High-magnetic-saturation-strength iron-based amorphous soft magnetic alloy and preparation method and application thereof

An iron-based amorphous, soft magnetic alloy technology, applied in the direction of magnetic circuits, magnetic materials, magnetic objects, etc. characterized by magnetic materials, can solve the problem of reducing soft magnetic performance and industrial service life, and electronic devices cannot be widely used, It is difficult to meet the requirements of industrial production and other problems, so as to achieve the effects of greatly increased industrial production benefits, excellent soft magnetic properties, and high magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

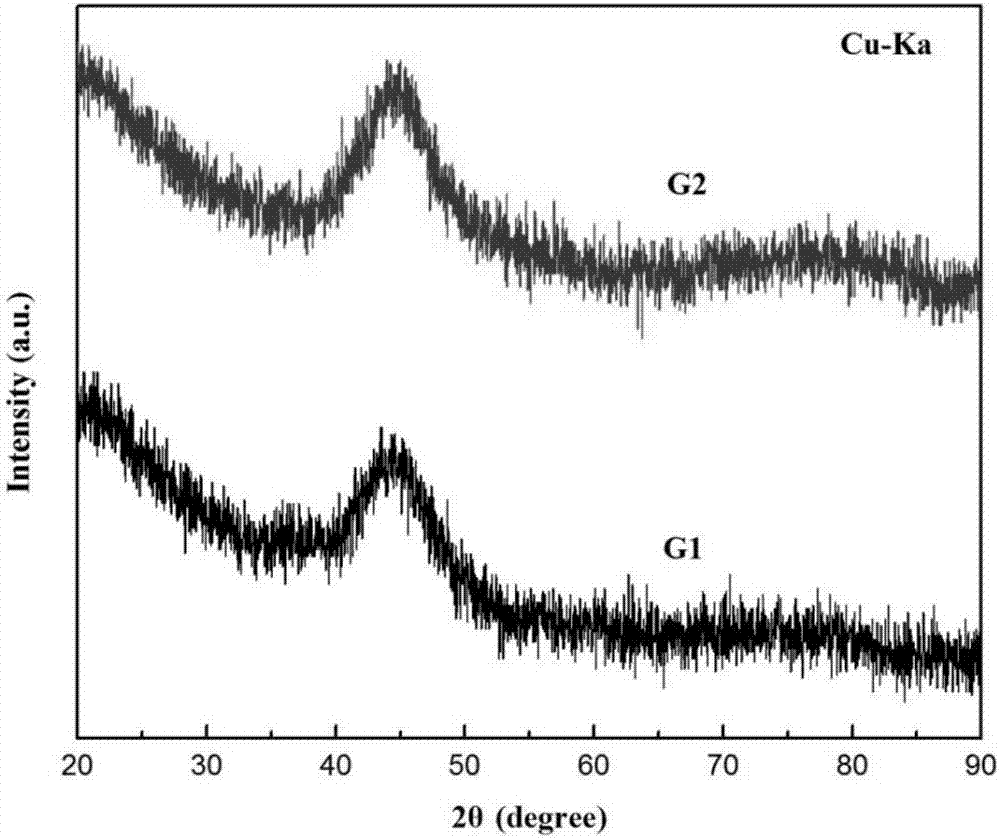

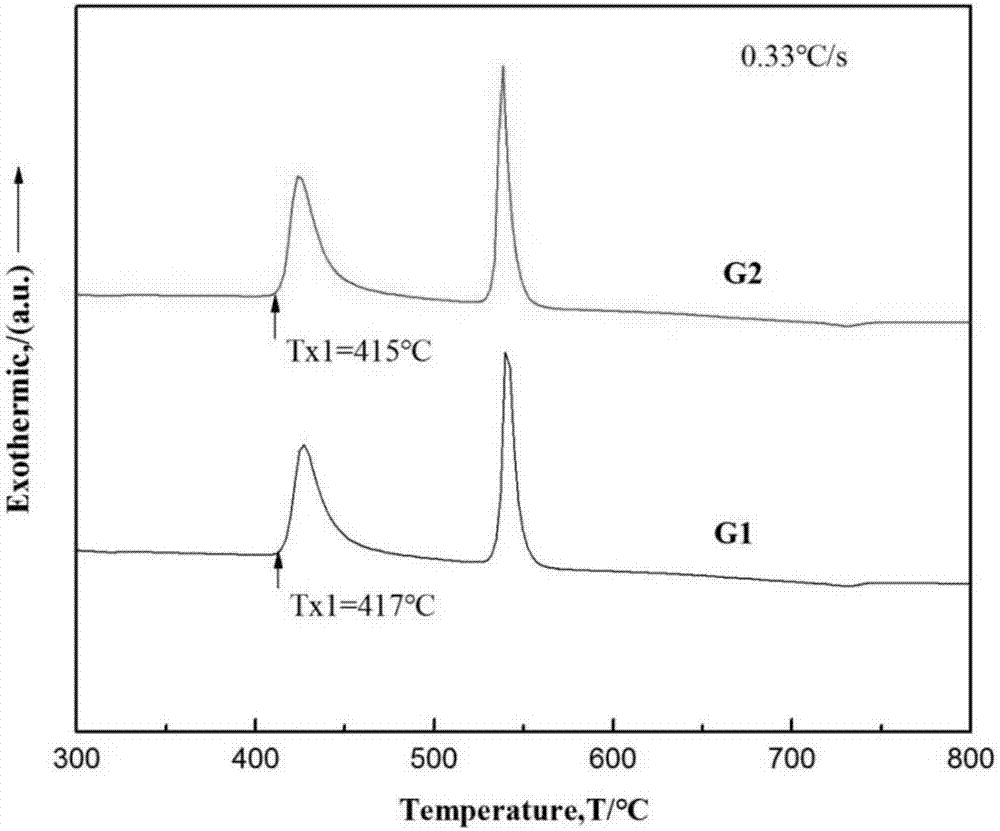

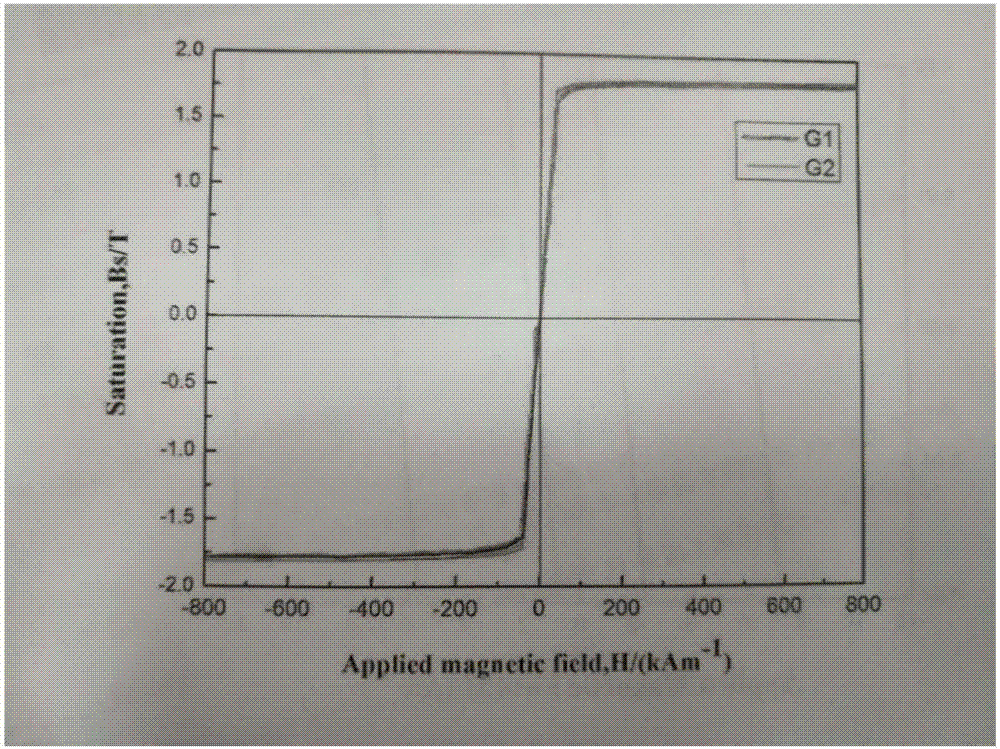

[0037] An iron-based amorphous soft magnetic alloy Fe 83.25 Si 2.37 B 12.24 P 1.45 Cu 0.69 , its preparation method comprises the following steps:

[0038] 1) Ingredients: Fe (99.9wt%), Si (99.999wt%), FeB (the content of Fe and B are 79.51wt%, 19.62wt%), Fe 3 P (the content of Fe and P are 84.4wt% and 15.6wt% respectively) and Cu (99.9wt%) are compounded according to the above element ratios.

