Parallel type mixing-magnetic-material-based composite-rotor-contained magnetic flux switching motor

A technology of magnetic flux switching motor and composite rotor, which is used in aerospace, wind power generation, electric vehicle, and motor manufacturing fields, can solve the problems of low relative utilization rate of permanent magnets, limited motor application occasions, magnetic saturation of stator teeth, etc. The effect of avoiding magnetic saturation, improving supersaturation and reducing torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

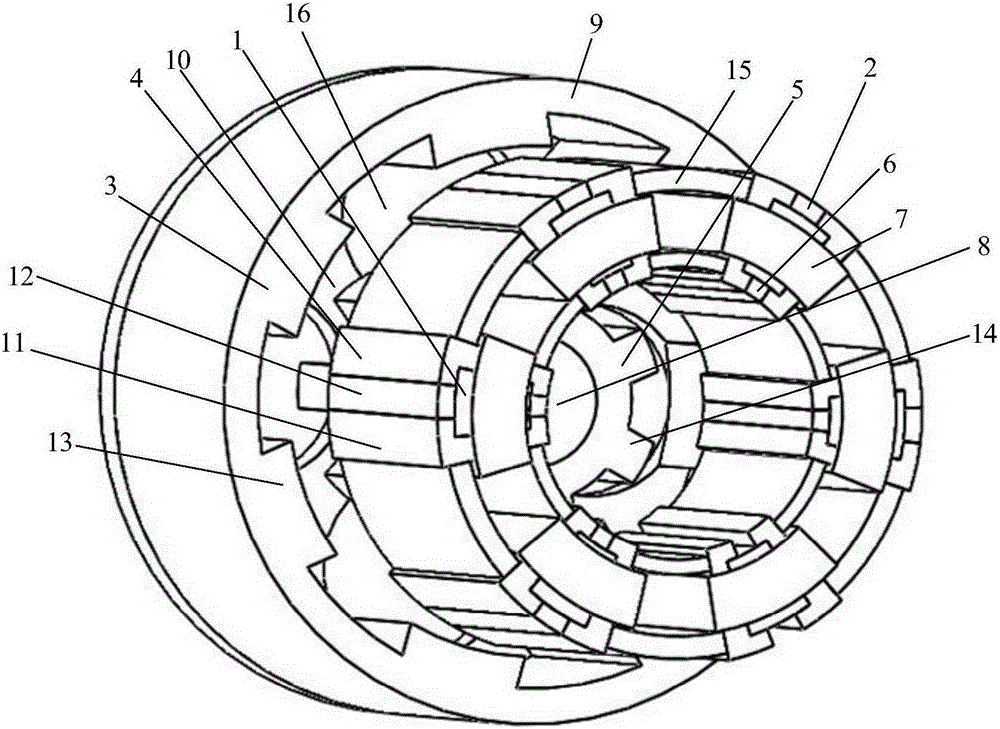

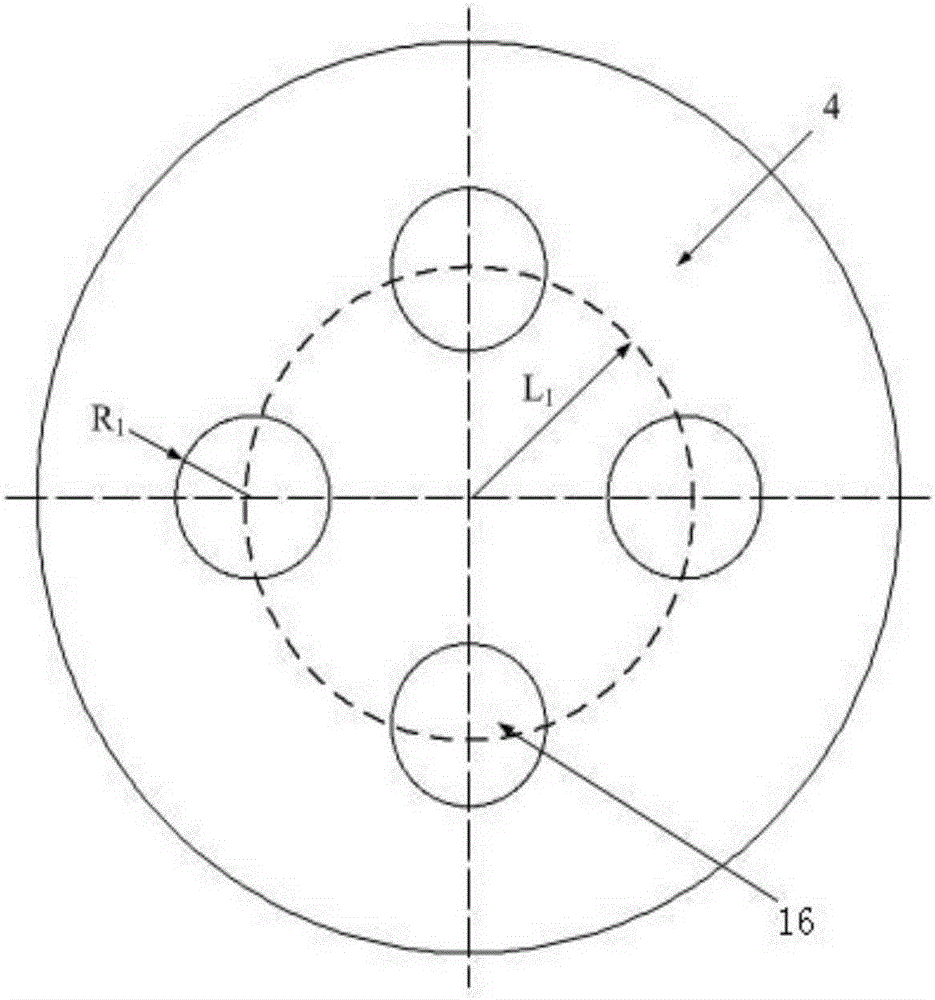

[0033] see figure 1 and figure 2 , the present invention consists of an outer rotor 3, a stator 4, an inner rotor 5, an armature winding 7 and a non-magnetic rotating shaft 8. The outer rotor 3 is coaxial with an empty stator 4 , the stator 4 is coaxial with an inner rotor 5 , and the inner rotor 5 is coaxially fixed on a non-magnetic rotating shaft 8 . An annular disc 10 is fixedly installed on the same axial end surface of the outer rotor 3 and the inner rotor 5, and the outer rotor 3 and the inner rotor 5 are fixedly connected together through the annular disc 10, and the connection method is riveting or welding, so that the outer rotor 3. The inner rotor 5 and the annular disk 10 form a compound rotor 9, which is an integral structure, and the stator 4, the compound rotor 9 and the non-magnetic rotating shaft 8 belong to a concentric and coaxial collar structure as a whole. In this way, the present invention sequentially includes the non-magnetic rotating shaft 8, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com