Modular magnetic coupling for underwater propeller

A modular, magnetic coupling technology, applied in electric brakes/clutches, permanent magnet clutches/brakes, electrical components, etc., it can solve the problems that the transmission torque is not as good as the tile shape and can only be magnetized radially.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

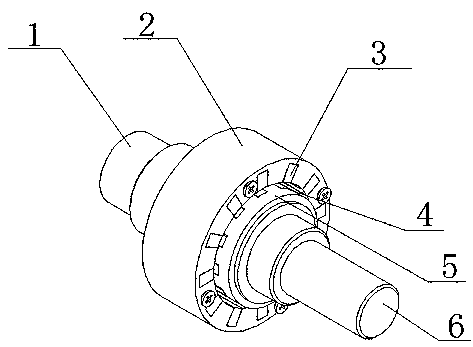

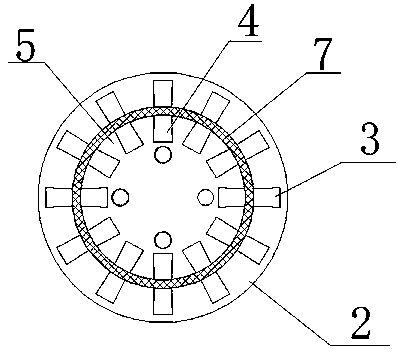

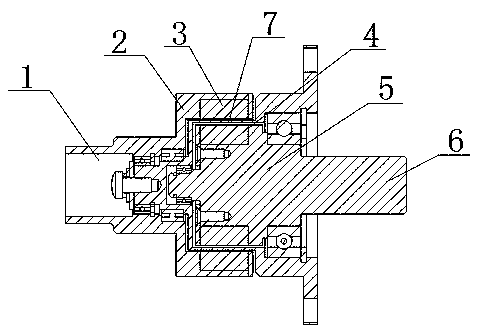

[0018] The present invention provides a modular magnetic coupling coupling for underwater propellers. The permanent magnets used combine the characteristics of tile-shaped and square permanent magnets. It is innovatively proposed that the use of wedge-shaped permanent magnets can not only change the magnetization direction, but also The direction of the magnetic field lines is gradually changed to maximize the magnetic flux density in the air gap of the device and increase the transmission torque. At the same time, it can effectively prevent the permanent magnet from being easily thrown out during high-speed rotation.

[0019] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings of the specification and specific implementations.

[0020] Such as Figure 1-Figure 3 Shown, a modular magnetic coupling coupling for underwater propulsion includes an input shaft 1, a fema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com