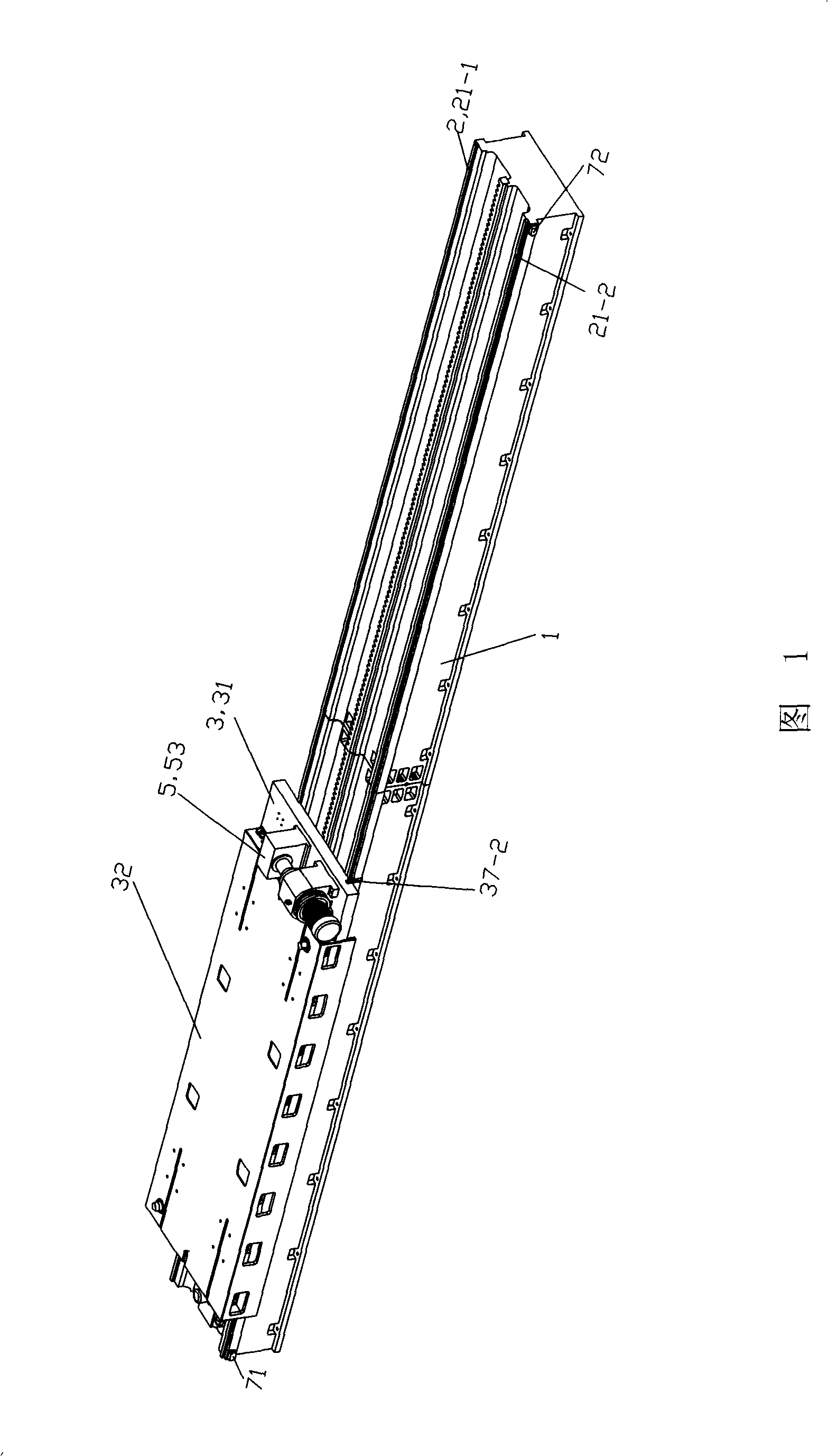

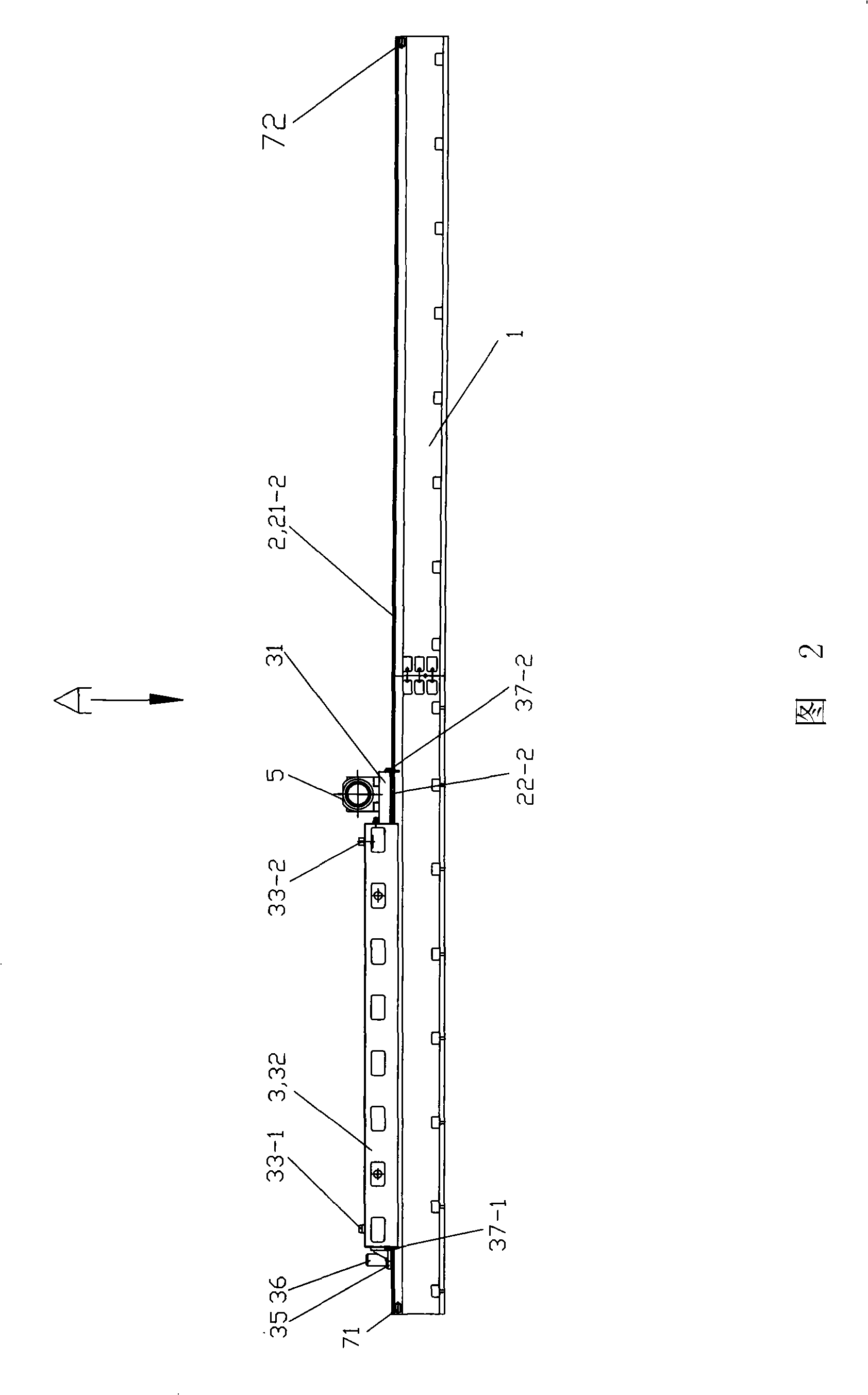

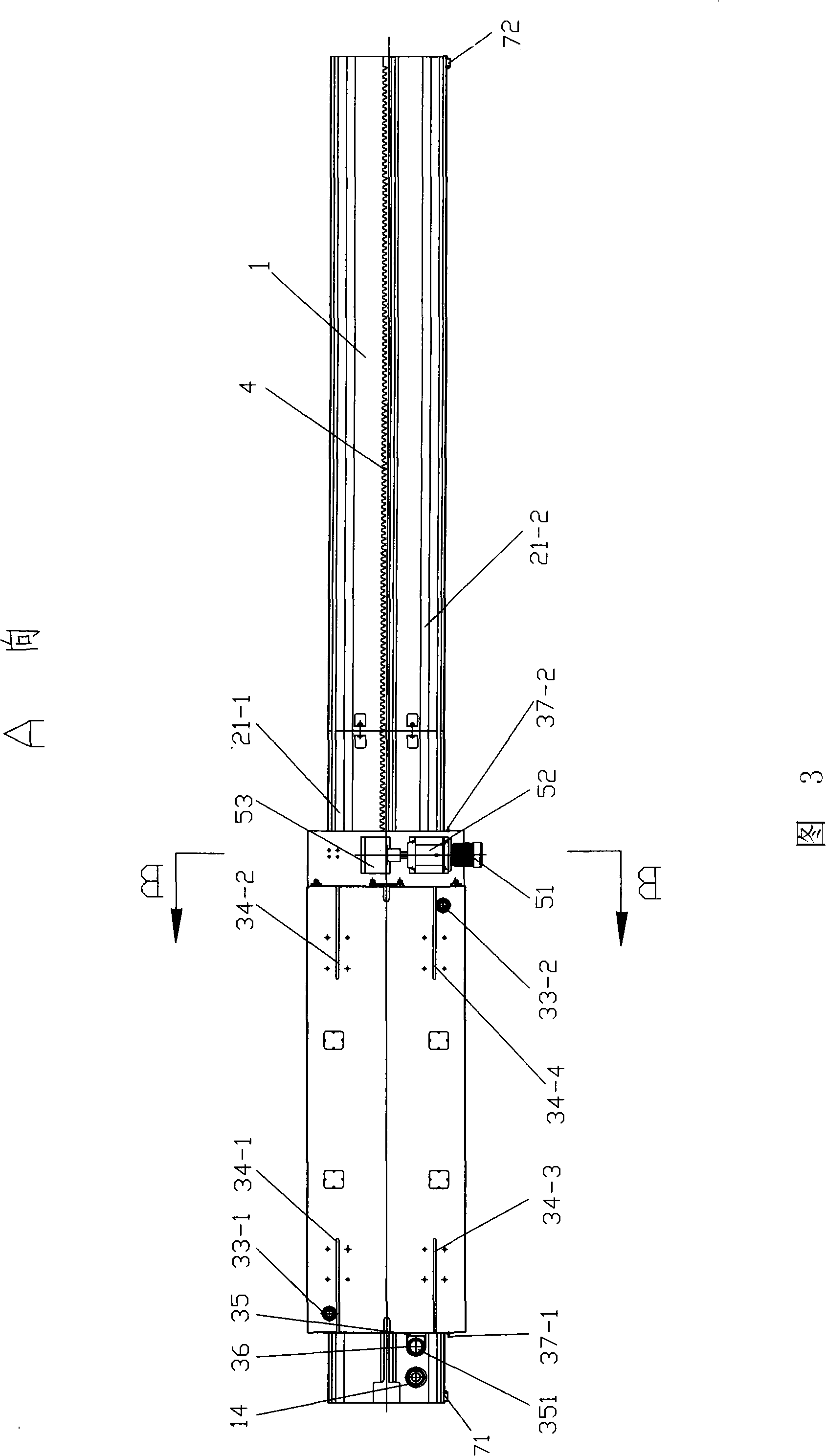

[0034] Referring to Figures 1 to 7, the mobile workbench includes a machine base 1, a linear guide pair 2, a working platform 3, a spur rack 4, a transmission mechanism 5, a first travel switch 71 and a second travel switch 72. This embodiment will be described according to the direction in which the working platform 3 moves along the linear guide rail as the front and rear directions.

[0035] see picture 1, Figure 4 and 5 , The base 1 includes left and right guide rail grooves 11-1 and 11-2 arranged in the front and rear directions on the left and right sides thereof, and a rack groove 12 arranged in the front and rear directions in the middle.

[0036] See Figure 3, Figure 5 and Figure 6 , there are two linear guide rail pairs 2 for outsourcing. Each linear guide rail pair 2 includes 1 guide rail and 4 sliders. Each slider is rollingly connected by its rollers in contact with the linear raceway of the guide rail. The guide rail 21-1 of the left linear guide rail pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com