[0039] 2) Melting the master alloy: place the prepared raw materials in an induction furnace, heat to 200-300°C above the melting point of the master alloy, and keep the temperature for a certain period of time to obtain a master alloy ingot; the holding time is set according to the actual situation; when using When preparing master alloys from high-purity raw materials, use mechanical pumps and molecular pumps to pump the induction furnace to a vacuum of 5.0×10 -3 MPa is filled with high-purity argon for protection to prevent P volatilization. The purity of argon is 99.99%. imp...

Embodiment 2

[0045] An Fe-based amorphous soft magnetic alloy Fe 83.5 Si 2.36 B 12.21 P 1.24 Cu 0.69 , its preparation method comprises the following steps:

[0046] 1) Ingredients: Fe (99.9wt%), Si (99.999wt%), FeB (the content of Fe and B are 79.51wt%, 19.62wt%), Fe 3 P (the content of Fe and P are 84.4wt% and 15.6wt% respectively) and Cu (99.9wt%) are compounded according to the above element ratios.

[0047] 2) Melting the master alloy: place the prepared raw materials in an induction furnace, heat to 200-300°C above the melting point of the master alloy, and keep the temperature for a certain period of time to obtain a master alloy ingot; the holding time is set according to the actual situation; when using When preparing master alloys from high-purity raw materials, use mechanical pumps and molecular pumps to pump the induction furnace to a vacuum of 5.0×10 -3 MPa is filled with high-purity argon for protection to prevent P volatilization. The purity of argon is 99.99%. impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com